Process for encapsulating stator coil in motor

A packaging process and inner stator technology, applied in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve problems such as insulation layer peeling and cracking, and achieve the effect of improving power, good thermal conductivity, and conducive to heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

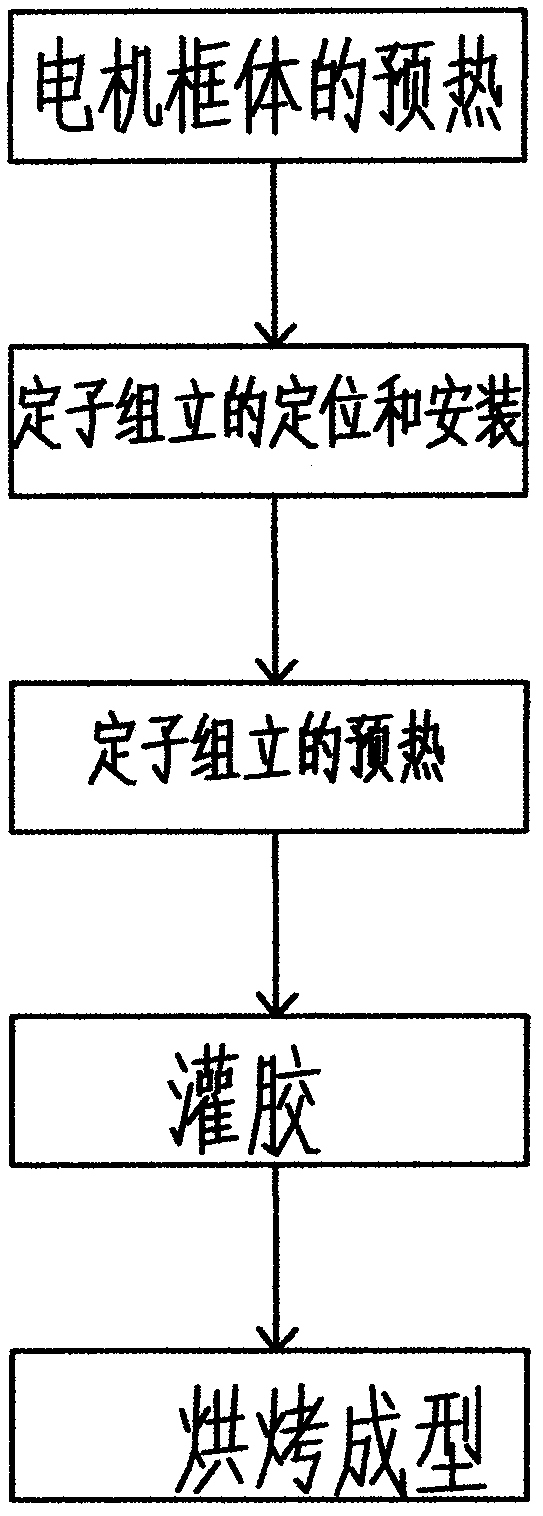

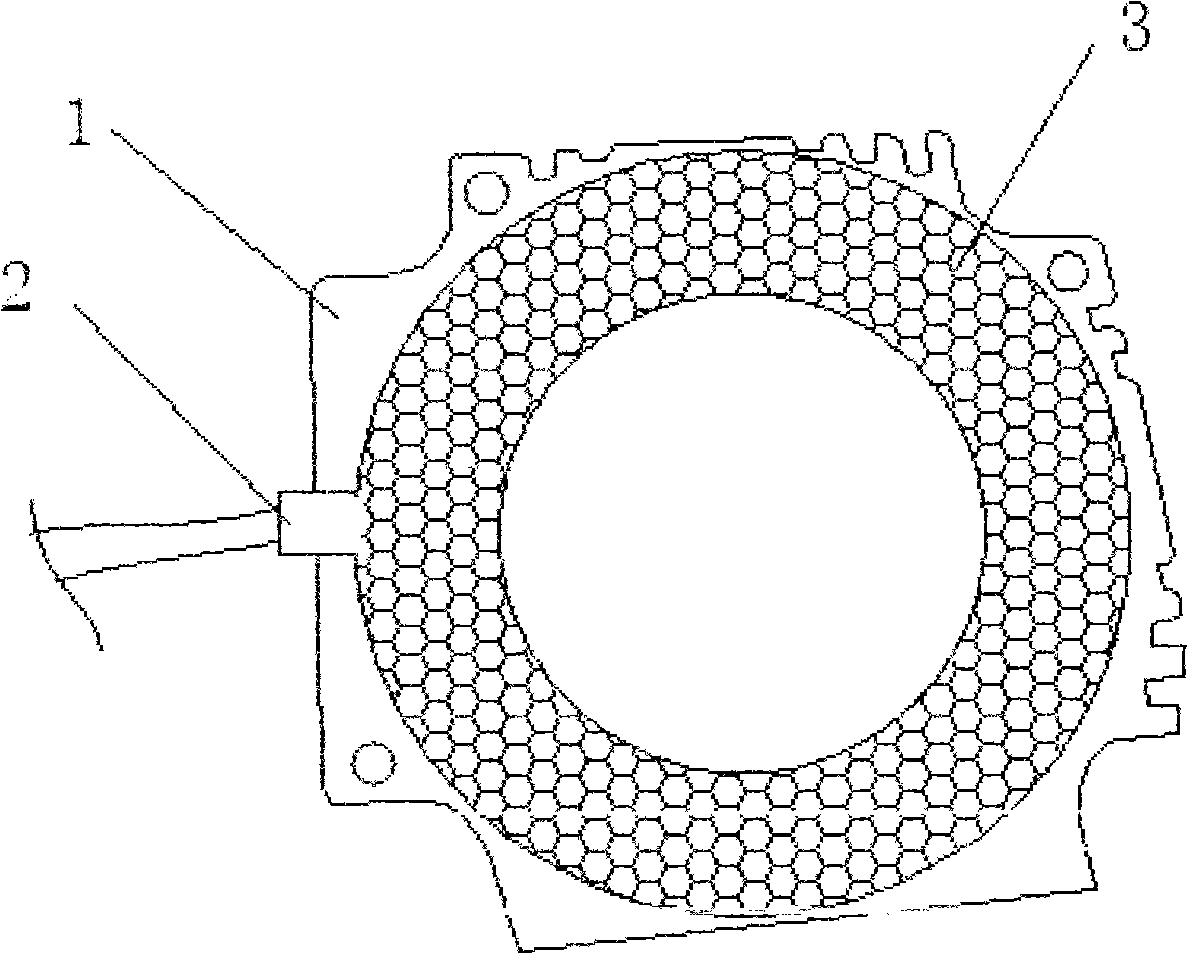

[0015] see figure 1 with figure 2 , this embodiment is to provide a kind of easy processing, good packaging performance, which is beneficial to the heat dissipation of high-power devices, increase the power, and can ensure the firmness and optimal thickness of the stator group of the motor. Process, its process steps include as follows:

[0016] (1) Preheating of the motor frame 1: first, preheat the motor frame in an oven at a temperature of 80° C. for one hour, so as to facilitate the installation of the stator assembly and the pouring of the potting glue.

[0017] (2) The positioning and installation of the stator assembly 2; then put the stator assembly 2 into the motor frame 1, the outlet line of the stator assembly 2 is pressed into the stator core groove of the motor frame 1, and the stator core The groove is U-shaped, which is convenient for the installation and position positioning of the stator assembly.

[0018] After the stator assembly 2 is positioned and fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com