Gluing device for lamination machine

A technology of glue sticking device and lamination machine, which is applied in battery assembly machine, sustainable manufacturing/processing, climate sustainability, etc. It can solve the problems of not sticking the tape very firmly, reverse side of battery separator, troubles of producers, etc. , to achieve the effect of ensuring firmness, preventing the reverse side of the diaphragm, and improving market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

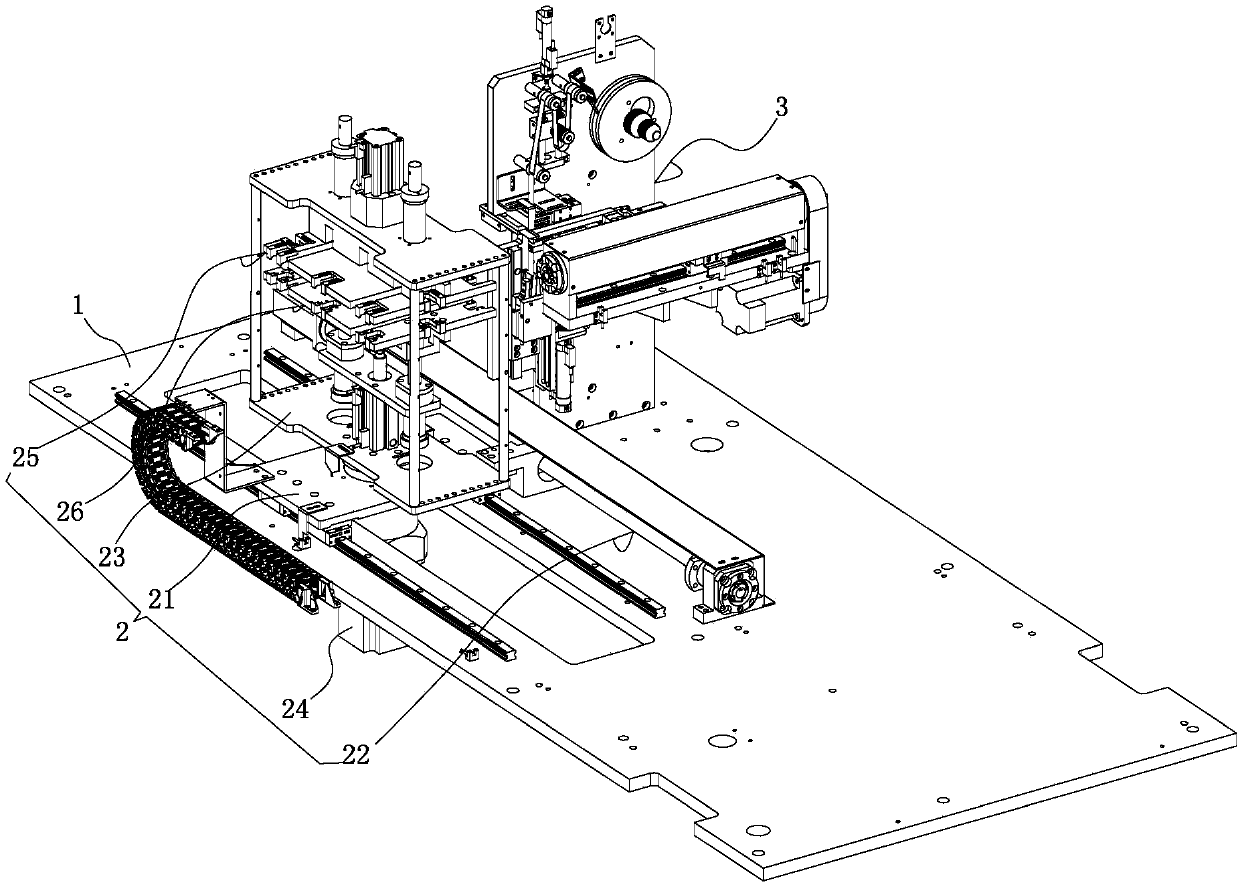

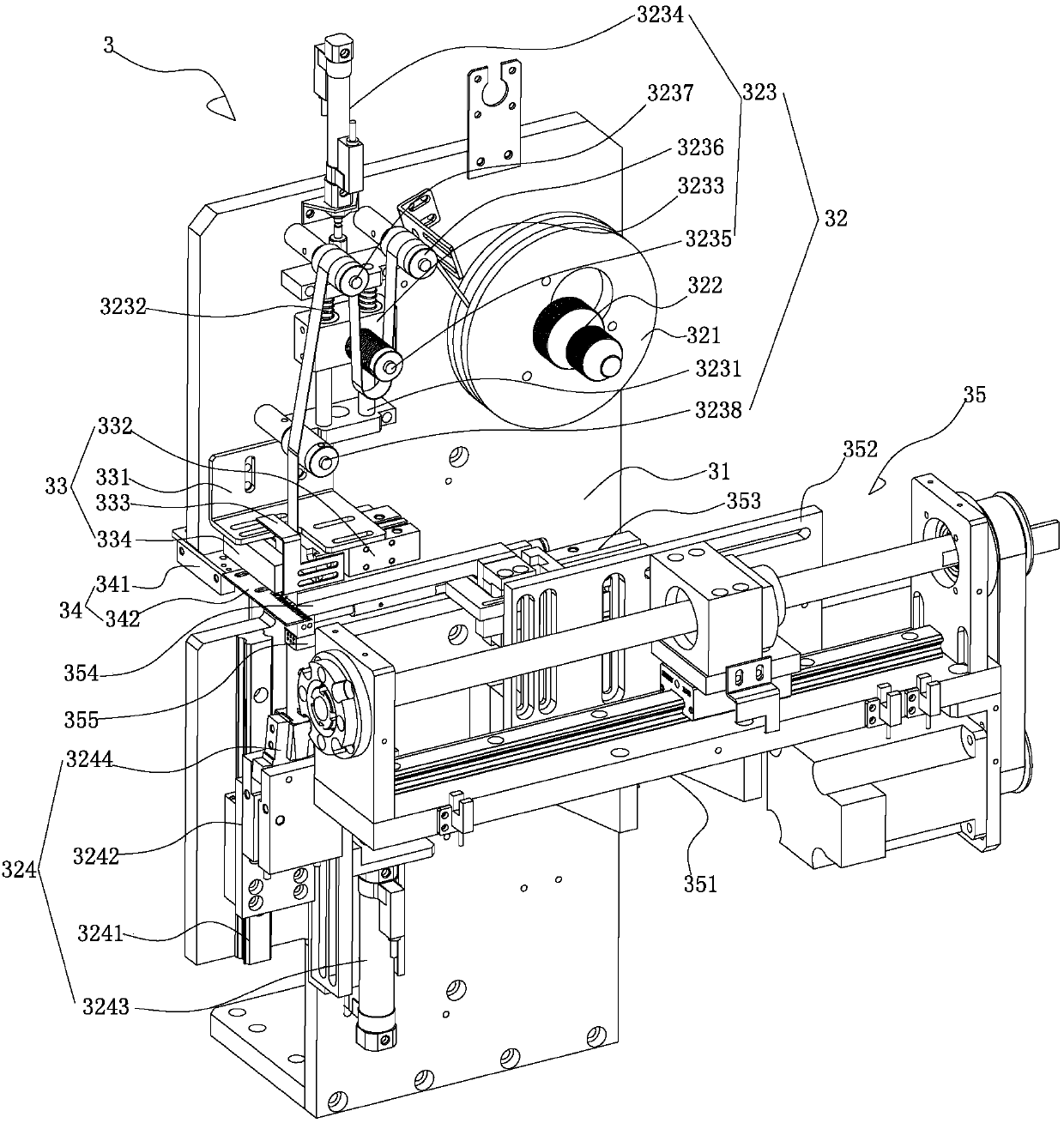

[0020] See Figure 1-3 Shown is a gluing device for a laminate machine, which includes: a substrate 1 , a gluing platform module 2 installed on the substrate 1 , and a gluing mechanism 3 adapted to the gluing platform module 2 .

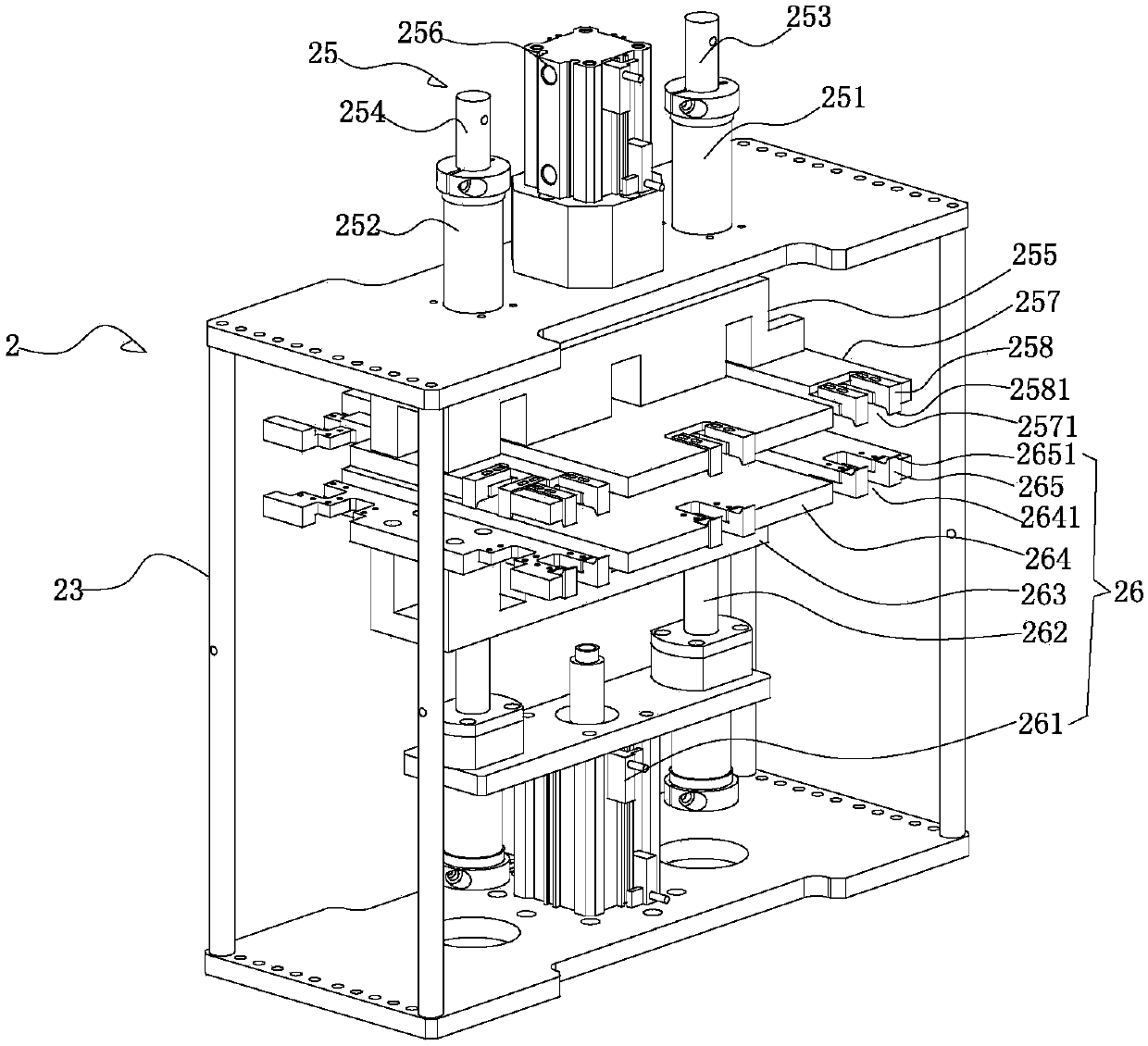

[0021] The gluing platform module 2 includes a moving base 21 movably installed on the base plate 1, a first linear drive module 22 installed on the base plate 1 and used to drive the moving base 21 to move horizontally, and a first linear drive module 22 installed on the moving base 21. The rotating frame 23, the motor assembly 24 installed on the lower end of the moving base 21 and used to drive the rotation of the rotating frame 23, the first positioning splint module 25 and the second positioning splint module 25 installed in the rotating frame 23 and can be mutually clamped or opened Plywood module 26, between the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com