Solar panel junction box shaping welding head assembly

A board junction box and solar energy technology, which is applied in the field of solar panel junction box stereotyped welding head components, can solve the problems of insufficient welding, unsightly welding, poor applicability, etc., and achieve the effect of firm solder joints, compact structure, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to make a clearer and clearer definition of the protection scope of the present invention.

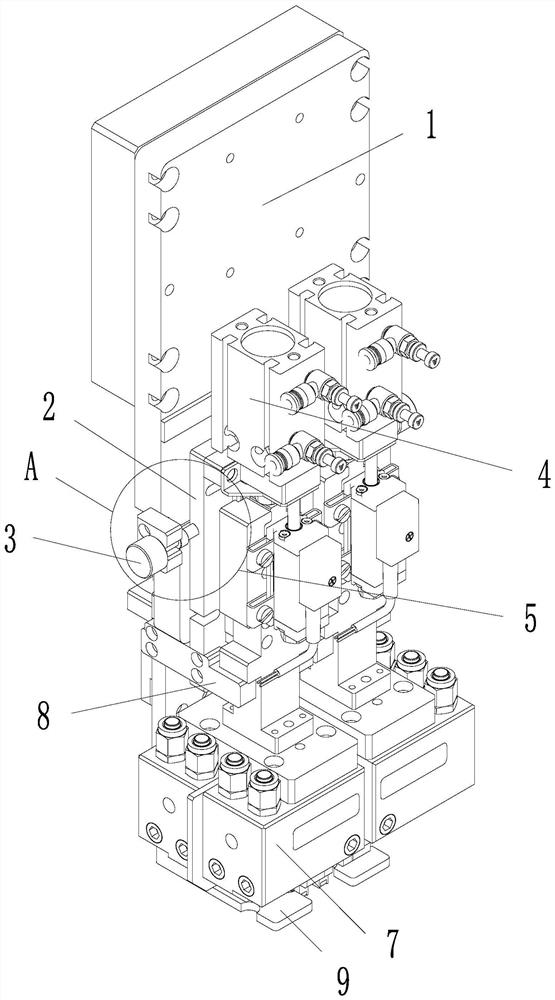

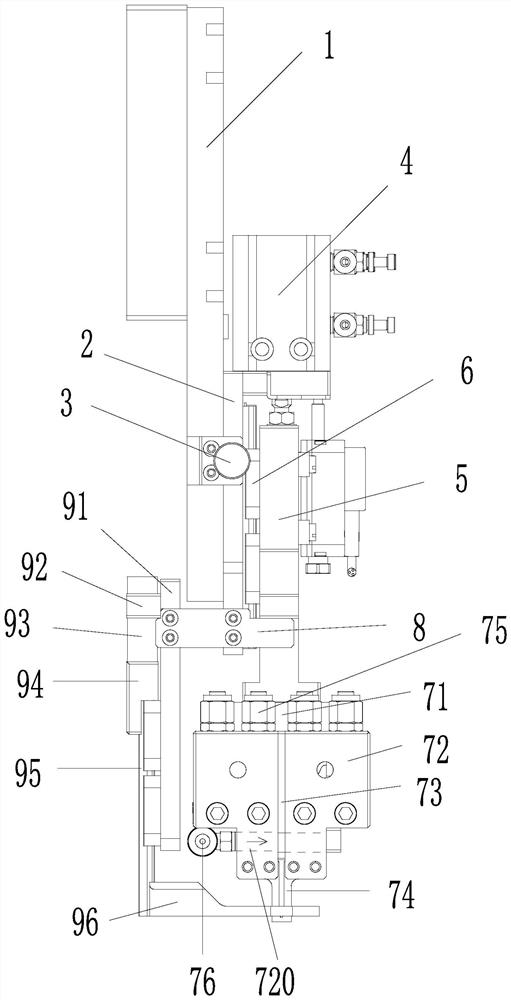

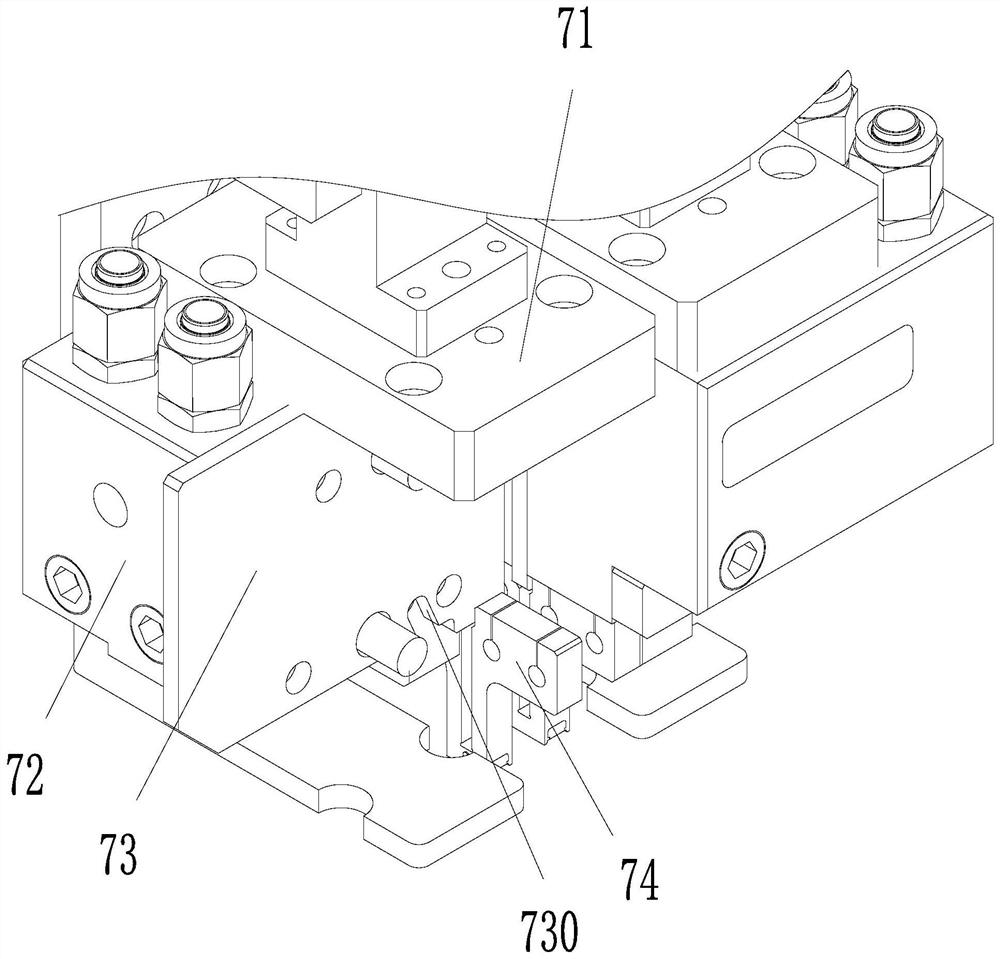

[0019]SeeFigure 1 to Figure 4, The embodiment of the present invention includes:

[0020]A solar panel junction box stereotyped welding head assembly. The solar panel junction box stereotyped welding head assembly includes a main mounting plate 1, a horizontal adjustment plate 2, an adjustment assembly 3, a guide rod cylinder 4, a lifting plate 5, and a linear slide 6. The welding head assembly 7, the limit block 8 and the pressure plate assembly 9. The main mounting plate 1 is equipped with two horizontal adjustment plates 2 with adjustable horizontal positions. The two sides of the main mounting plate 1 are installed with functions acting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com