Constant pressure throttling device for natural gas well

A throttling device and natural gas technology, which is applied in wellbore/well valve devices, wellbore/well parts, earthwork drilling and production, etc., can solve problems affecting work efficiency, gas wells cannot be produced normally, etc., and achieve faster production efficiency , the effect of preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

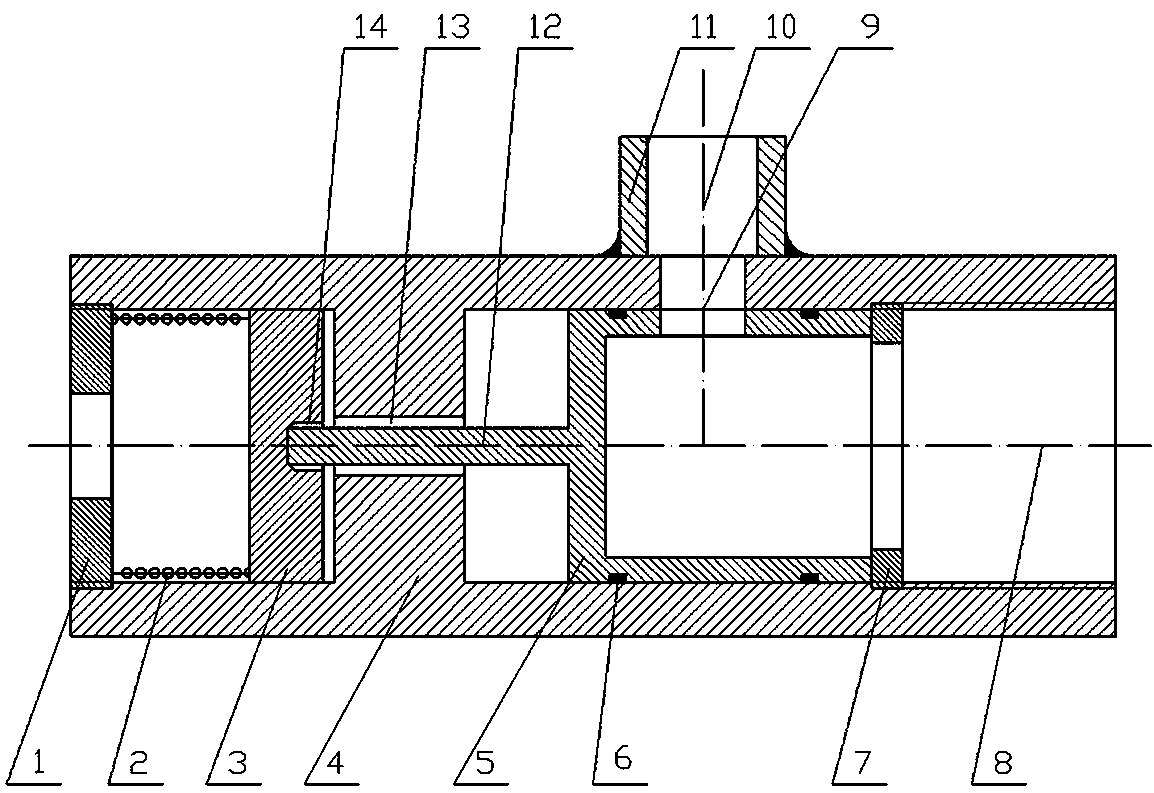

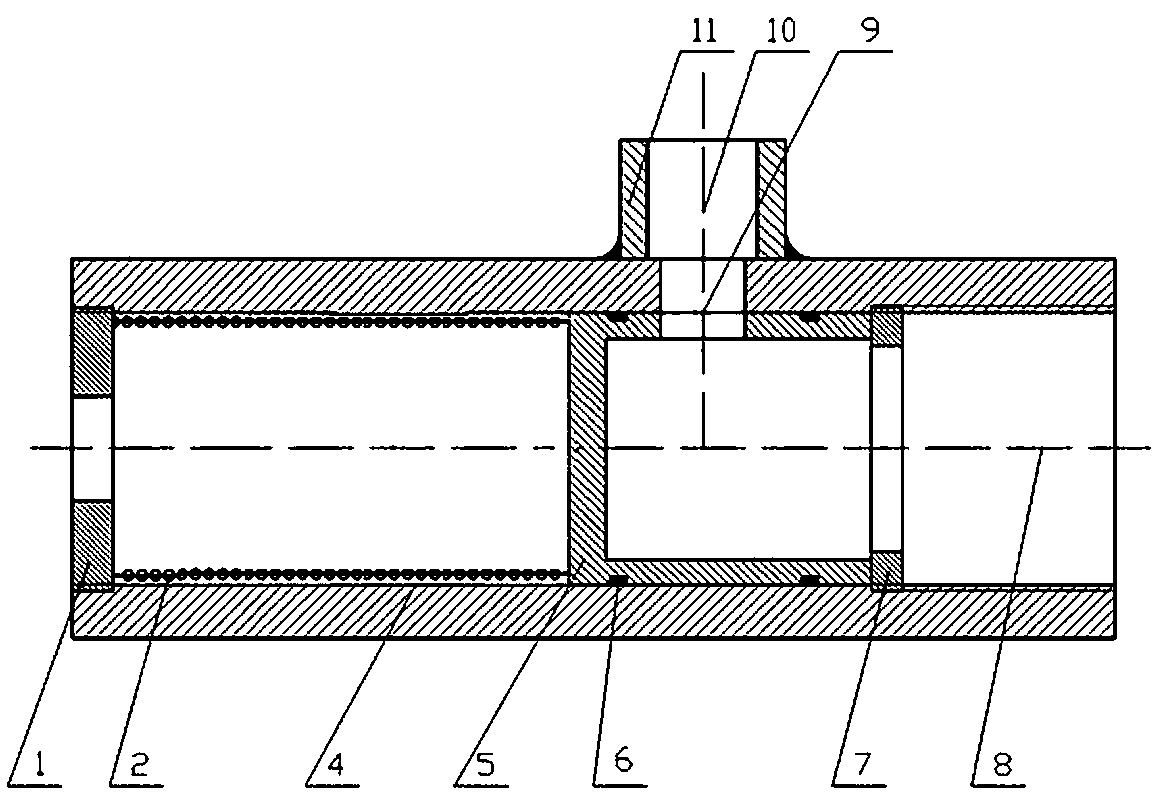

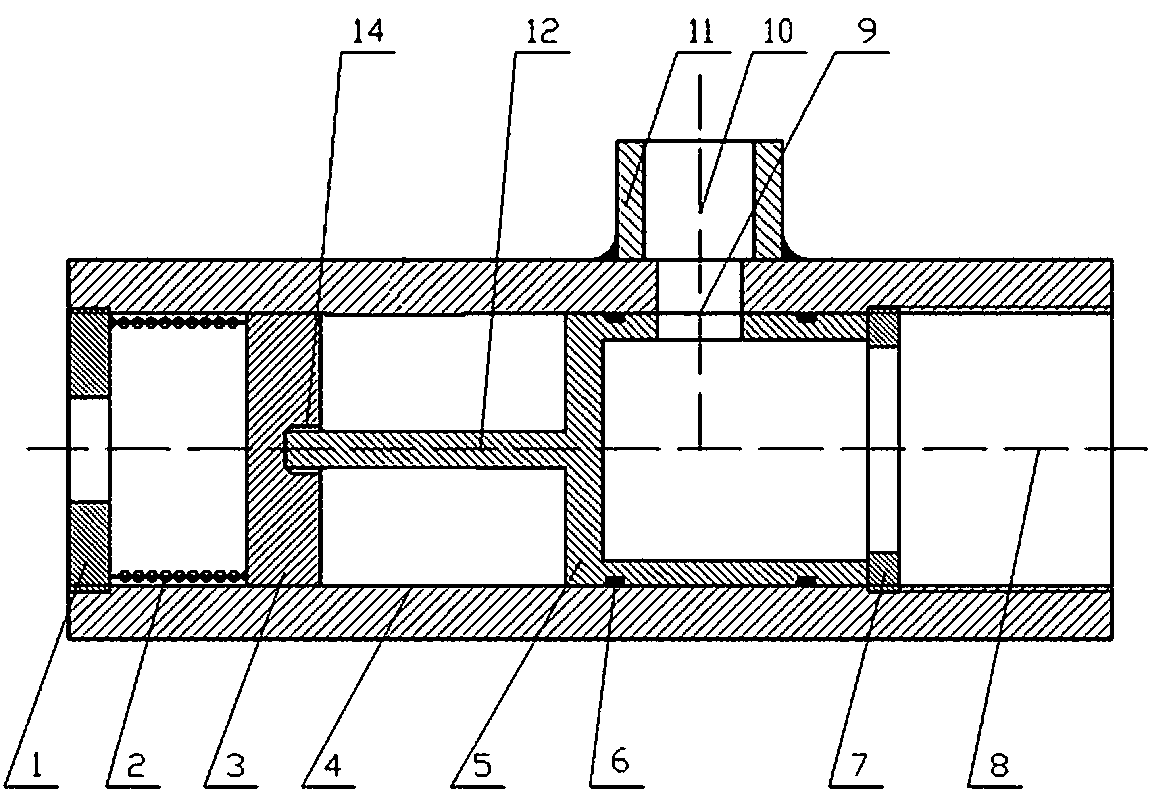

[0027] Specific embodiment one of the natural gas well constant pressure throttling device of the present invention, as figure 1 As shown, a gas well constant pressure throttling device includes three parts: a housing 4 , a piston 5 , and a balance weight 3 . The left and right ends of the housing 4 are provided with threaded holes, the left end threaded hole is provided with a compression spring limiter 1 for connecting the compression spring 2, and the right end threaded hole is provided with a piston limiter 7 for limiting the piston rod , The compression spring limiter 1 and the piston limiter 7 work together to ensure that the piston rod can reciprocate without breaking away from its range of motion. The position corresponding to the upper side of the casing 4 and the piston 5 is provided with a flow-limiting hole 9 , the flow-limiting hole 9 commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com