Blast-furnace iron tap channel side wall thickness detection device and method thereof

A blast furnace tapping and thickness detection technology, which is applied in the direction of mechanical thickness measurement, etc., can solve the problems of inability to measure the thickness of the side wall of the blast furnace tapping trench, large errors, affecting the judgment of the tapping trench, etc., and achieves simple structure, accurate detection and use. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

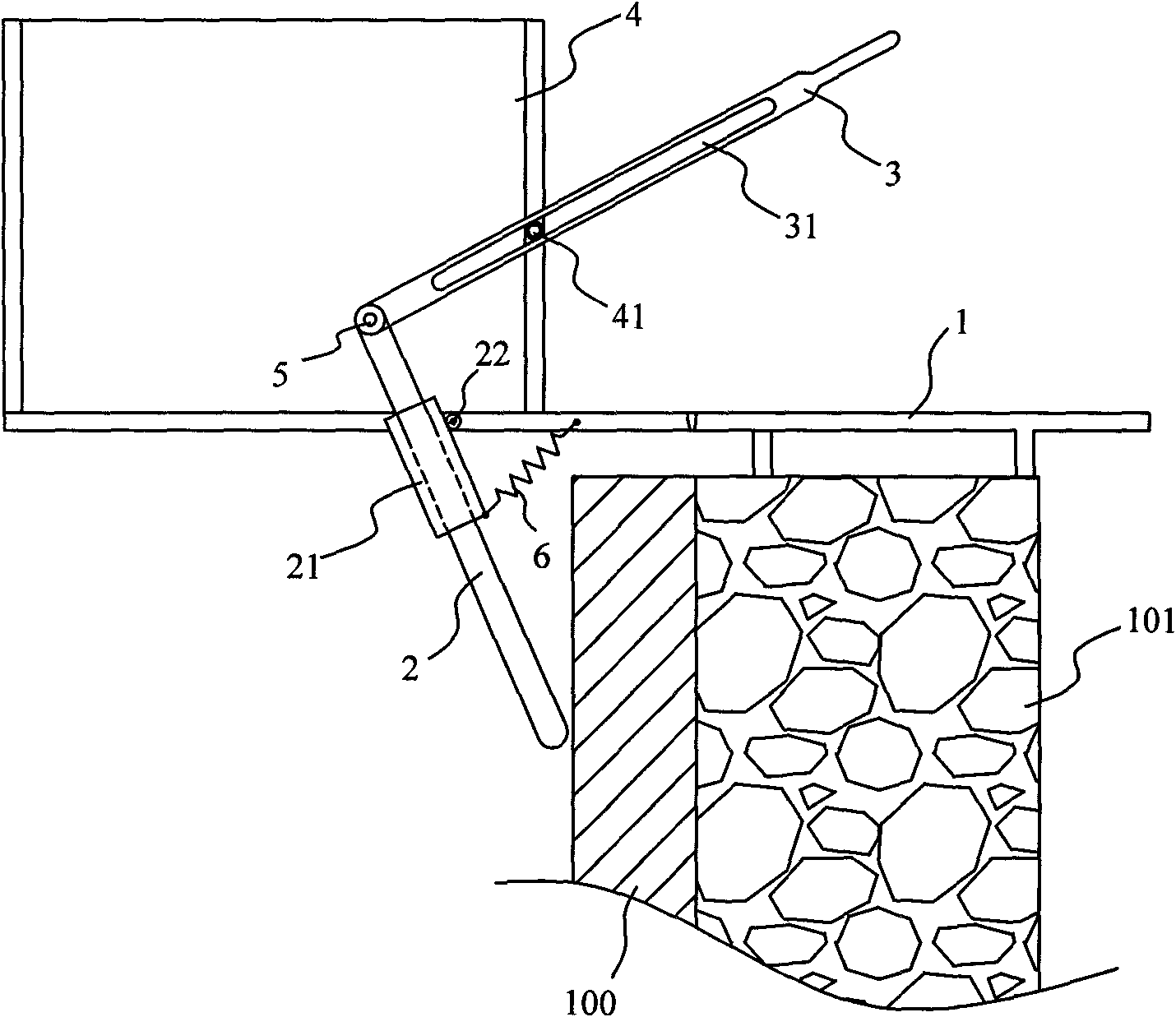

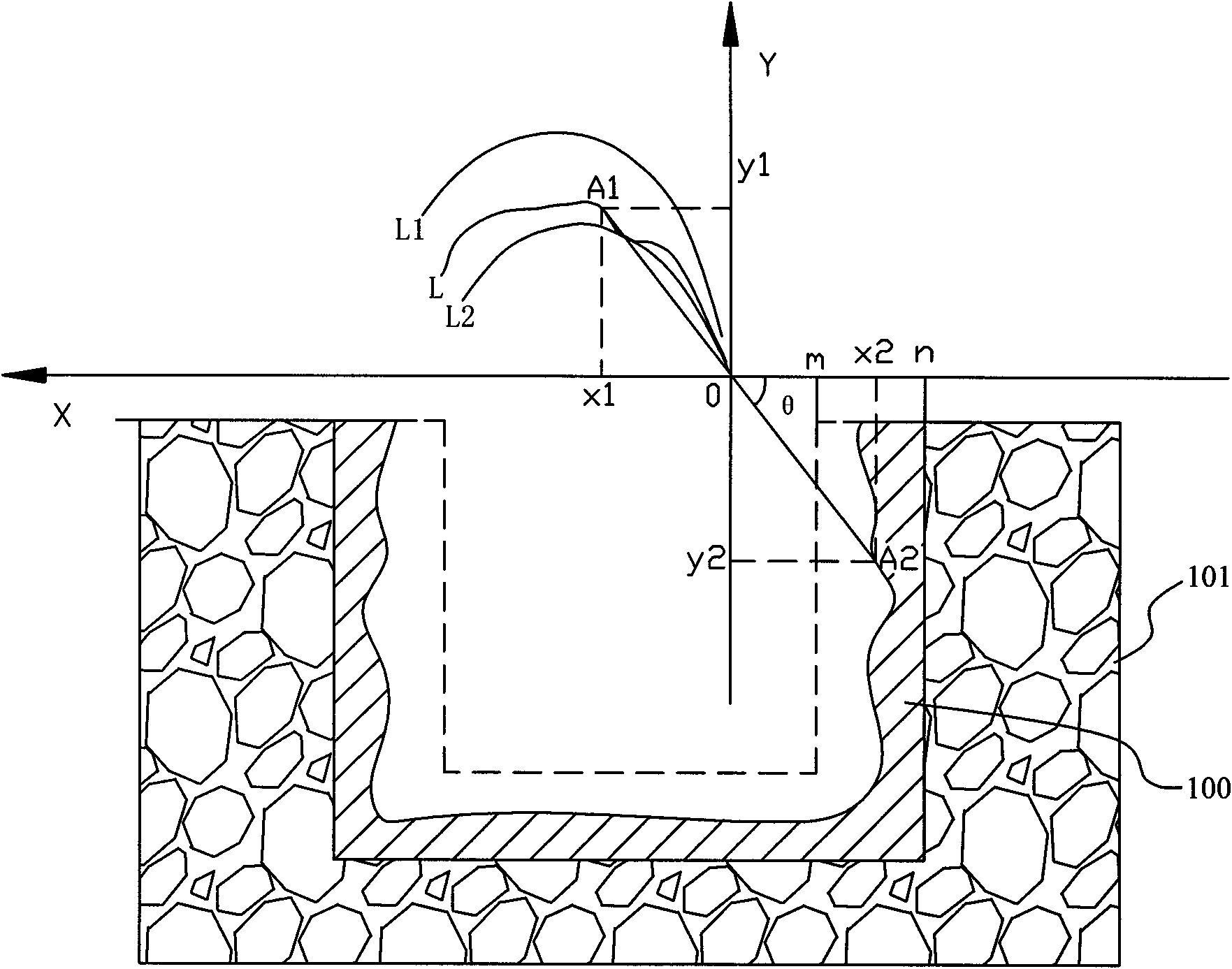

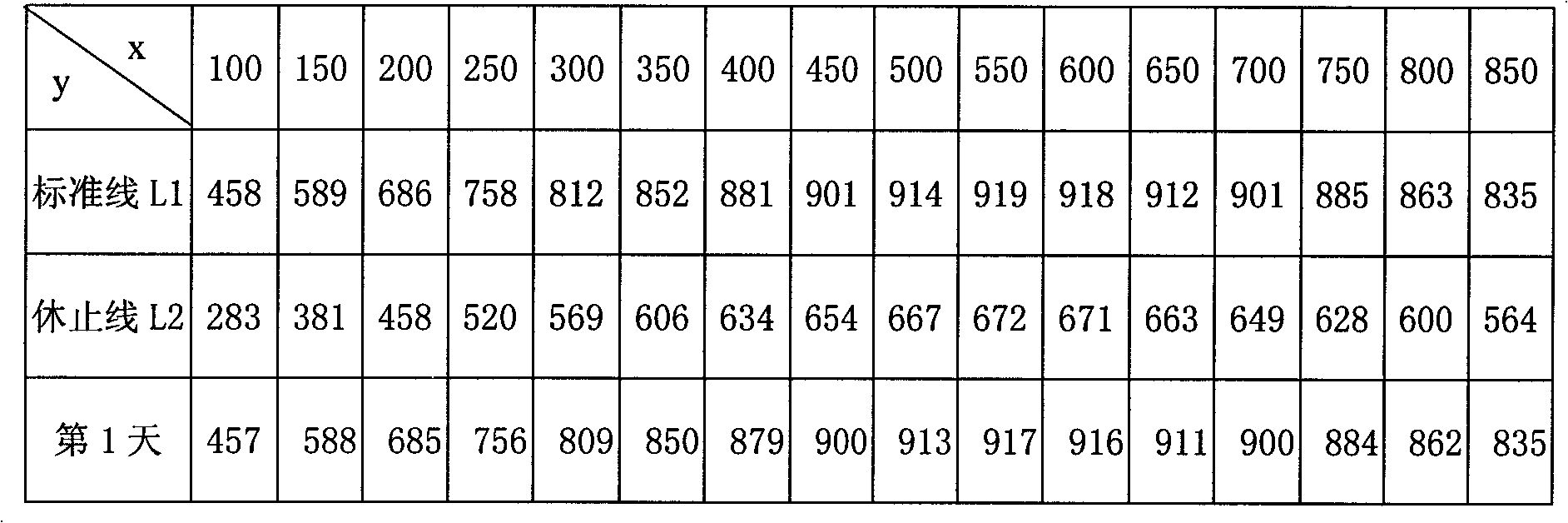

[0015] figure 1 It is a schematic diagram of the blast furnace tapping channel side wall thickness detection device of the present invention, as figure 1 As shown, the device for detecting the thickness of the side wall of the blast furnace tapping channel of the present invention includes: a base 1, a measuring rod 2, a sleeve 21, a pushing rod 3, a track plate 4 and a pin 5 with a stone pencil. The base 1 is fixed on the hearth 101 of the tapping trough of the blast furnace.

[0016] The sleeve 21 is connected to the base 1 through a pin shaft 22, and the sleeve 21 can rotate around the pin shaft 22; the measuring rod 2 is inserted in the sleeve 21, and can be opposite to the sleeve The cylinder 21 slides; the push rod 3 and the measuring rod 2 are connected through the latch 5 with a stone pencil, and the push rod 3 is provided with a guide groove 31; the track board 4 is fixed on the base 1 , the track plate 4 is provided with a guide pin 41 , and the guide pin 41 is pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com