Production equipment of copper foil of negative current collector of ultra-thin lithium battery

A technology for production equipment and battery negative electrode, which is applied in the field of ultra-thin lithium battery negative current collector copper foil production equipment, which can solve the problem that the tensile strength and elongation of copper foil are not ideal, and it cannot mass produce lithium battery copper foil below 9μ. problems such as mass production, to achieve the effect of shortening the production process, facilitating promotion and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

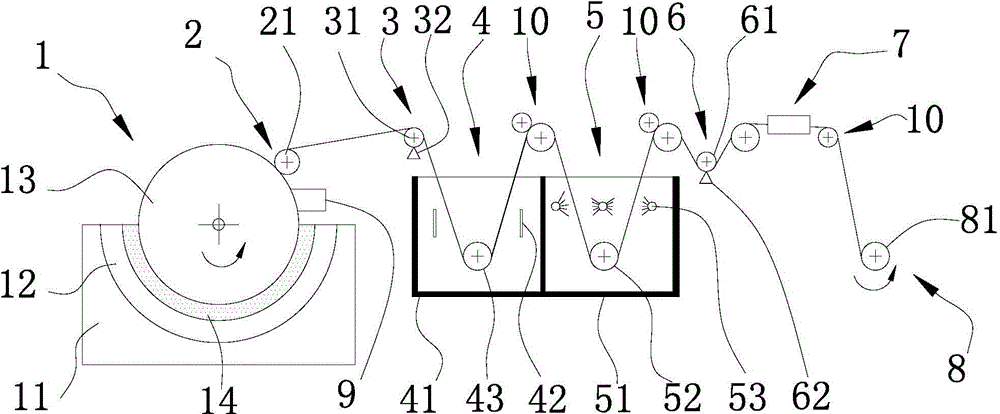

[0018] see figure 1 , a kind of ultra-thin lithium battery negative current collector copper foil production equipment provided by this embodiment, it comprises a control box, it also comprises the attachment device 1 that is connected with described control box, and is controlled by it, separation device 2, the second A tension detection device 3, an anti-oxidation device 4, a cleaning device 5, a second tension detection device 6, a baking device 7 and a receiving device 8, the attachment device 1, the separation device 2, the first tension detection device 3, the anti-tension The oxidation device 4, the cleaning device 5, the second tension detection device 6, the baking device 7, and the receiving device 8 are arranged in sequence. The attachment device 1 includes an anode support frame 11, an anode tank 12 and a cathode roller 13 adapted to the anode tank 12, the anode tank 12 is fixed on the anode support frame 11, and the cathode The roller 13 is movably arranged on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com