Automatic control method for cool-constant-temperature ore discharging of sinter ore furnace

A technology for sintering and ore furnaces, applied to furnace control devices, furnaces, furnace components, etc., can solve problems such as high or low ore temperature, increase the amount of finished ore, reduce the amount of returned ore, and achieve safe and economical operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

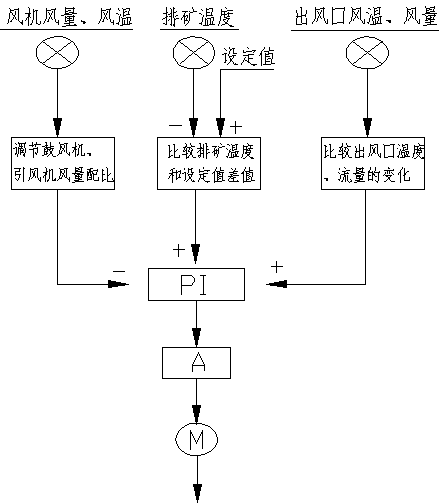

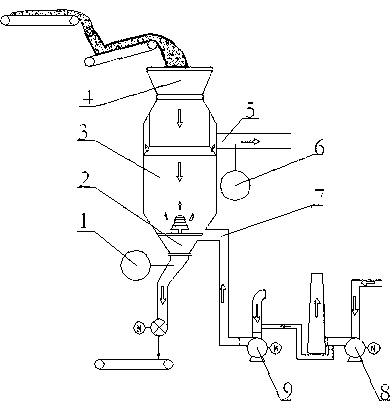

[0019] As shown in the figure, the specific implementation method is as follows:

[0020] An automatic control method for cold-fixed temperature discharge of sinter furnaces, including the steps of crushing and screening of sinter discharged from a sintering machine through a crushing device, and passing through a sinter conveying device through a cooling furnace 3 feeding port 4 Enter the cooling step in the cooling furnace 3, and then discharge the ore material from the discharge port 2 to the cooling furnace 3 through the discharge device, and discharge as the sinter is cooled, through the temperature detection device installed at the discharge port of the cooling furnace 3 1 Detect the ore discharge temperature, and compare the temperature with the set temperature value. The set temperature value can be adjusted and set according to the size of the cooling furnace 3 and the amount of ore discharge. Generally, the set temperature is 100°C. The ore discharge temperature is h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com