Control method of variable deceleration point of friction hoist based on variable load

A control method and hoist technology, which are applied to lifting equipment, transportation and packaging in mines, etc., can solve the problems of poor operation economy of friction hoists, increased crawling distance, and large changes in load properties, and achieve safe and economical realization. running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

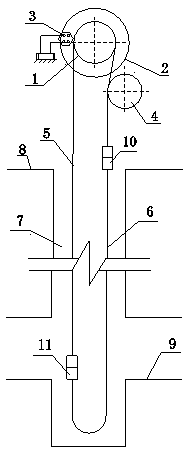

[0022] exist figure 1Among them, the friction drum 1 is connected with the main shaft of the friction hoist and rotates synchronously. A friction liner with a certain friction coefficient is fixed around it. The friction liner is covered with a hoisting wire rope 5, and the two ends of the hoisting wire rope 5 are connected to the cage A10, the cage B11, the friction drum 1 rotates, relying on the friction force between the lifting wire rope 5 and the friction lining on the friction drum 1 to drive the cage A10 and cage B11 to reciprocate up and down; the brake disc 2 is a circular steel plate, fixed on the friction drum 1 Above, pressure is applied by the disc brake 3 to generate a braking torque; the disc brake 3 applies positive pressure to the brake disc 2 through a pre-compressed butterfly spring to generate friction and form a braking t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com