Construction method for slope supporting and reinforcing

A construction method and technology for slopes, applied in excavation, foundation structure engineering, sheet pile walls, etc., can solve the problems of large influence of soil properties and inability to provide pull-out resistance, and achieve stable slopes, pull-out and shear resistance Strong and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] For a better understanding of the present invention, the following examples are further descriptions of the present invention, but the content of the present invention is not limited to the following examples.

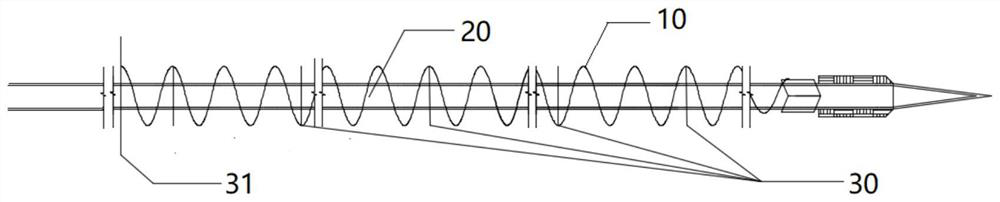

[0036] The invention provides a construction method for slope support and reinforcement, the construction process of which is as follows: figure 1 shown, including the following steps:

[0037] S1: Use an excavator to excavate the foundation pit, reserve a 20cm protective layer, manually excavate, and remove the loose soil before supporting;

[0038] S2: Use a level and a total station to determine the drilling position according to the design requirements and the subsequent fixing position of the steel mesh. Drill the hole at the determined position and the depth of the hole must meet the anchoring depth, and use a high-pressure air pipe to remove the dust and dust in the hole. debris blown out;

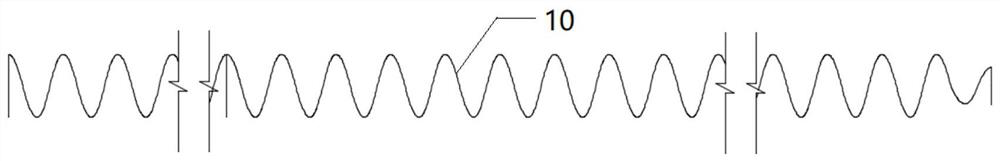

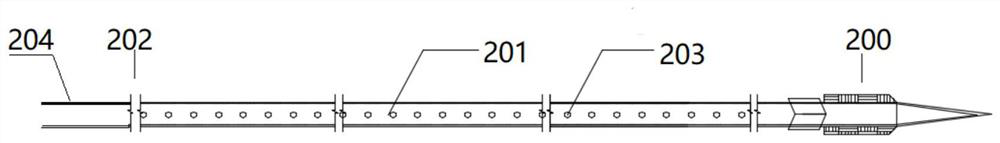

[0039] S3: if figure 1 , figure 2 and image 3 As shown to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com