Method for partially electroplating lead-indium alloys on petal-shaped rotors

A local electroplating and petal-shaped technology, applied in jewelry and other directions, can solve problems such as detachment from tooling and tilting of hanging, and achieve the effect of complete coating, fine crystallization and consistent color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044]The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

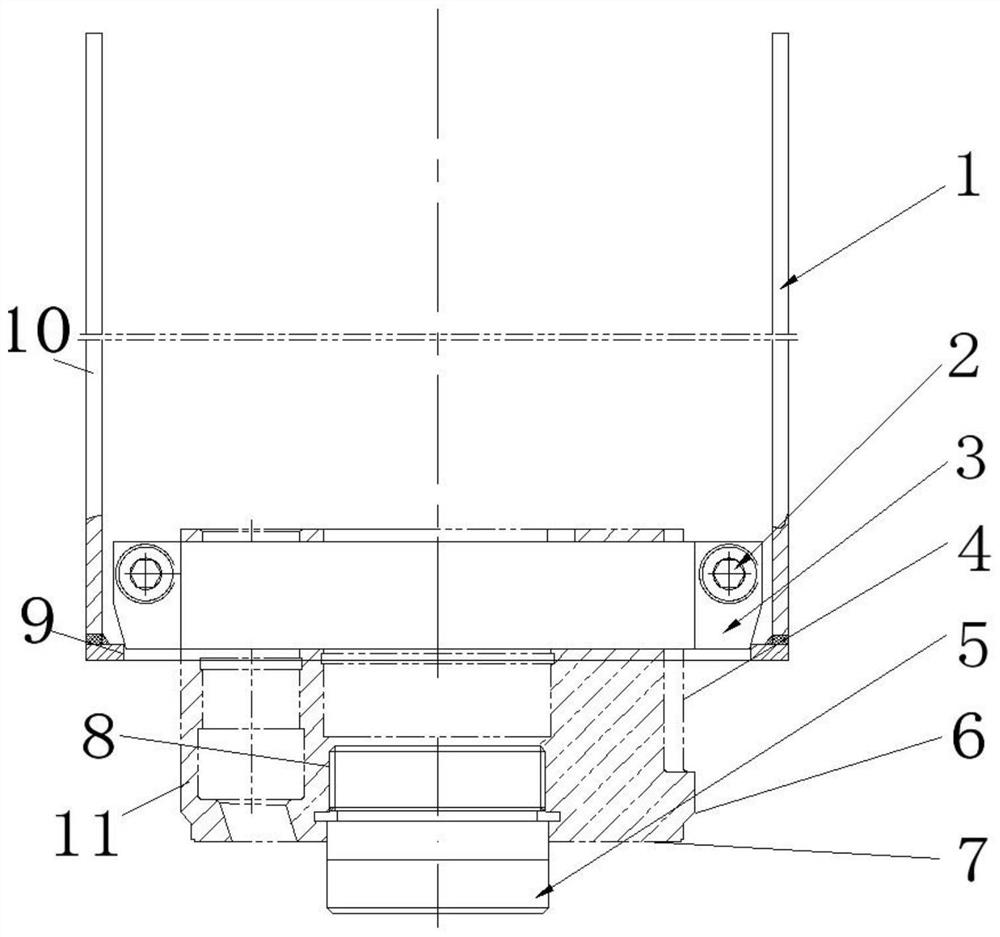

[0045] Example. A method for partial electroplating of lead-indium alloy on a petal-shaped rotor, comprising the following steps: Figure 1-13 shown, including the following steps:

[0046] (1) Degreasing with organic solvent;

[0047] (2) Protection: use insulating tape, tape or tooling for protection;

[0048] (3) Mounting and hanging:

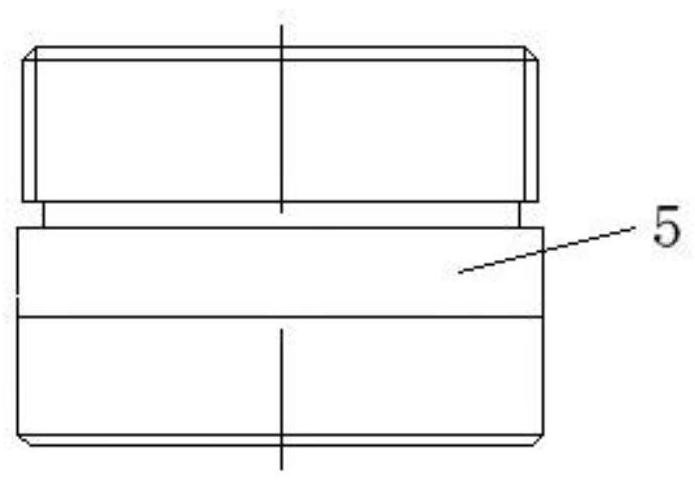

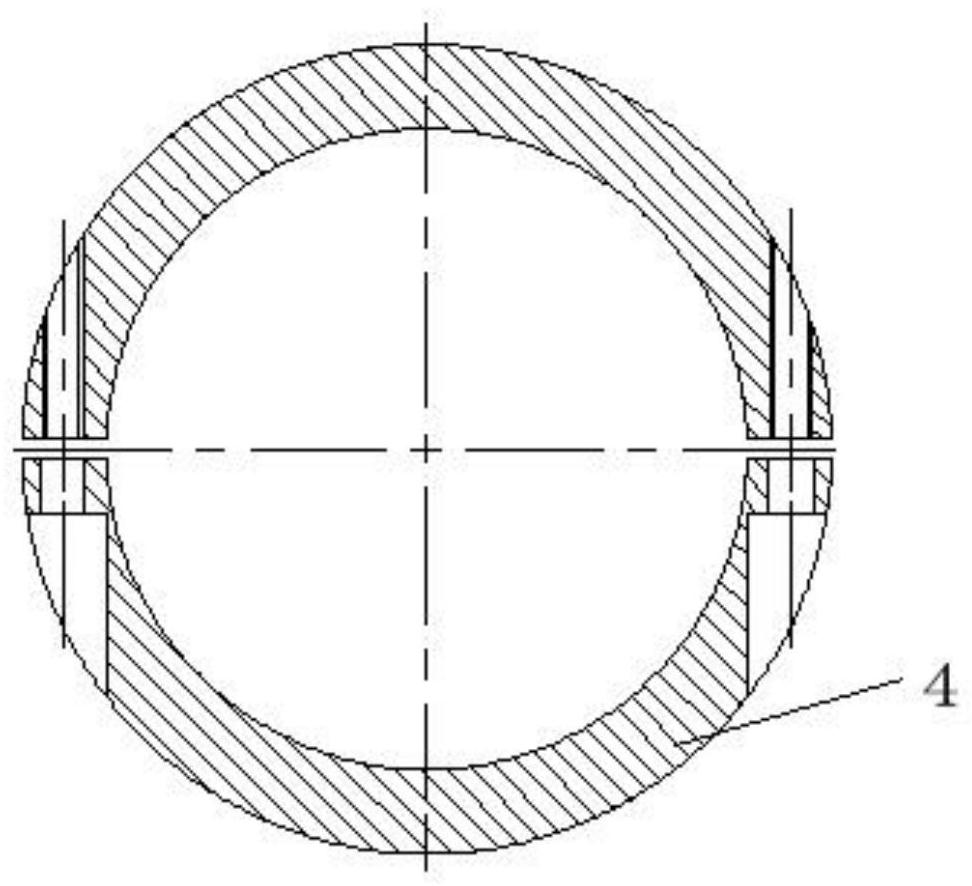

[0049] 3.1 Before electroplating, use electroplating tooling to hang the petal-shaped rotor 11 workpiece. The electroplating tooling is composed of hanger 1, hexagon socket head bolt 2, clamp 3 and plug 5. When installing and hanging, turn the electroplated end face 7 of the workpiece downward, first block the inner hole 8 on the electroplated end face 7 of the workpiece with a plug 5, and clamp the clamp 3 at the position of the petal shape 4 on the outer surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com