Patents

Literature

45results about How to "Improve waxing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

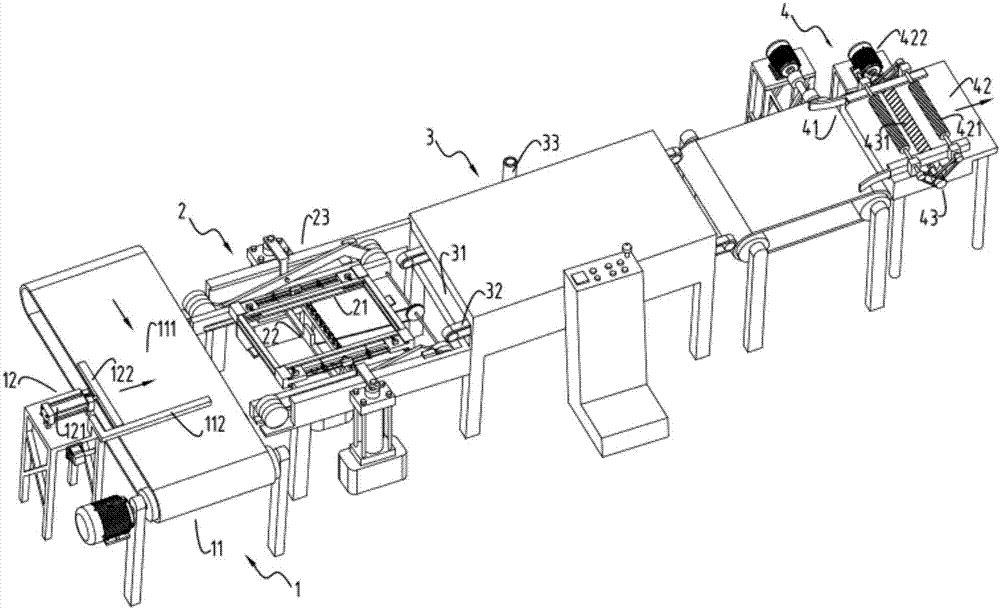

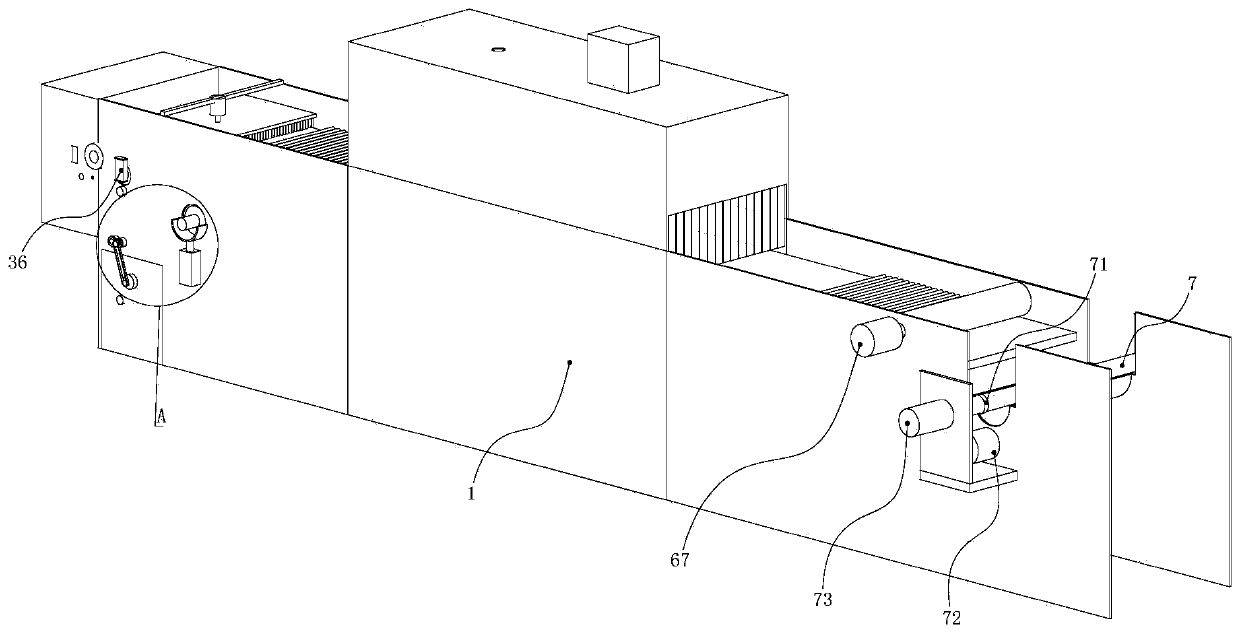

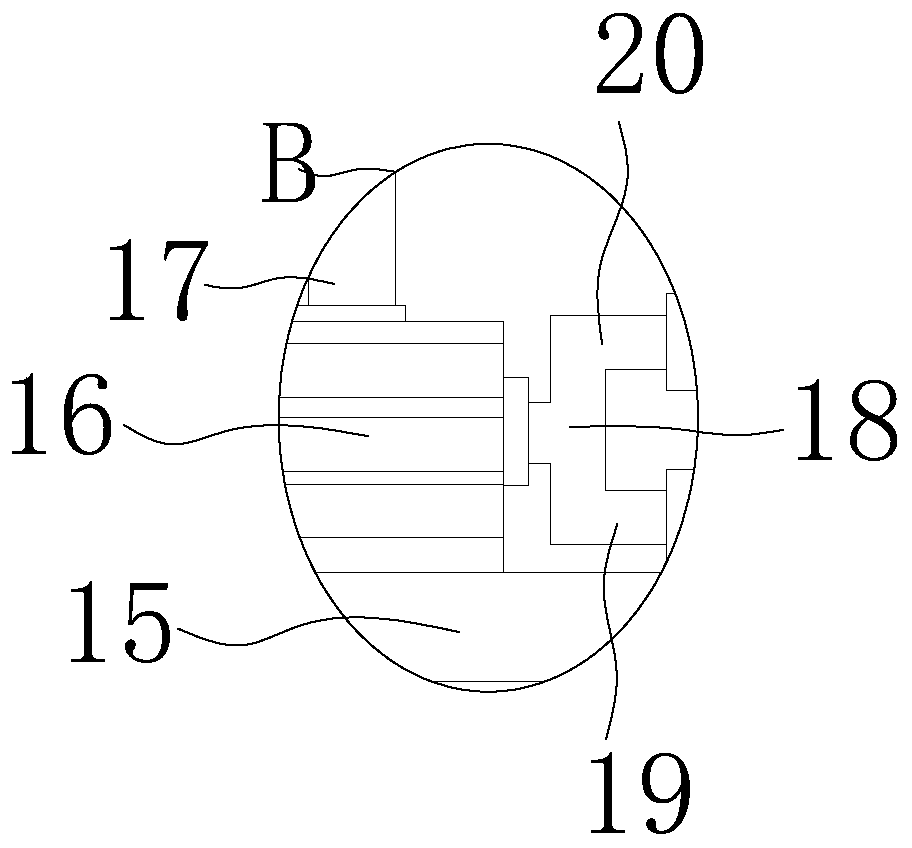

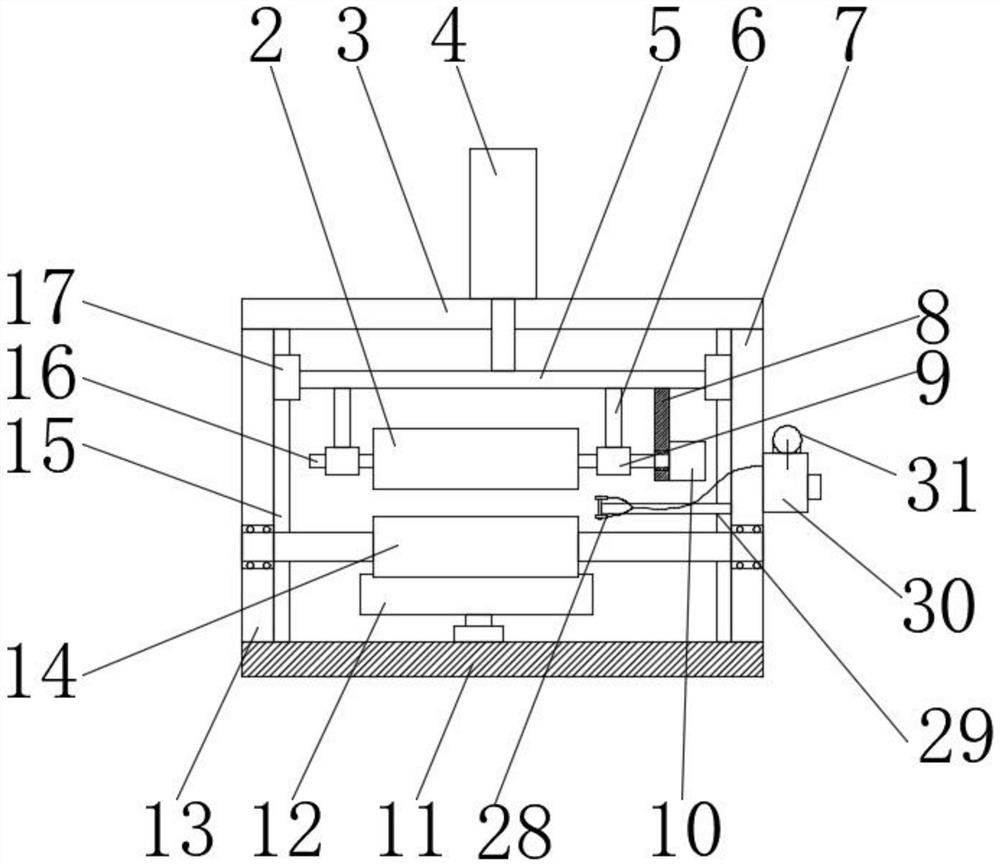

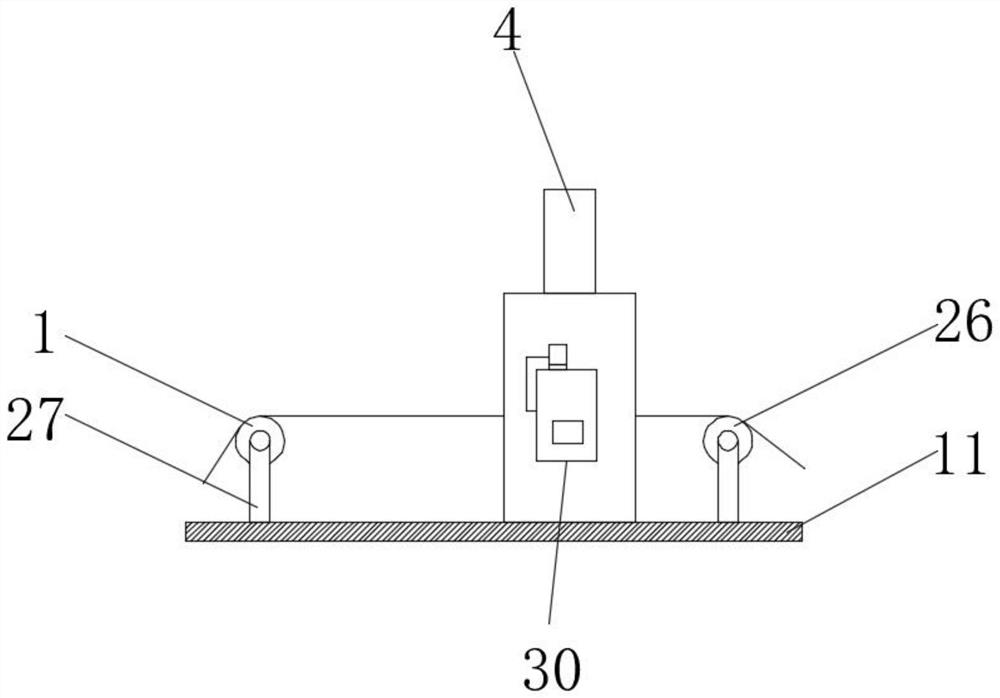

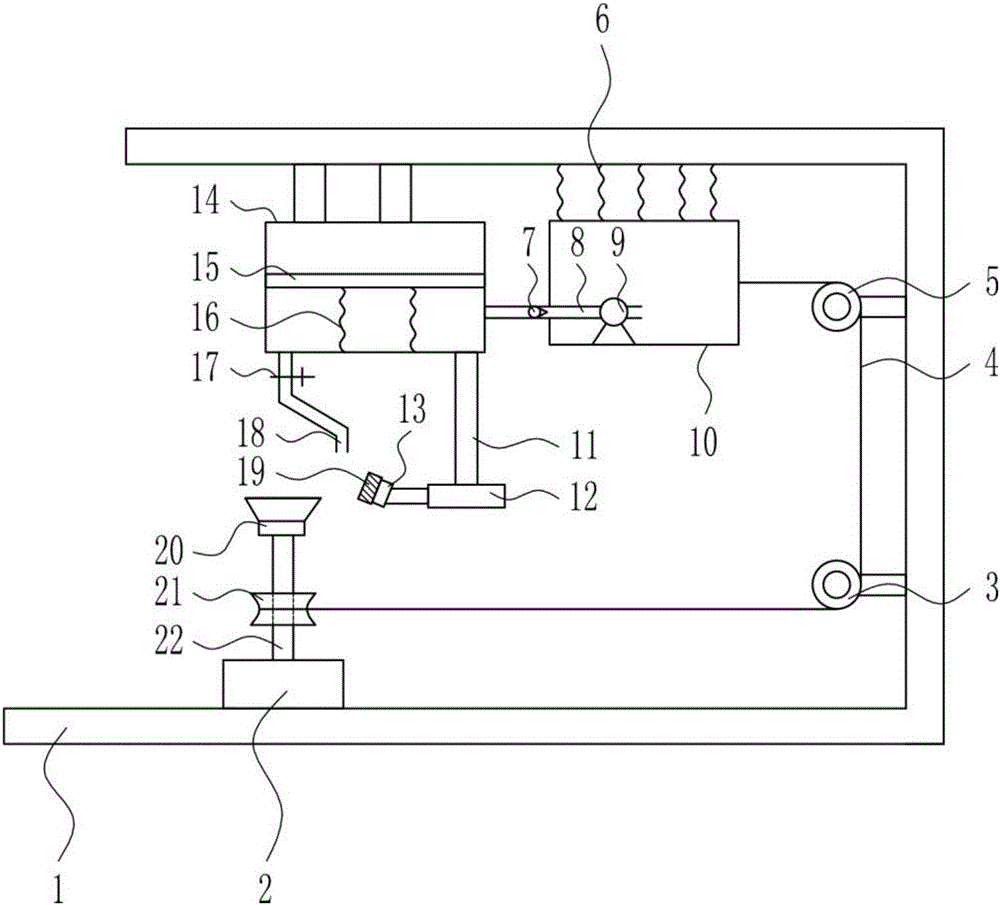

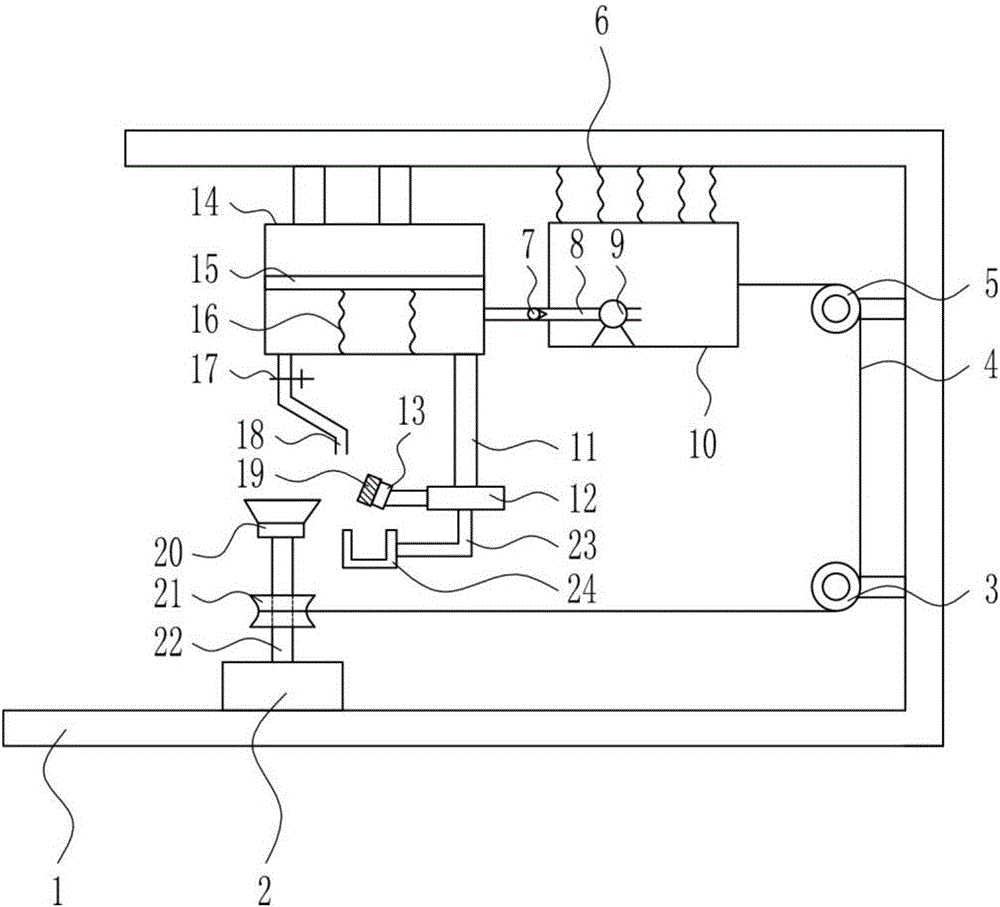

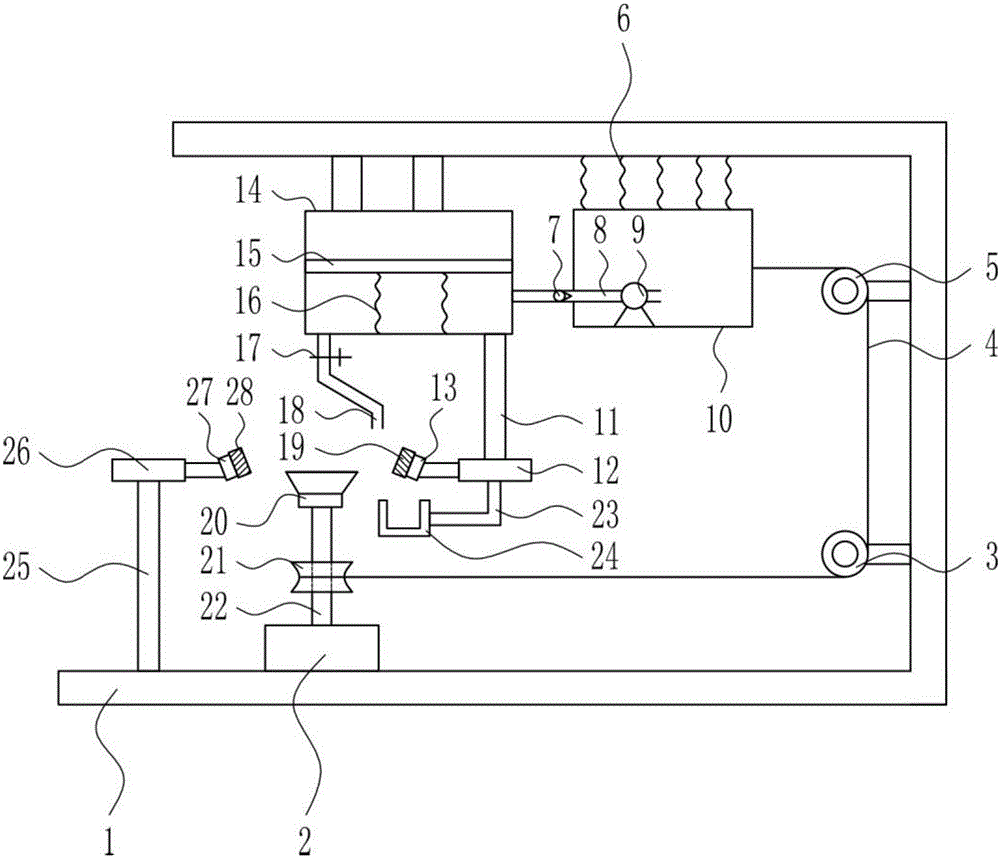

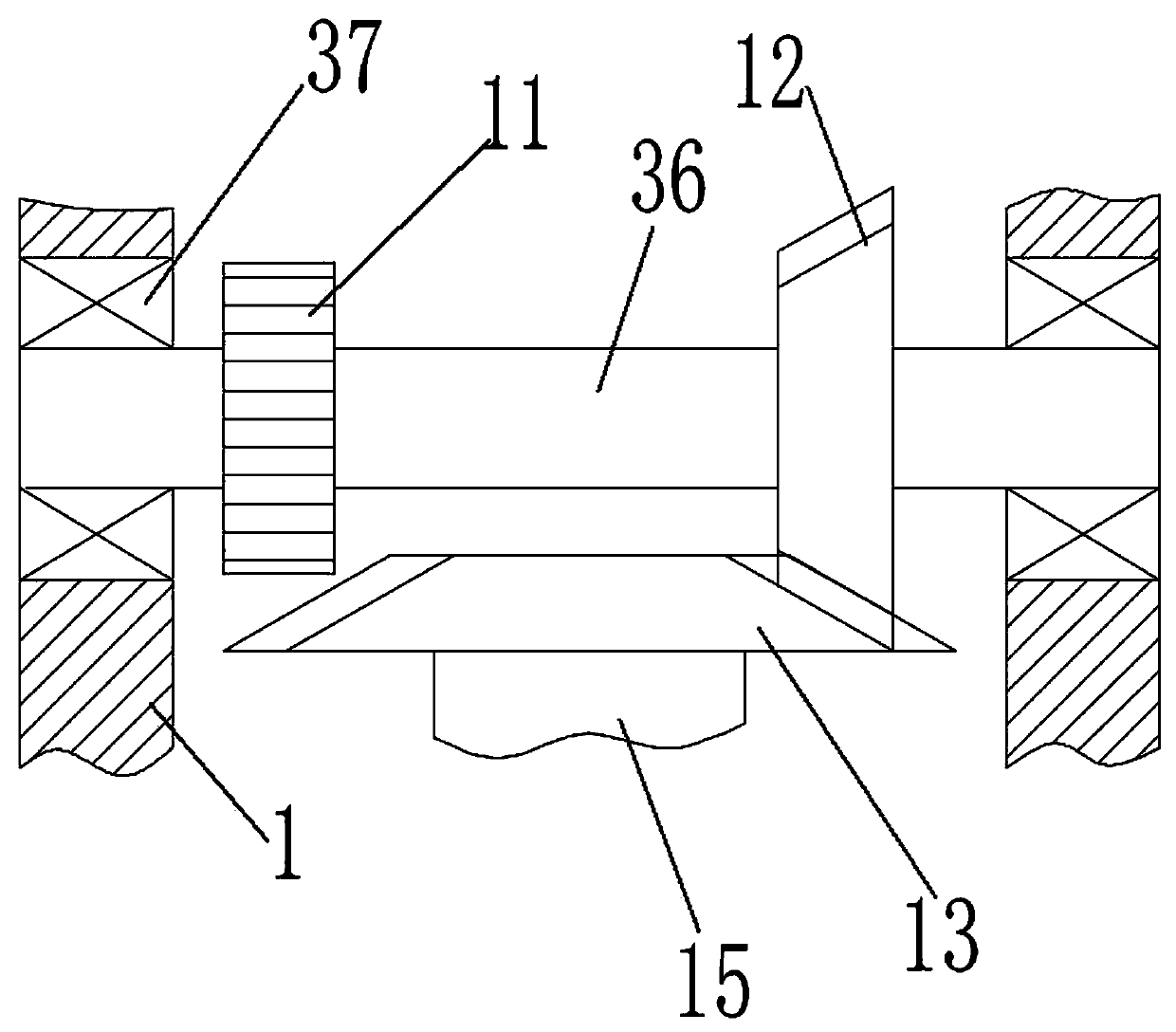

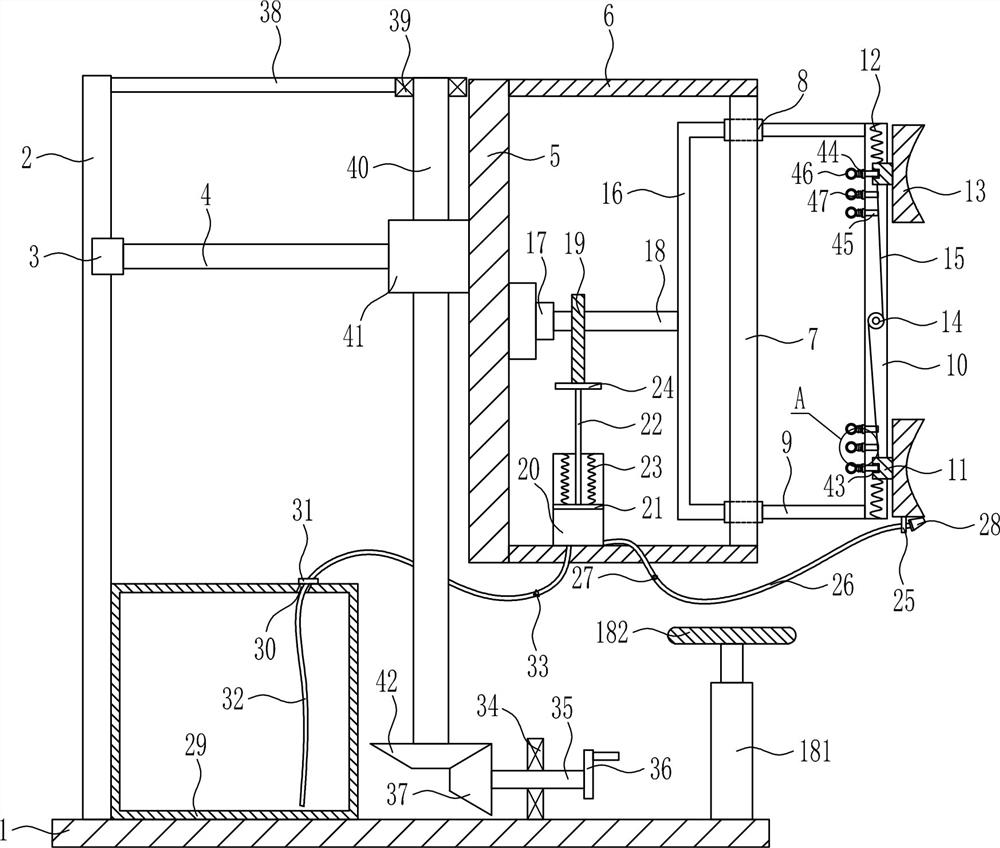

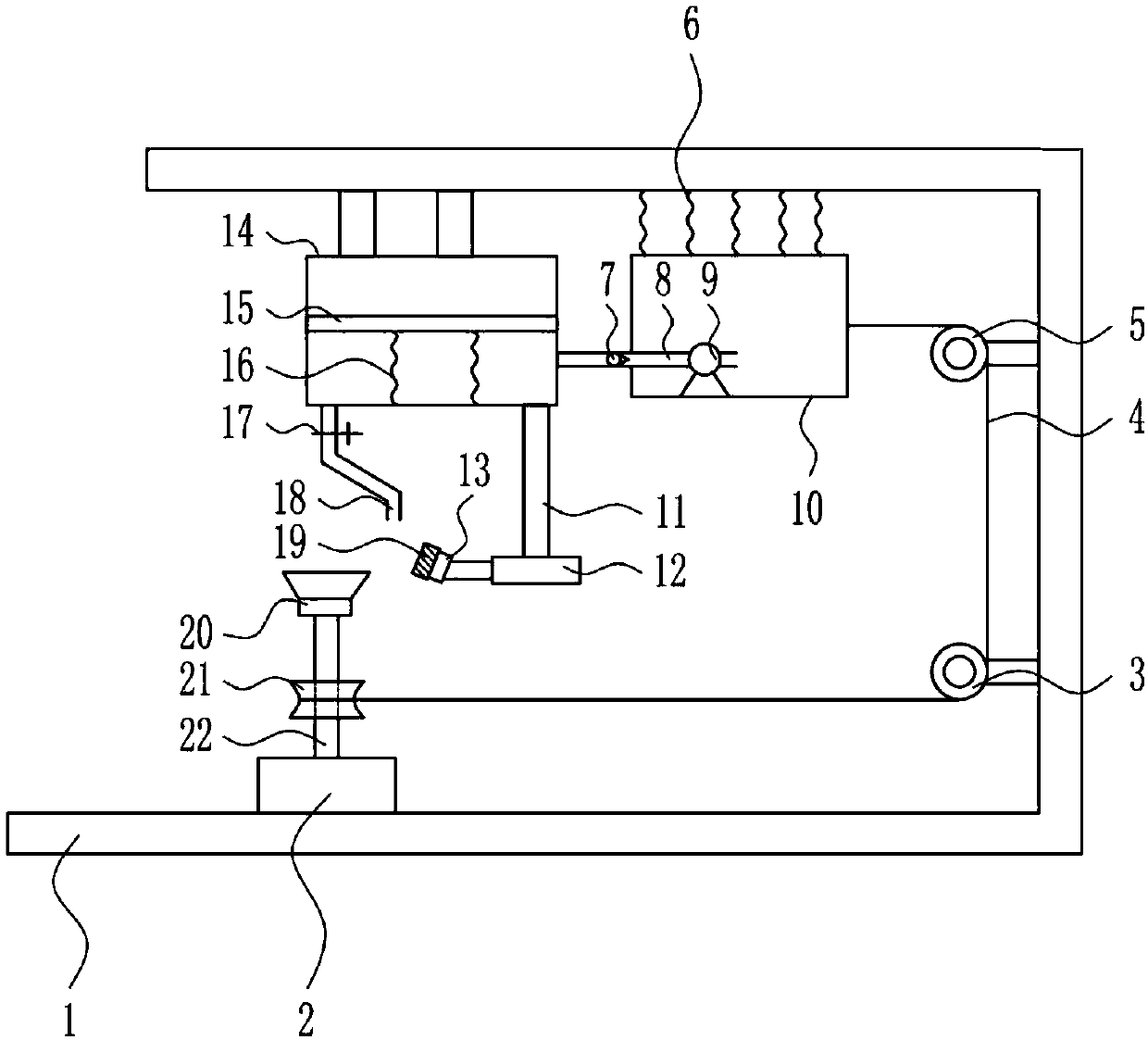

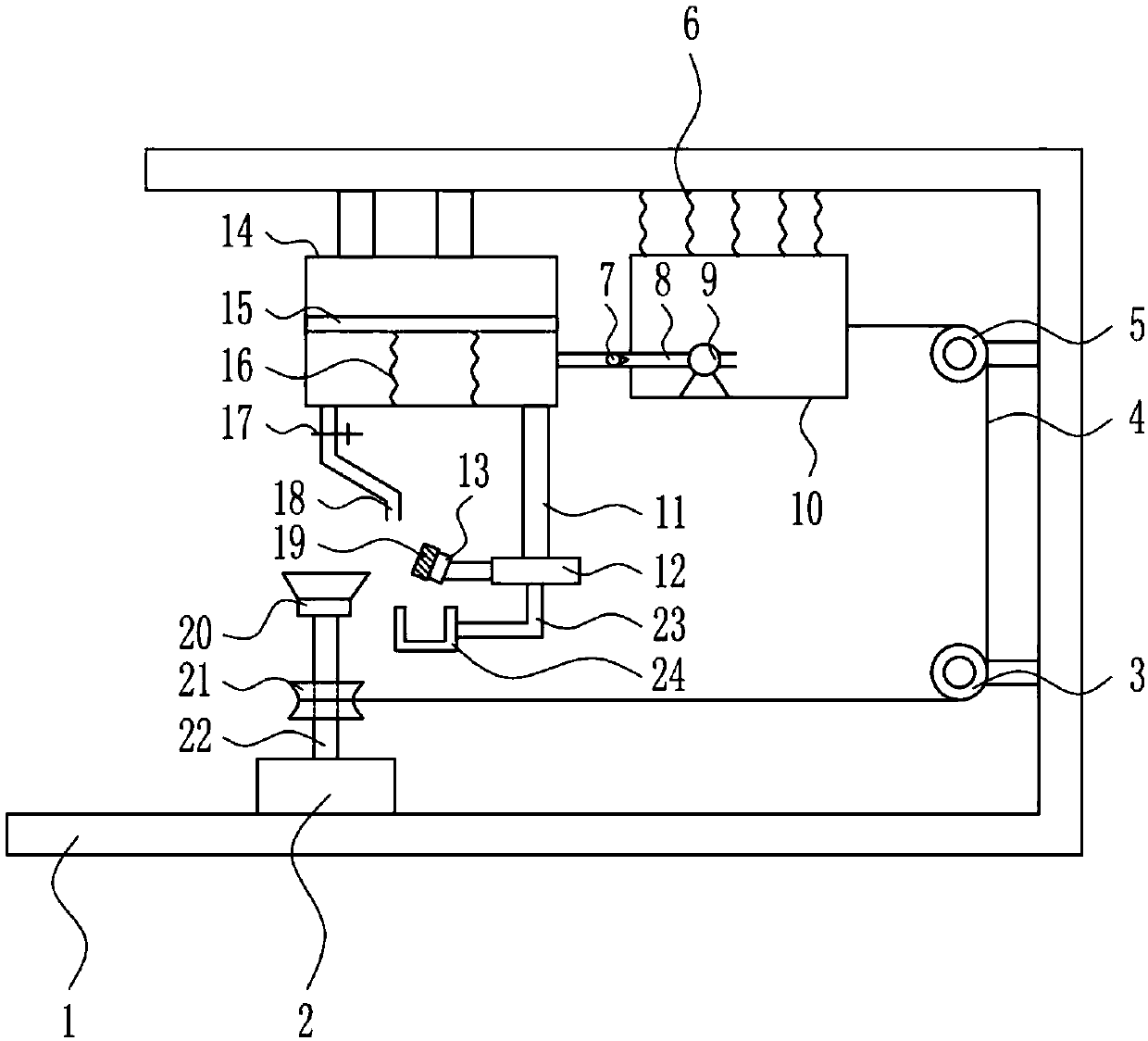

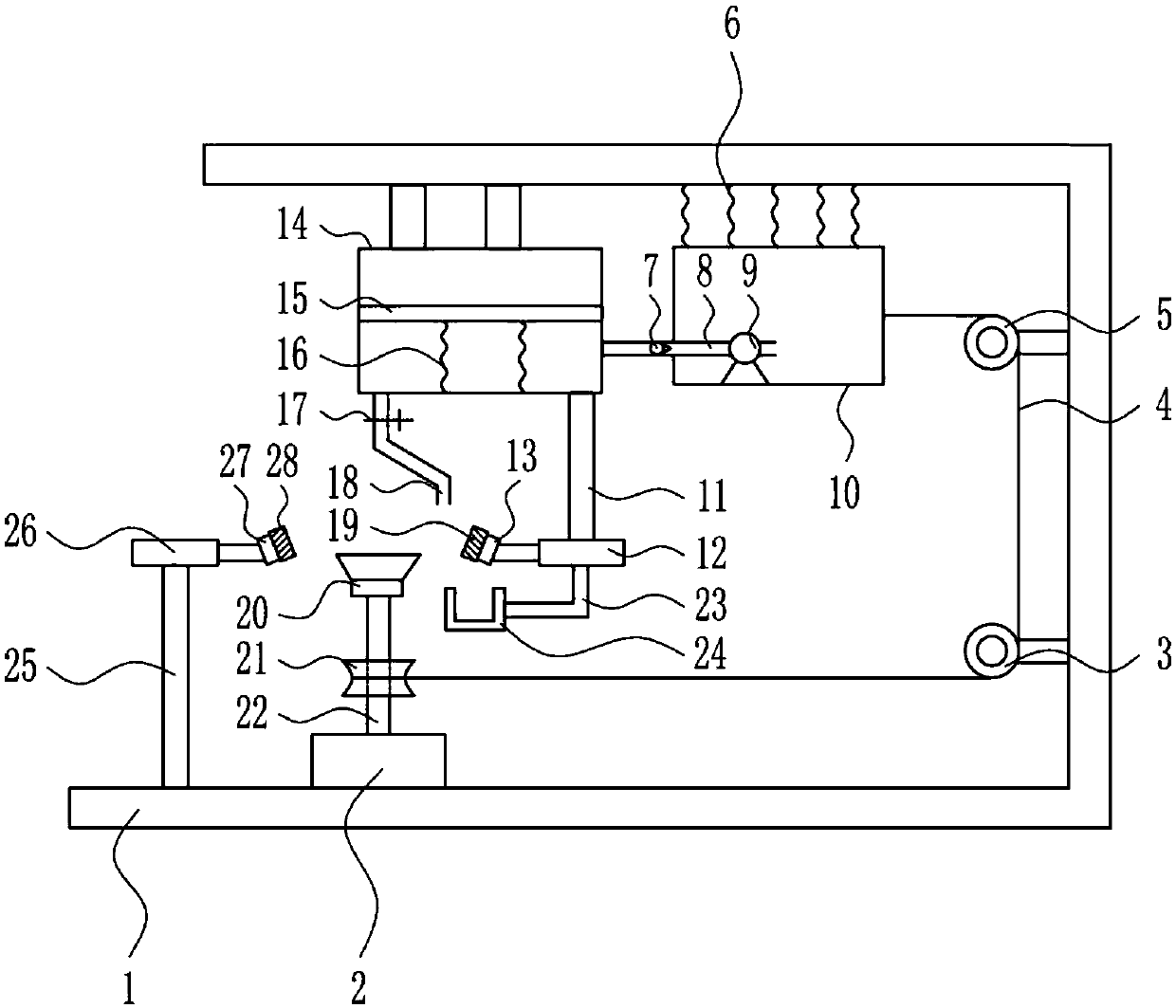

Ceramic tile surface waxing treatment production line

InactiveCN106938227AWaxes quickly and evenlyDry fastSpraying apparatusPretreated surfacesProduction lineWax treatment

The invention relates to a tile surface waxing treatment production line, which includes a positioning feeding part, the positioning feeding part is used to position and push the delivered tiles backward; a turning waxing part is arranged on the Positioning the rear end of the feeding part, the turning waxing part is used to wax the tiles pushed by the positioning feeding part; the drying part, the drying part is arranged at the rear end of the turning waxing part, and the drying part is used for It is used to dry the ceramic tiles output after being waxed by the turned waxing part; the polishing part is arranged at the rear end of the drying part, and the polishing part is used to perform surface waxing on the ceramic tiles output after the drying process of the drying part Polishing of the first layer; it overcomes the problems of tile waxing and wax surface polishing that do not have the function of integrated continuous processing, low efficiency and labor-intensive waxing process and uneven waxing.

Owner:湖州裕尚卫浴有限公司

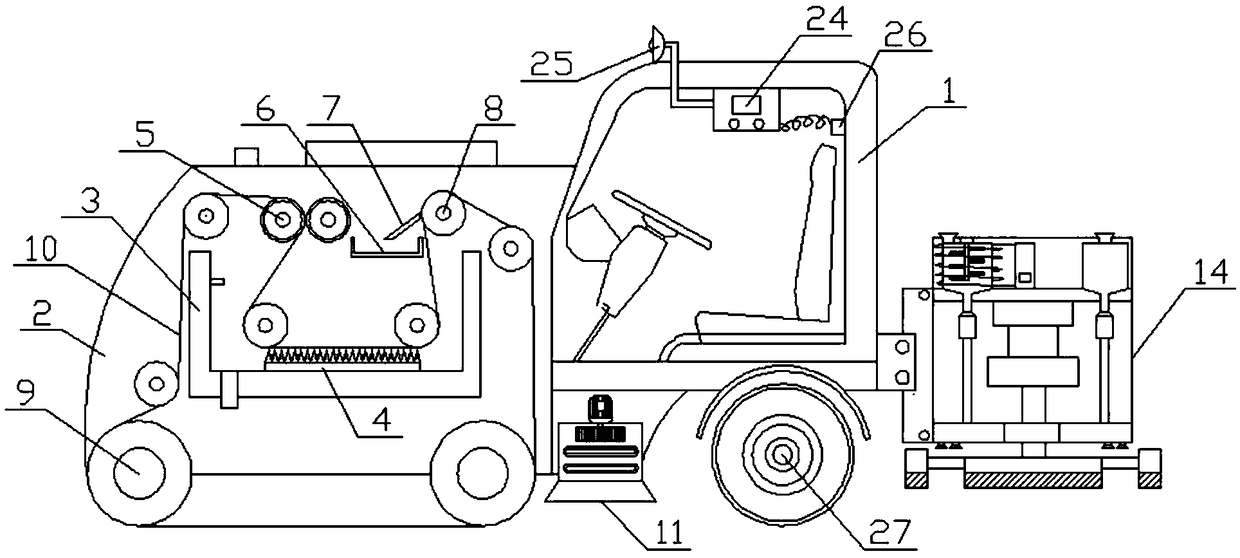

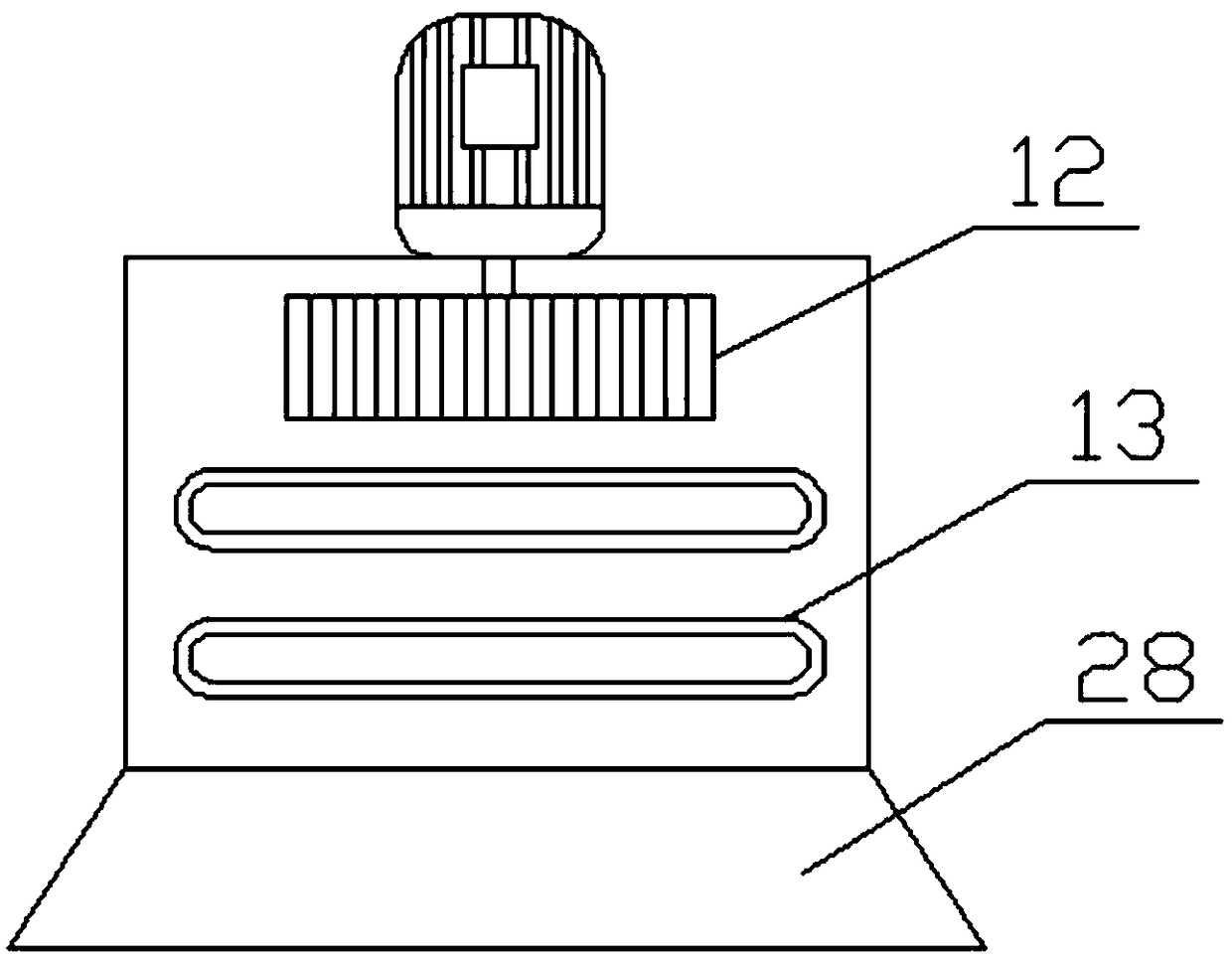

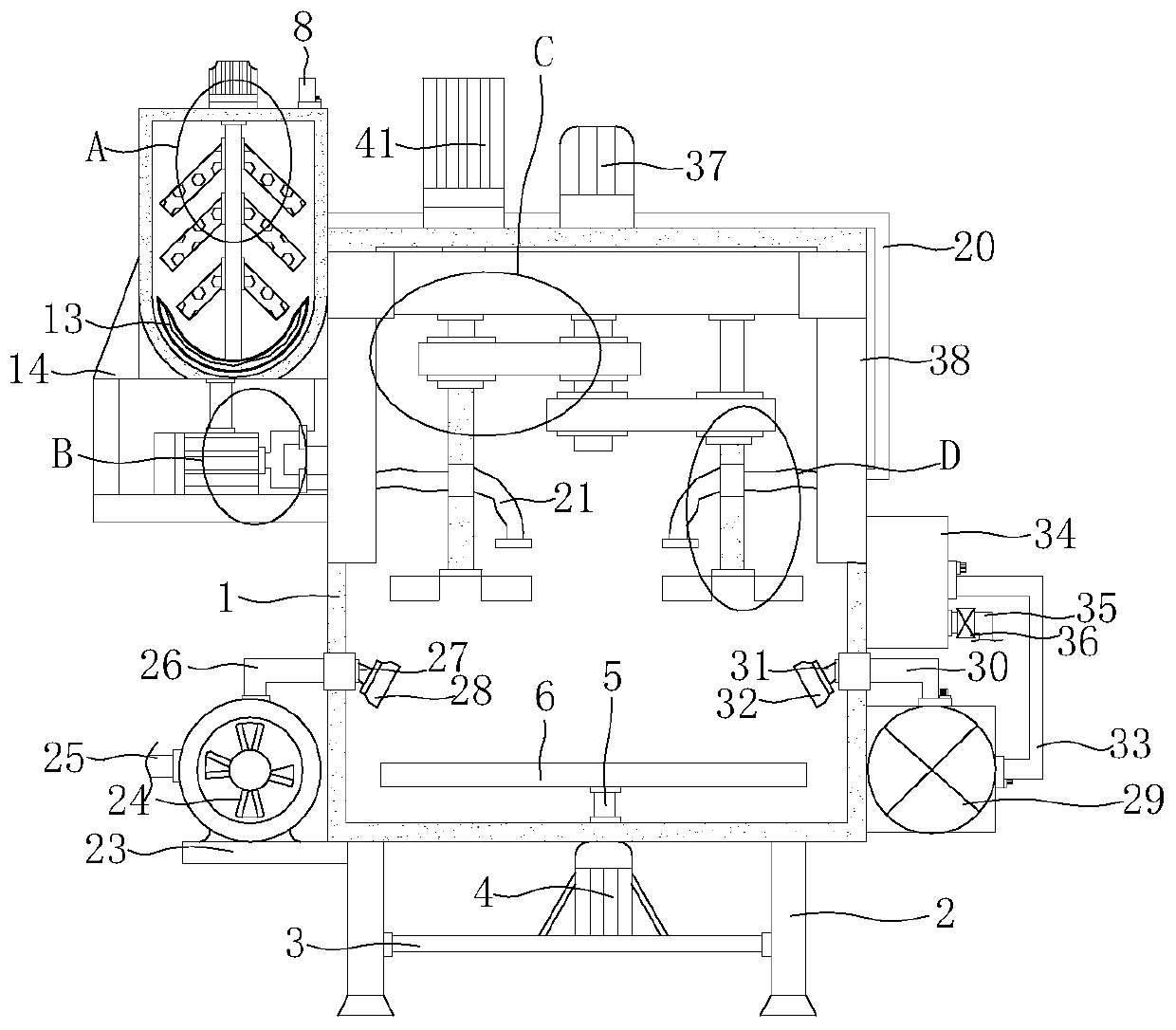

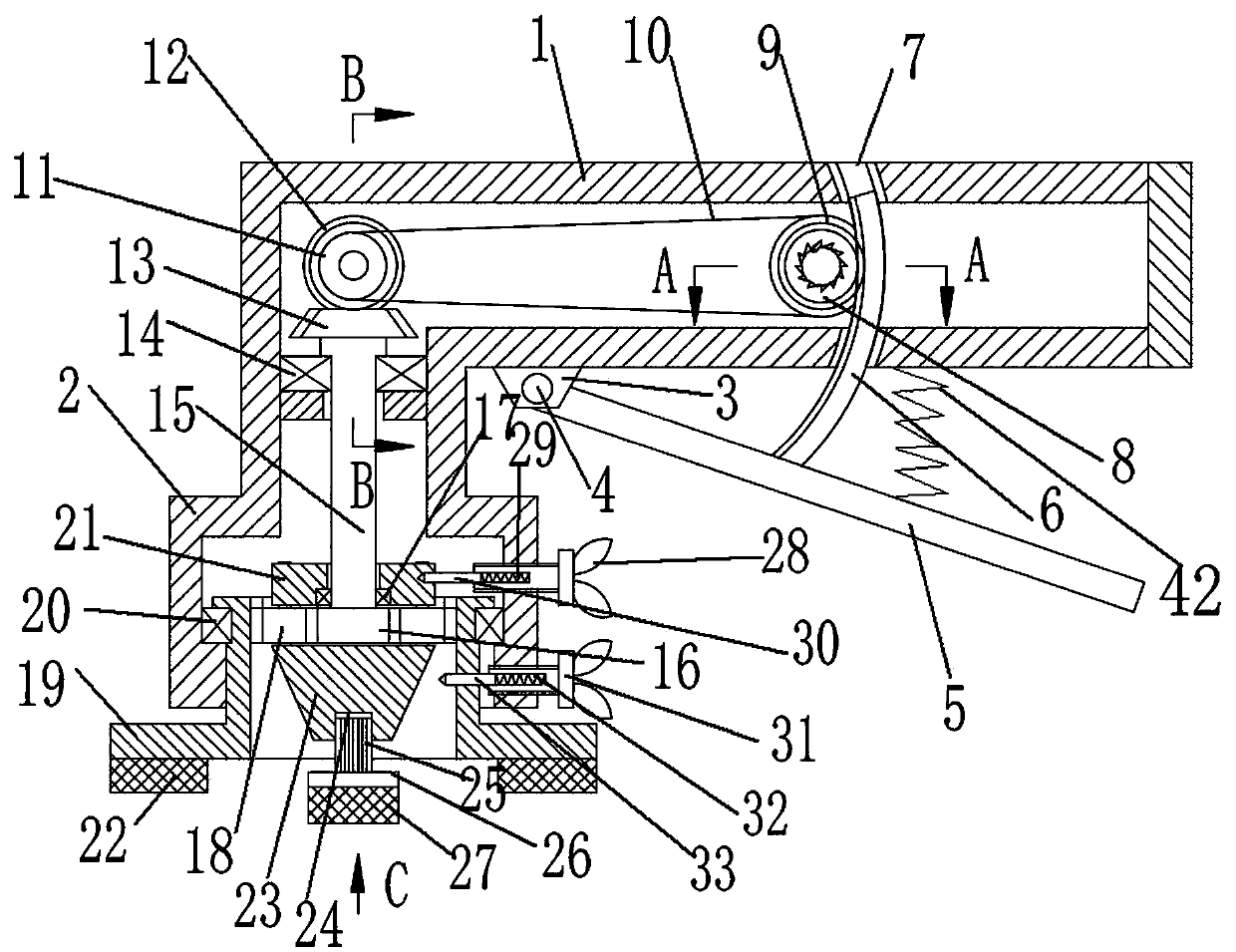

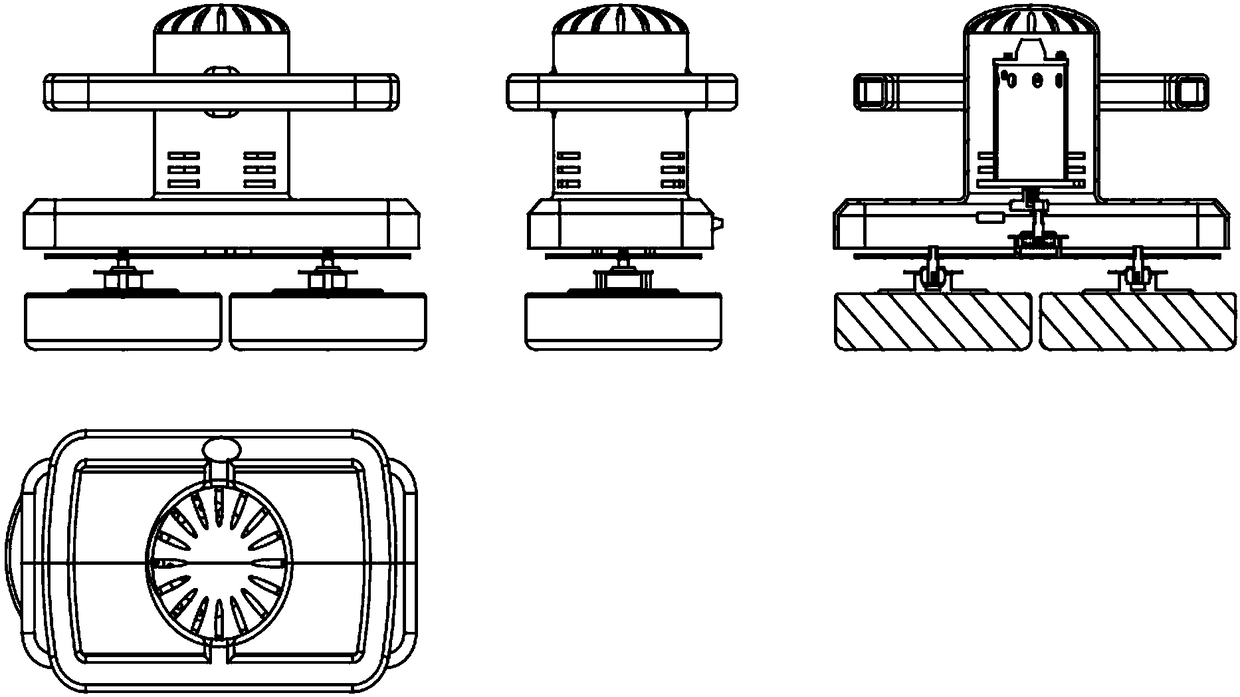

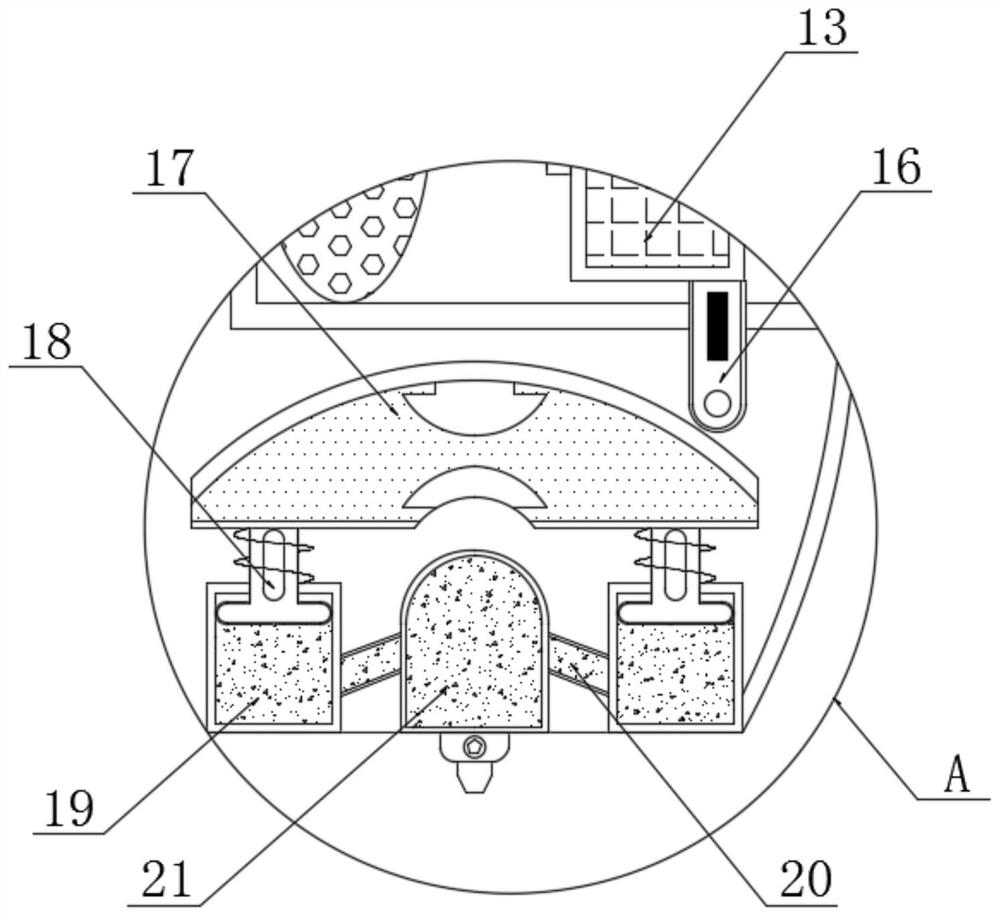

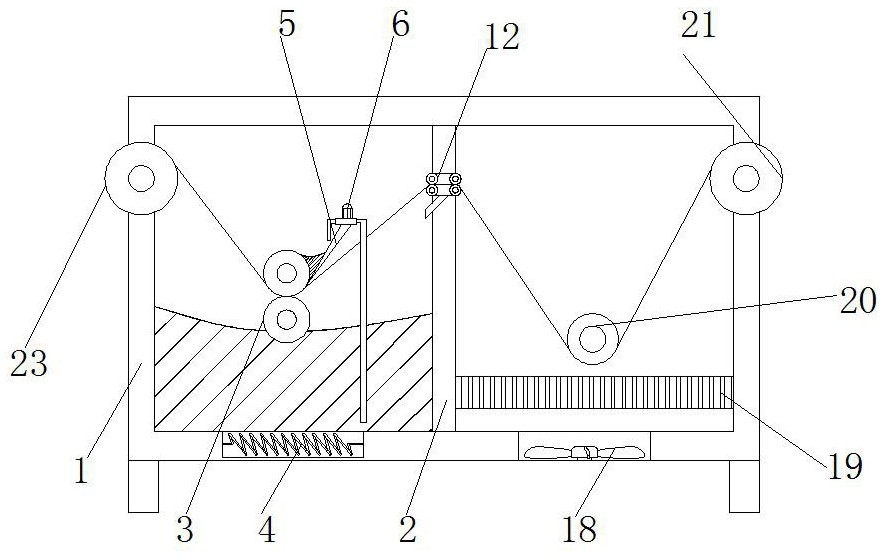

Floor scrubbing device for indoor basketball court

InactiveCN109222759AImprove cleaning efficiencyAvoid accidentsCarpet cleanersFloor cleanersWaxDrive wheel

The invention discloses a floor scrubbing device for an indoor basketball court. The device includes an operating room. A water tank is arranged in the middle of a cavity of the floor scrubbing device. At that left and right side of the upper end of the brush, left side of squeeze wheel, right end of scraper, a guide roller is arranged at the lower end of the left side of the outer wall of the water tank and the upper end of the right side of the outer wall of the water tank, the left and right ends of the bottom of the outer wall of the floor cleaning device are provided with driven wheels, The left end of the bottom of the outer wall of the operation room is provided with a drying device, the lower end of the right side of the outer wall of the operation room is fixedly connected with awaxing device through a connecting piece, the left end of the upper surface of the support plate is provided with a wax melting box, and the right end of the upper surface of the support plate is provided with a polishing agent box. The invention relates to the technical field of modern sports service. The present indoor basketball court scrubbing device achieves the purpose of simple and convenient operation, high floor cleaning efficiency, good drying effect and high waxing efficiency, and realizes the integration of cleaning, drying and waxing.

Owner:张庭瑞

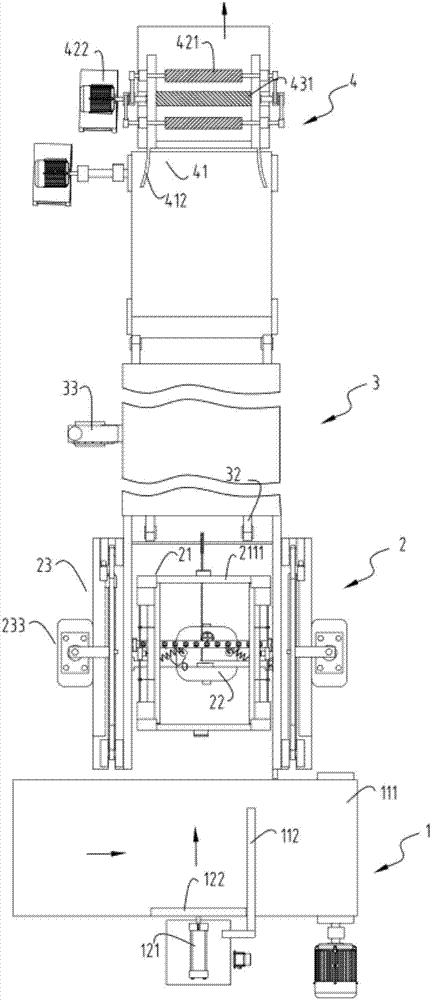

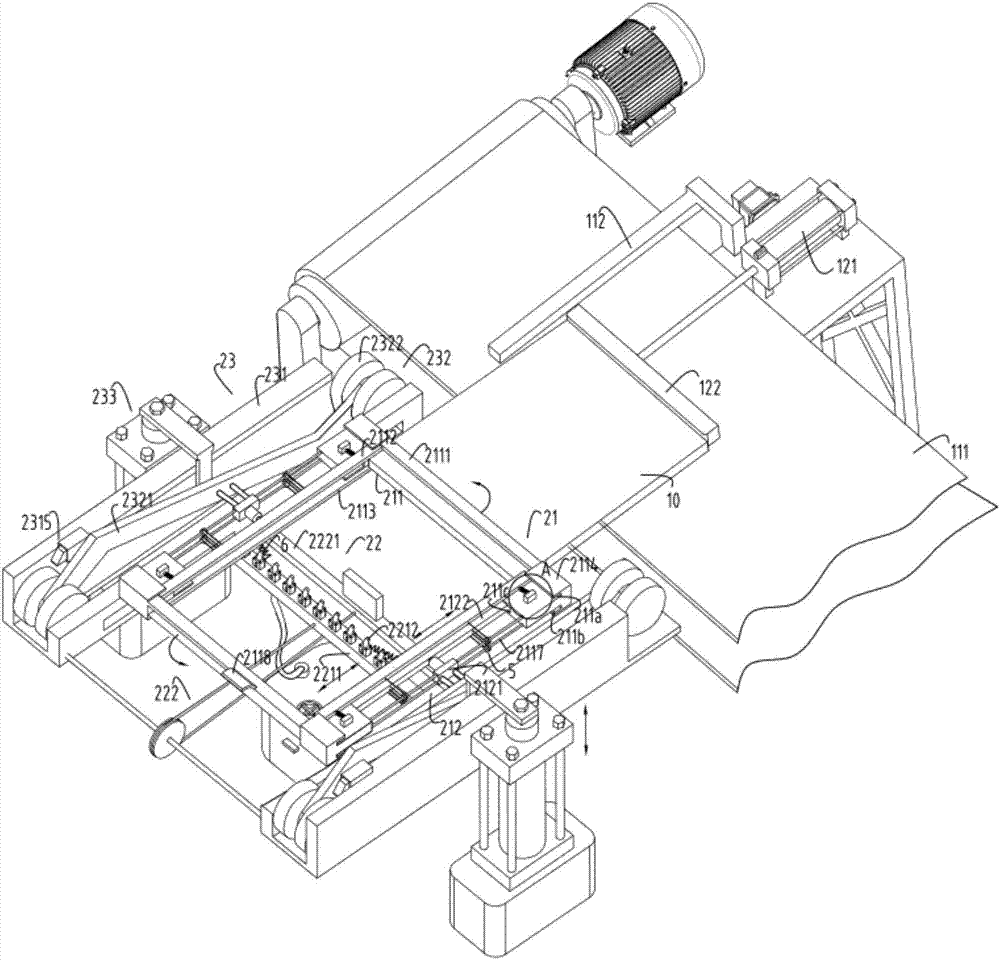

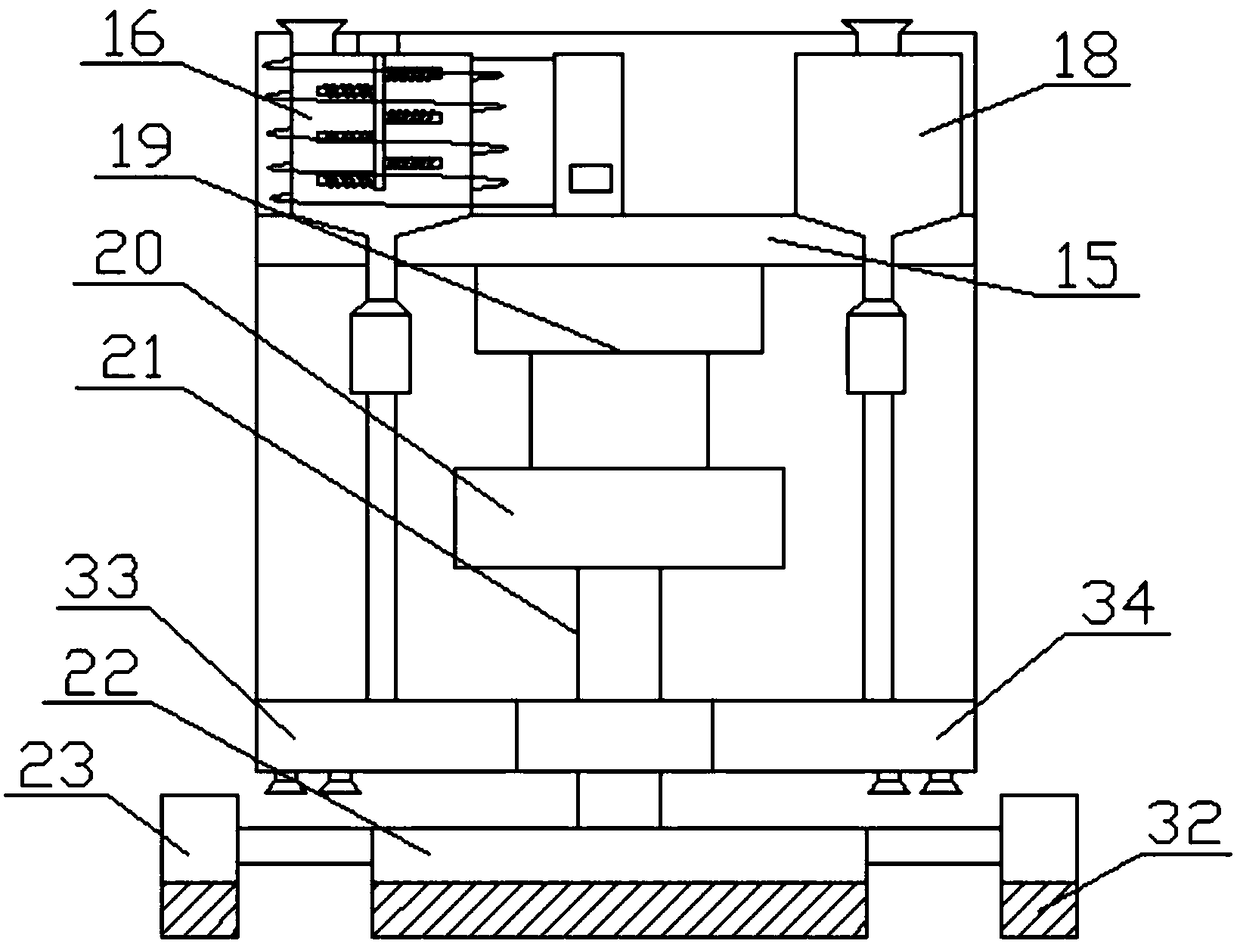

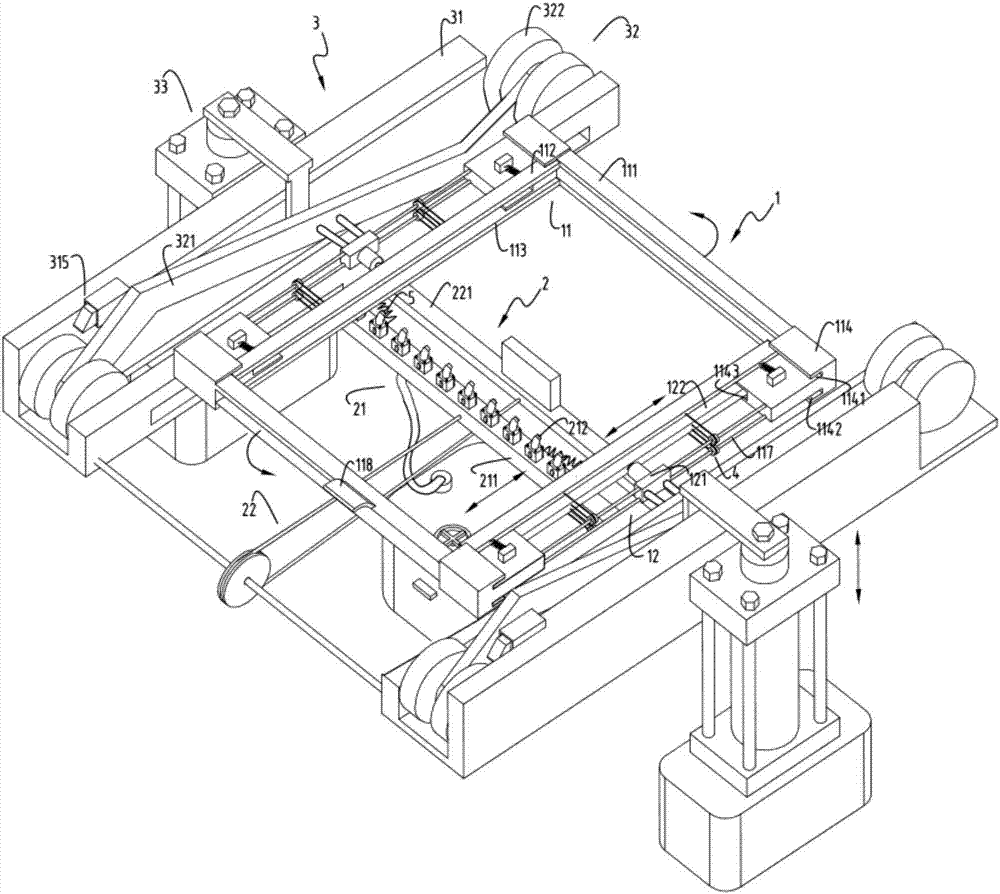

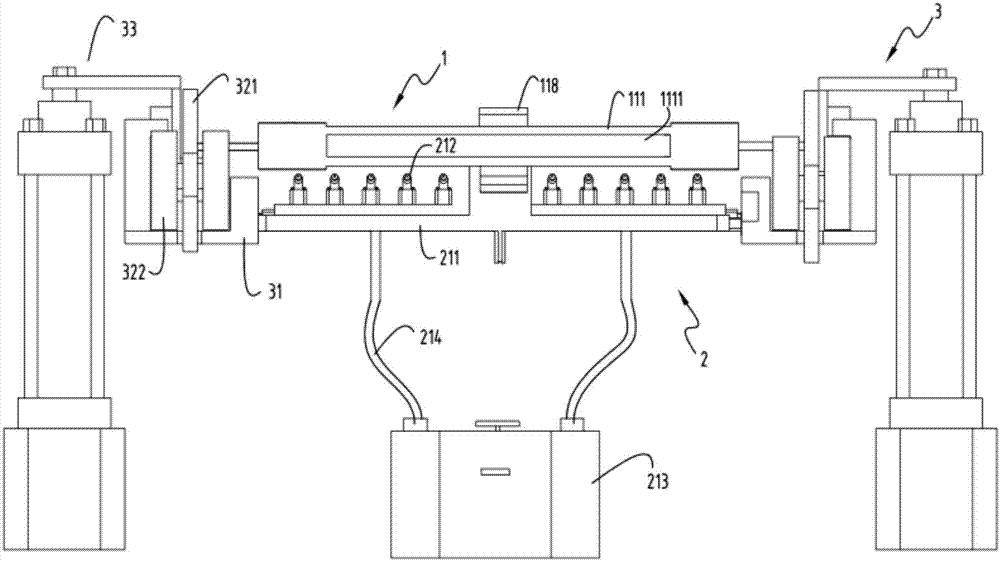

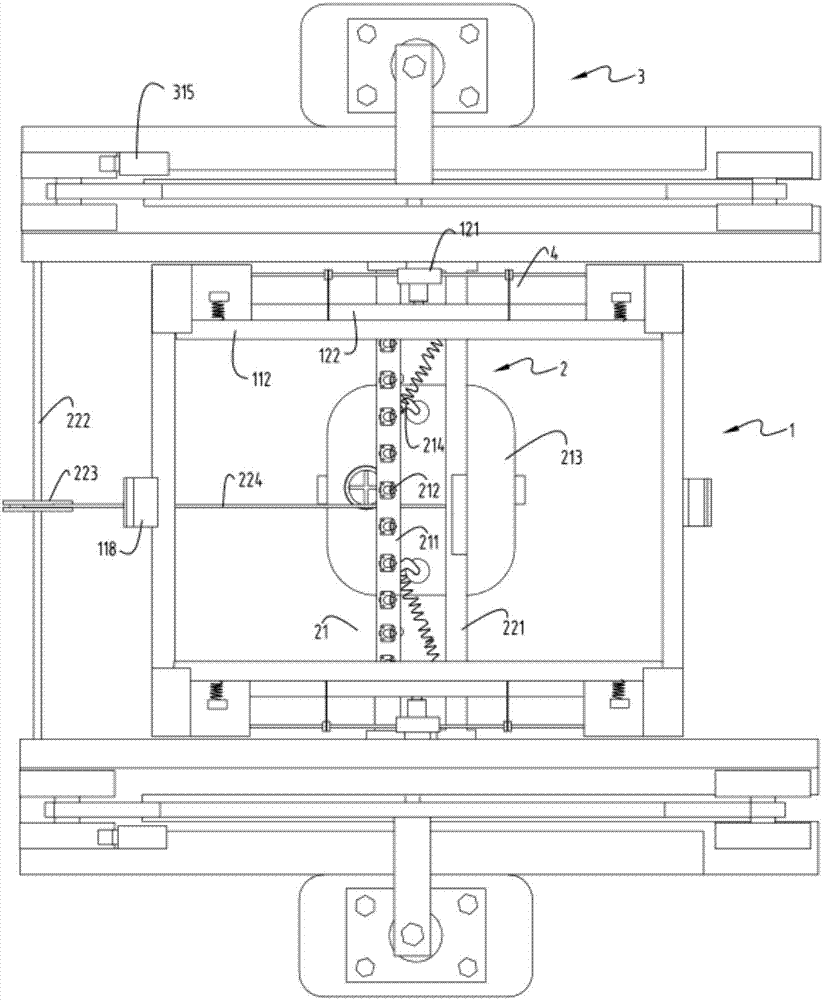

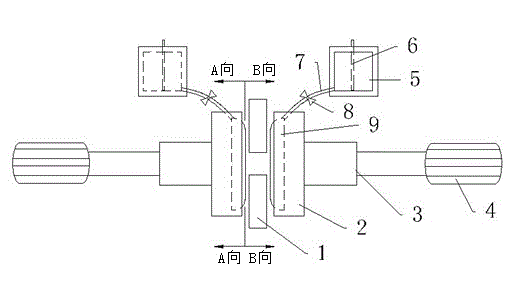

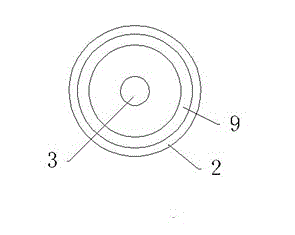

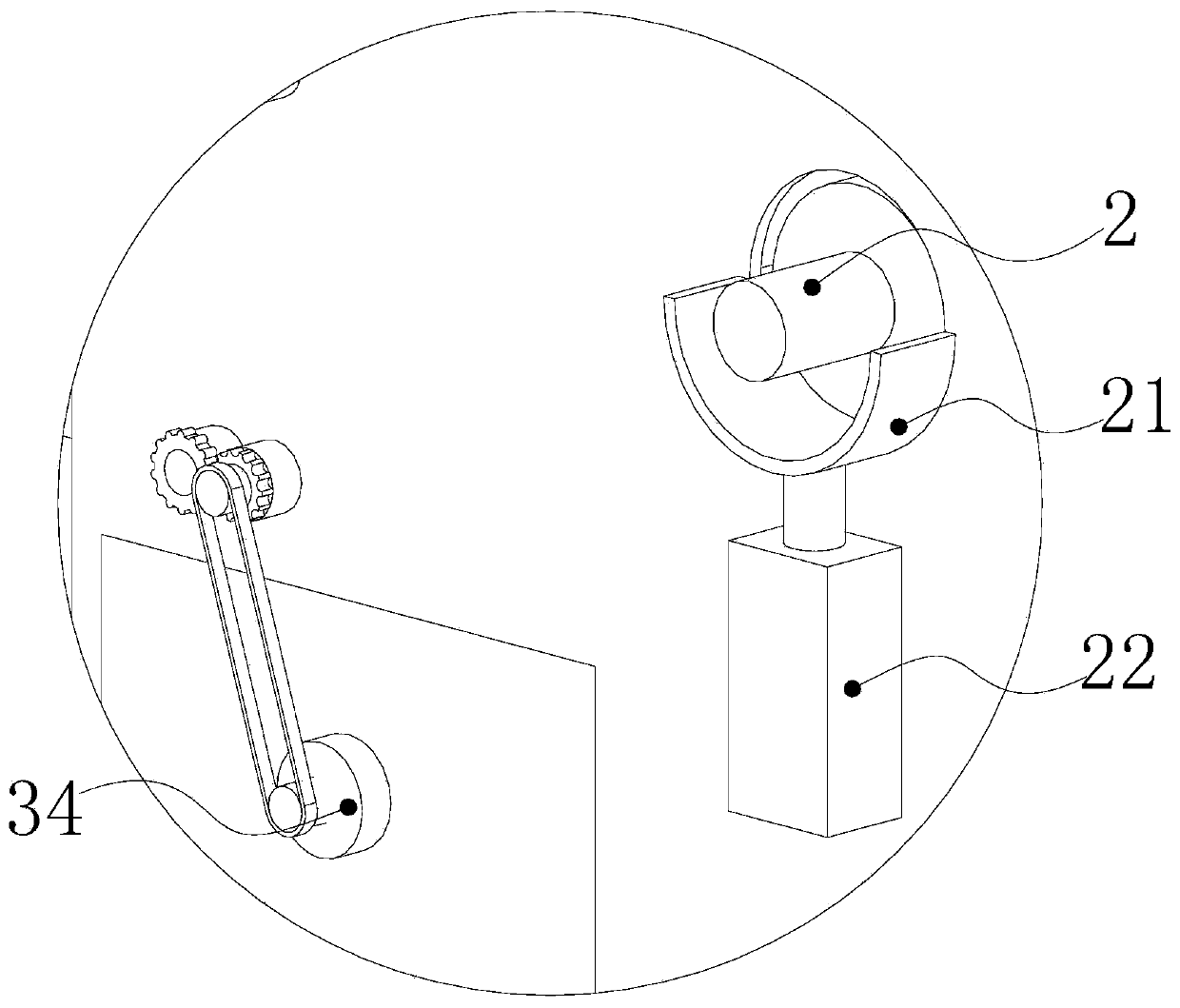

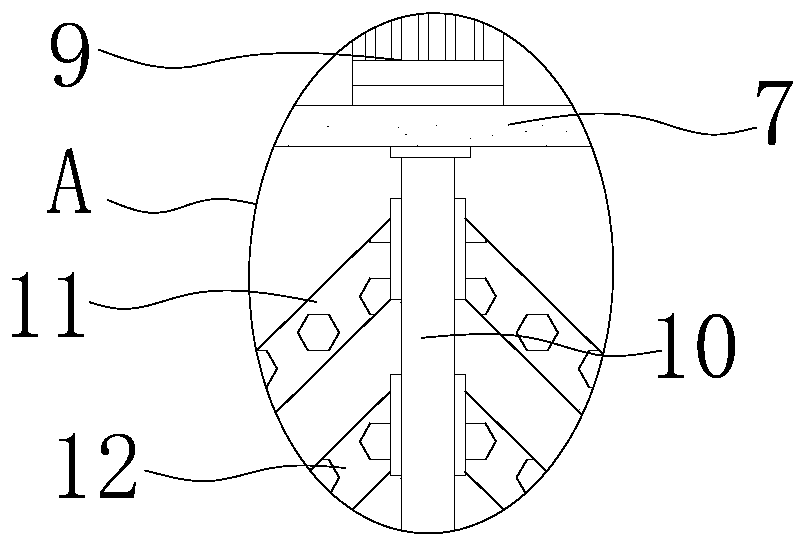

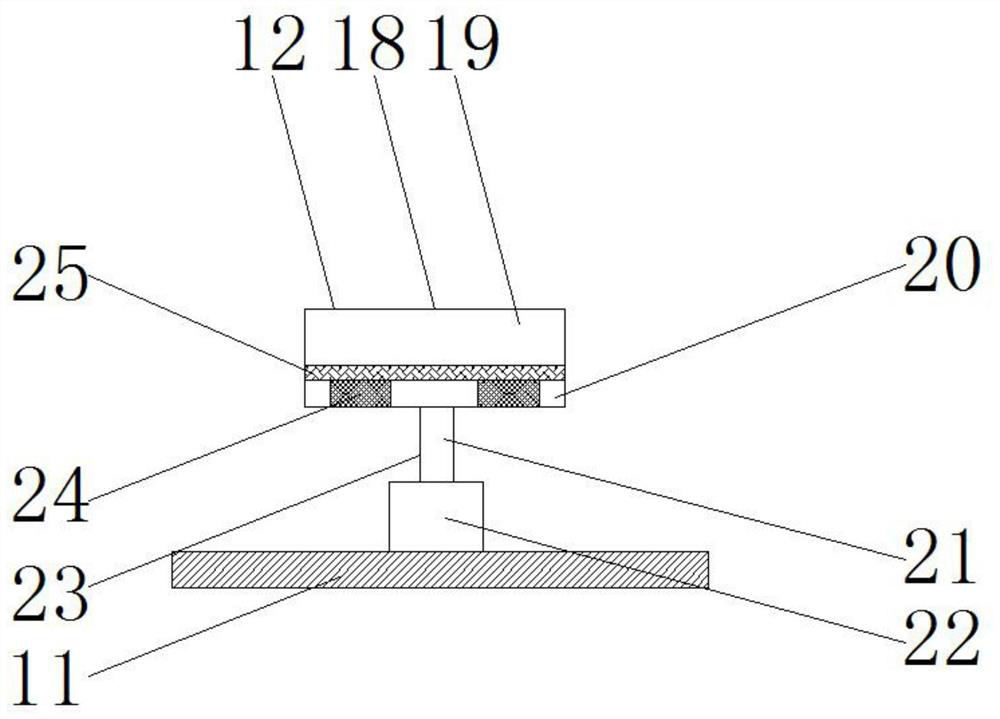

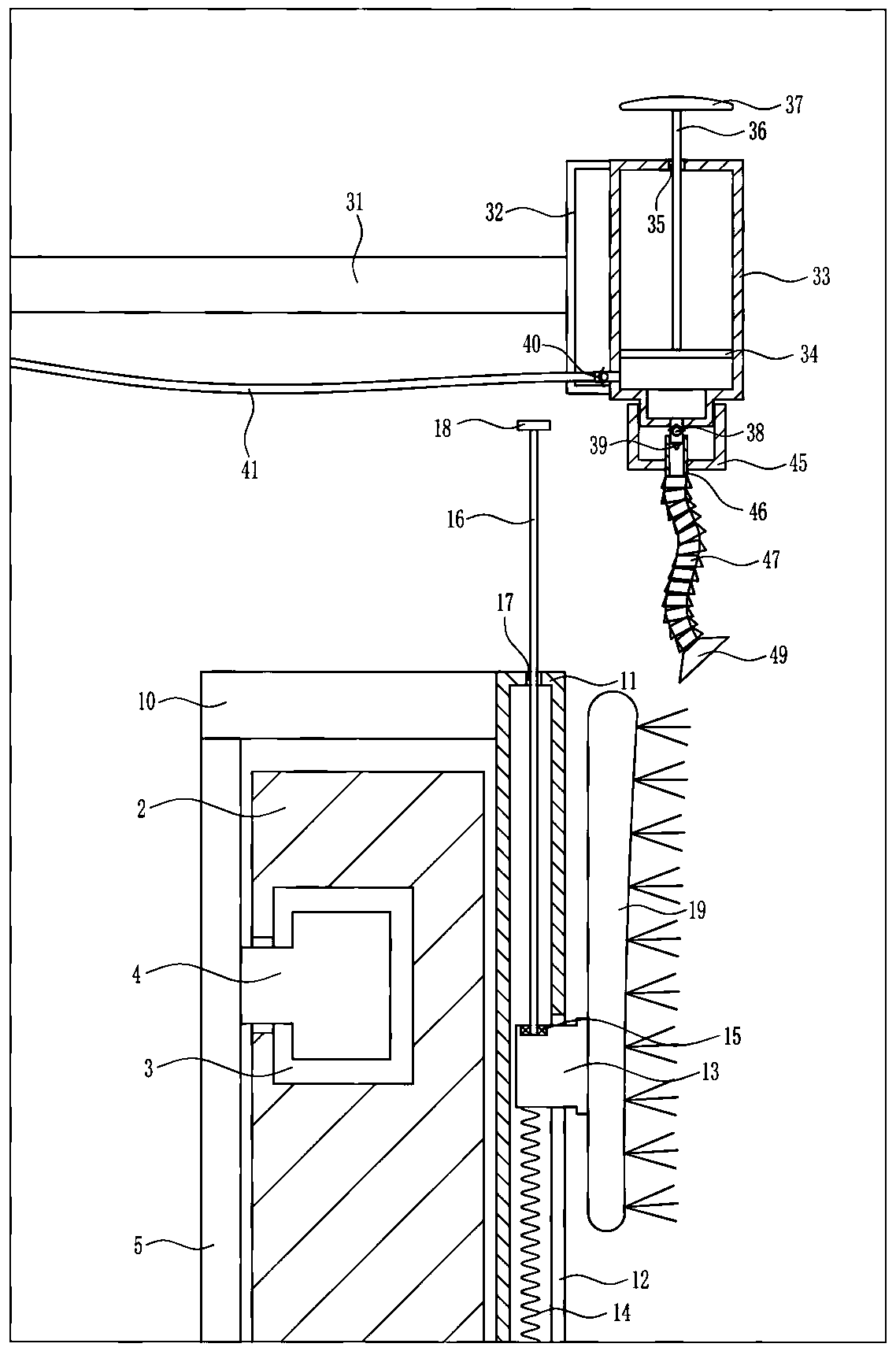

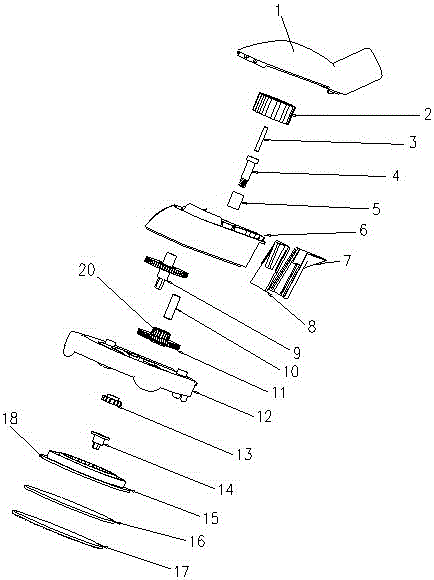

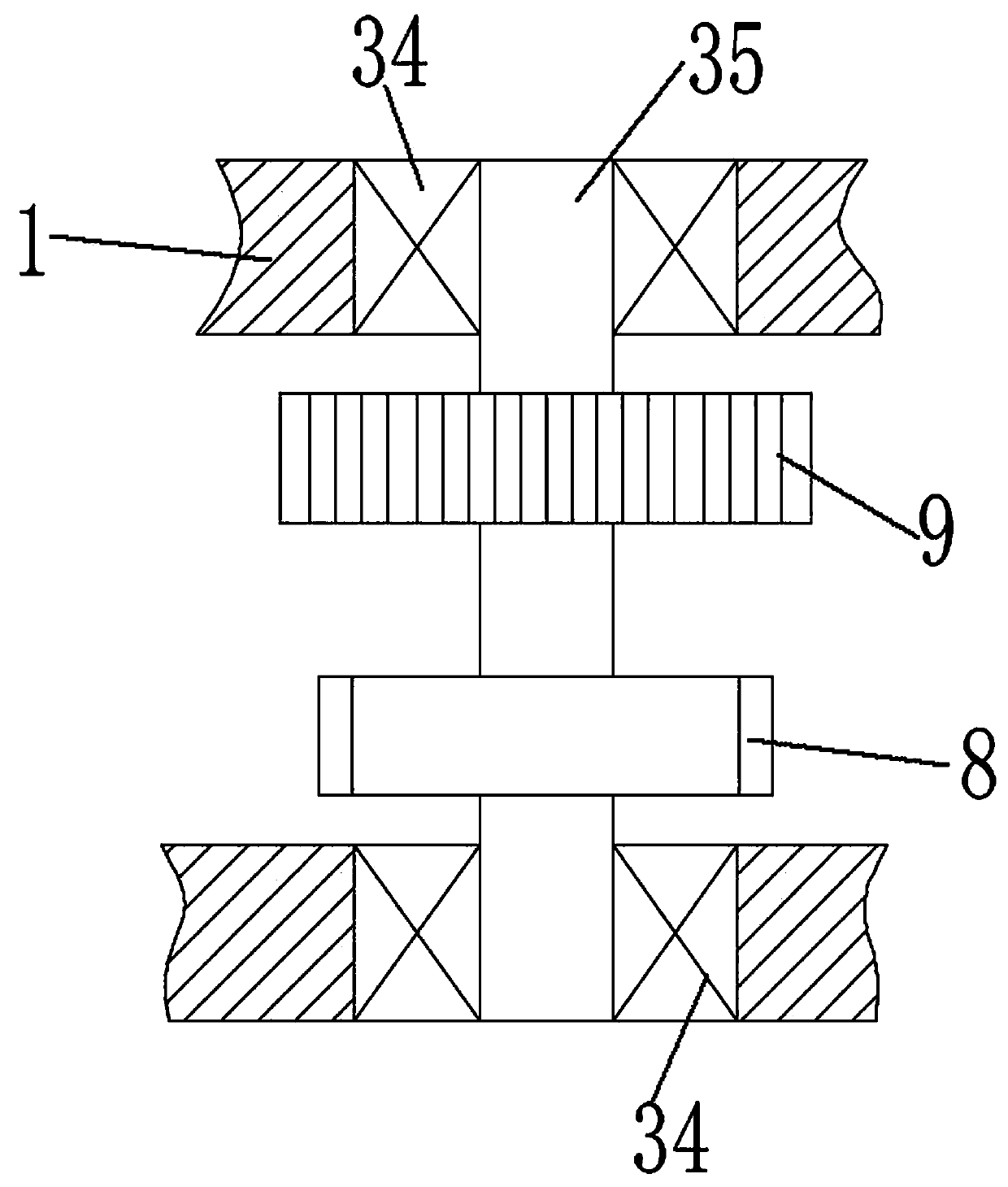

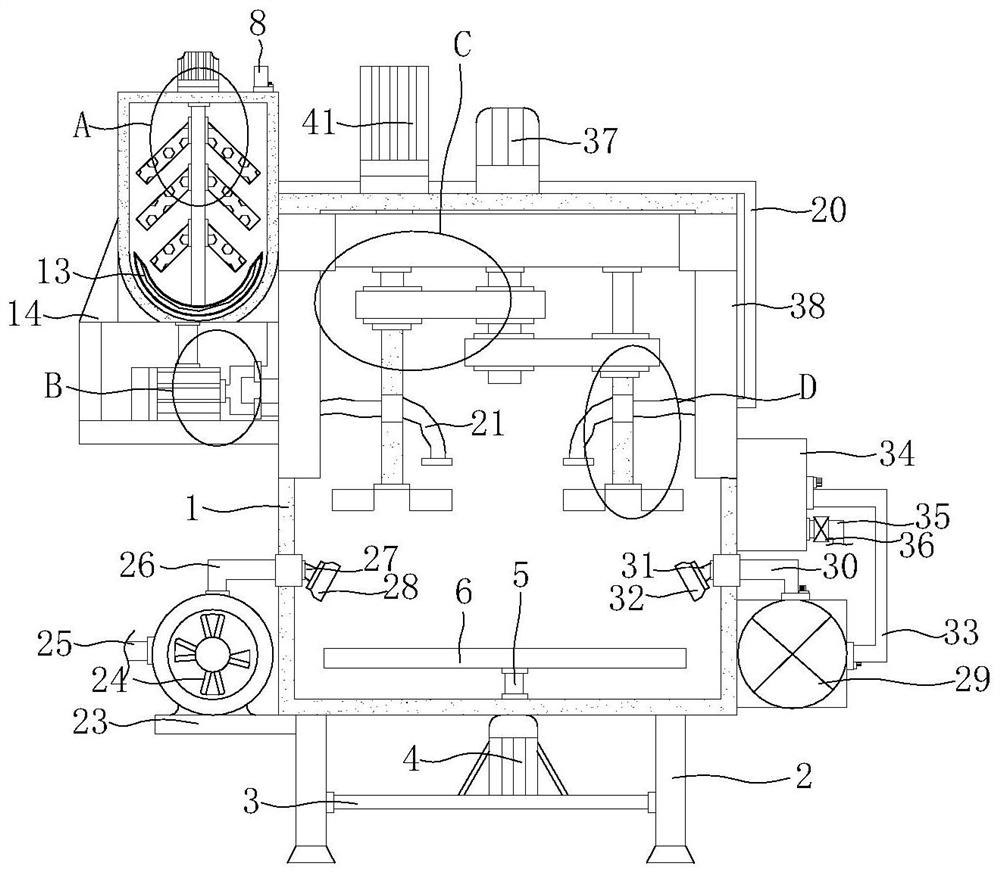

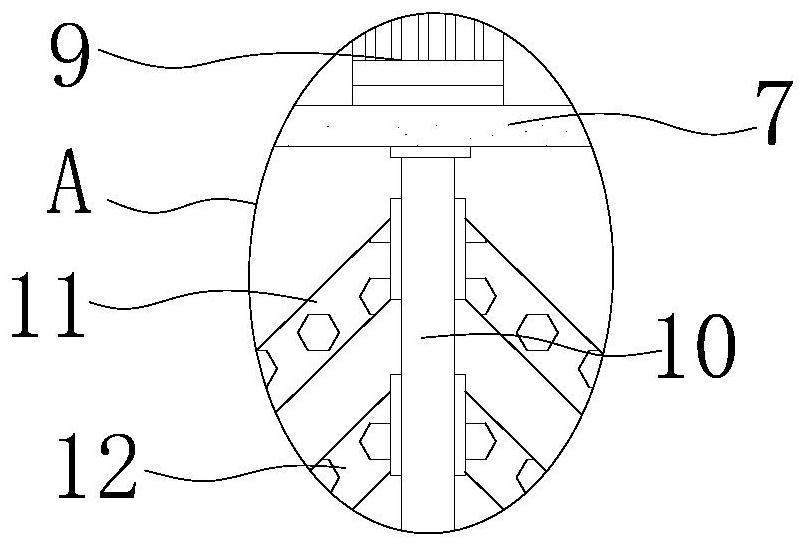

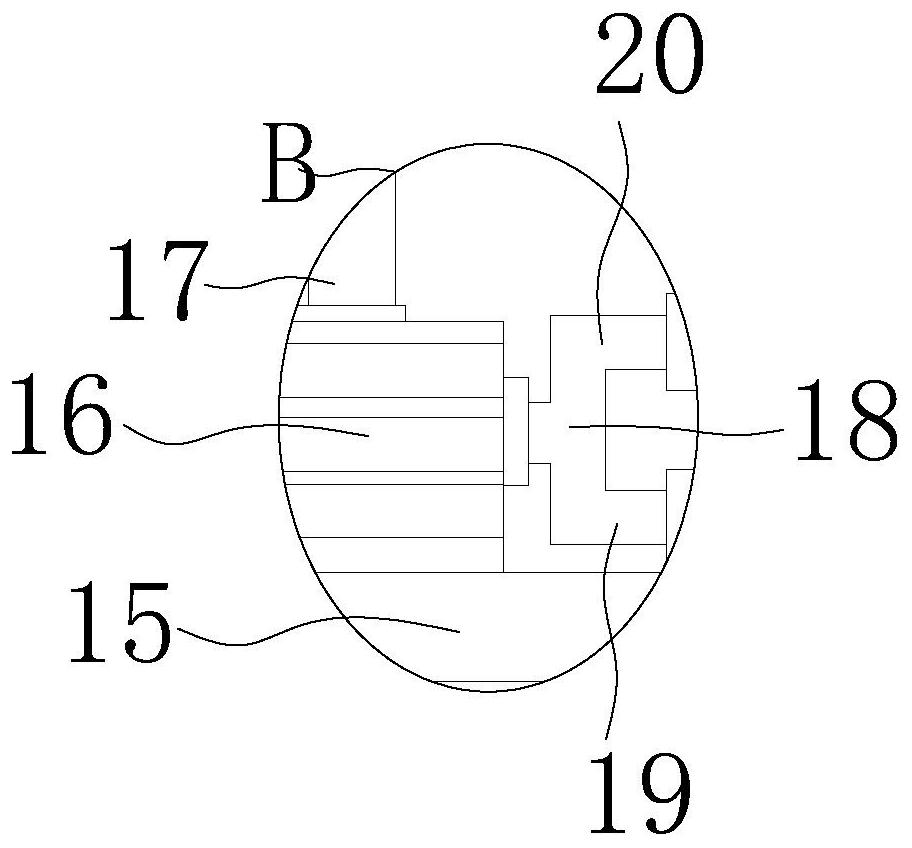

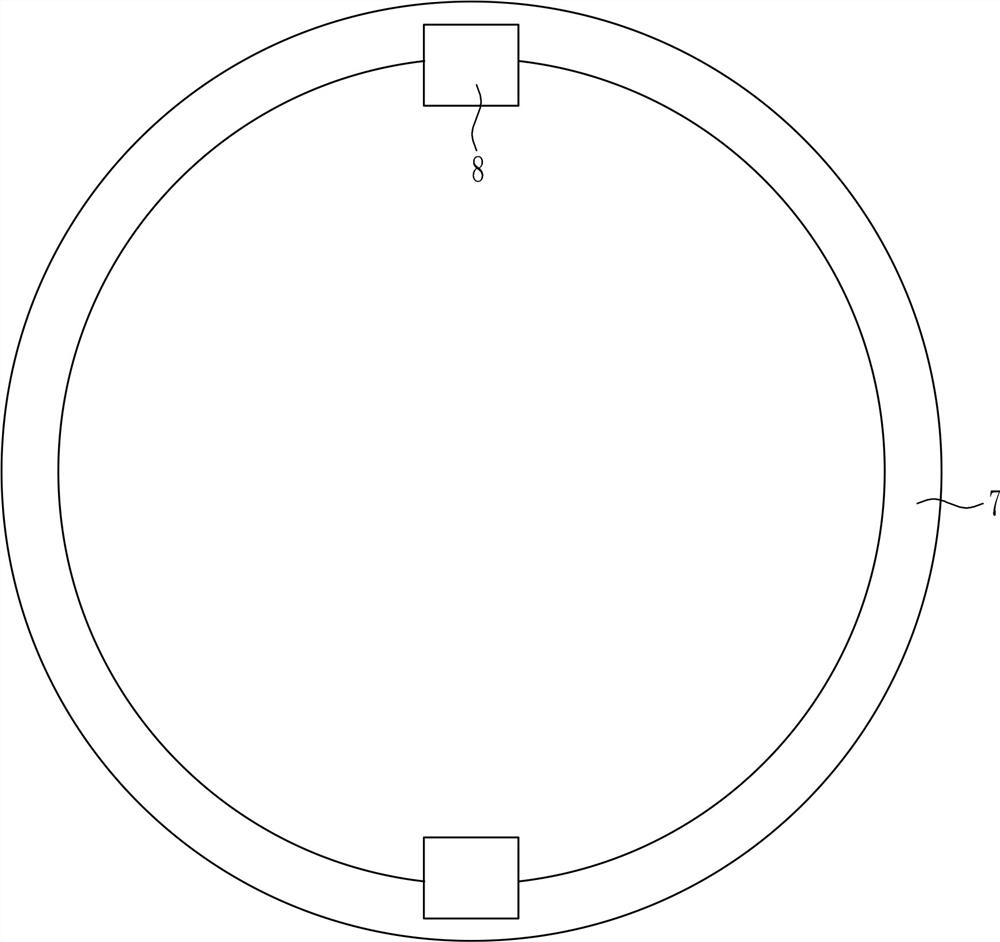

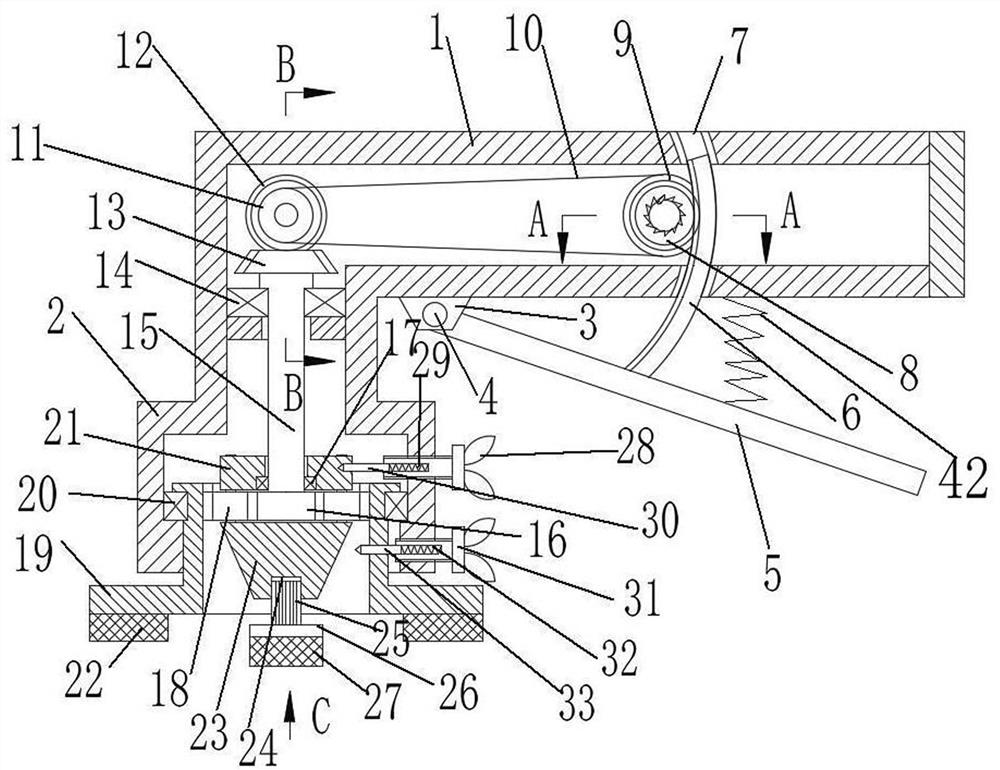

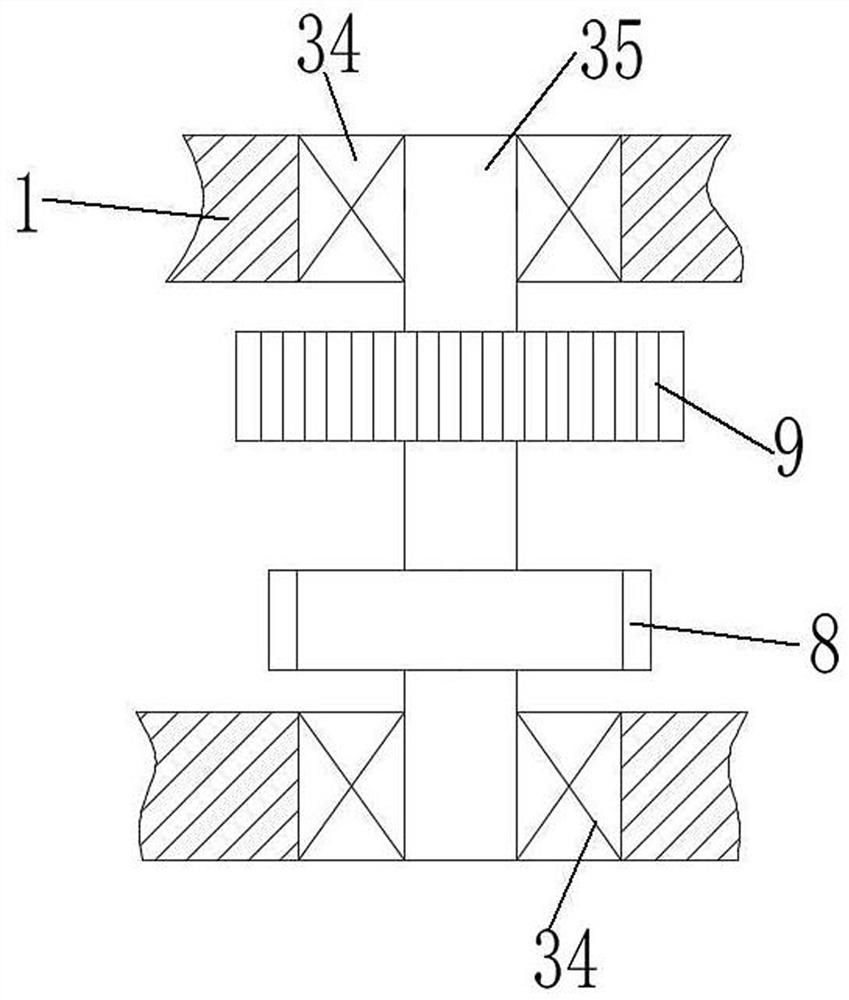

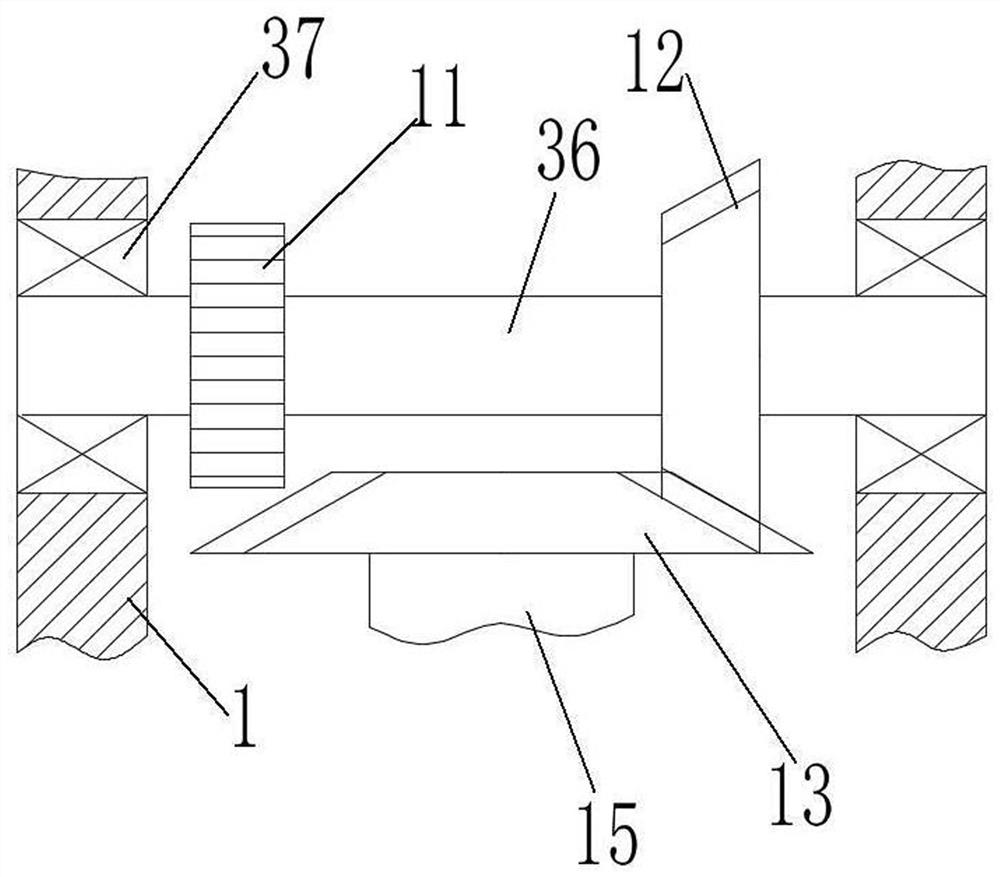

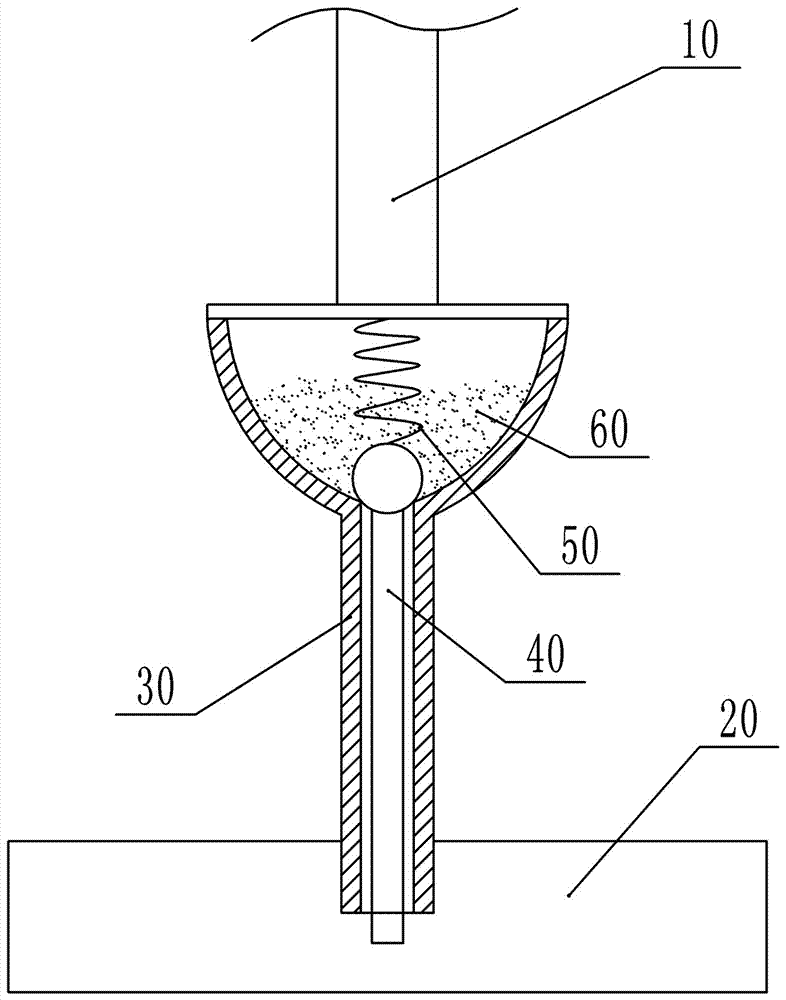

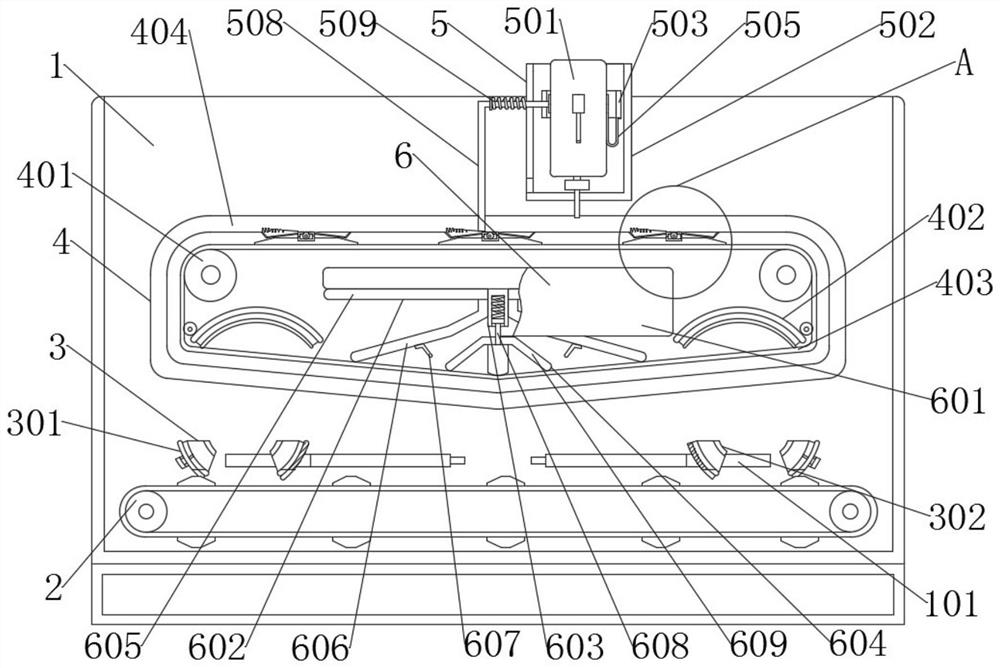

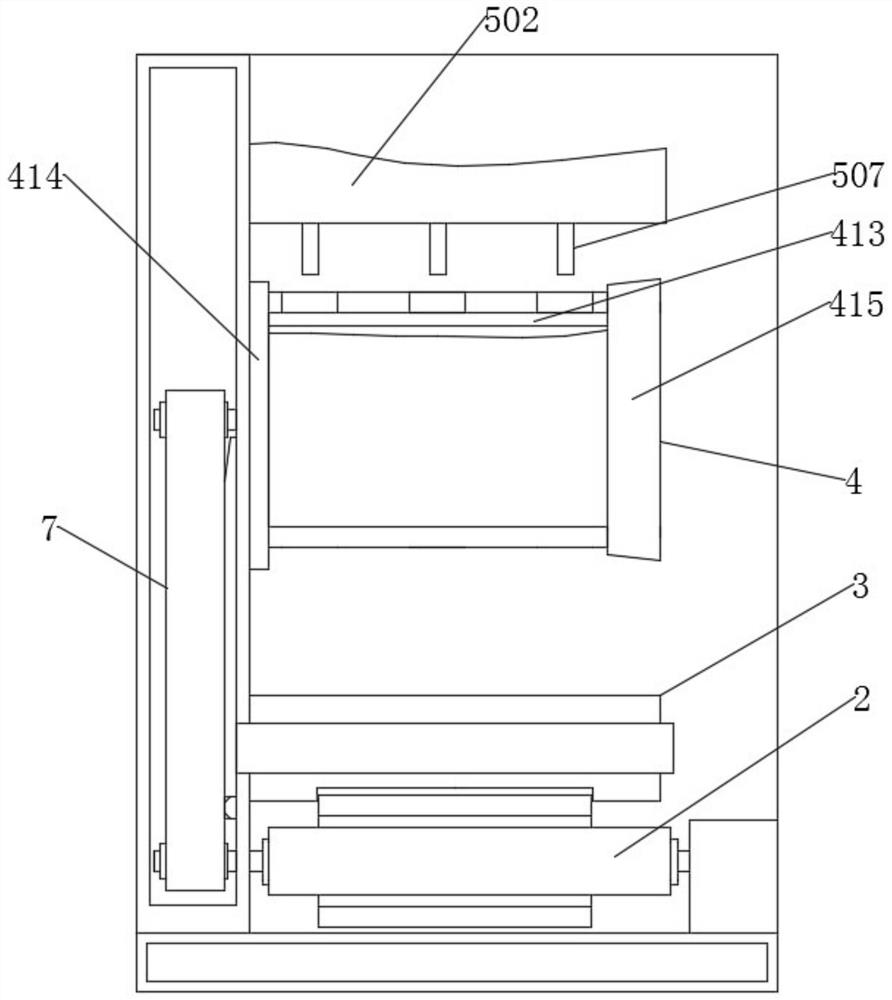

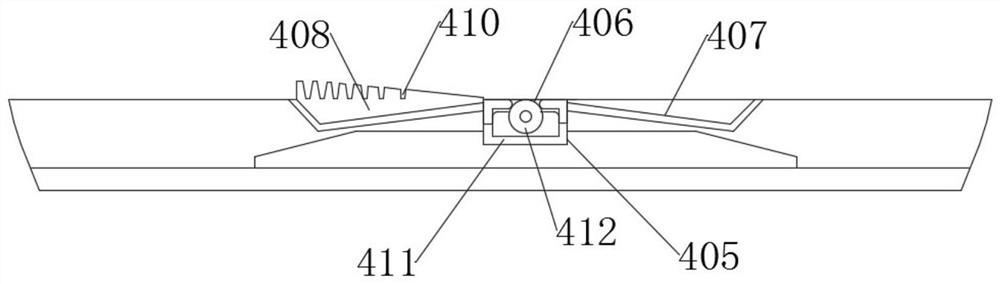

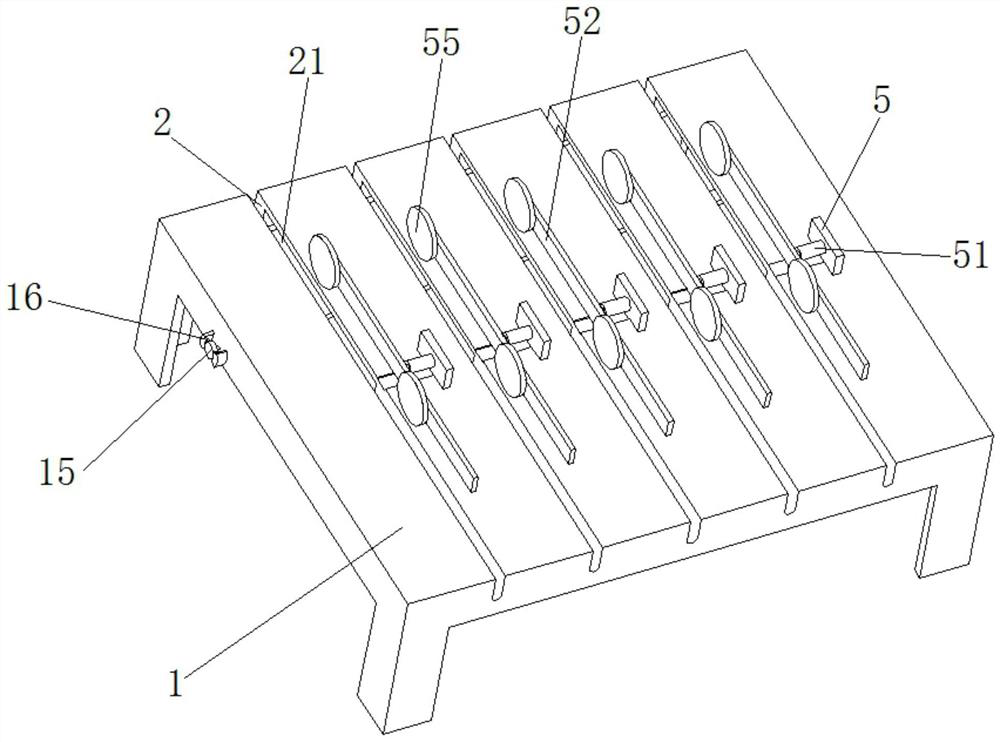

Ceramic tile turnover and automatic waxing equipment

InactiveCN106914362ASpray wax quickly and evenlyNo chance of dripping onto tilesSpraying apparatusWaxMaterials science

The invention relates to ceramic tile turnover and automatic waxing equipment which comprises a clamping and locating part, a sliding wax spray part and a rotating part. The clamping and locating part comprises a supporting mechanism used for locating and supporting ceramic tiles to be turned over and waxed, and a clamping mechanism used for clamping the ceramic tiles. The sliding wax spray part is used for waxing the surfaces of the ceramic tiles and comprises a wax spray mechanism and a transmission mechanism. The rotating part is used for driving the clamping and locating part and the ceramic tiles to be turned over together and meanwhile driving the wax spray mechanism through the transmission mechanism to move in the front-and-back direction to wax the ceramic tiles. The rotating part comprises a supporting seat, a turnover device fixedly connected with the supporting mechanism and a lifting device used for driving the turnover device to slide and be turned over along the supporting seat. The wax spray mechanism comprises a wax spray seat and multiple wax spray heads. The problems that ceramic tile waxing cannot be automatic and continuous, waxing efficiency is low, manpower is consumed, wax is prone to dripping onto the ceramic tiles, and waxing is not uniform are solved.

Owner:湖州裕尚卫浴有限公司

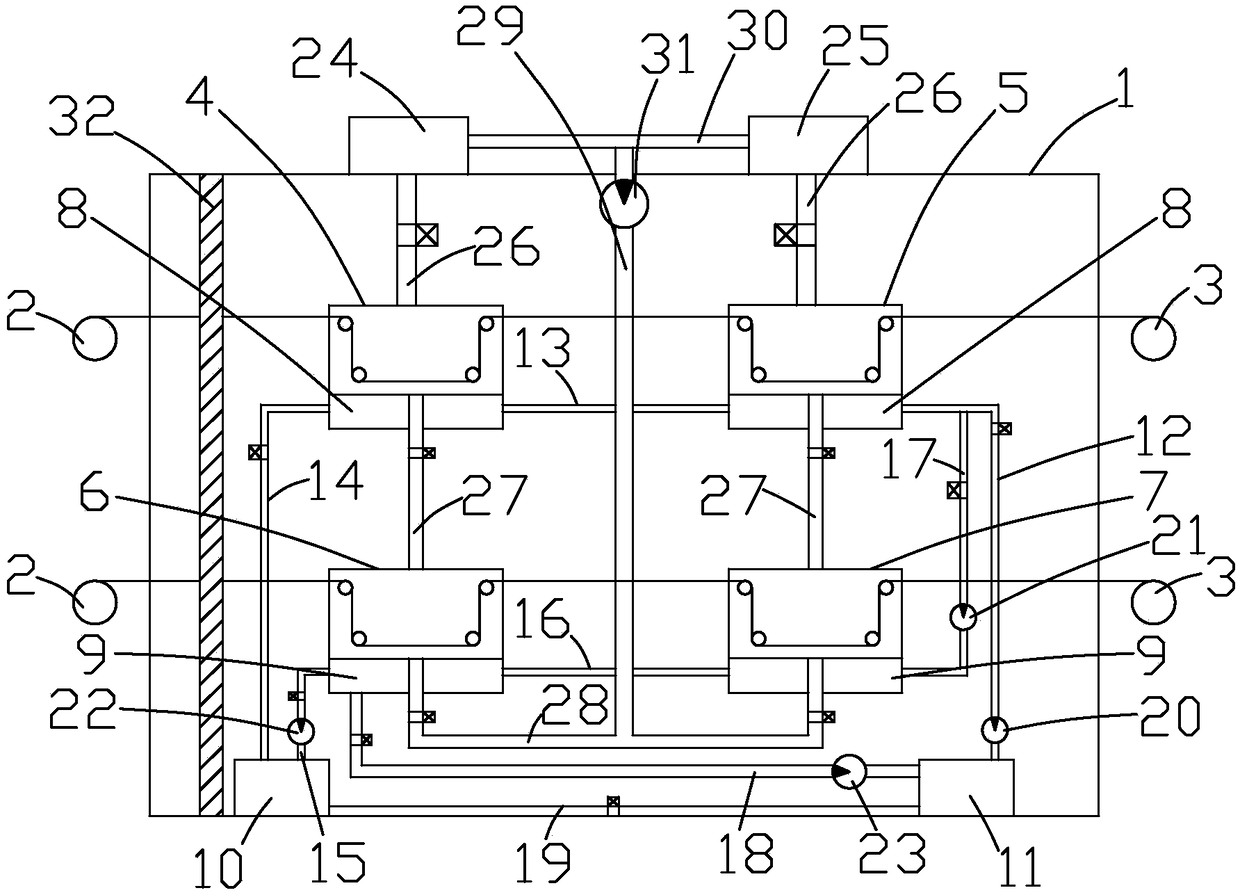

Yarn waxing device for textile machinery

The invention discloses a yarn waxing device for textile machinery. The yarn waxing device comprises a box body, yarn feeding rollers and yarn receiving rollers; the box body is internally provided with a first main waxing box, a first auxiliary waxing box, a second main waxing box, a second auxiliary waxing box, a wax supply device and a cold and hot water system; the wax supply device is separately communicated with the first main waxing box, the first auxiliary waxing box, the second main waxing box and the second auxiliary waxing box; the cold and hot water system is separately connected to the first main waxing box, the first auxiliary waxing box, the second main waxing box and the second auxiliary waxing box; baffles are arranged between the first main waxing box and the yarn feedingrollers and between the second main waxing box and the yarn feeding rollers. The yarn waxing device is simple in structure and high in practicability, not only are the waxing effect and quality of yarn improved, but also recycling of wax can be realized, waste of the wax is reduced, the wax is transformed between a solid state and a liquid state, and the automation degree of the yarn waxing device is greatly increased.

Owner:桂林市盛茏纺织有限公司

Paper tube waxing machine

InactiveCN102909154AImprove waxing efficiencyQuality is easy to controlLiquid surface applicatorsCoatingsFuel tankPulp and paper industry

A paper tube waxing machine comprises a paper tube fixing clamp, wherein wax cloth rings are arranged at two ends of the paper tube fixing clamp and are fixed at a periphery groove of the surface of a rotary disc, the groove is communicated with a wax oil tube, and telescopic rods are arranged outside the rotary disc and are connected with a motor by a transmission element; and the other end of the wax oil tube is communicated to a wax oil box which adopts a thermostat and is internally provided with a heating tube, and a flow valve is arranged in the wax oil tube. According to the paper tube waxing machine, two ends of a paper tube can be mechanically and continuously waxed, the paper tube waxing efficiency is improved, the waxing time is shortened, and the waxing quality is convenient to control.

Owner:吴江久升纸业有限公司

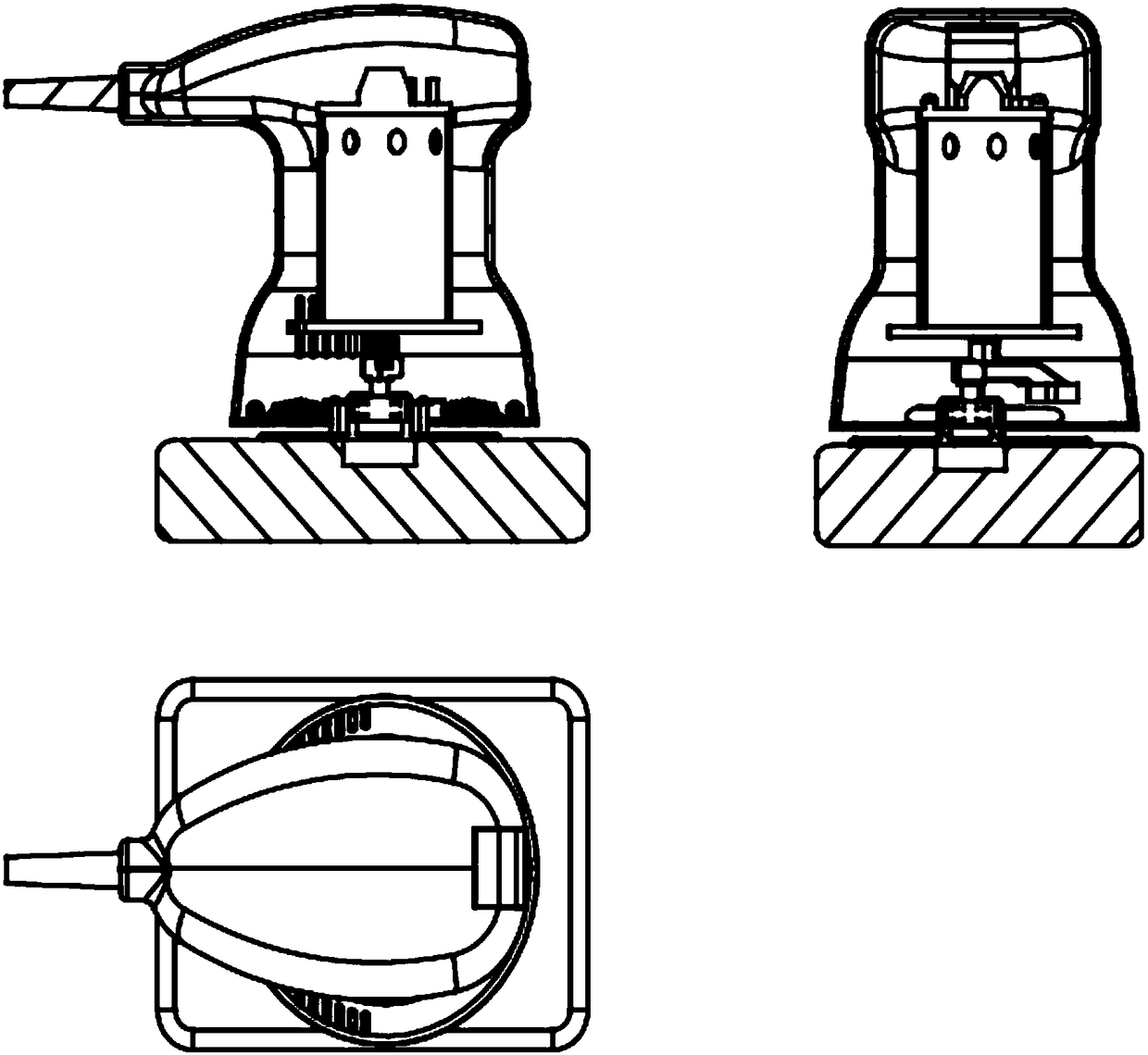

Waxing device for production of wood-plastic floor

InactiveCN108745804ANo need for manual applicationHeight adjustableLiquid surface applicatorsCoatingsWaxMotor drive

The invention discloses a waxing device for production of a wood-plastic floor. The waxing device comprises a shell. A grip handle is fixed to the outer wall of one side of the shell through a screw,and an obliquely-arranged supporting rod is fixed to the bottom end of the outer wall of the other side of the shell through a screw. A spherical hinge is arranged at the top end of the supporting rod, and the supporting rod is rotationally connected with a feeding pipe of a T-shaped structure through the spherical hinge. A sleeve is fixed to the outer wall of the top end of the shell through a screw. A first opening is formed in the outer wall of one side of the sleeve, and a communicating pipe is connected to the inner wall of the first opening in a clamped mode. The end, away from the sleeve, of the communicating pipe is connected with the top end of the feeding pipe in a sleeving mode. According to the waxing device, a motor is started through a control switch, so that an output shaftof the motor drives a rotating rod to rotate, and a polishing disc is driven to rotate by the rotating rod; and the outer wall of the polishing disc is sleeved with a sponge sleeve so that wax on thefloor can be directly polished, manual waxing is not needed, labor saving is achieved, and the waxing efficiency is accelerated greatly.

Owner:程欢

Automobile waxing machine with a continuous discharge structure

InactiveCN109109830AImprove waxing efficiencyEasy to applyVehicle servicing/repairingTorsion springEngineering

The invention provides an automobile waxing machine with a continuous discharge structure. The machine comprises a waxing body, a handle, a rotating shaft, a manual control mechanism, a mounting block, a handle, a first screw rod, a second screw rod, an extrusion mechanism, a third screw rod, a ring plate, a box body, a connecting pipe, a center column, a chute, a storage chamber, a discharge hole, a storage chamber, a discharge mechanism, a pressure bar, a discharge plate, a spring, a sponge plate, a mounting plate, a fastening mechanism, a fixing plate, a torsion spring, a pressure plate anda fastening column. The automobile waxing machine with the continuous discharge structure can realize polishing, discharge simultaneously, improve waxing efficiency, and the design of the discharge hole can disperse the wax block and be convenient for coating. The operator can also control the wax discharge amount by adjusting the number of revolutions of the first screw to make the wax dischargeprocess more accurate and controllable. By fastening the sponge plate with fastening mechanism, the sponge plate can be installed and disassembled more conveniently.

Owner:ANHUI UNIV OF SCI & TECH

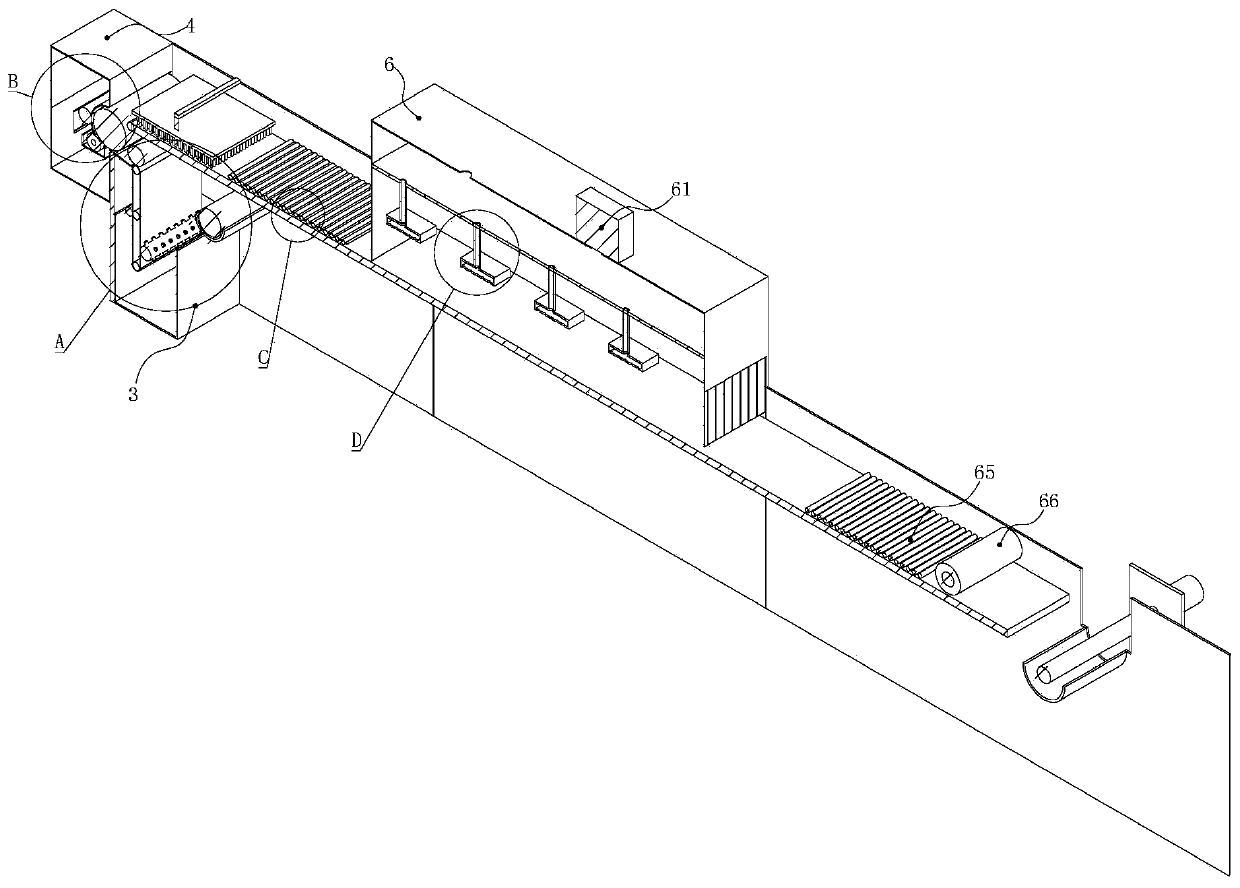

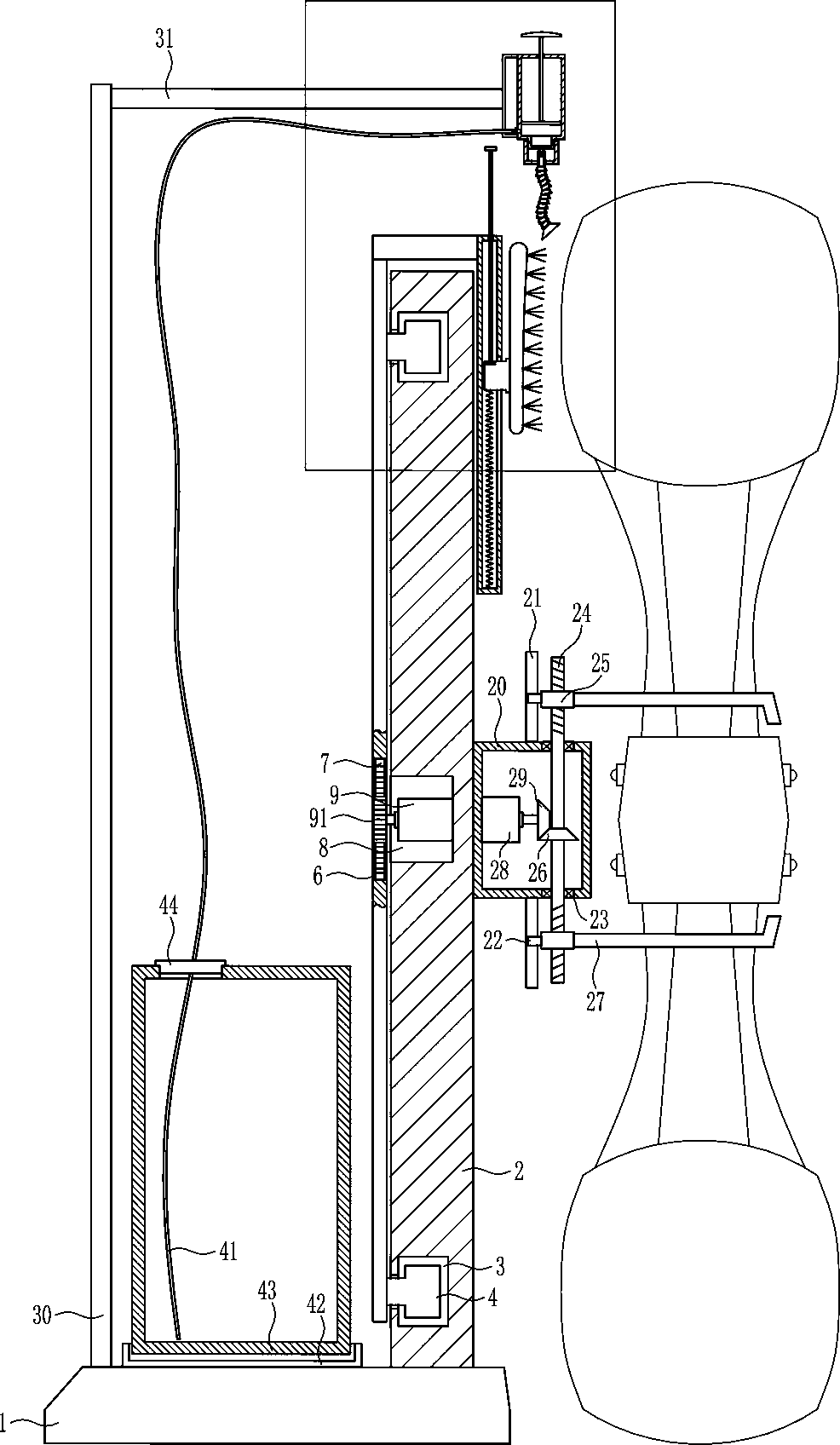

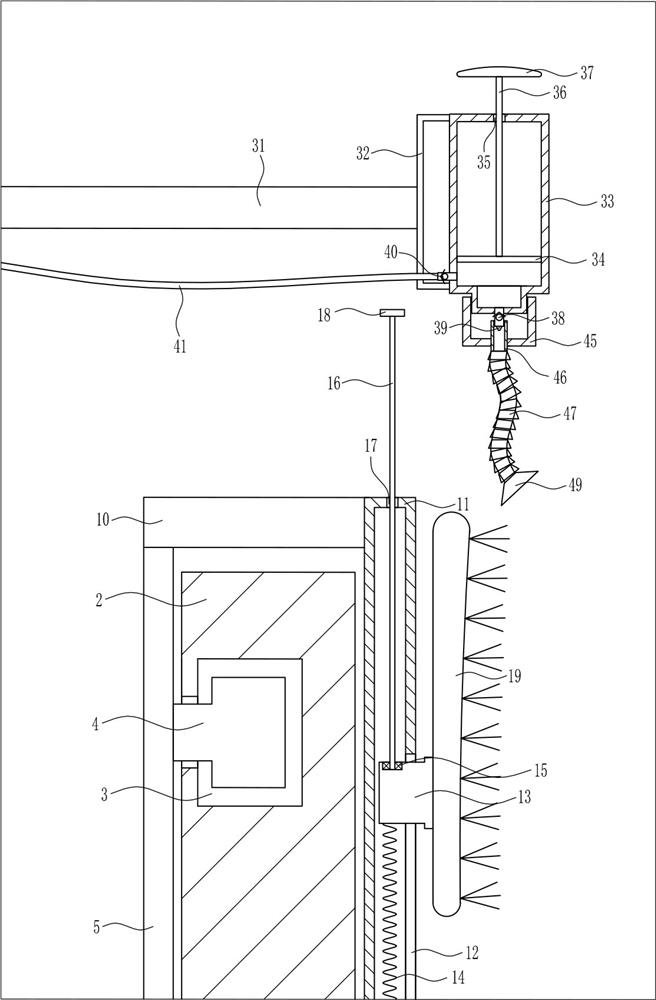

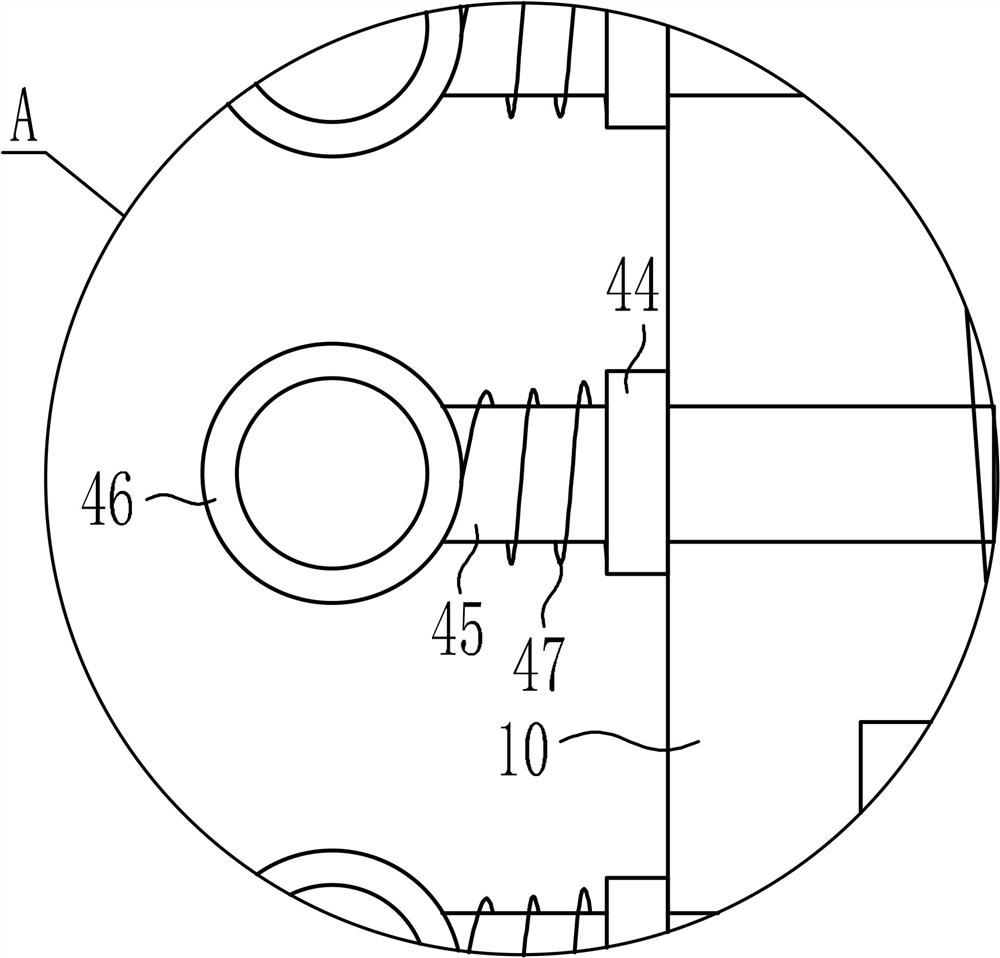

Automatic waxing system for leather

InactiveCN109880946AImprove waxing efficiencyFreeze fastLeather pressing/rollingLeather/skins/hides/pelt chemical treatment apparatusWaxEngineering

The invention discloses an automatic waxing system for leather. The automatic waxing system for the leather comprises a rack, a material loading device, a leather cleaning device, a leather waxing device, a leather drying device, a leather polishing device and a leather collection device, wherein the leather cleaning device comprises a water tank, a first driving roller arranged in the water tank,a second driving roller corresponding to the first driving roller, a cleaning element sheathed to the first driving roller and the second driving roller, a first driving element for driving the firstdriving roller to rotate, a cleaning mechanism used for cleaning the cleaning element, and a pressure mechanism used for pressing the leather to the second driving roller; the leather driving devicecomprises a drying box arranged on the rack, a warm air machine, an air sending mechanism and a material outlet arranged on the side wall of the drying box. Through the warm air machine, hot air can be introduced into the drying box so as to blow the leather in the drying box, liquid wax is quickly solidified without drying , and leather waxing efficiency is improved.

Owner:杭州翼兔网络科技有限公司

Wooden bottom plate surface waxing device with dust removal function

ActiveCN111067425AQuality improvementEasy to useCarpet cleanersFloor cleanersDust controlStructural engineering

The invention discloses a wooden bottom plate surface waxing device with a dust removal function, and relates to the technical field of wood floors. The wooden bottom plate surface waxing device withthe dust removal function comprises a box body, supporting legs are welded to the bottom of the box body, the number of the supporting legs is four, connecting plates are welded to the adjacent side walls of the supporting legs, a placing table is arranged in the box body, a fixing plate is welded on the outer wall of the other side of the box body, a first pressure pump is welded to the top of the fixing plate, a first feeding pipe is installed at a feeding end flange of the first pressure pump, the end, away from the first pressure pump, of the first feeding pipe is fixedly connected with the shell, the first feeding pipe is communicated with the interior of the shell, and a three-way pipe is installed at a discharging end flange of the first pressure pump. The device is ingenious in design and convenient to operate, the working efficiency is effectively improved, the working efficiency is conveniently improved, the time cost is further reduced, and the device is convenient to promote and use.

Owner:湖州南浔小浪花信息科技有限公司

Mechanical waxing device capable of improving liquidity of wax liquid

PendingCN112442777AReduce frictionReduced deterioration of yarn hairinessTextiles and paperElectric machineryYarn

The invention discloses a mechanical waxing device capable of improving liquidity of wax liquid. The mechanical waxing device comprises a motor, an air cylinder, a wax block containing bin, a waxing roller and a height adjusting device, wherein an upper-layer wax block and yarn rotate in opposite directions through rotation of the motor, a friction force between the upper surface of the yarn and the upper-layer wax block is further increased, and then a yarn waxing effect is improved; meanwhile, the air cylinder is used for driving a moving rod to move on a sliding rail, so that the upper-layer wax block makes contact with the upper surface of the yarn all the time, the upper surface of the yarn is prevented from being separated from the upper-layer wax block, and thus the waxing effect ofthe upper surface of the yarn is guaranteed; a friction coefficient value of the surface of the yarn is reduced through waxing, so that friction between the yarn is reduced, and deterioration of yarnhairiness is effectively reduced; and a hot air system blows air to the waxing structure, so that the liquidity of the wax liquid can be improved, the waxing effect can be increased and the waxing efficiency can be improved.

Owner:武穴市宽创机电科技有限公司

Stable waxing device for porcelain artworks

The invention relates to a waxing device, especially to a stable waxing device for porcelain artworks. The invention provides a stable waxing device for porcelain artworks and with uniform waxing effect so as to solve the technical problem. The stable waxing device for porcelain artworks comprises a support, a motor, a second guide pulley, a stay wire, a first guide pulley, a first spring, a non-return valve, a flexible pipe, an infusion pump, a second box, a first pole and the like. A first box is positioned at the left side of second springs. The second springs are symmetrically arranged at two sides of the bottom inside the first box. The upper ends of the second springs are connected to a piston which matches the first box. The bottom of the first box is provided with a drain pipe and the first pole. The effect of uniform waxing is achieved. With alternative-type clockwise rotation and anticlockwise rotation of porcelain, the porcelain is roundly waxed by sponge. Then, the porcelain waxing effect is better.

Owner:新昌县利拓科技有限公司

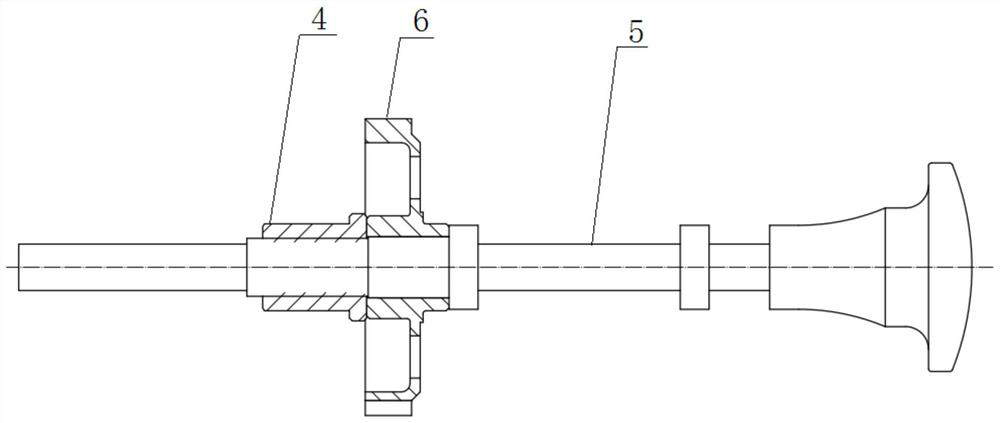

Waxing device for vehicle tires

ActiveCN109433506AAvoid sorenessEasy to waxLiquid surface applicatorsCoatingsCircular discGear wheel

The invention relates to a waxing device, in particular to a waxing device for vehicle tires. The waxing device for the vehicle tires can prevent the ache of arms, and can improve the waxing efficiency. According to the technical scheme, the waxing device for the vehicle tires comprises a base plate, a fixed plate, an annular slide block, a disc, an inner gear ring, a speed reducing motor, a firstgear, a connecting plate, a mounting frame, a connecting block, a spring and a first bearing base; the fixed plate is connected to the right side of the top of the base plate; an annular chute is formed in the left side surface of the fixed plate; the annular slide block is arranged in the annular chute; the disc is connected to the left side surface of the annular slide block; and a first opening is formed in the middle part of the disc. An arc brush is alternately rotated forwards and reversely to be in contact with the vehicle tires for waxing of the tires; and clamping plates are approached to each other to fix the vehicle tires without needing manual holding of the vehicle tires for waxing, so that the manual workload are reduced.

Owner:NANJING HANERSI BIOLOGY TECHNOLOGY CO LTD

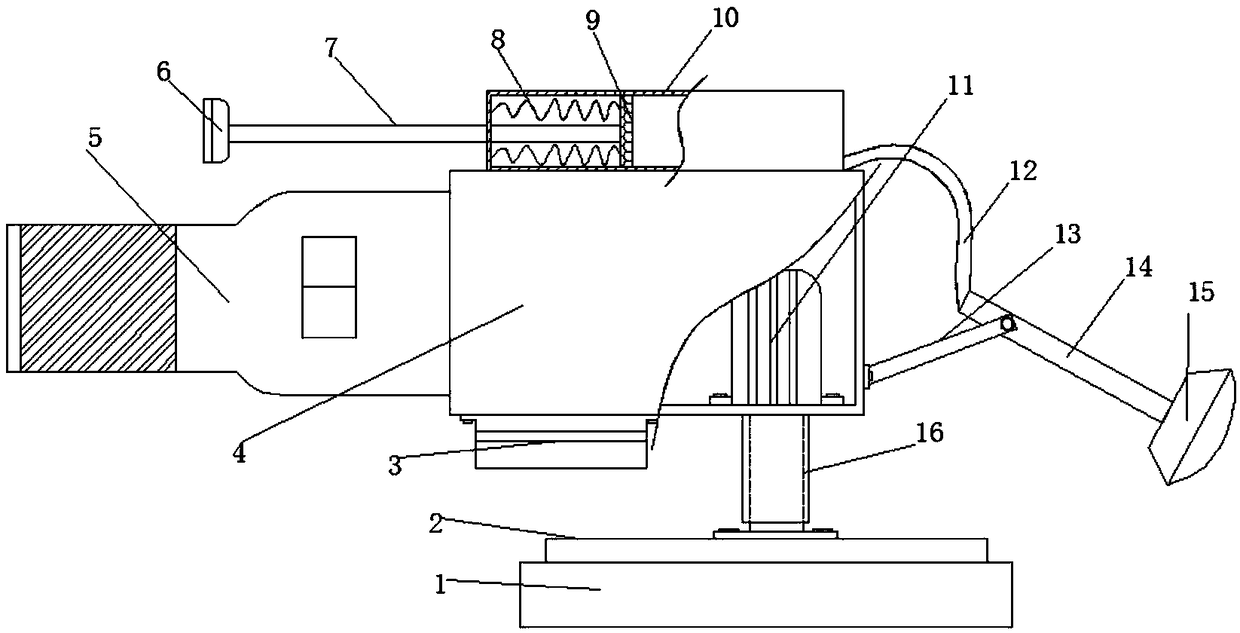

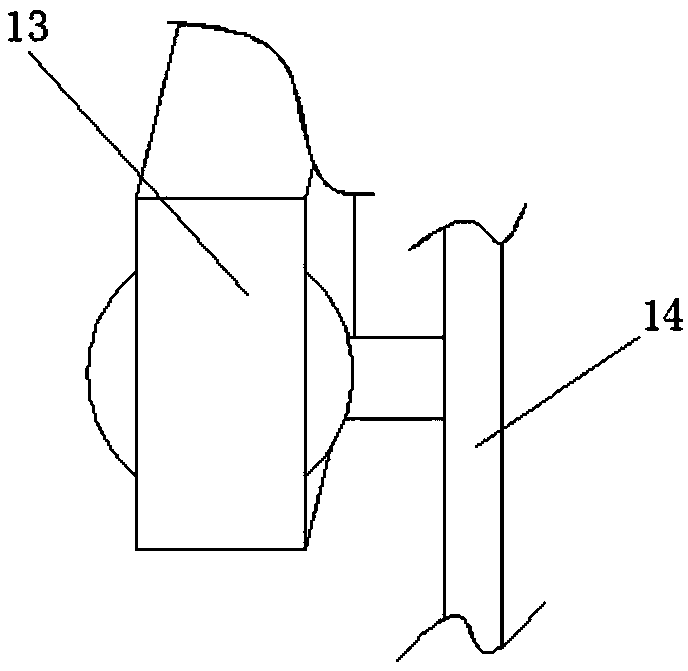

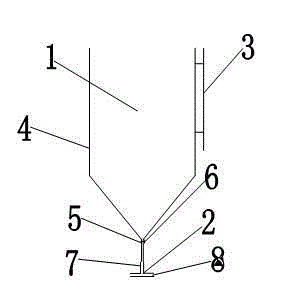

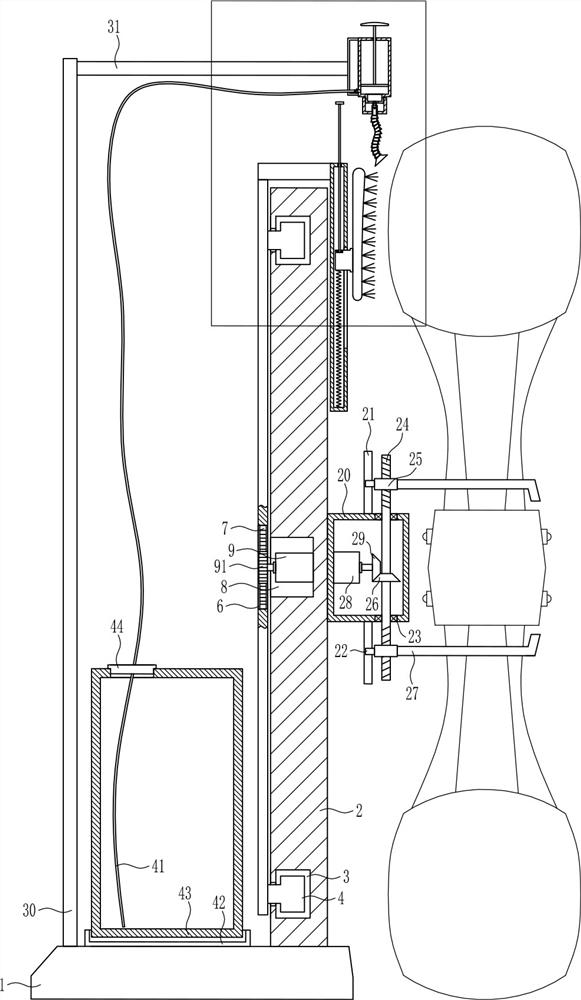

Waxing device for two-for-one twister

The invention discloses a waxing device for two-for-one twister. The waxing device for two-for-one twister comprises a wax dropping device and a waxing device and is characterized in that the wax dropping device comprises a wax storing tank and a dropping hole, the wax storing tank is provided with a liquid level balancer for keeping the liquid wax liquid level coincident and stabilizing the wax dropping speed. The waxing device is T-branch pipe, the wax receiving pipe and the dropping hole are concentric for dropping the wax into the waxing device through the dropping hole, and the yarn contacts the liquid wax through the waxing pipe for waxing for the yarn. The waxing device for two-for-one twister is simple in structure, the yarn can be directly waxed after two-for-one twisting operation, the waxing amount is controlled, the waxing is even and the waxing device for two-for-one twister is suitable for promotion use for wide range.

Owner:GUANGXI UNIV

Special sealing wax for kiwi fruit tree branches and preparation method of special sealing wax

The invention relates to special sealing wax for kiwi fruit tree branches and a preparation method of the special sealing wax. The special sealing wax for kiwi fruit tree branches comprises the following components in parts by weight: 80 to 120 parts of beewax, 50 to 100 parts of olive oil, 1 to 5 parts of Vaseline, 5 to 8 parts of a thickening agent and 75 to 120 parts of a sterilizing liquid. The special sealing wax for kiwi fruit tree branches is soft in texture, and can coat the ends of the kiwi fruit tree branches at normal temperature; the two ends of the kiwi fruit tree branches are sealed, so that moisture cannot be lost and the kiwi fruit tree branches are convenient to store, the ends of the kiwi fruit tree branches cannot be damaged, and the grafting survival rate is extremely high; and effective sterilization can be carried out on the ends of the kiwi fruit tree branches effectively by adding the sterilizing liquid, the ends are prevented from being rotted, the viscosity ofthe whole sealing wax can be increased through the thickening agent, and the sealing effect is improved.

Owner:赤壁神山兴农科技有限公司

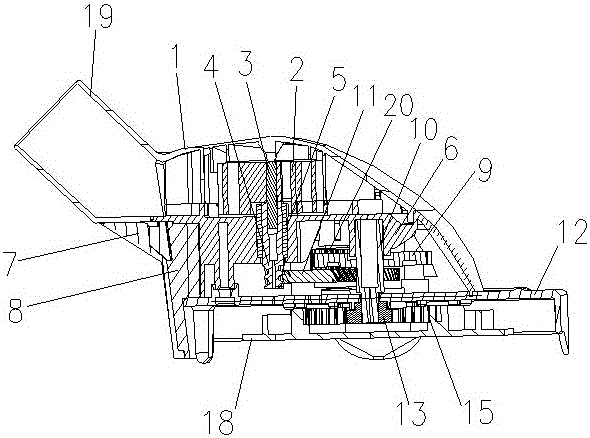

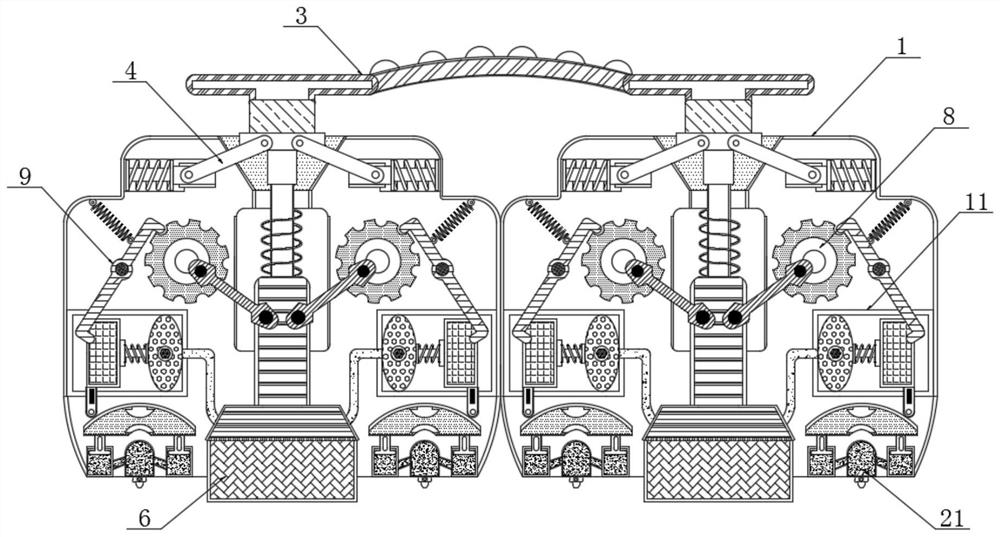

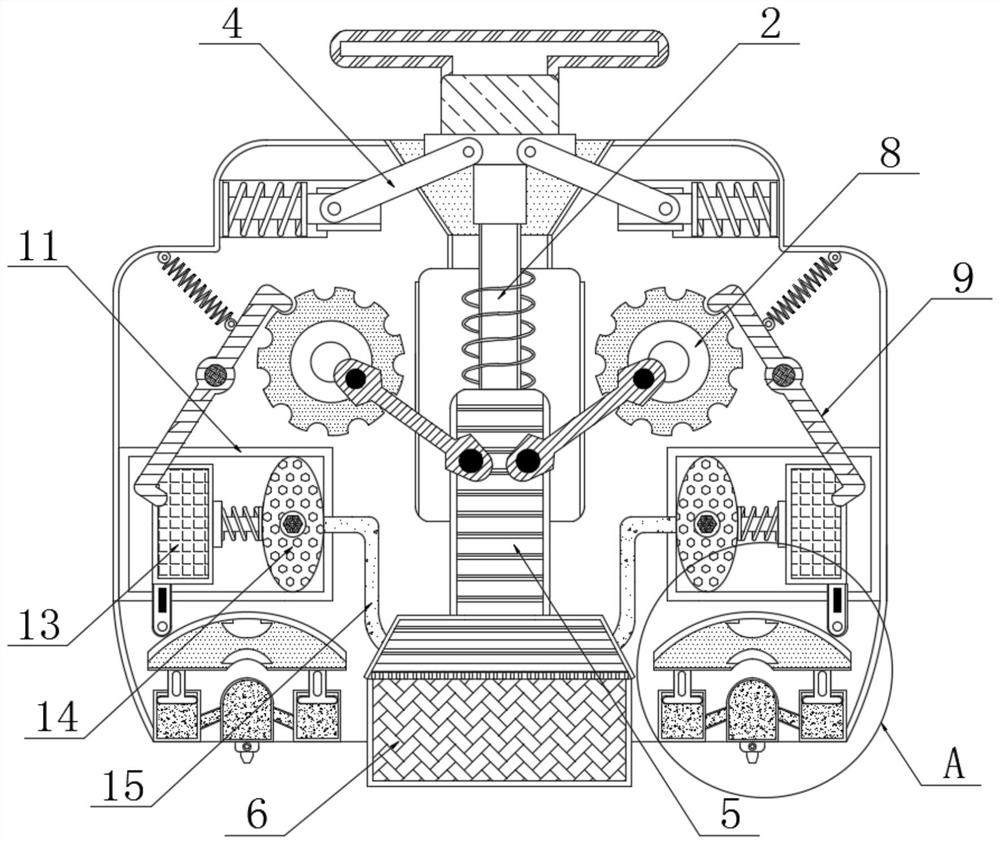

A floor furniture waxing device

InactiveCN104352205BImprove waxing efficiencyMachine detailsFloor surfacing/polishing machinesWaxSpur gear

The invention discloses a floor furniture waxing device which comprises an upper cover and a lower cover, wherein a wind wheel, a worm, a second spur gear, a helical gear, a planet gear and an internal planet gear are arranged inside the cavity surrounded by the upper cover and the lower cover; a wind wheel shaft is arranged in the center of the wind wheel in the axial direction; the wind wheel shaft is used for connecting the wind wheel with the worm; teeth on the worm are meshed with those on the helical gear; a first spur gear which is coaxial with the helical gear is arranged on the helical gear; the teeth of the first spur gear are meshed with those of the second spur gear; a gear shaft is arranged in the center of the second spur gear in the axial direction; the planet gear sleeves the outer end of the gear shaft; the planet gear is positioned inside the internal planet gear; the outer teeth of the planet gear are meshed with inner teeth of the internal planet gear; the internal planet gear is posited outside the lower cover; and a waxing cloth is arranged on the outer side surface of the internal planet gear. The floor furniture waxing device is used together with a dust collector and can be used for wax a floor automatically, the time and the labor are saved, and the waxing efficiency is high.

Owner:苏州万事达塑胶制品有限公司

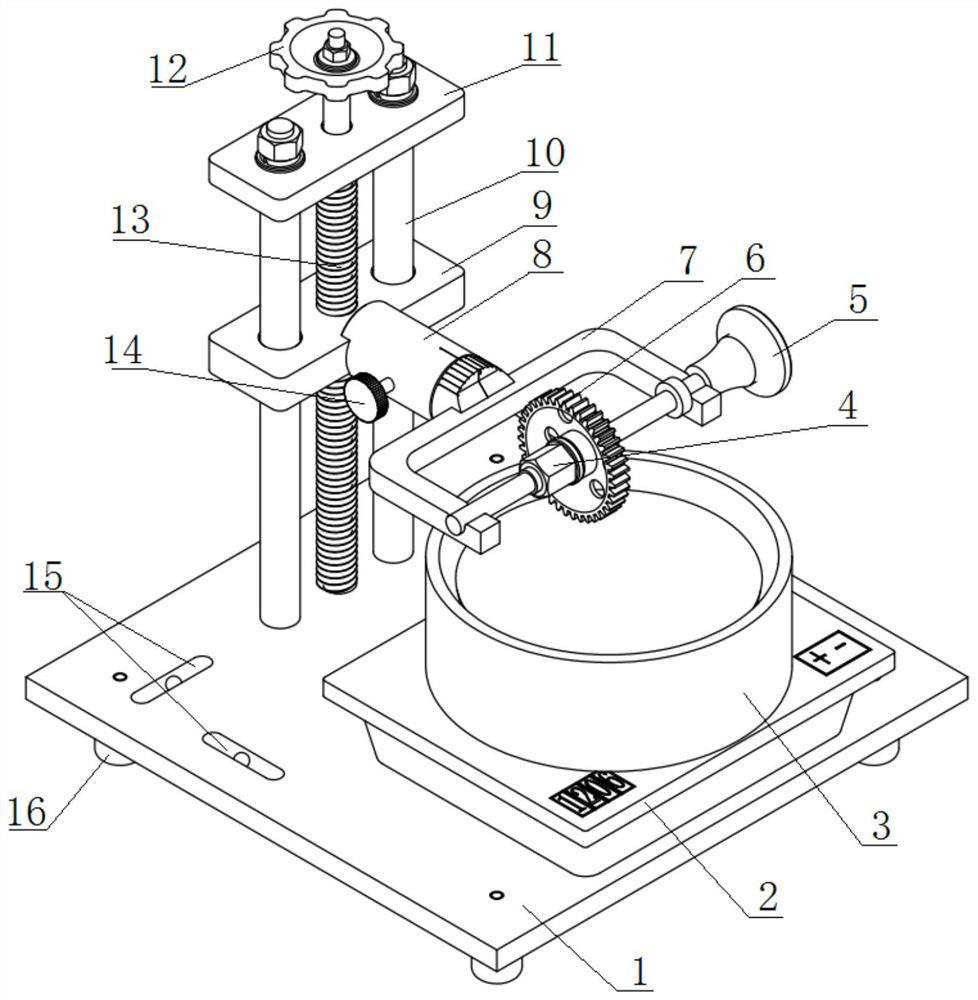

Gear waxing device and waxing method therefor

The invention discloses a gear waxing device and a waxing method therefor, and belongs to the technical field of gear waxing. The device comprises a base, a lifting assembly, a support frame and a gear clamping assembly; an electric furnace is provided on the base; a wax pot is provided on the electric furnace; the lifting assembly is arranged on the base; the support frame is connected with the lifting assembly; the gear clamping assembly is movably connected with the support frame; and the gear clamping assembly and the support frame are both located above the wax pot. In the waxing process,the tooth surface of a gear can be completely immersed in wax liquid, waxing is uniform and comprehensive, and the whole tooth surface of the gear can be comprehensively protected by wax. The depth of the gear immersed in the wax liquid is equal to the tooth height of the gear; a stepped shaft is slowly rotated during waxing to prevent the wax on the tooth surface from flowing to the rim or the hub of the gear; and the wax is used for the tooth surface of the gear without causing waste. The tooth surfaces of a straight gear and a bevel gear can be waxed, and a plurality of straight gears canbe clamped on the stepped shaft for waxing at the same time, so that the practicability is high.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

Solid car wax waxing device

InactiveCN111469027AImprove waxing efficiencySave human effortGrinding drivesPortable grinding machinesGear driveGear wheel

The invention discloses a solid car wax waxing device. The device is characterized in that a sponge block II is fixed in a lower wheel carrier through a detachable connecting mechanism, a gear ring isfixed relative to a shell through a gear ring locking device, an upper wheel carrier and the lower wheel carrier rotate after a sun gear rotates after the gear ring of a planetary gear set is fixed,an arc gear is driven to move upwards by pulling and pinching a pressing handle at the moment, the arc gear drives a gear to rotate, at the moment, the sun gear rotates, the lower wheel carrier rotates to drive the sponge block II to rotate, the sponge block II rotates in a wax box to enable the surface of the sponge block II to be pasted with wax, and then the sponge block II is pressed on automobile paint to paste the wax to the surface of the automobile paint. The sponge blocks II are taken down through the detachable connecting mechanism, then locking of the gear ring locking mechanism isrelieved, the upper wheel carrier is locked through an upper wheel carrier locking mechanism, the sun gear rotates to drive the gear ring to rotate after a wheel carrier of the planetary gear set is locked, and sponge blocks I are symmetrically arranged on the two sides of the lower end of the gear ring, so that the surface of the automobile paint can be polished in a circle drawing mode, and waxis evenly smeared on the surface of the automobile paint.

Owner:SHANDONG TRANSPORT VOCATIONAL COLLEGE

Waxing device for automobile tires

ActiveCN109433506BAvoid sorenessEasy to waxLiquid surface applicatorsCoatingsCircular discGear wheel

Owner:NANJING HANERSI BIOLOGY TECHNOLOGY CO LTD

A wooden floor surface waxing device with dust removal function

ActiveCN111067425BQuality improvementEasy to useCarpet cleanersFloor cleanersDust controlStructural engineering

The invention discloses a wooden floor surface waxing device with dust removal function, which relates to the technical field of wooden floors. The wooden floor surface waxing device with dust removal function includes a box body, the bottom of the box body is welded and installed with support legs, the number of support legs is four groups, and the adjacent side walls of the support legs are welded and installed with connecting plates. The inside of the box is provided with a placing platform, the outer wall of the other side of the box is welded and installed with a fixed plate, the top of the fixed plate is welded and installed with a first pressure pump, and the flange of the feed end of the first pressure pump is installed with a first feed pipe , the end of the first feed pipe away from the first pressure pump is fixedly connected to the shell, the first feed pipe communicates with the inside of the shell, and a tee pipe is installed on the flange of the discharge end of the first pressure pump. The invention is ingenious in design, easy to operate, effectively increases work efficiency, facilitates improvement of work efficiency, further reduces time cost, and is convenient for popularization and use.

Owner:湖州南浔小浪花信息科技有限公司

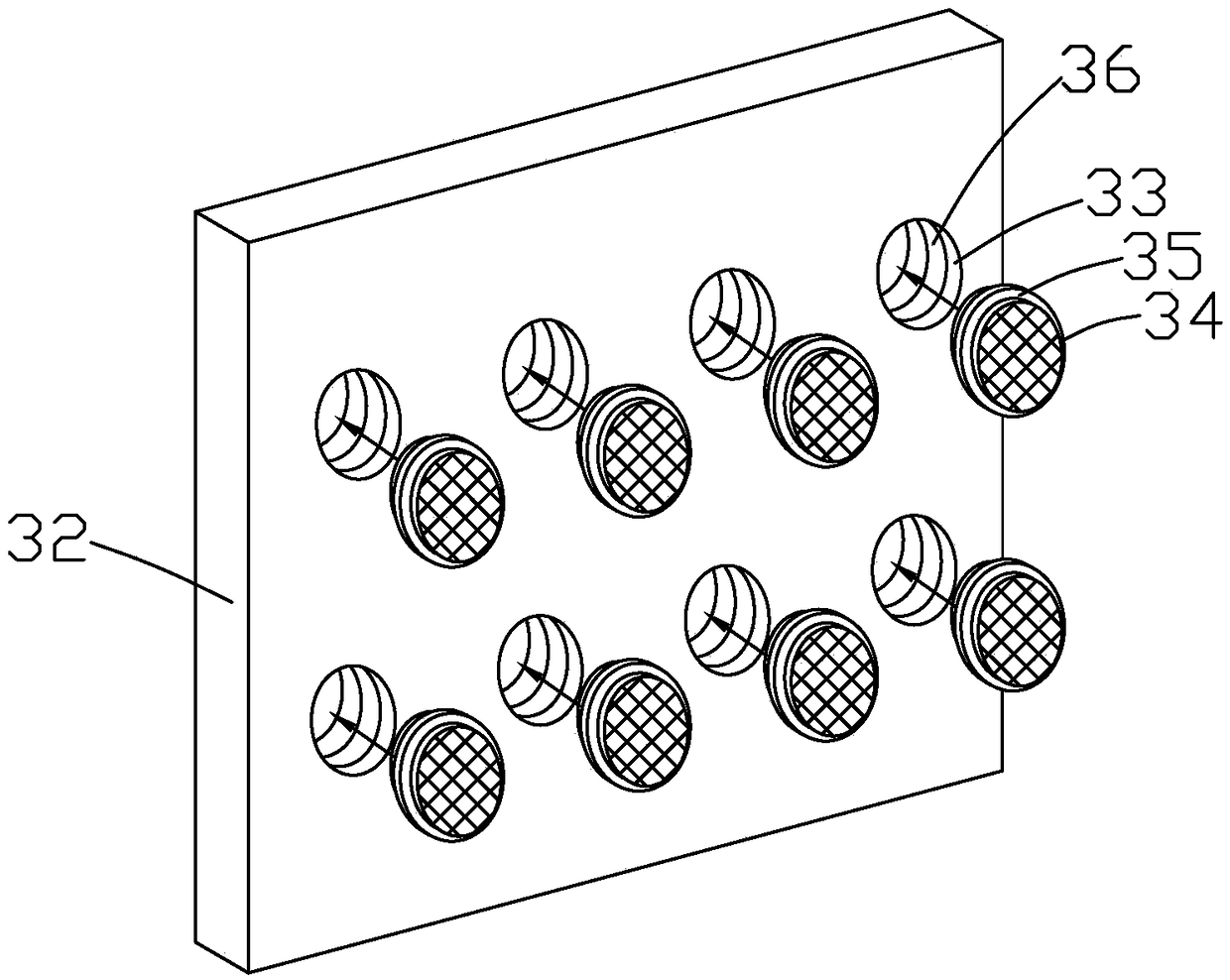

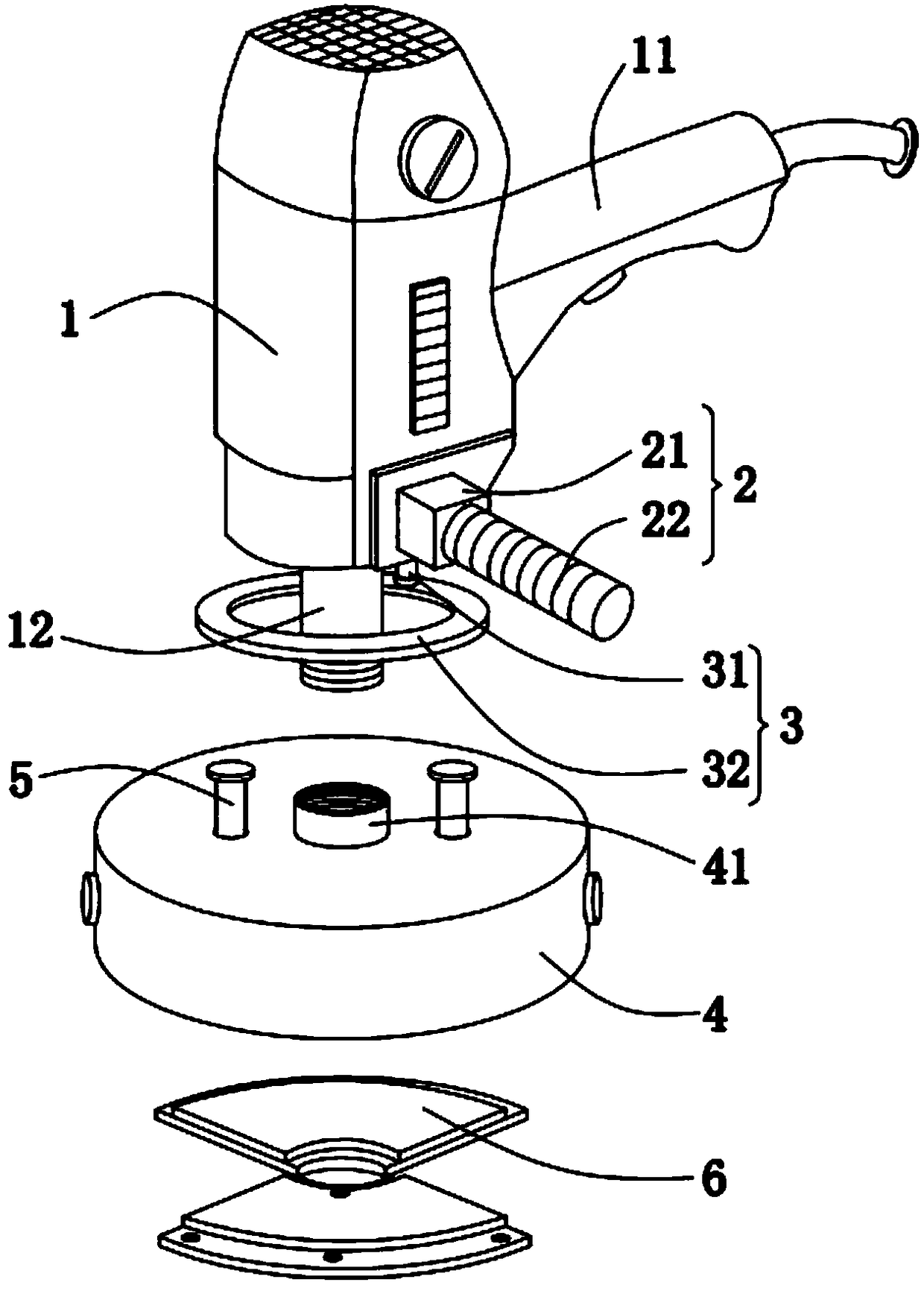

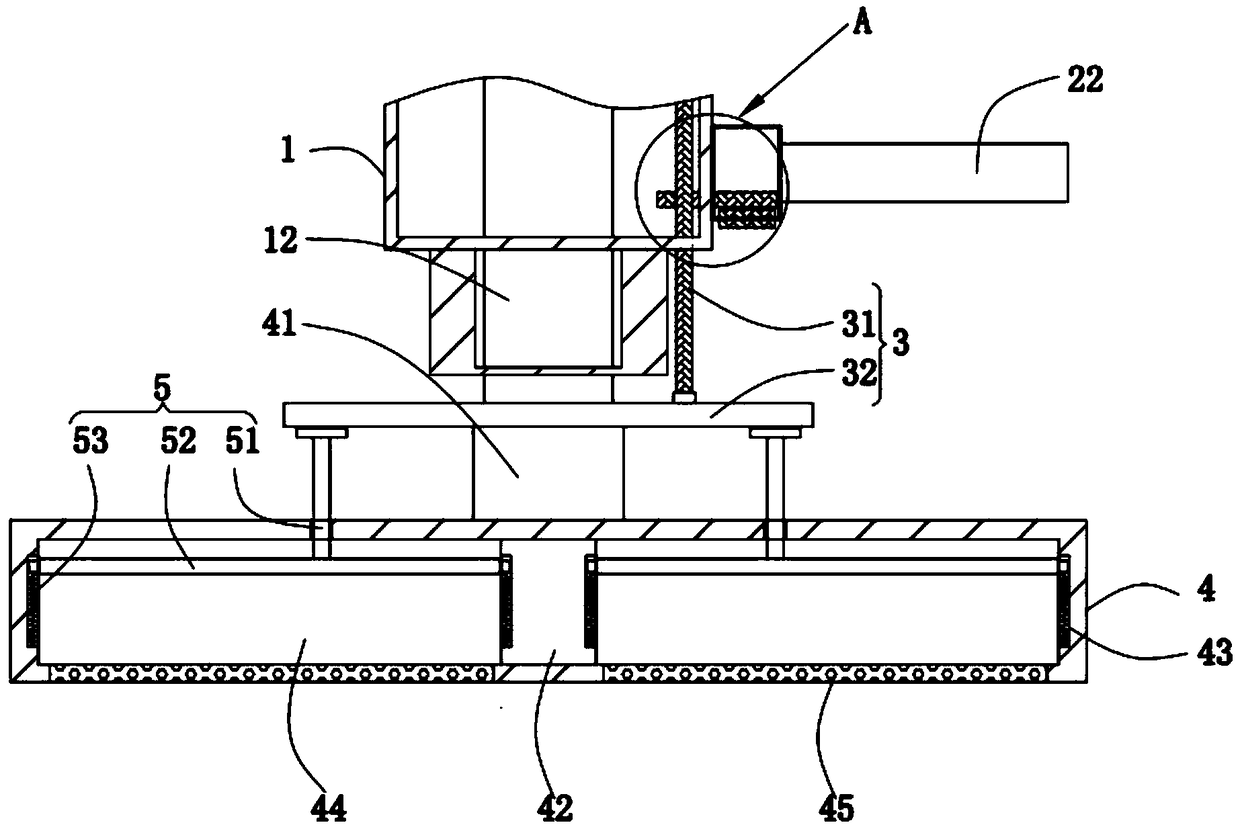

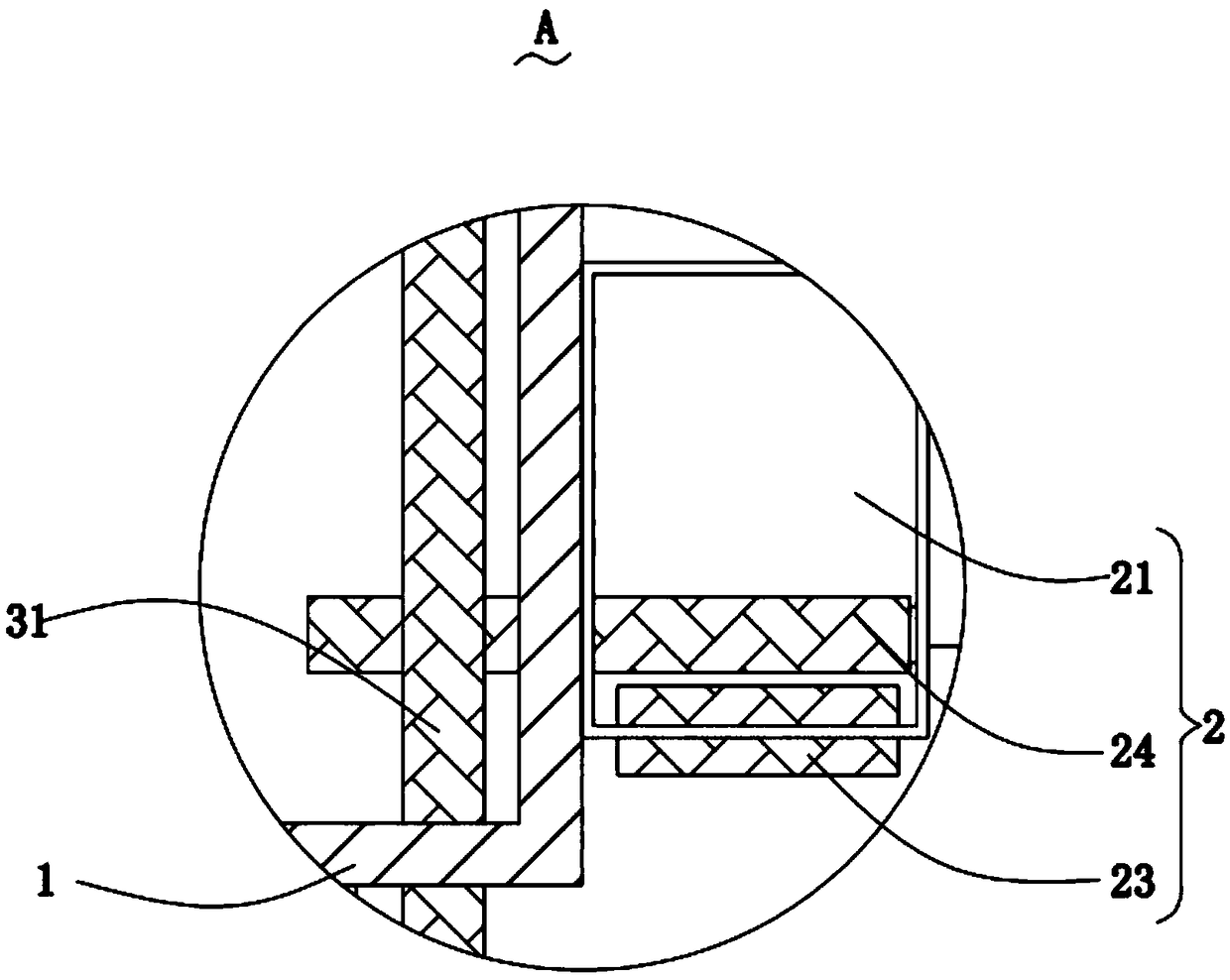

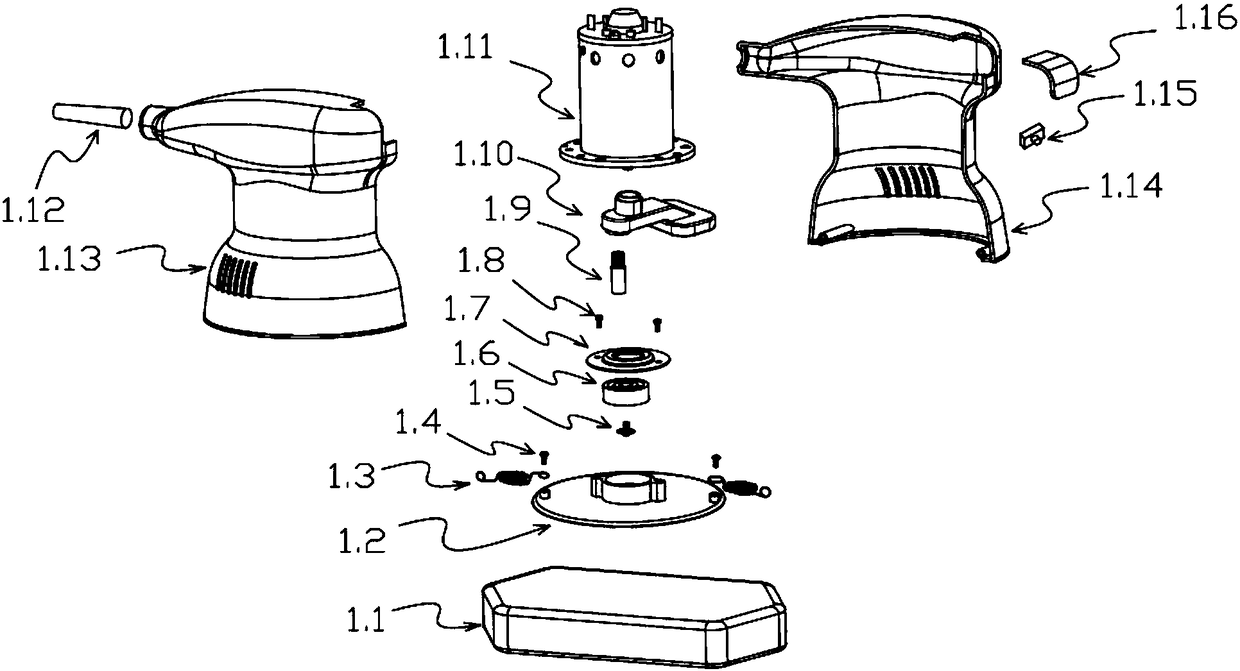

Wax-polishing machine with micro-vibration mode

PendingCN108437946ASolve operational problemsSolve the problem of poor waxing effectVehicle servicing/repairingEngineeringSnubber

A wax-polishing machine with a micro-vibration mode disclosed by the invention consists of an outer case group, a power assembly, a vibration assembly and a waxing assembly, wherein the outer case group comprises a left outer case, a right outer case, a handle and a connecting plate; the power assembly comprises a direct current (DC) permanent magnet motor, a rectifier bridge and a power cord; thevibration assembly comprises an eccentric block, a vibration plate and dampers; the waxing assembly comprises a waxing plate and a waxing plate base; the alternating current (AC) of an external AC power source is converted into the DC permanent magnet motor through the power cord and the rectifier bridge; the eccentric block is fixed on the main shaft of the DC permanent magnet motor; the eccentric block performs a circular motion of the same rotational speed along with the DC permanent magnet motor; and the dampers are mounted between the vibration plate and the left outer case and between the vibration plate and the right outer case. The wax-polishing machine with the micro-vibration mode eliminates the inertia rotation of the waxing plate through the resistance generated by damping components, and transmits the deflection generated by the eccentric block to the waxing plate, so that the waxing plate only produces the micro-vibration mode in the circumferential direction and eliminates a self-rotation mode.

Owner:王向东

Waxing device for car tire maintenance

ActiveCN109092585BEasy to waxEasy waxing and maintenanceLiquid surface applicatorsLiquid spraying apparatusTire maintenanceLiquid storage tank

The invention relates to a waxing device, in particular to a waxing device for automobile tire maintenance. According to the waxing device for the automobile tire maintenance, the labor intensity canbe reduced, and the waxing efficiency is improved. According to the technical scheme, the waxing device for the automobile tire maintenance comprises a bottom plate, a first sliding rail, a first sliding block, a connecting plate, a vertical plate, a fixed plate, an annular sliding rail and the like. The first sliding rail is connected to the left side of the top of the bottom plate, the first sliding rail is provided with the first sliding block, the connecting plate is connected to the right side surface of the first sliding block, and the vertical plate is connected to the right side surface of the connecting plate. According to the waxing device for the automobile tire maintenance, an arc-shaped rubber block rotates and is in contact with a tire, so that the tire is coated with wax liquid on the arc-shaped rubber block, and waxing maintenance is carried out on the automobile tire; and the wax liquid in a liquid storage tank can be sprayed on the automobile tire through a spray headwhen a piston moves up and down, so that the arc-shaped rubber block is not required to be manually and uniformly coated with the wax liquid, and the manual labor amount is reduced.

Owner:山东万物生机械技术有限公司

Solid car wax waxing device

InactiveCN111469027BImprove waxing efficiencySave human effortGrinding drivesPortable grinding machinesGear driveGear wheel

A solid car wax waxing device. First, the sponge block II is fixed in the lower wheel frame through a detachable connection mechanism, and the ring gear is fixed relative to the housing through the ring gear locking device. Since the ring gear of the planetary gear set is fixed, the rear sun After the wheel rotates, the upper wheel frame and the lower wheel frame rotate. At this time, pull and pinch the pressure handle to drive the arc gear to move up. The arc gear drives the gear to rotate. At this time, the sun gear rotates, and the lower wheel frame rotates to drive the sponge block II to rotate. The sponge block II is rotated in the wax box to make the surface stick to the wax, and then the sponge block II is pressed on the car paint, so as to stick the wax to the car paint surface. Remove the sponge block II through the detachable connection mechanism, then release the lock of the ring gear locking mechanism, and lock the upper wheel carrier through the upper wheel frame locking mechanism. After the wheel carrier of the planetary gear set is locked, the sun gear The rotation will drive the ring gear to rotate. Since the sponge block I is symmetrically arranged on both sides of the lower end of the ring gear, it will be polished on the surface of the car paint in a circle, so that the wax is evenly applied to the paint surface.

Owner:SHANDONG TRANSPORT VOCATIONAL COLLEGE

Waxing device for cars

ActiveCN105292080BSimple design and operationImprove sealingPolishing machinesCarpet cleanersWaxEngineering

This patent belongs to the field of being used for the exterior of land vehicles, and specifically discloses a waxing device for automobiles, including a motor, a waxing brush, a material storage cylinder, a push rod, an elastic member and a material storage cylinder. The lower end of the storage tank communicates with the waxing brush, and the upper end is coaxially connected with the output shaft of the motor. The material storage cylinder is funnel-shaped, and the push rod is slidably arranged at the bottom of the material storage cylinder. The top of this push rod is welded with spheroid, and this spheroid is tangent to the mouth inner wall of funnel shape, and the bottom of this push rod is fixed on the waxing brush. The upper end of the elastic member is connected on the material storage cylinder, and the lower end is connected on the top of the push rod. Compared with the traditional manual waxing method, the wax can be automatically replenished only by increasing the pressure on the waxing brush, without stopping the motor and manual feeding, and the waxing efficiency is high.

Owner:CHONGQING TENGTONG IND DESIGN

A stable waxing device for craft porcelain

The invention relates to a waxing device, especially to a stable waxing device for porcelain artworks. The invention provides a stable waxing device for porcelain artworks and with uniform waxing effect so as to solve the technical problem. The stable waxing device for porcelain artworks comprises a support, a motor, a second guide pulley, a stay wire, a first guide pulley, a first spring, a non-return valve, a flexible pipe, an infusion pump, a second box, a first pole and the like. A first box is positioned at the left side of second springs. The second springs are symmetrically arranged at two sides of the bottom inside the first box. The upper ends of the second springs are connected to a piston which matches the first box. The bottom of the first box is provided with a drain pipe and the first pole. The effect of uniform waxing is achieved. With alternative-type clockwise rotation and anticlockwise rotation of porcelain, the porcelain is roundly waxed by sponge. Then, the porcelain waxing effect is better.

Owner:新昌县利拓科技有限公司

An automatic waxing device

ActiveCN111299058BImprove waxing efficiencyAvoid situations where waxing operations cannot be performedLiquid surface applicatorsCleaning using toolsPulleyRaw material

An embodiment of the present invention discloses an automatic waxing device, which includes a pulley fixing frame. A pulley driving belt is installed on the bottom side wall of the pulley fixing frame. Two pulley fixing frames are provided directly above the pulley driving belt. The connected pulley clamping frame is provided with a continuous waxing mechanism connected to the pulley fixing frame above the pulley clamping frame. A raw material extrusion frame is connected to the continuous waxing mechanism above the pulley fixing frame. It is equipped with a driving device that drives the pulley to drive the belt and the continuous waxing mechanism. This equipment releases the operator's hands when in use, improves the waxing efficiency, and can also use the flattening roller on the waxing belt to flatten the off-road pulley. Crush stubborn debris and scrape away the crushed debris through the embedded grooves on the storage cotton block, so as to facilitate debris removal and storage operations and avoid uneven waxing or damage to the waxing head. , causing the waxing operation to be affected.

Owner:斯威克斯体育产业发展有限公司

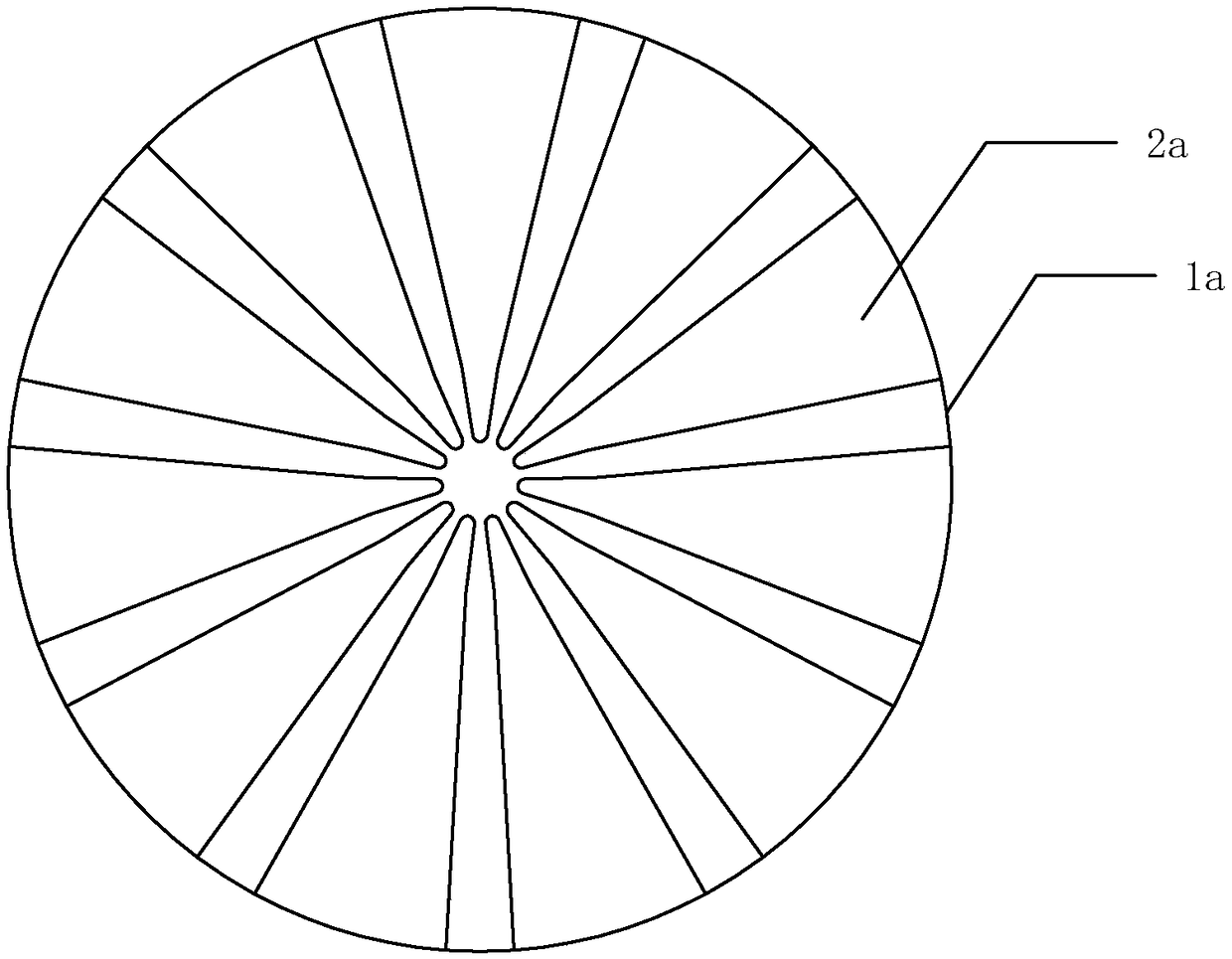

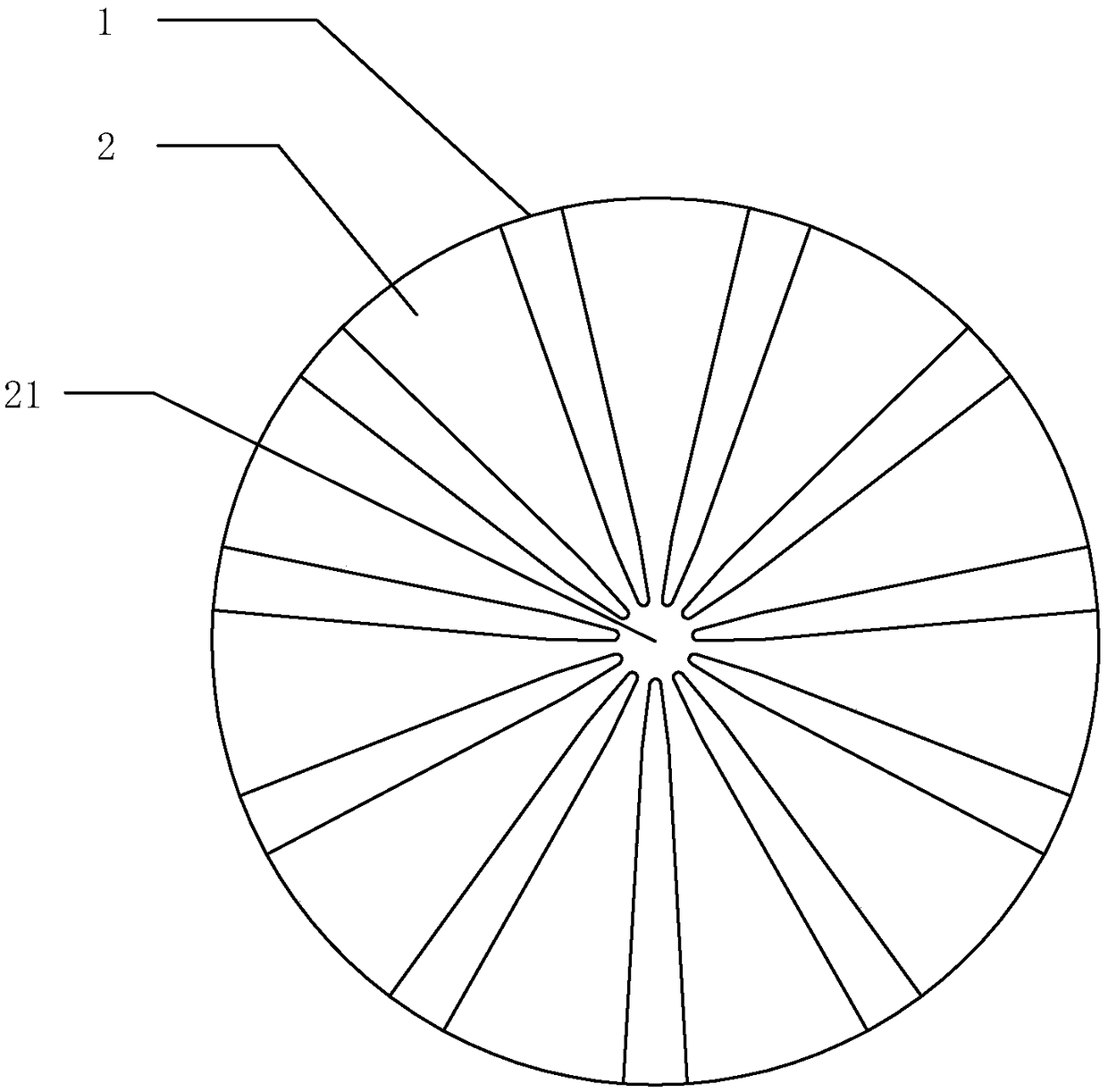

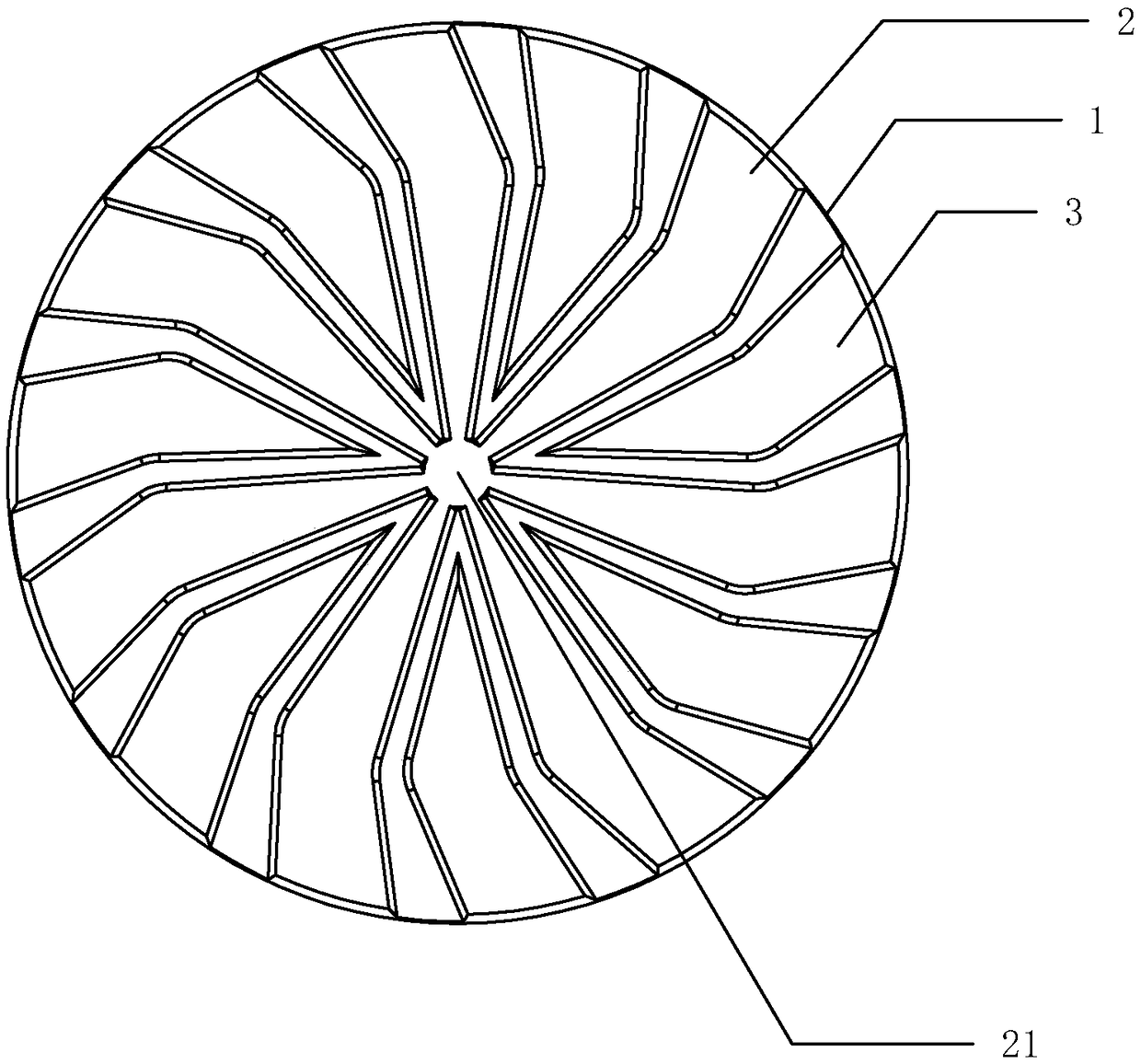

Waxing impeller

InactiveCN109318135AEvenly distributedExpand the working areaFlexible-parts wheelsImpellerEngineering

The invention discloses a waxing impeller. The waxing impeller comprises a disk body and a plurality of blades, wherein the blades protrude out of the lower surface of the disk body; the blades are integrally distributed around the center of the disk body; the head ends of the blades are located at the peripheral edge of the disk body, and the tail ends of the blades are located in the center position of the disk body; the tail ends of at least two of the multiple blades are connected continuously. According to the waxing impeller, the shape and structure of an existing impeller are improved;under the action of centrifugal force generated during operation and the capillary phenomenon, a liquid film below one blade can extend to the location below the other blade from the continuous location, so that the covering area of the liquid film is effectively increased, the waxing effect is enhanced, and the grinding and polishing efficiency is improved. The waxing impeller can be applied to various occasions where workpieces need to be waxed and polished.

Owner:广东工科机电有限公司

Waxing maintenance device for wardrobe surface scratch treatment

ActiveCN114367420AFully absorbedApply evenlyLiquid surface applicatorsCoatingsEngineeringStructural engineering

The invention relates to the technical field of furniture, and discloses a waxing maintenance device for wardrobe surface scratch treatment, a first pressing rod is movably embedded and connected into a shell, a handle is fixedly connected to the top end of the first pressing rod and located on the outer side of the shell, and limiting rods are movably connected to the two sides of the outer surface of the first pressing rod; a second pressing rod is fixedly connected to the bottom end of the first pressing rod, a sponge block is fixedly connected to the bottom end of the second pressing rod, first connecting rods are movably connected to the two sides of the outer surface of the second pressing rod correspondingly, a gear is movably connected to one end of each first connecting rod, and an adjusting rod is movably connected to the position, located on one side of the gear, in the shell. The wax liquid bag enables wax liquid in the wax liquid bag to be discharged into the sponge block along the liquid guide pipe, the interior of the sponge block can fully absorb the wax liquid and evenly smear the wax liquid on the surface of the cabinet body, the tedious step that the sponge block is used for continuously dipping the wax liquid is omitted, and waste caused by dripping of the wax liquid can be prevented.

Owner:南京辉腾机械铸造有限公司

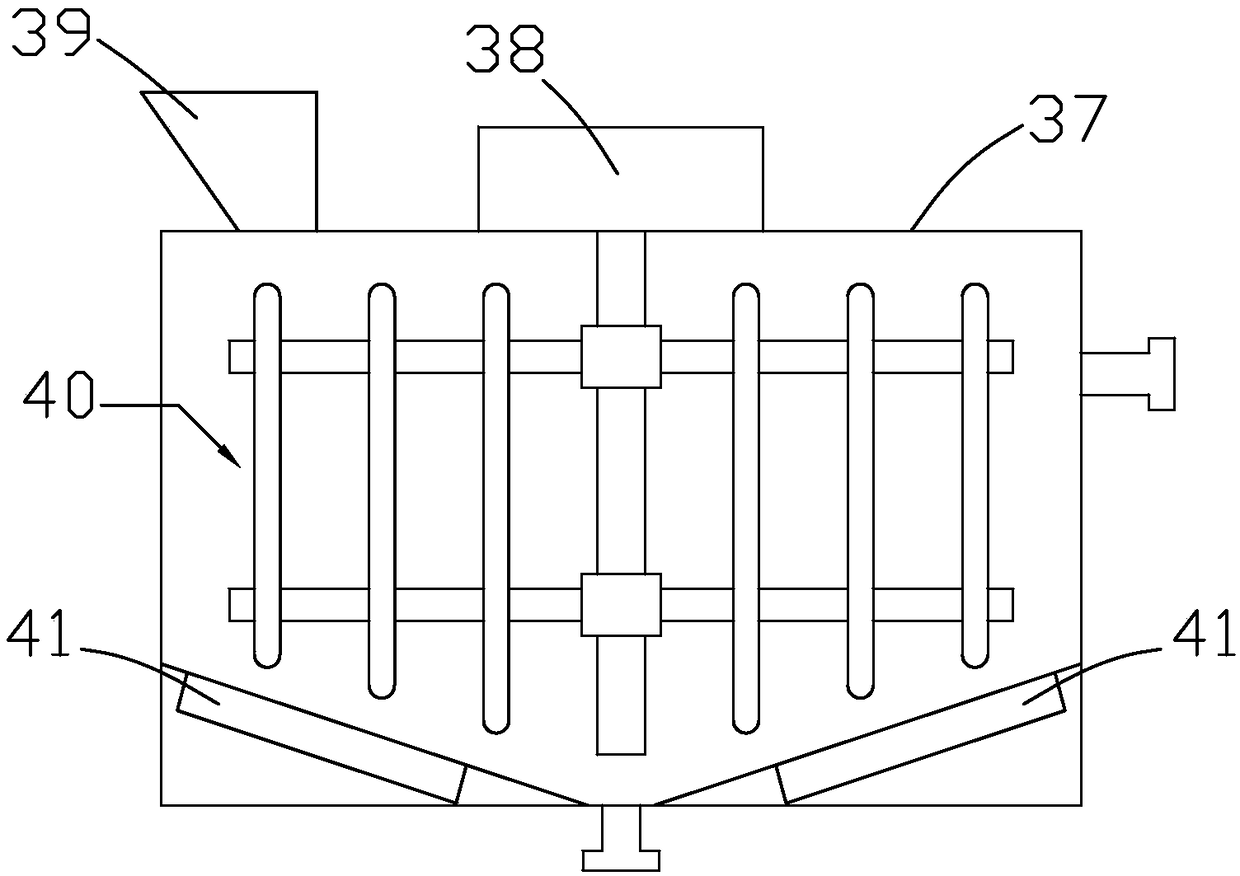

Yarn waxing equipment for textile processing

ActiveCN112411063AWaxing dense and evenImprove waxing efficiencyLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsYarnEngineering

The invention discloses yarn waxing equipment for textile processing. The yarn waxing equipment comprises a box body, a baffle is fixed to the inner wall of the box body and divides the box body intoa waxing chamber and a drying chamber, a waxing mechanism is arranged in the waxing chamber, a mounting groove is formed in the bottom of the waxing chamber, and an electric heating wire is fixed to the inner wall of the mounting groove; and the waxing mechanism comprises a first waxing carrier roller, a second waxing carrier roller, a driven gear, a driving gear and a first servo motor. By usingthe first waxing carrier roller, the second waxing carrier roller, the driven gear, the driving gear and the first servo motor which are arranged on the waxing mechanism, wax oil can be rotationally smeared to the bottoms of yarns through the second waxing carrier roller, meanwhile, an inclined plate and an oil well pump are utilized to smear the tops of the yarns, and the waxing efficiency of theyarn is improved; and by using a yarn inlet pipe, a shock absorber, a yarn pressing carrier roller, a scraping piece and a filter screen which are arranged on an oil scraping mechanism, redundant waxoil on the surface can be scraped off, and waxing is more uniform.

Owner:SUZHOU SHAOCHENG TEXTILE SCI & TECH

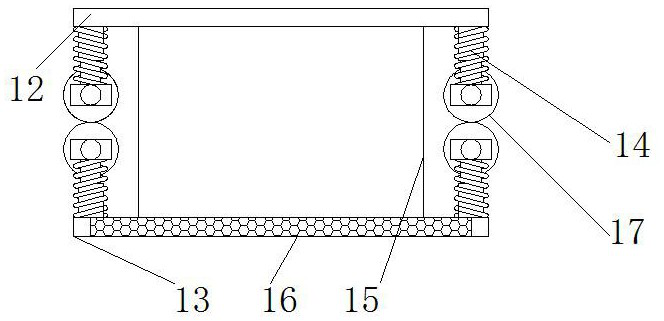

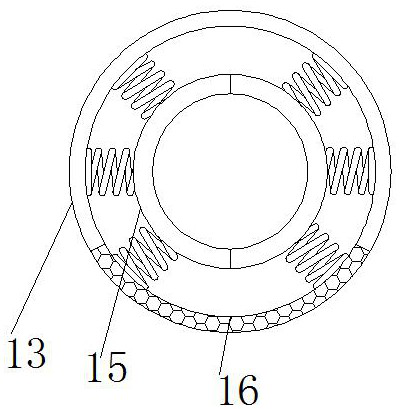

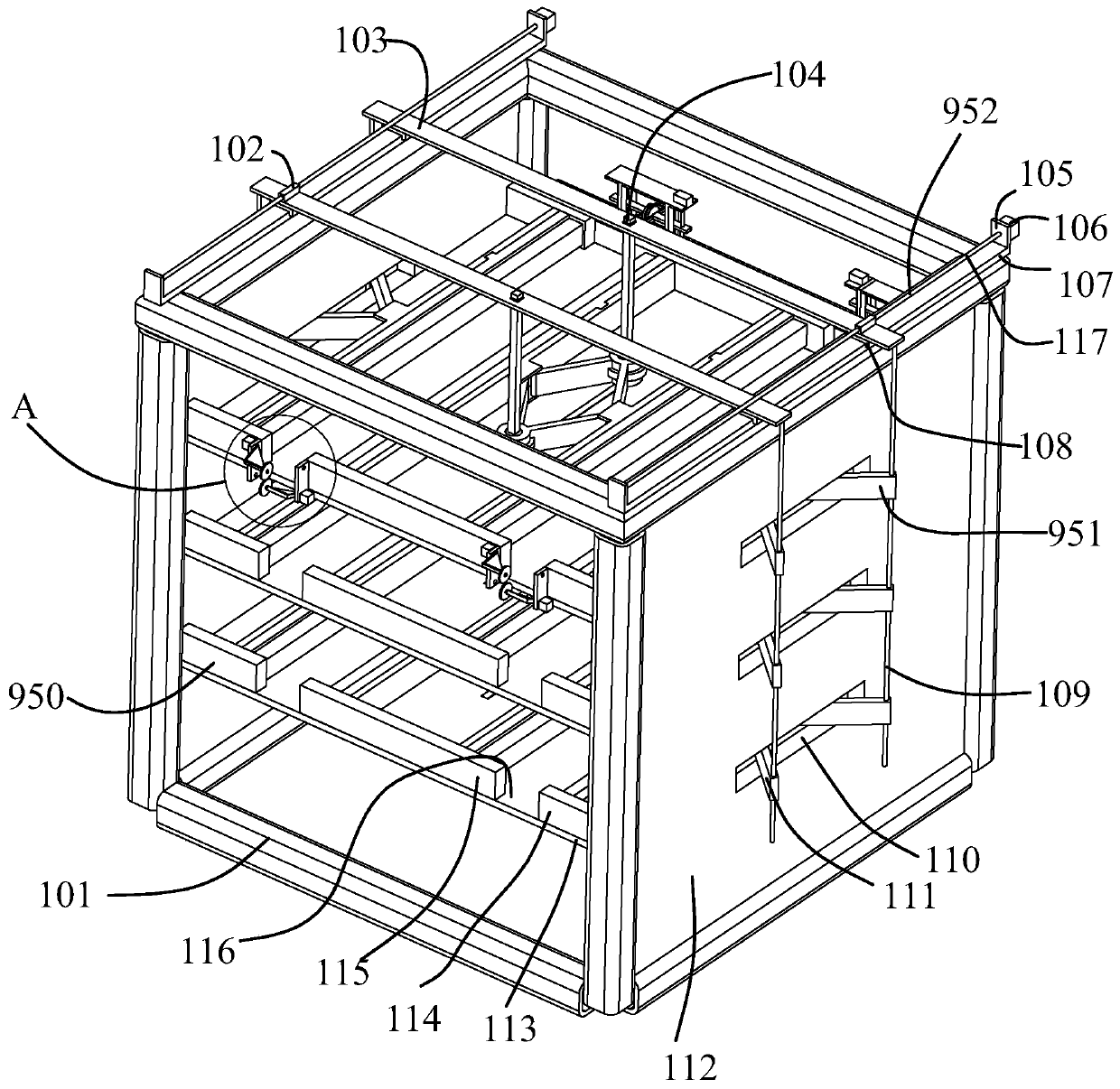

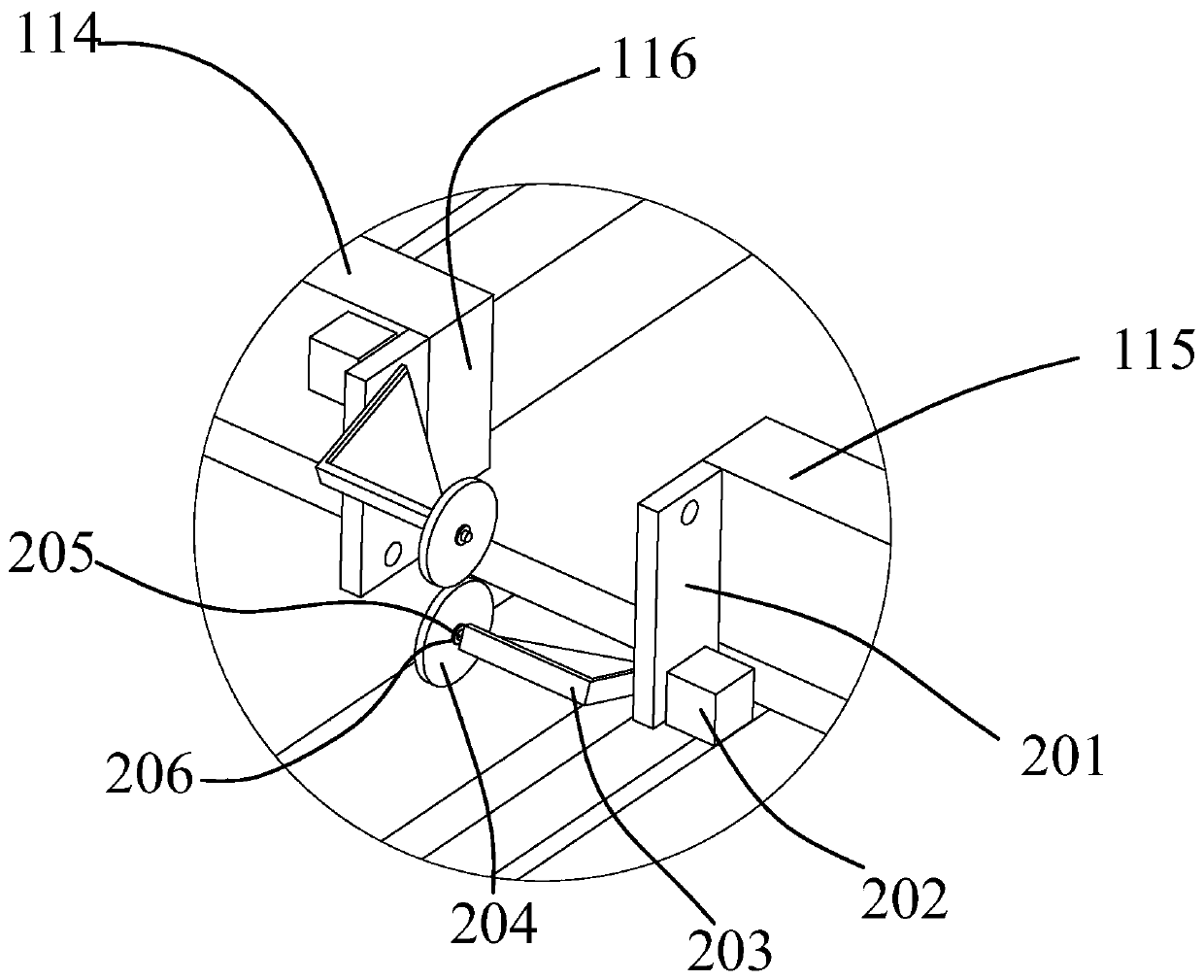

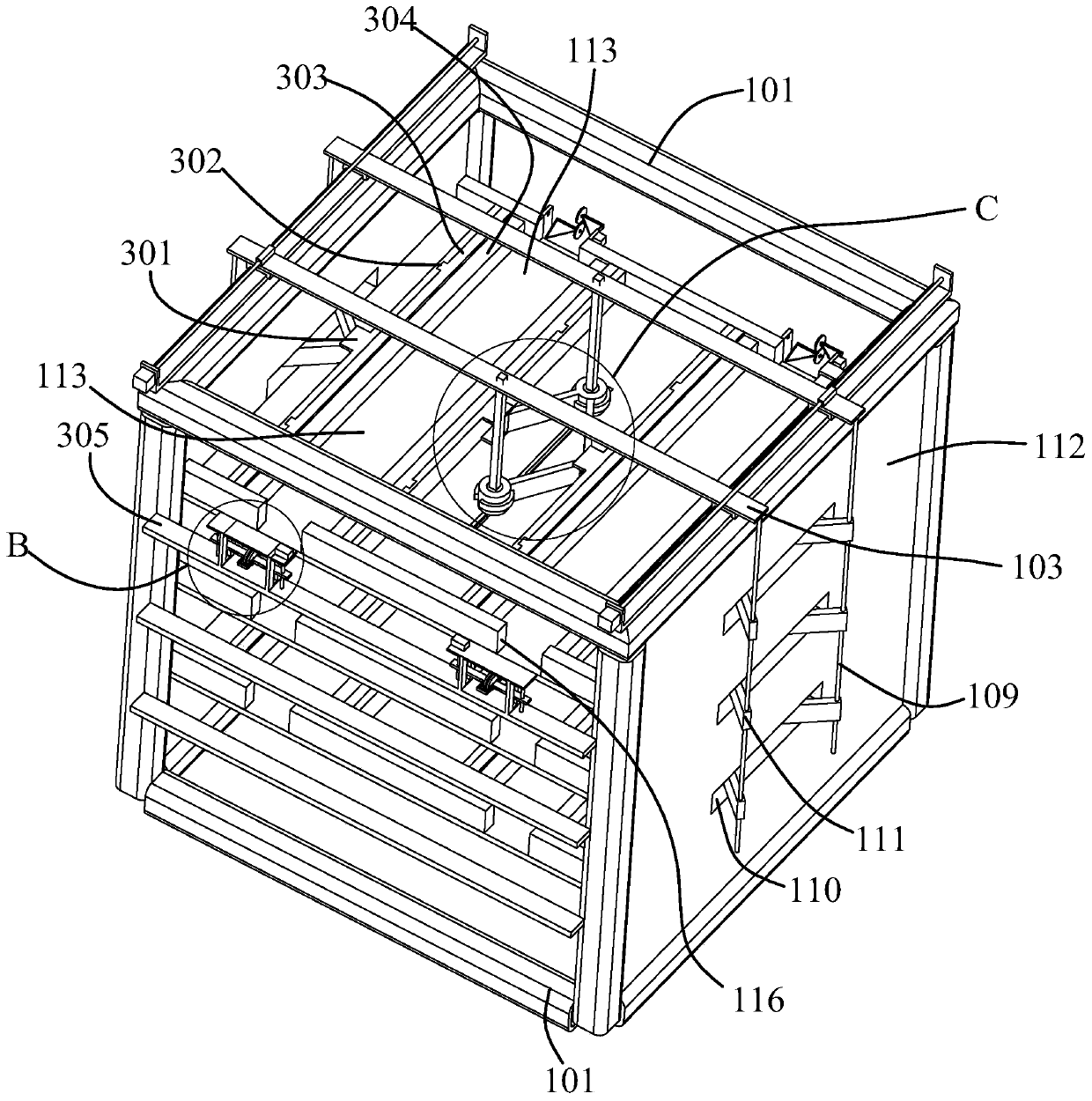

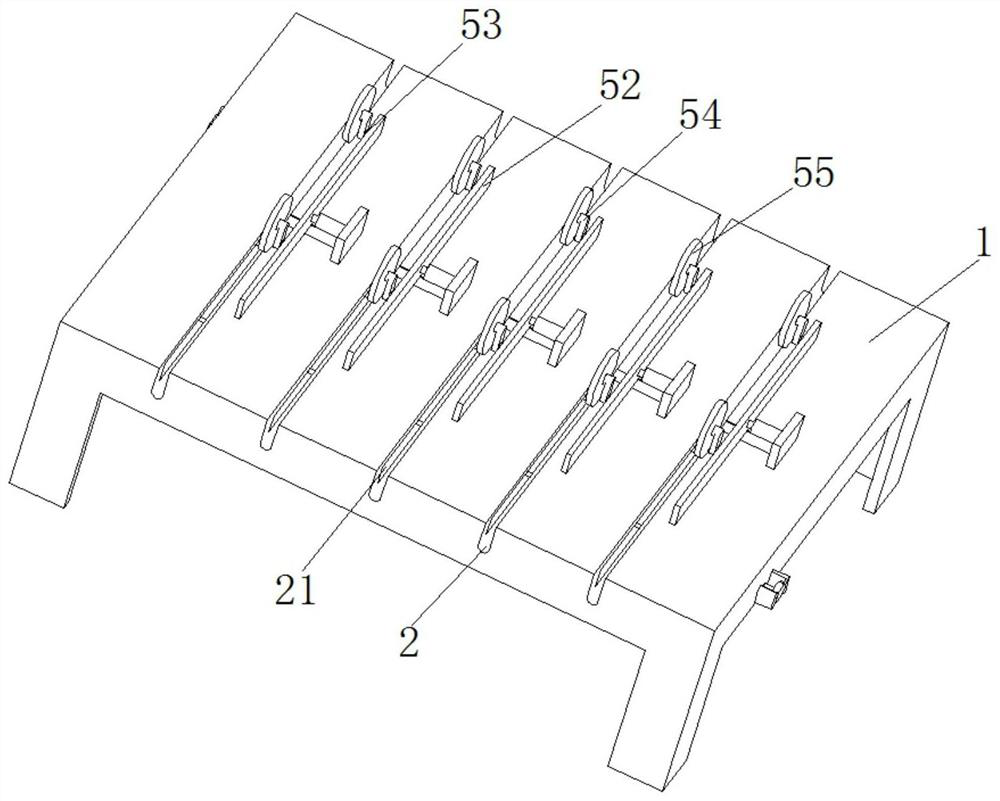

A large-volume textile waxing equipment

ActiveCN110318136BRealize guidanceRealize the waxing processTextiles and paperStructural engineeringMechanical engineering

The invention discloses a large-scale textile thread waxing device. The large-scale textile thread waxing device structurally comprises a frame of a frame structure, the frame is a square body bracket, left and right symmetrical vertical plates are fixedly arranged inside the frame, at least three platform devices used as platforms for lining of textile threads are disposed between the vertical plates, waxing devices capable of simultaneously clamping and waxing the textile threads are arranged correspondingly above the platform devices, and a driving device located on the upper end surface ofthe frame and used for driving the waxing device to operate is disposed above the waxing devices. The platform devices, the waxing devices and the driving device are adopted by the device, guiding the textile threads is achieved, a waxing process of the textile threads in horizontal and vertical directions is achieved by adopting a corresponding structure, in the process, a linkage structure is utilized, the working efficiency of the device is improved, and the waxing processing process of the large-scale textile threads is achieved.

Owner:湖南东信棉业(茶陵)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com