Automatic waxing system for leather

A leather, automatic technology, applied in the direction of leather dipping, leather drying, leather flattening/rolling, etc., can solve problems such as inability to guarantee uniformity of application, low application efficiency, and influence on waxing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

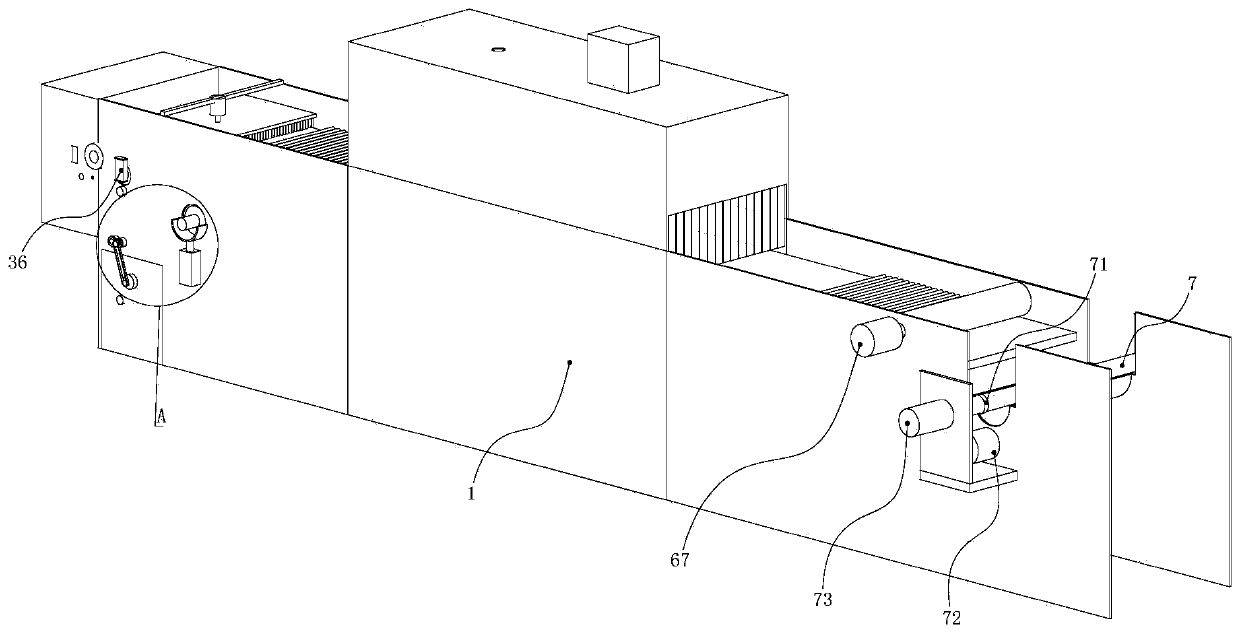

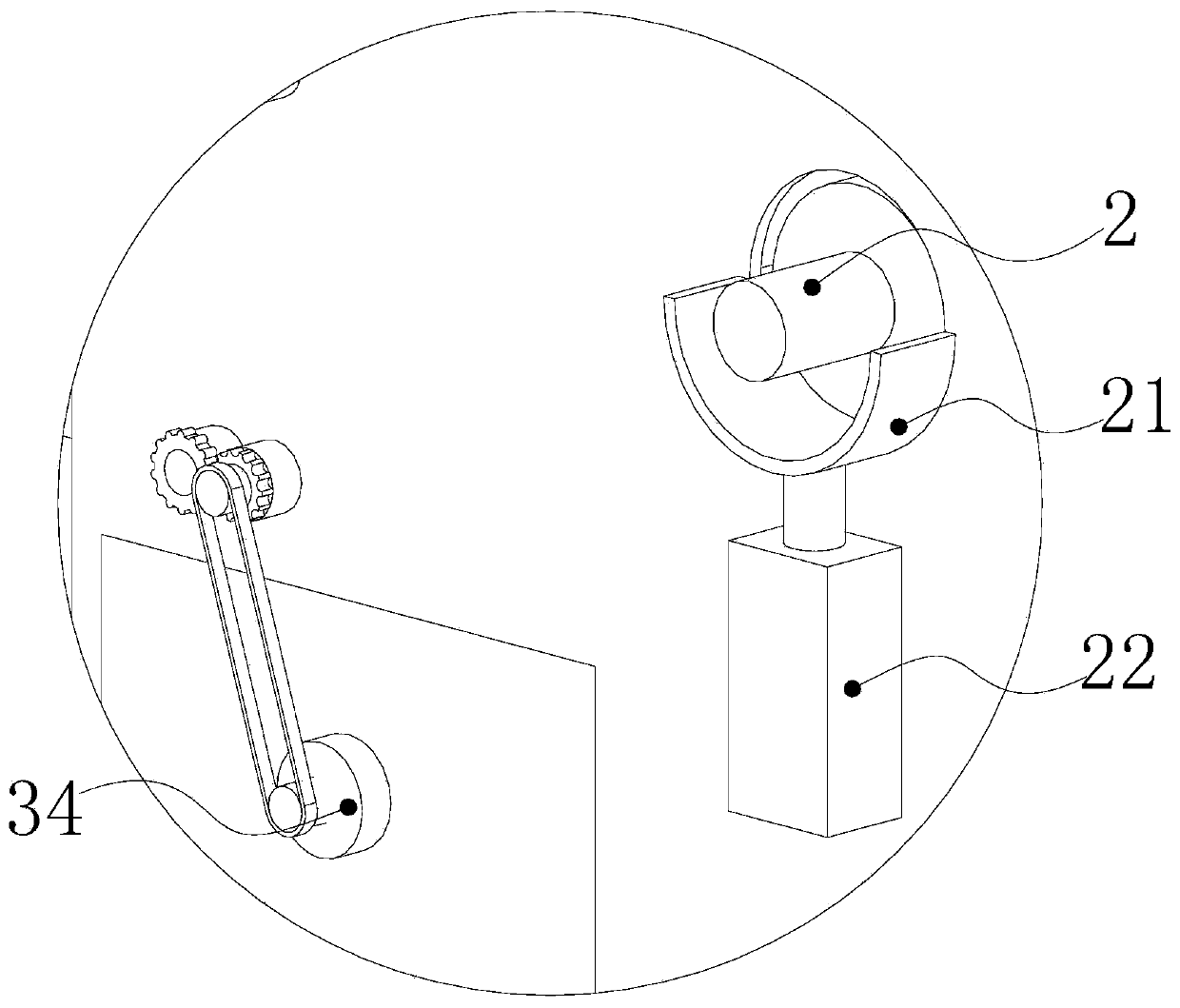

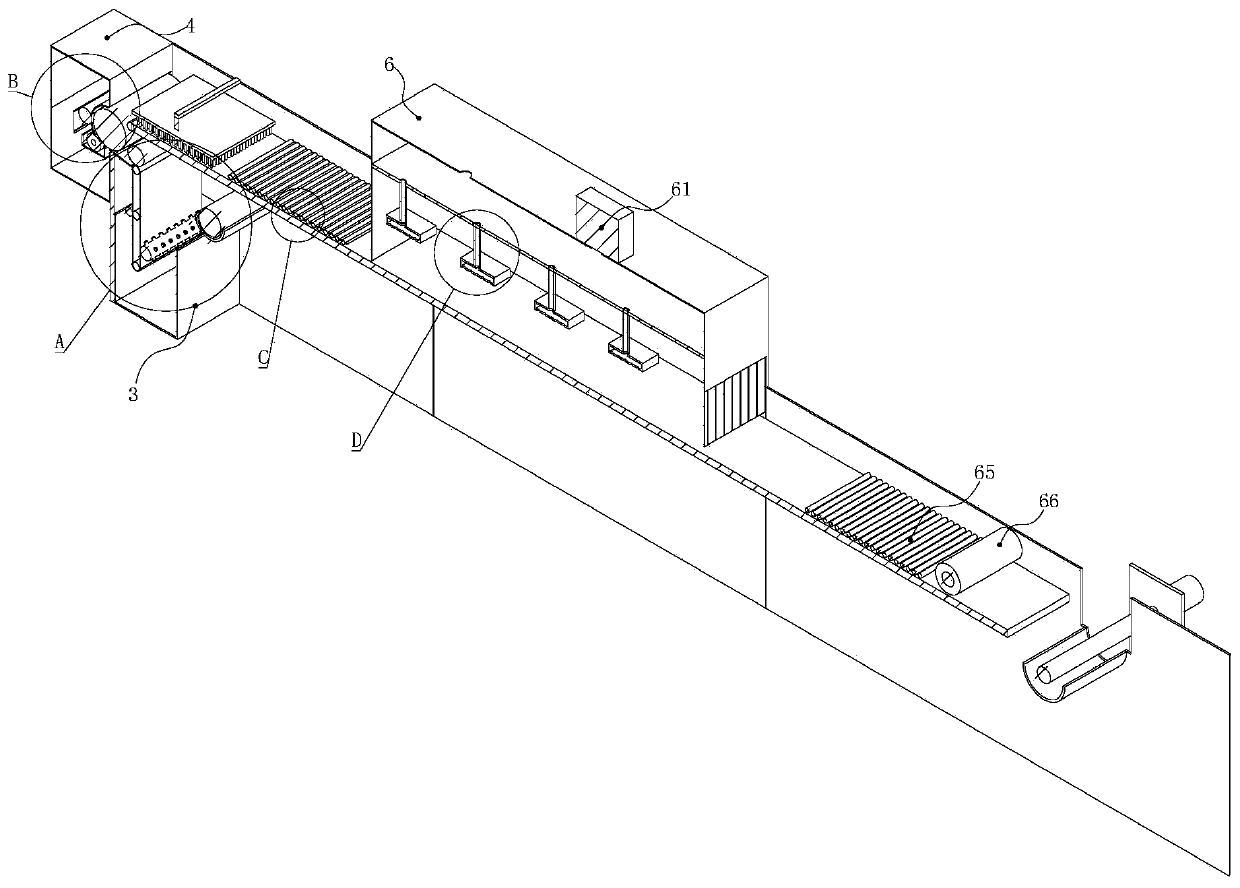

[0022] Such as Figure 1-9 Shown, a kind of leather automatic waxing system comprises frame 1, feeding device, leather cleaning device, leather waxing device, leather drying device, leather polishing device and leather collecting device, and described feeding device includes feeding Roller 2, jack, arc-shaped supporting plate 21 and supporting plate driving member 22, described feeding roller 2 selects conventional cylinder for winding leather, and described jack is opened symmetrically on both sides of frame 1, is used for Insert the feeding roller, the arc-shaped supporting plate 21 is located directly below the socket, and is fixed on the output end of the supporting plate driving part, and the supporting plate driving part 22 is a conventional cylinder, fixed on both sides of the frame 1, Then when feeding, only need to insert the feeding roller wrapped with leather into the socket, and hold up the feeding roller through the supporting plate, so that the feeding roller can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com