Waxing impeller

An impeller and blade technology, applied in the field of waxing impellers, can solve the problems of poor finish of finished brick surface, high loss rate of waxing impellers, large wax consumption, etc. The effect of reduced installed capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

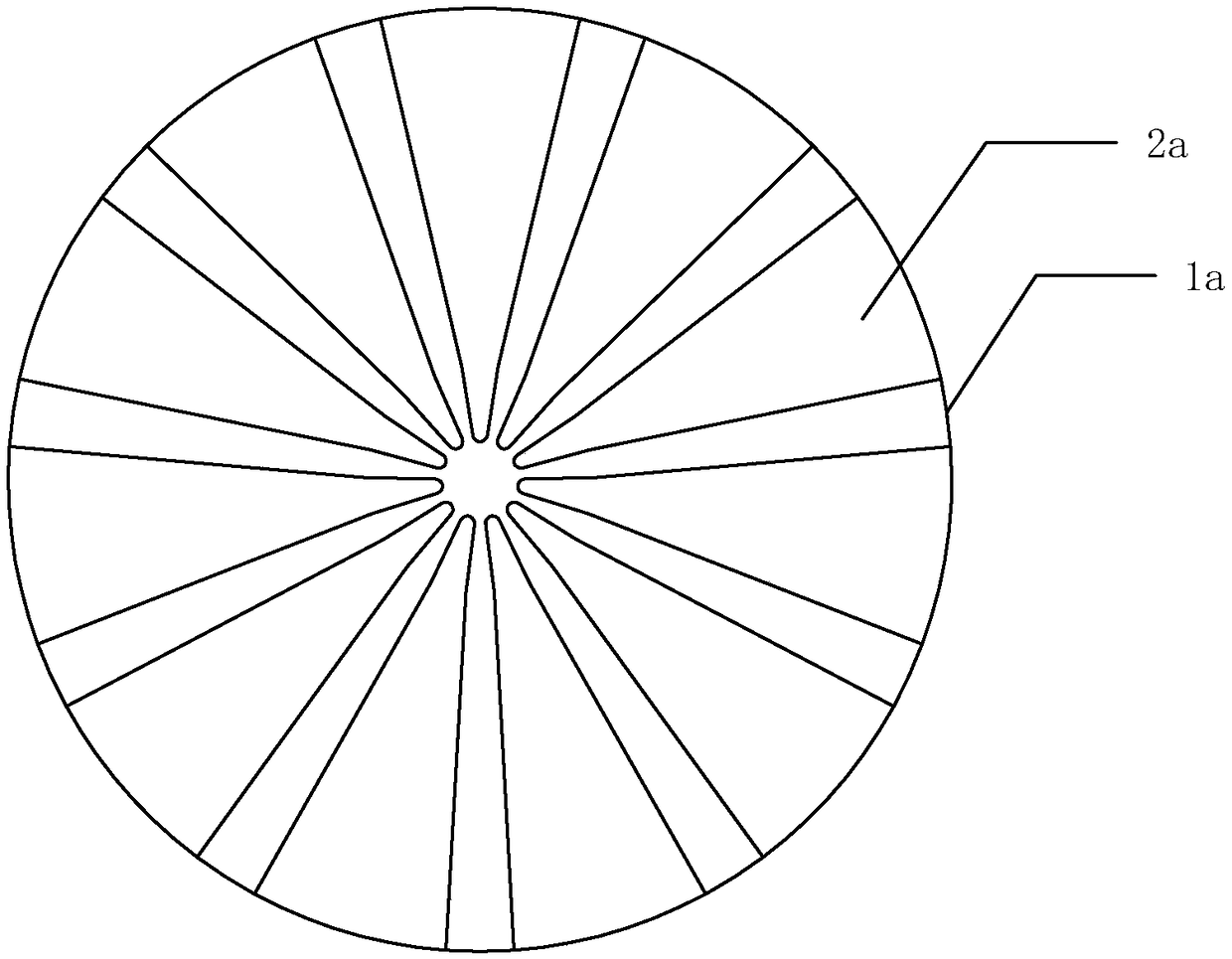

Embodiment 1

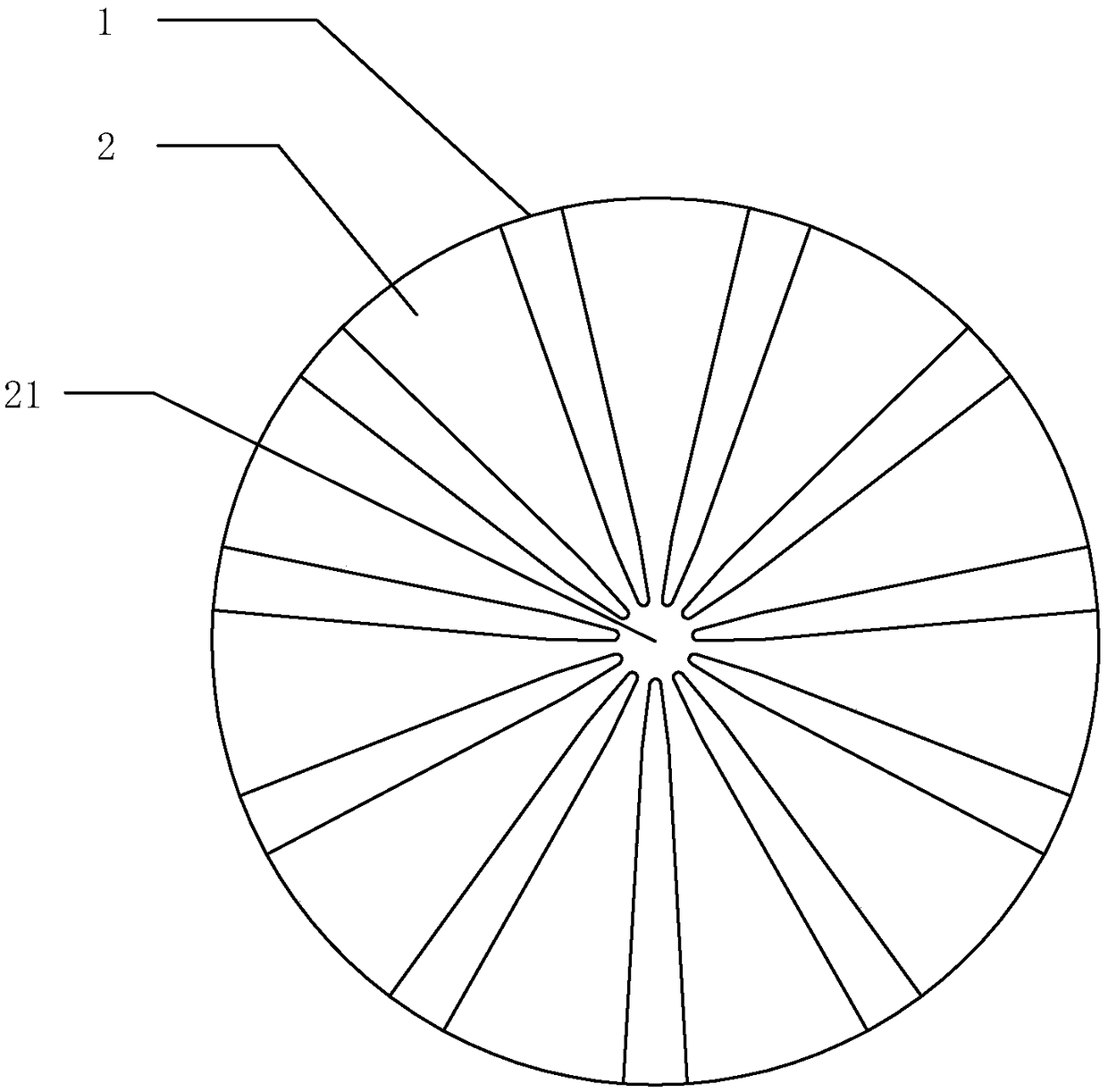

[0024] Continue to refer to figure 2 , in this embodiment, the ends of the plurality of blades 2 are continuous with each other to form a continuous area 21 . Such a structural design is more convenient to manufacture, and the liquid film can easily spread freely from the part of the blade that has been overstocked to other blade positions with uneven pressure and less waxy water below, and can automatically adjust and adapt the coverage without affecting the impeller. Originally, there is an inherent chip removal space between blades and blades, so it has a good grinding and polishing effect.

Embodiment 2

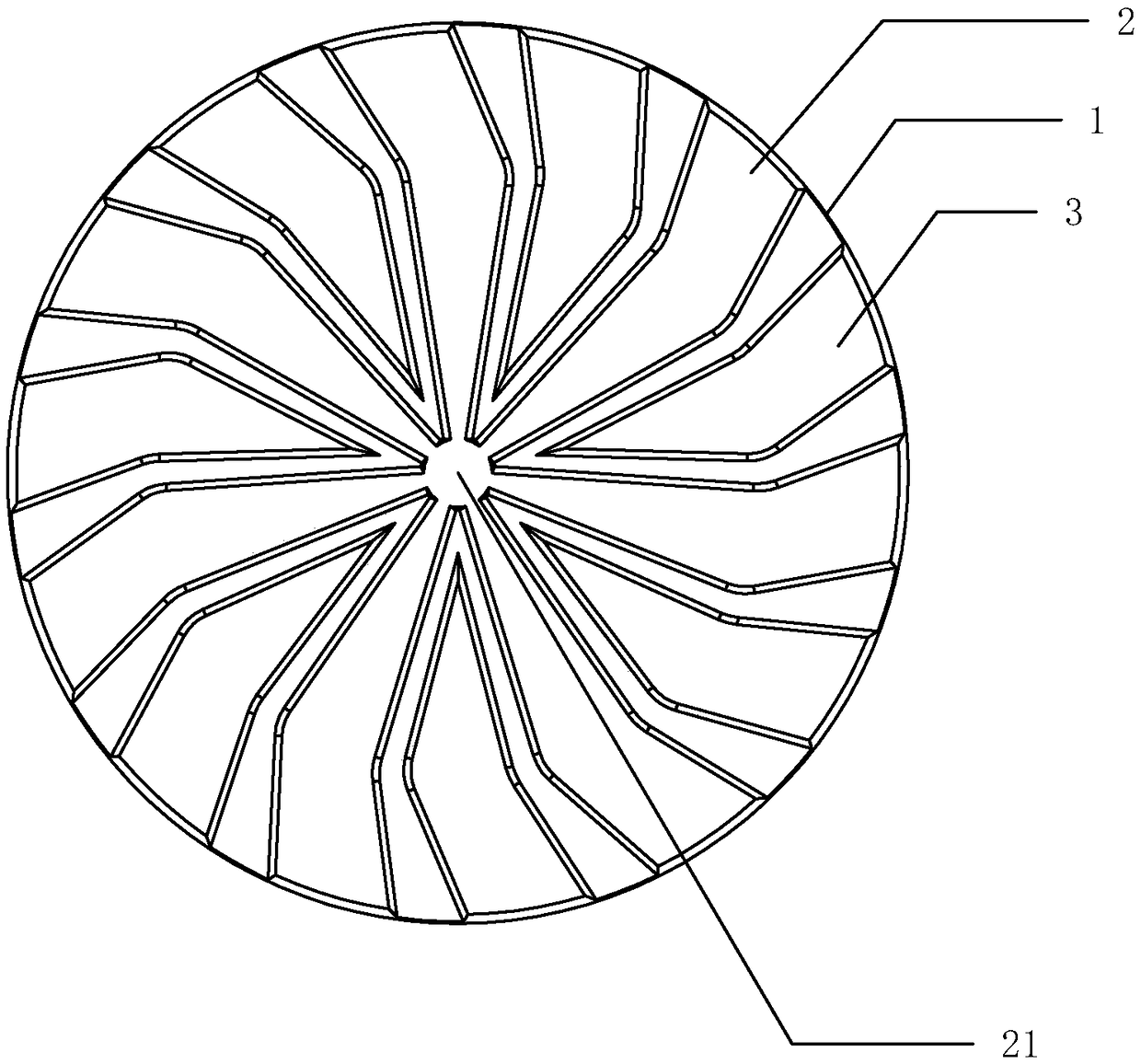

[0026] refer to image 3 , the basis of this embodiment is roughly the same as that of Embodiment 1, but different changes are made to the continuity scheme of the blades, and the continuous means of discrete intervals are adopted. That is to say, there are at least two discontinuous blade groups on the disc body 1, and each of the discontinuous blade groups includes two blades 2 that are continuous at the ends of each other and the blades that are located between the two blades 2 and are also from the lower part of the disc body 1. At least one auxiliary blade 3 protrudes from the surface, and the auxiliary blade 3 and the blade 2 are not connected to each other.

[0027] This embodiment introduces the concepts of intermittent blade group and auxiliary blade, but it is added for the convenience of structural description. In specific production practice, the auxiliary blade and the blade can be regarded as the same physical part, except that the ends of the blades are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com