A Method for Improving the Surface Glossiness of Blended Yarn

A technology of blended yarn and glossy surface, applied in the direction of yarn, textile and papermaking, textile/flexible product manufacturing, etc. Guaranteed uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

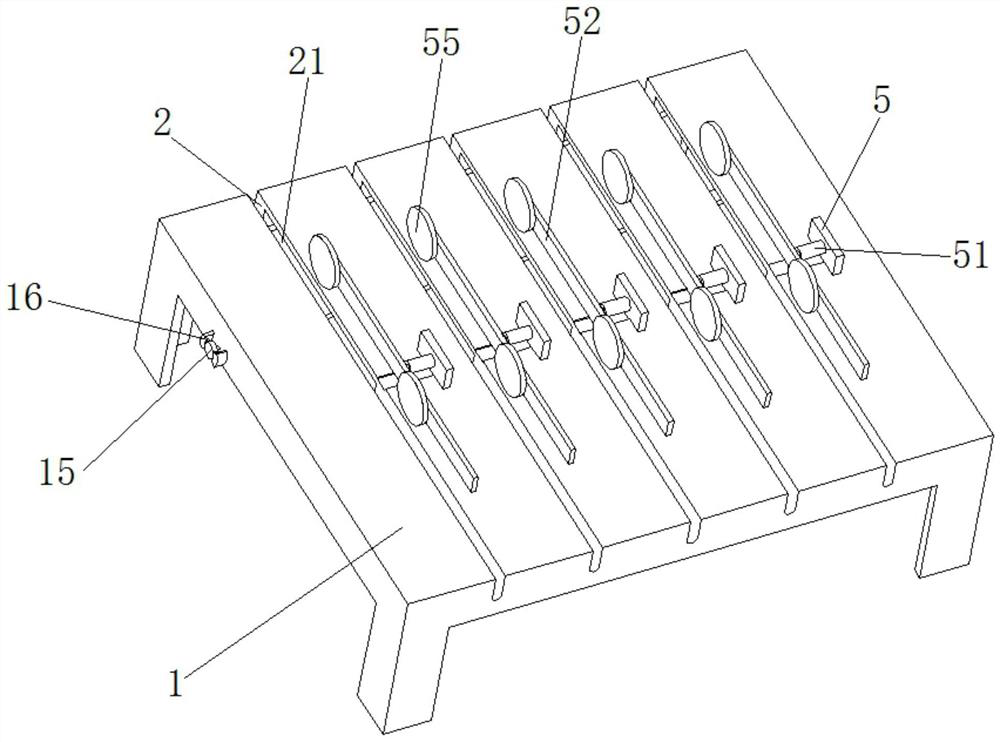

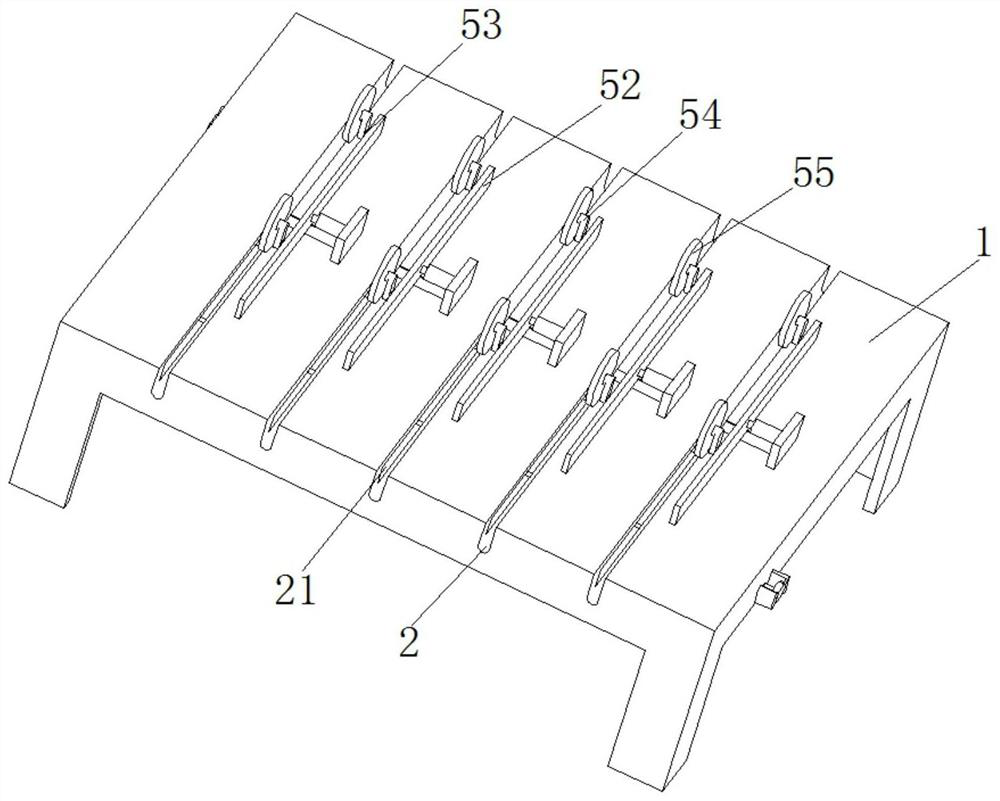

[0029] As shown in Figure 1 to Figure 7, a method for improving the surface gloss of a blended yarn, which uses a blended yarn

[0036] One end of the fixing plate 32 away from the fixing groove 3 is fixedly installed with a connecting block 4, and the connecting block 4 is provided with a through hole 41.

[0043] The basic principles, main features and advantages of the present invention have been shown and described above. Technicians in the industry should

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com