Solid car wax waxing device

A kind of car wax and solid technology, which is applied in the direction of grinding drive, vehicle maintenance, transportation and packaging, etc. It can solve the problems of manual operation, time-consuming and labor-intensive, etc., and achieve the effect of improving efficiency and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

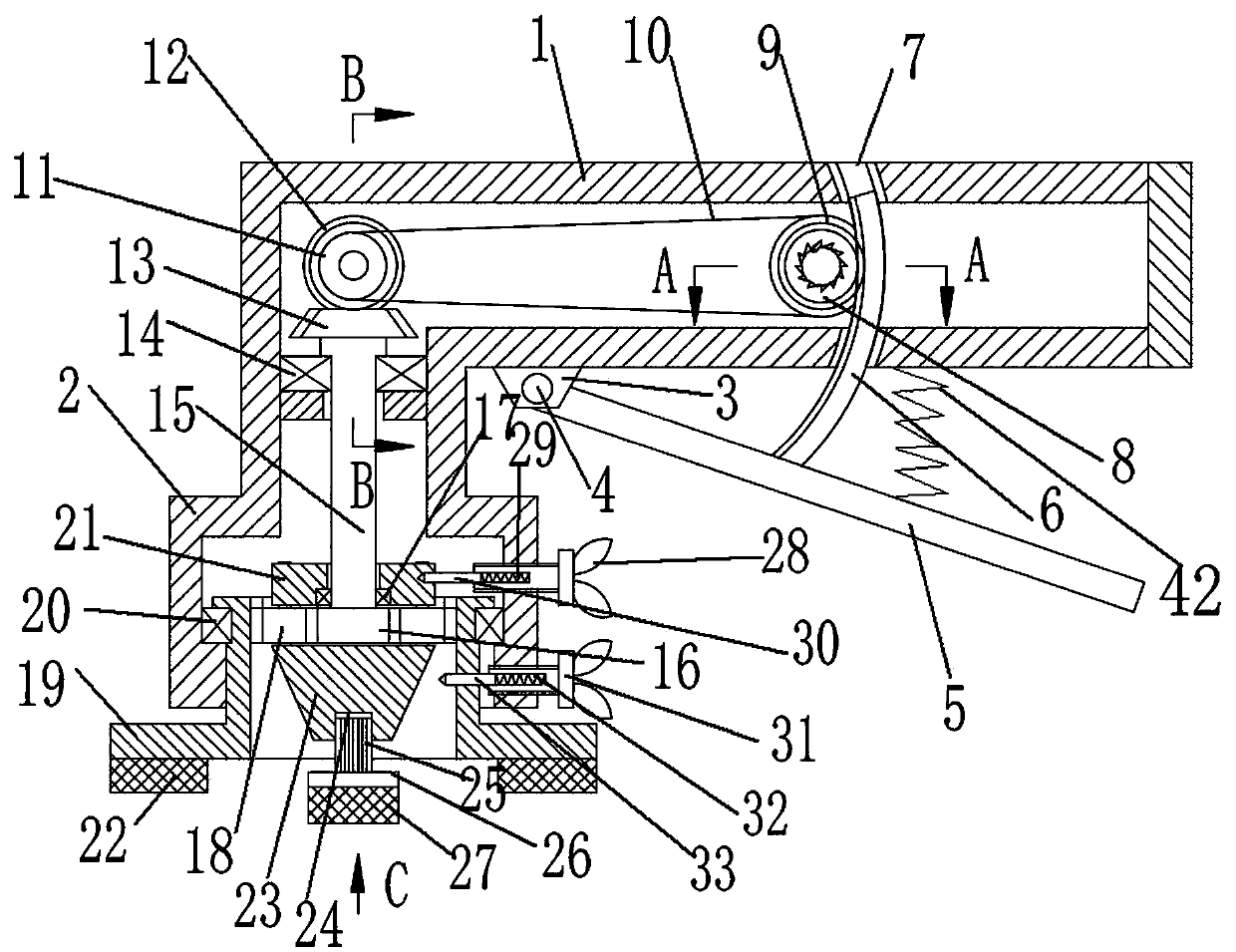

[0025] Attached below figure 1 Attached Image 6 The present invention will be further explained.

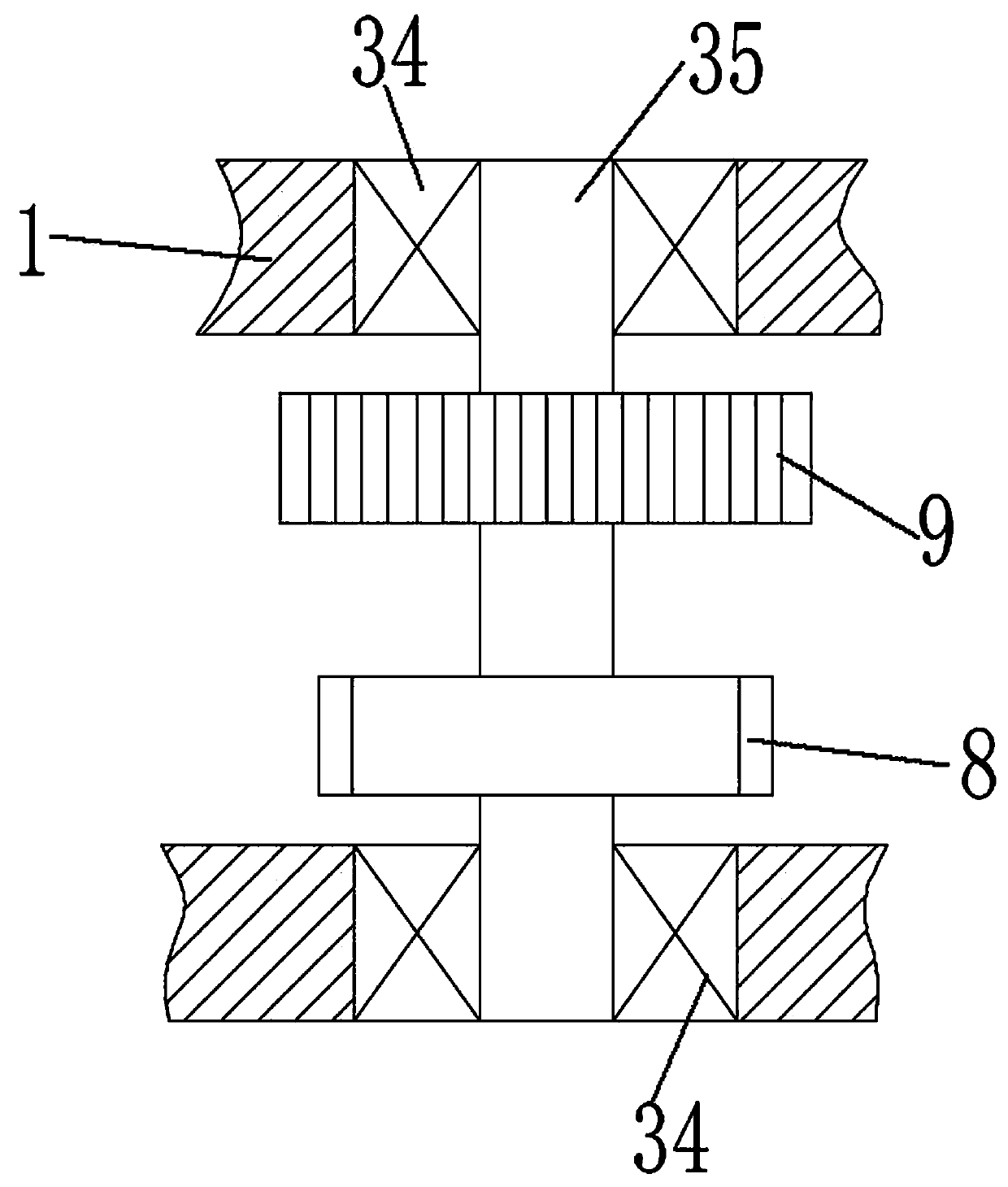

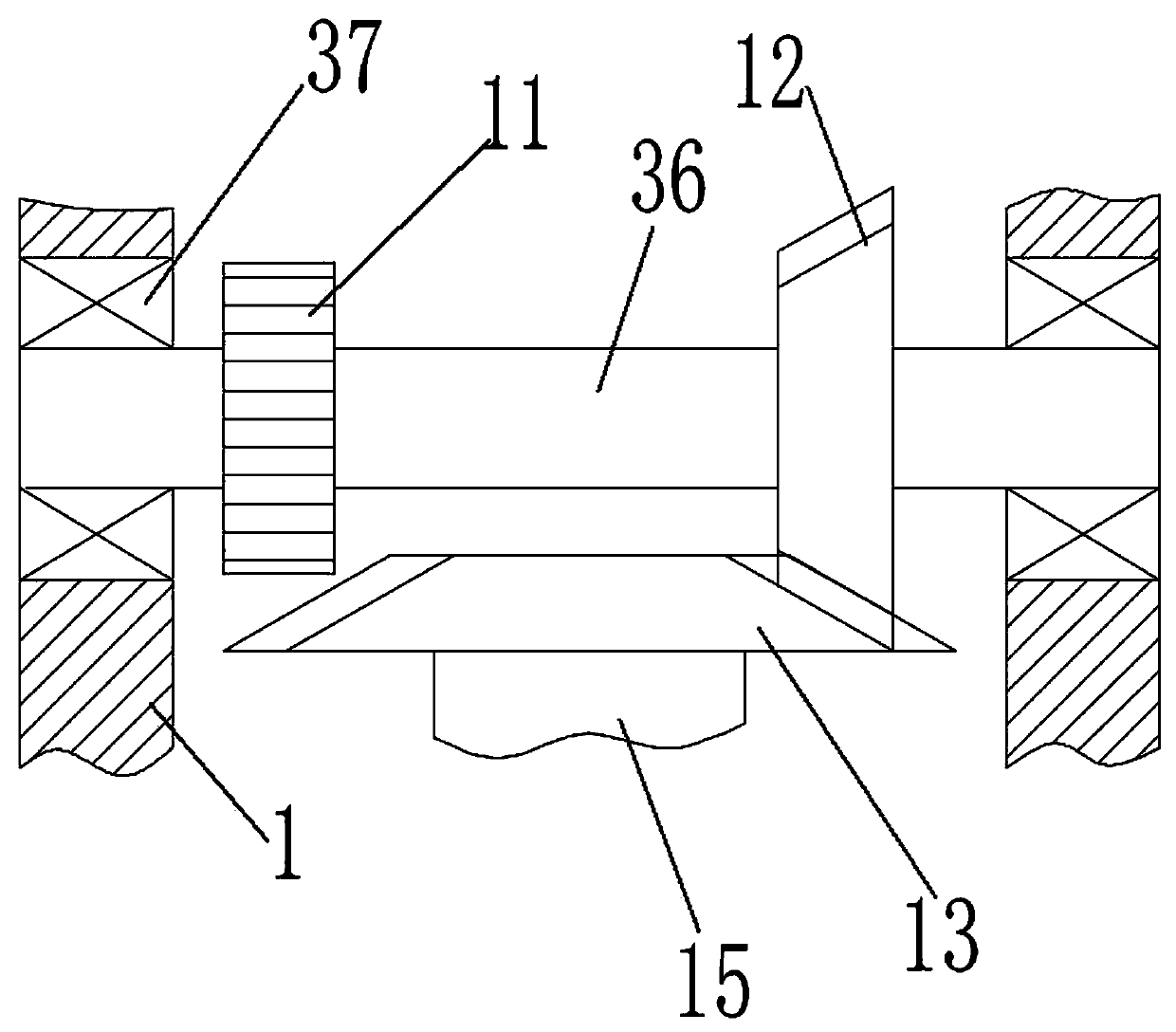

[0026] A solid car waxing device, comprising: a handle 1, a housing 2 is arranged below the front end, a spindle 15 is installed in the housing 2 to rotate in a vertical direction through a bearing I 14; an ear seat 3 is arranged on the handle 1 Below, the head end of the pressing handle 5 is hingedly mounted on the ear seat 3 through the pin 4, one end of the spring III 42 is connected to the pressing handle 5, and the other end is connected to the handle 1. The shaft I 35 is horizontally mounted on the handle through a bearing IV 34 In 1, a gear 8 is fitted on the shaft Ⅰ 35, a circular arc gear 6 is provided on the pressing handle 5, a guide hole 7 is provided on the handle 1, and the circular arc gear 6 is inserted in the guide hole 7 and is connected to the gear When the spring III 42 is in the free state, the gear 8 meshes with the uppermost end of the arc gear 6. The inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com