Waxing device for cars

A technology for automobiles and storage tanks, which is applied in the external field of land vehicles, can solve the problems of troublesome manual waxing operation and low waxing efficiency, and achieve the effects of good sealing, simple operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments:

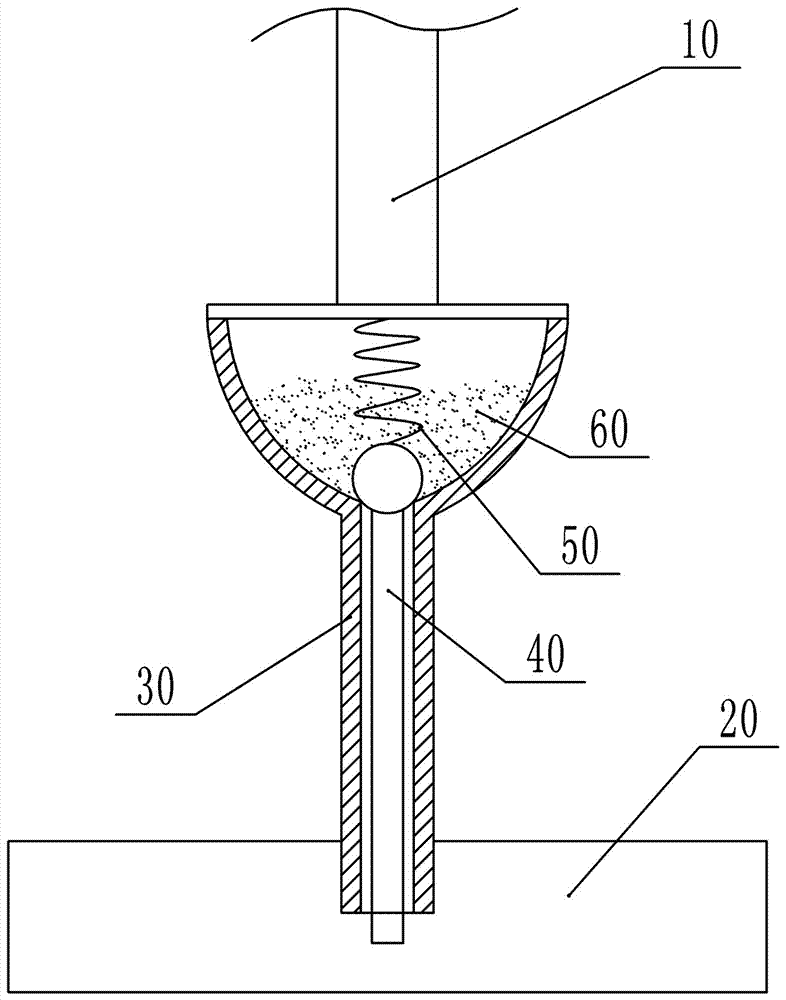

[0013] The reference signs in the accompanying drawings of the description include: the output shaft 10 of the motor, the waxing brush 20 , the material storage cylinder 30 , the ejector rod 40 , the elastic member 50 and the wax material 60 .

[0014] Such as figure 1 As shown, the waxing device for automobiles includes a motor, a waxing brush 20 , a storage tank 30 , a push rod 40 , an elastic member 50 and a storage tank 30 . The lower end of the material storage cylinder 30 communicates with the waxing brush 20, and the upper end is coaxially connected with the output shaft 10 of the motor. The material storage cylinder 30 is funnel-shaped, and the ejector rod 40 is slidably arranged on the lower part of the material storage cylinder 30 . The top of the push rod 40 is welded with a sphere, which is tangent to the inner wall of the funnel-shaped mouth, and the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com