Continuous chemical reaction method and detonation reactor using continuous chemical reaction method

A chemical reaction and reactor technology, applied in the field of detonation reactors, to achieve the effect of simple design and operation, controllable design and operation, and shortened length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

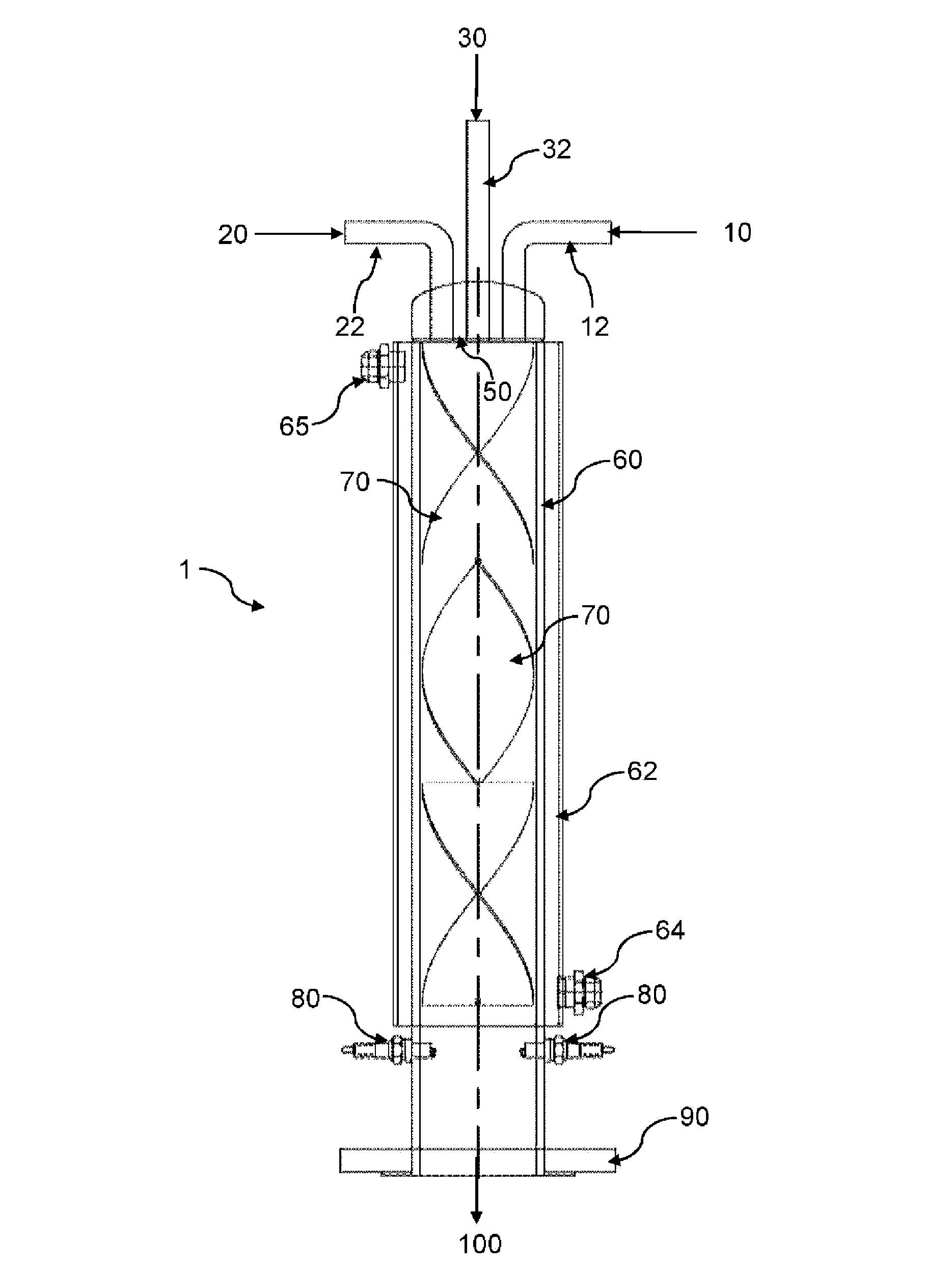

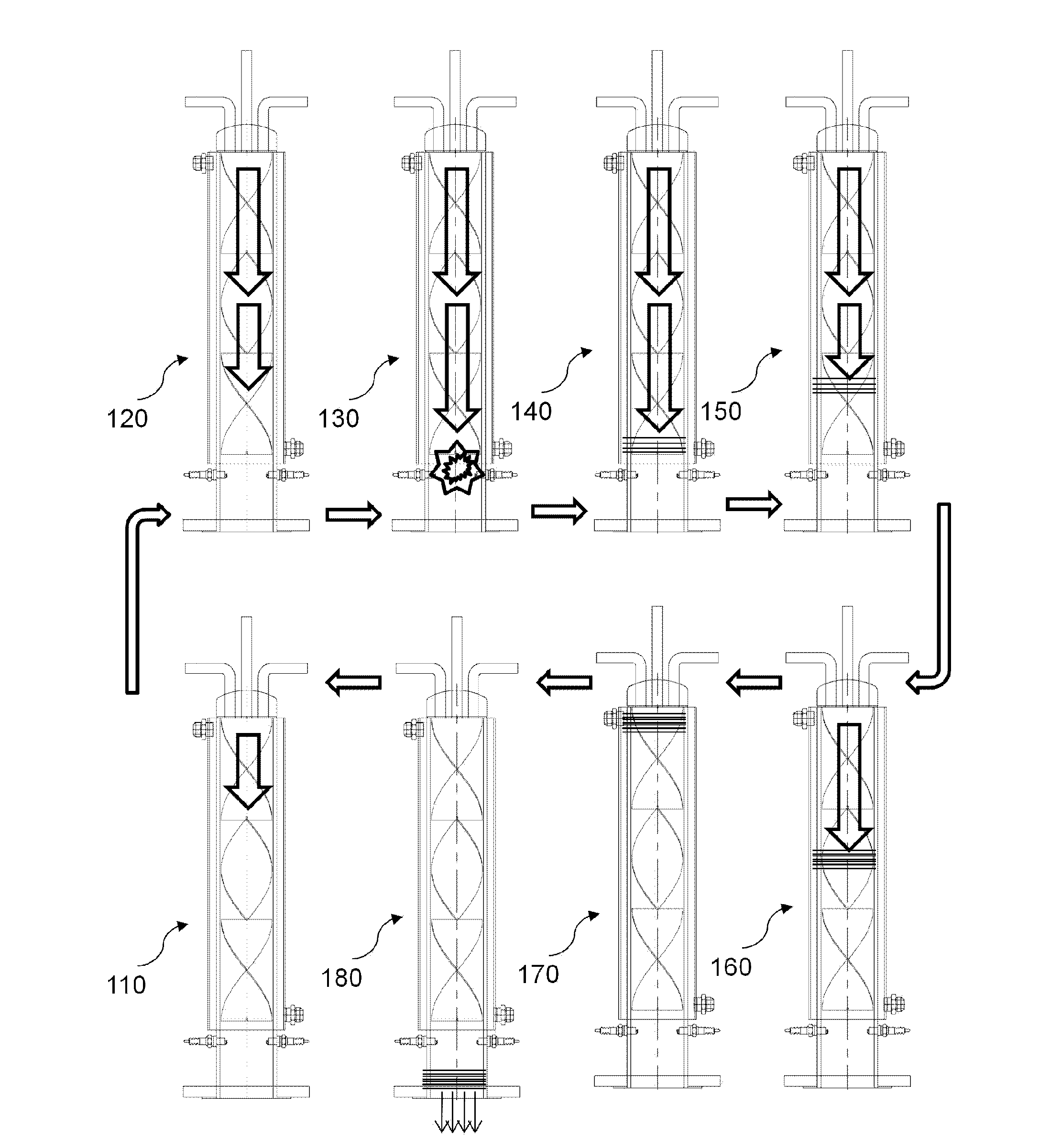

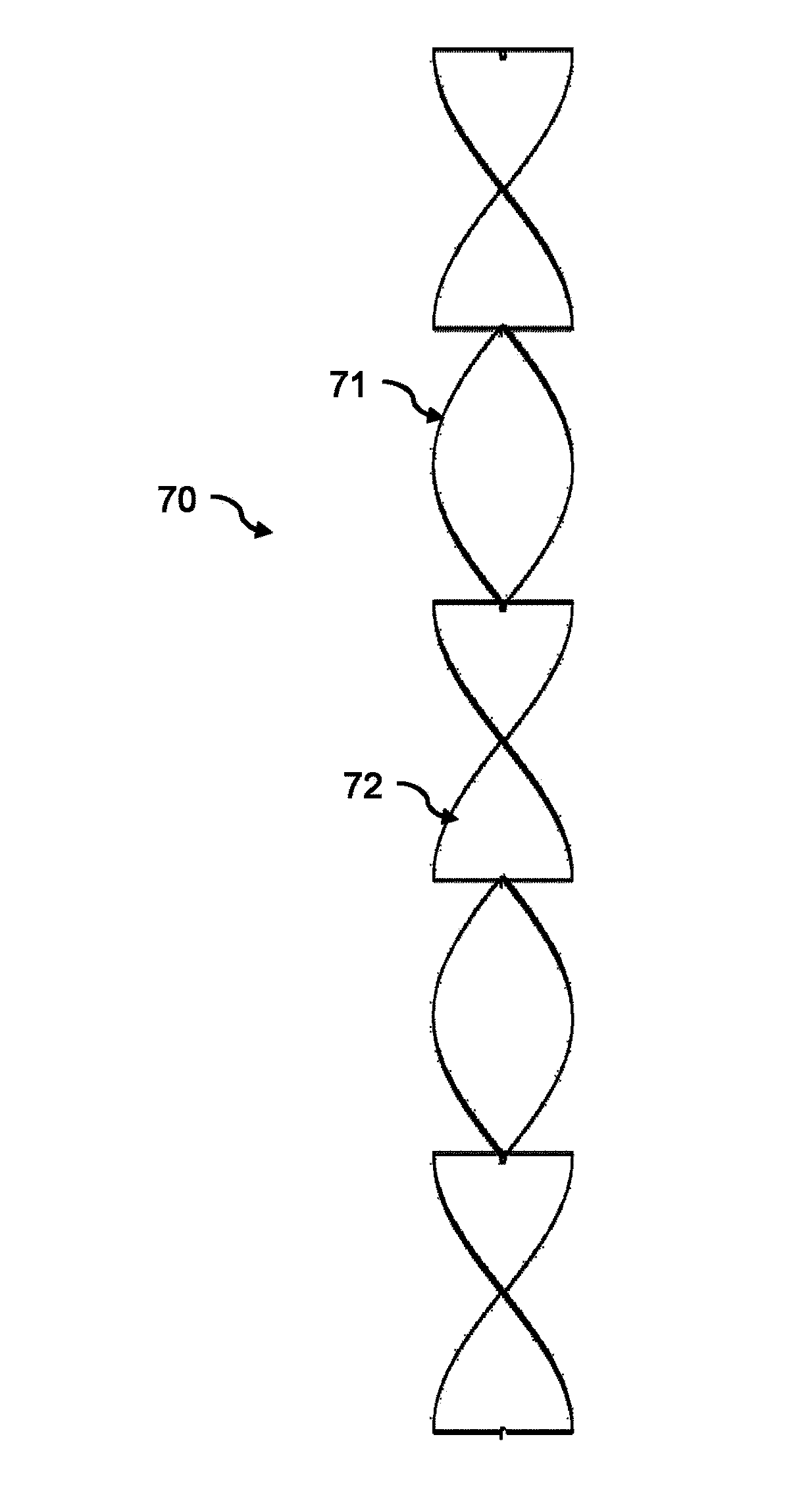

[0085] Main purpose of the present invention is to provide a kind of continuous chemical reaction method using gas countercurrent detonation shock wave and the detonation reactor applying the method, such as figure 1 Shown; Use method of the present invention and mode of operation thereof, detailed as figure 2 shown. The accompanying drawing is a preferred embodiment using the method of the present invention, and its principle and operation mode will be described below.

[0086] First, the flammable gas reactant 10 is continuously sent into the detonation reactor body 60 through the flammable gas reactant feed pipe 12, and the chemical reactant 20 that needs to be reacted or destroyed at high temperature is continuously injected through the chemical reactant feed pipe 22 Into the detonation reactor body 60, at the same time, the air / oxidizer / auxiliary 30 required for the chemical reaction is continuously injected into the detonation reactor body 60 through the air / oxidant / au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com