Waxing device for two-for-one twister

A double twister and wax storage technology, applied in textiles and papermaking, etc., can solve the problems of low utilization rate of wax blocks, poor waxing effect, uneven waxing, etc. High wax efficiency and uniform waxing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

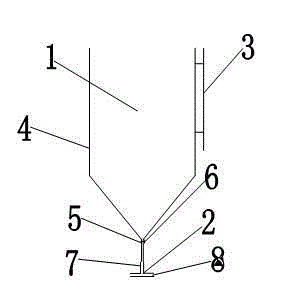

[0017] Such as figure 1 As shown, a kind of waxing device for two-for-one twisters described in this embodiment comprises that it includes dripping wax equipment 1 and waxing equipment 2, and described dripping wax equipment includes wax storage tank 4 and dripping hole 5 , and there is a liquid level balancer 3 on the wax storage tank 4, which can ensure that the liquid wax liquid level remains consistent, thereby stabilizing the speed of dropping wax. The waxing equipment is a T-shaped three-way pipe, and the waxing pipe 7 is opposite to the dripping hole 5, so that the wax can be dripped into the waxing equipment 2 from the dripping hole 5, and the yarn is contacted with the liquid wax through the waxing pipe 8 to reach The purpose of waxing the yarn.

[0018] When in use, open the liquid level balancer 3 so that the liquid level of the wax remains constant, open the valve 6, and at the same time pass the yarn horizontally through the waxing pipe 8 and move quickly, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com