Patents

Literature

75results about How to "Evenly waxed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cleaning-waxing-integrated washing agent for automobile and preparation method thereof

ActiveCN103361195ASimple production processReduce manufacturing costSurface-active detergent compositionsDetergent compounding agentsSolventWax

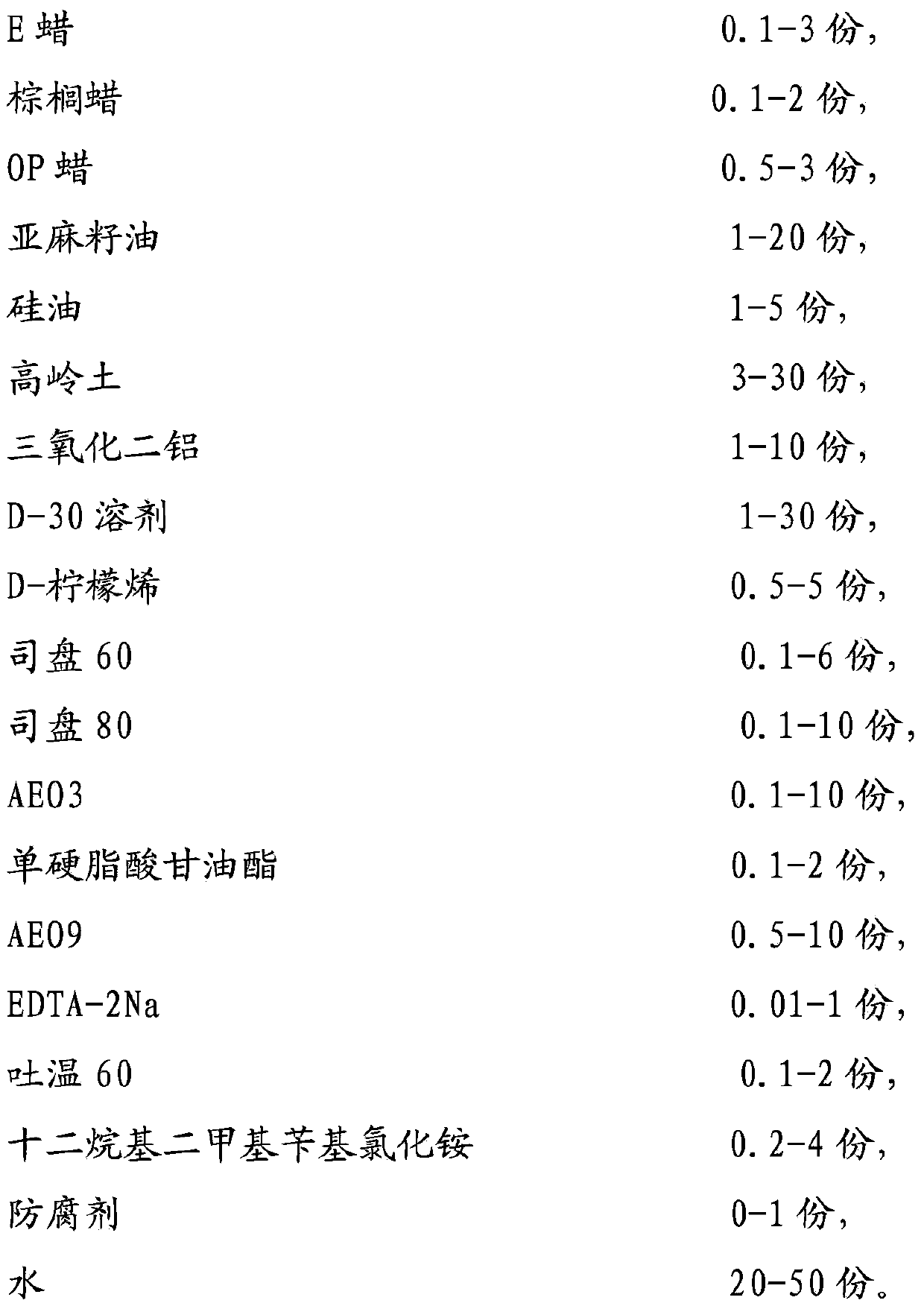

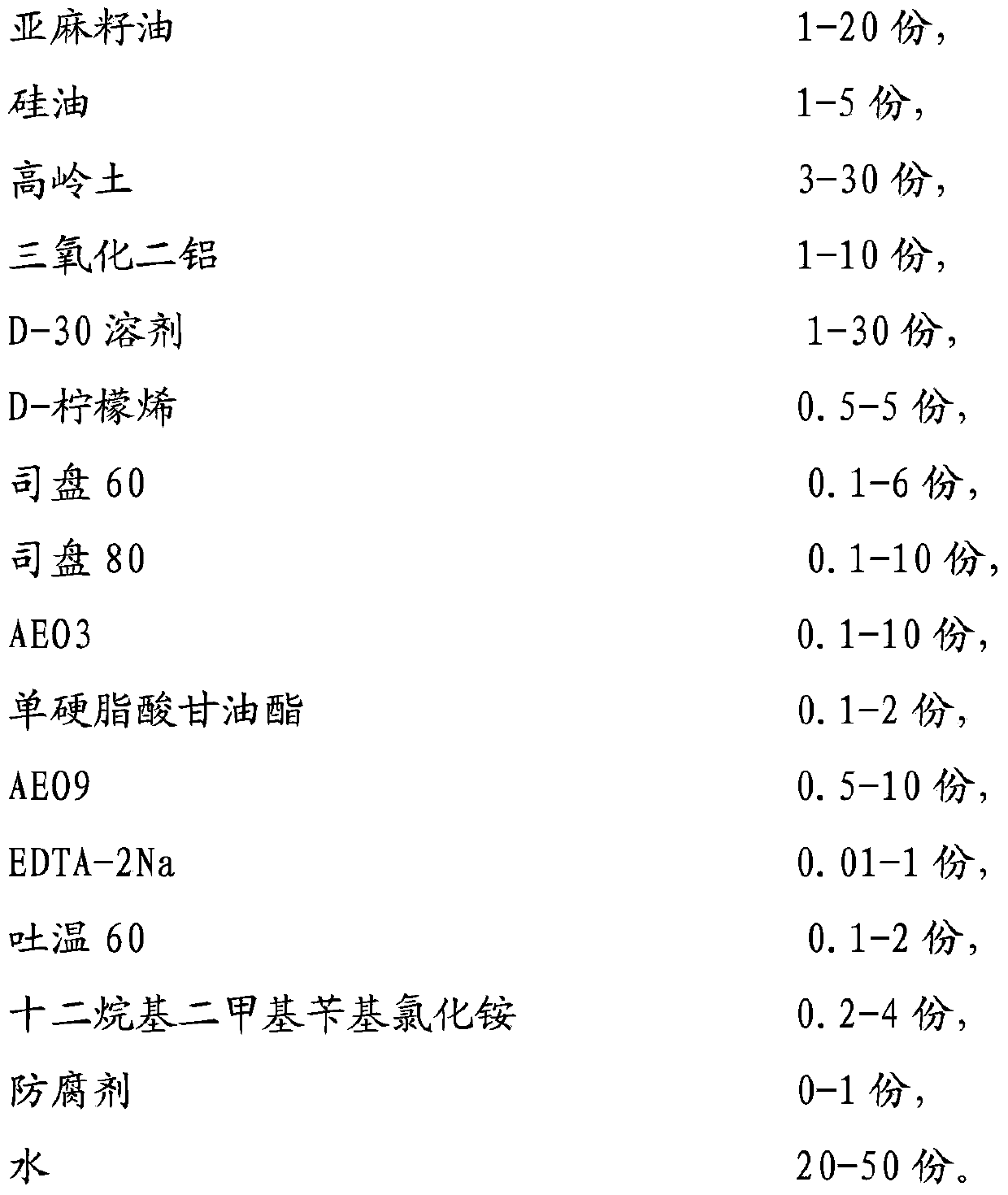

The invention discloses a cleaning-waxing-integrated washing agent for an automobile and a preparation method thereof. The cleaning-waxing-integrated washing agent is prepared by mixing 0.1 to 3 parts of E wax, 0.1 to 2 parts of palm wax, 0.5 to 3 parts of OP wax, 1 to 20 parts of flaxseed oil, 1 to 5 parts of silicone oil, 3 to 30 parts of kaolin, 1 to 10 parts of alumina, 1 to 30 parts of a D-30 solvent, 0.5 to 5 parts of D-limonene, 0.1 to 6 pars of Span 60, 0.1 to 10 parts of Span 80, 0.1 to 10 parts of AEO 3, 0.1 to 2 parts of glycerin monostearate, 0.5 to 10 parts of AEO 9, 0.01 to 1 part of EDTA-2Na, 0.1 to 2 parts of Tween 60, 0.2 to 4 parts of dodecyl dimethyl benzyl ammonium chloride, 0 to 1 part of an antiseptic and 20 to 50 parts of water. The preparation method is simple and needs low cost; the product, i.e., the washing agent, is convenient to use, and an automobile has high brightness after usage of the product.

Owner:潍坊光华精细化工有限公司

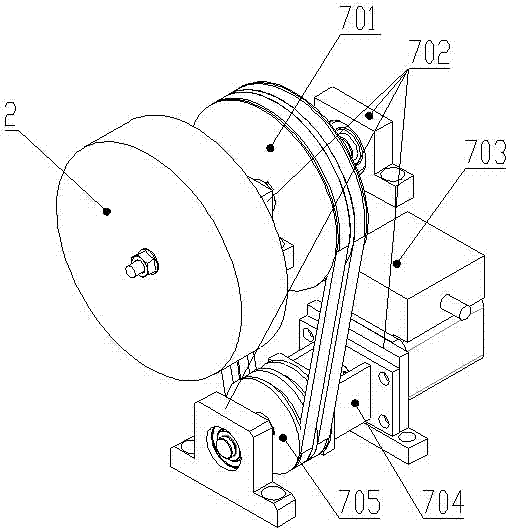

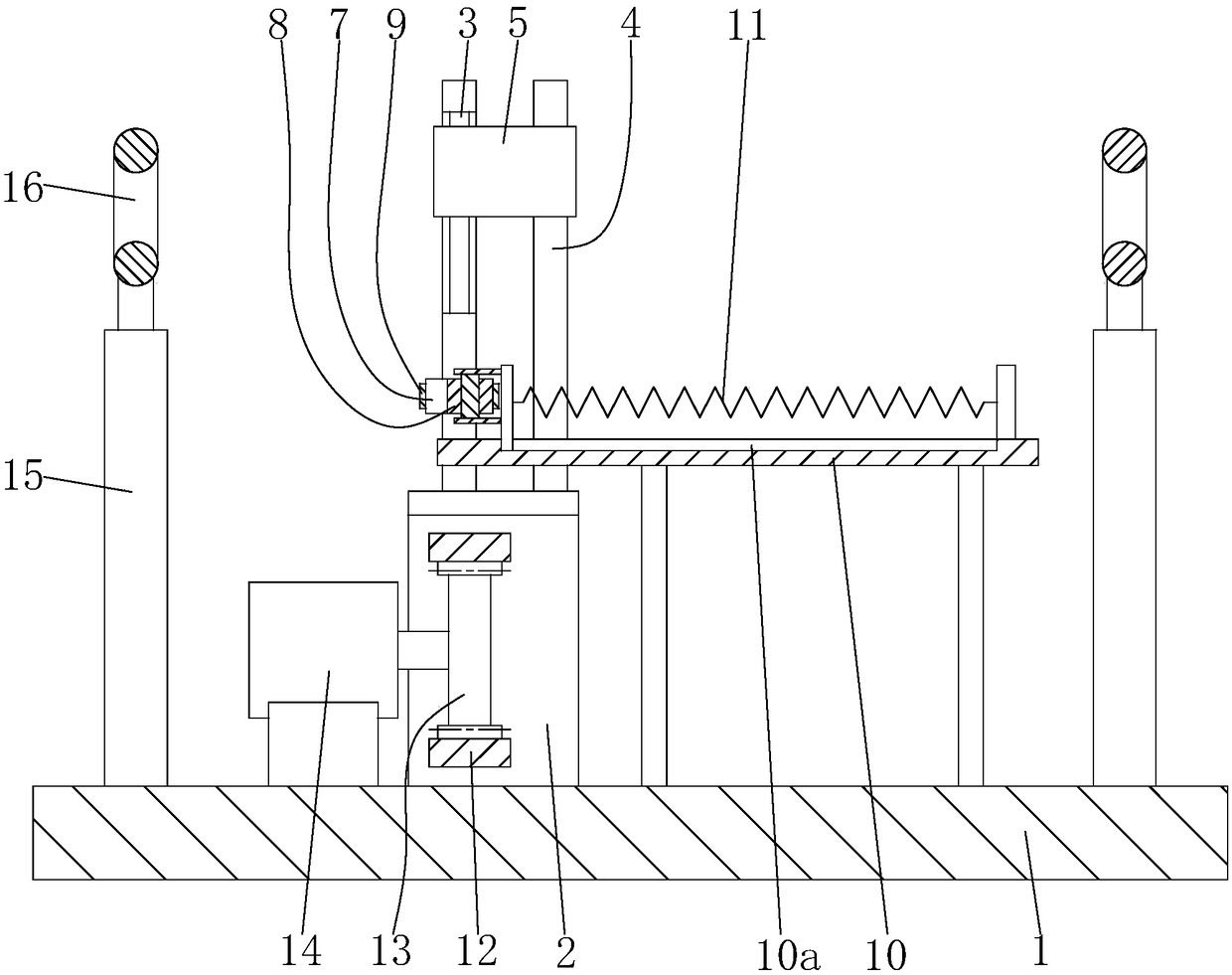

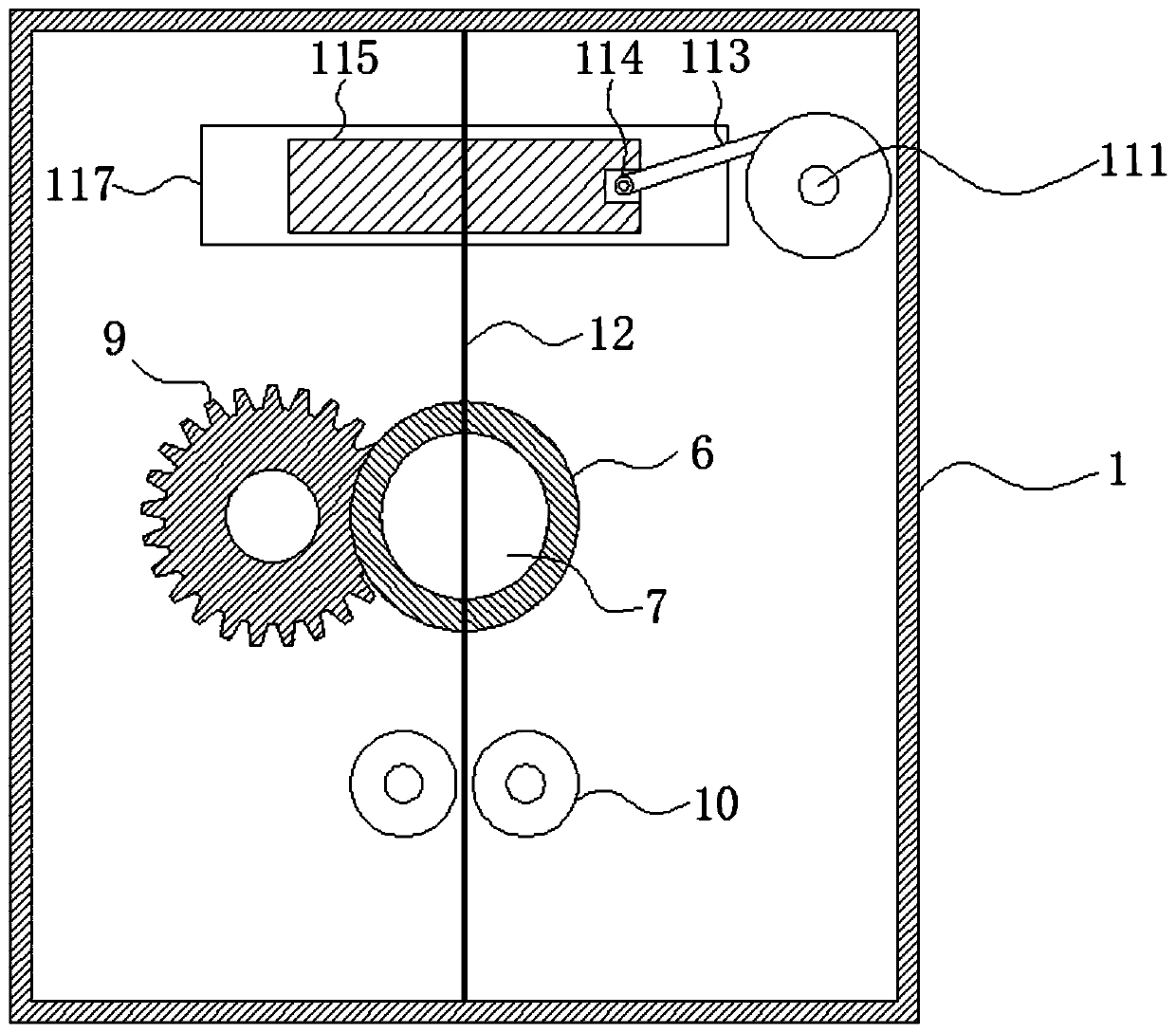

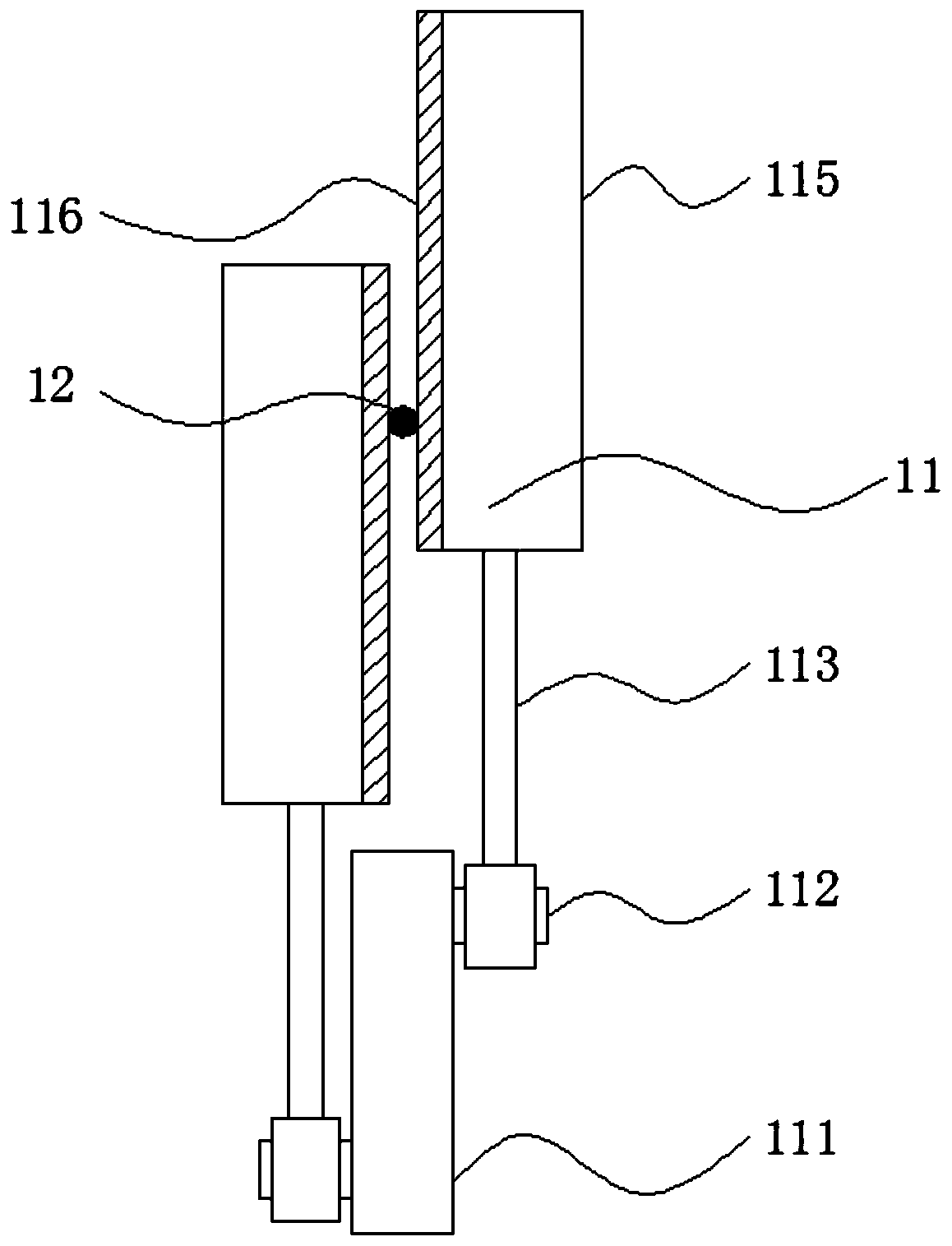

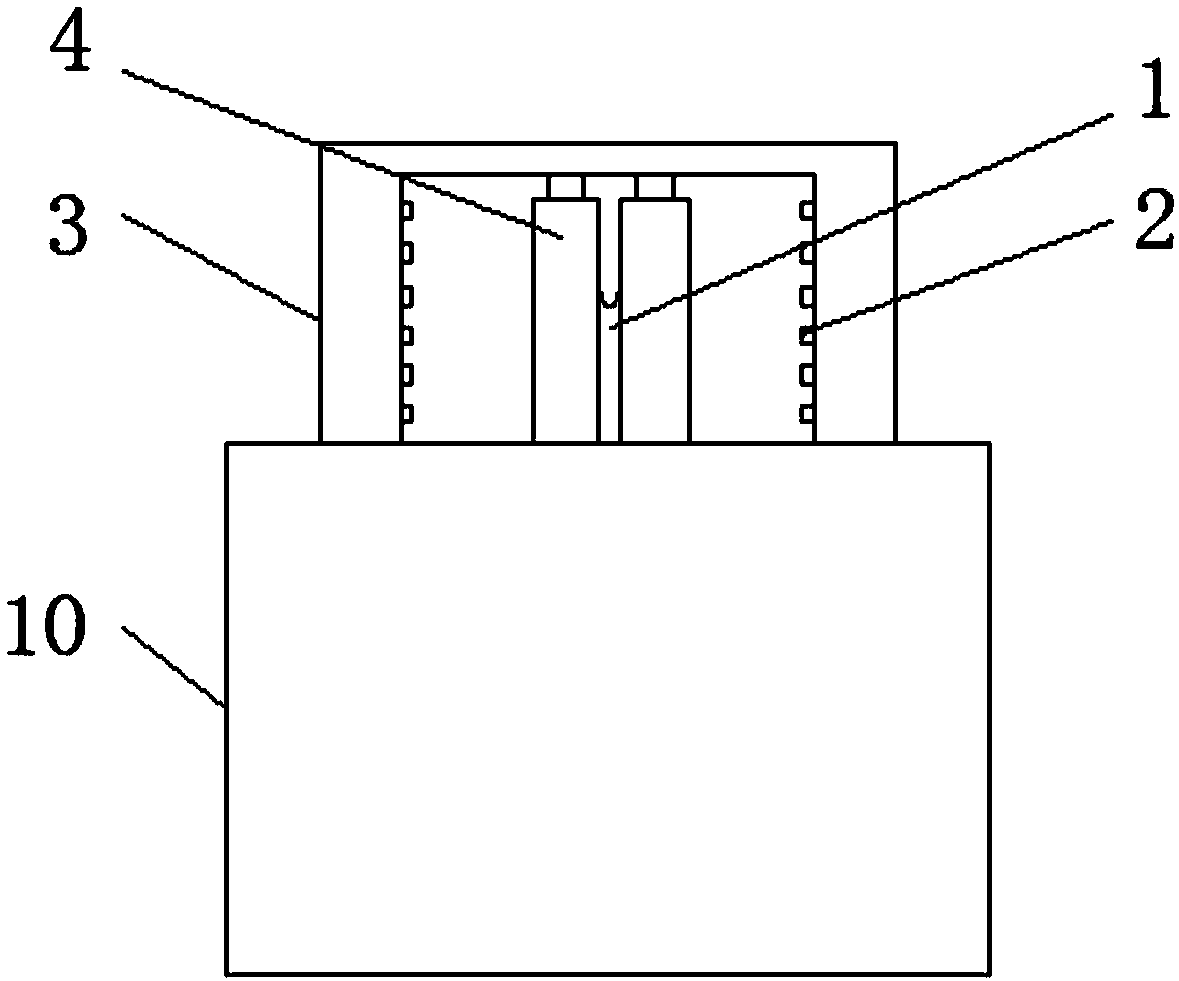

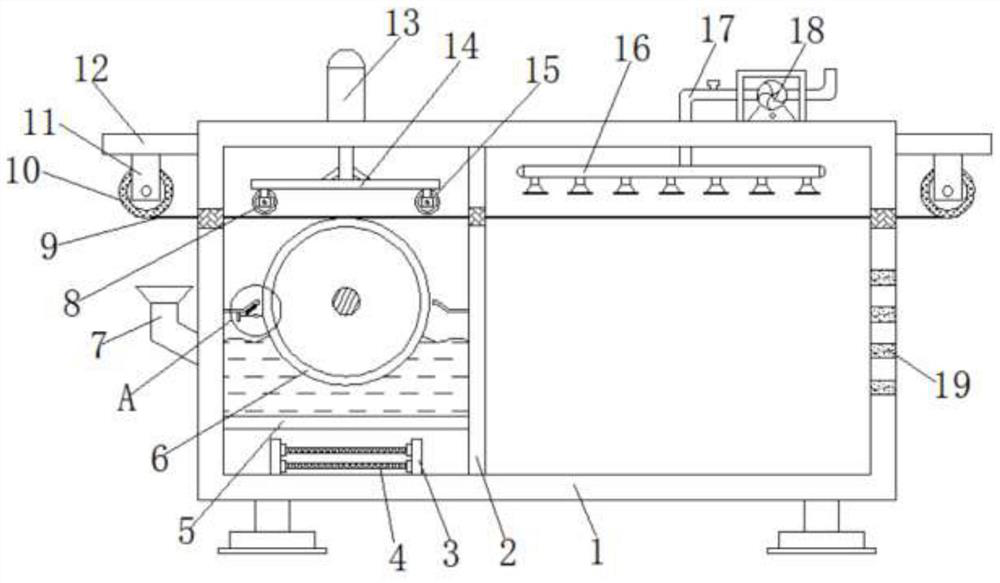

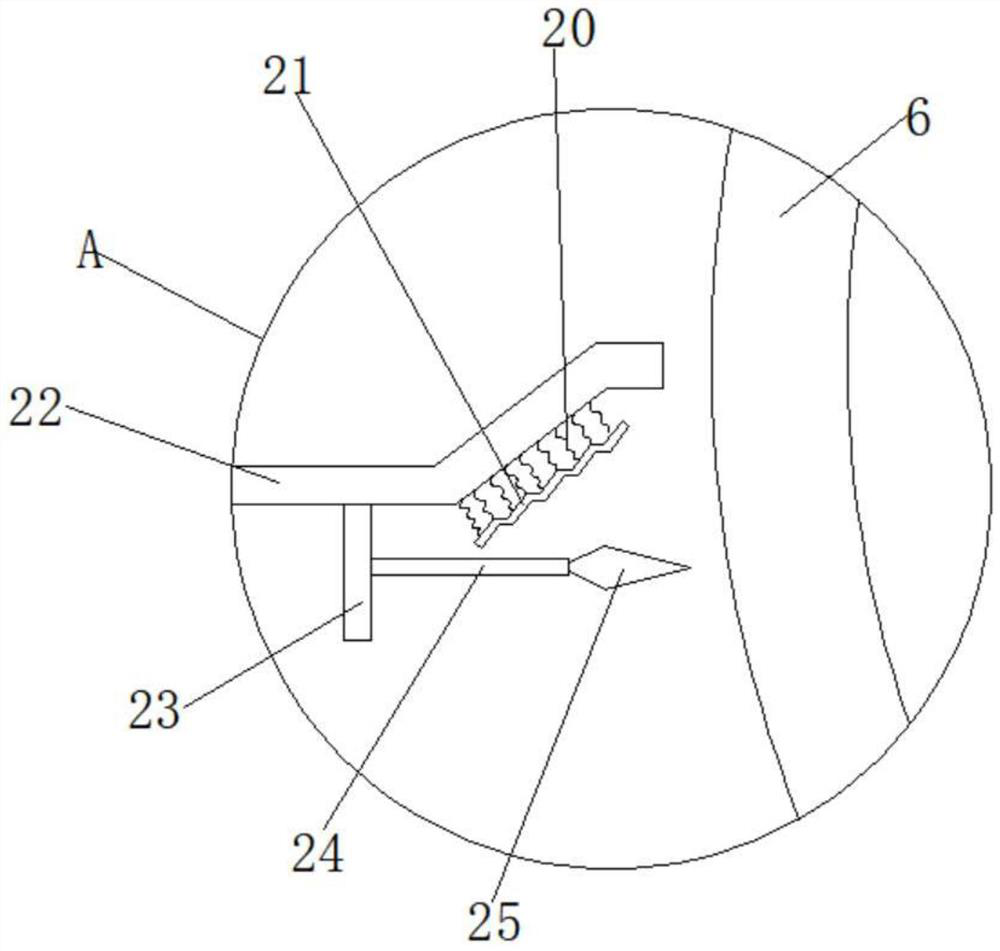

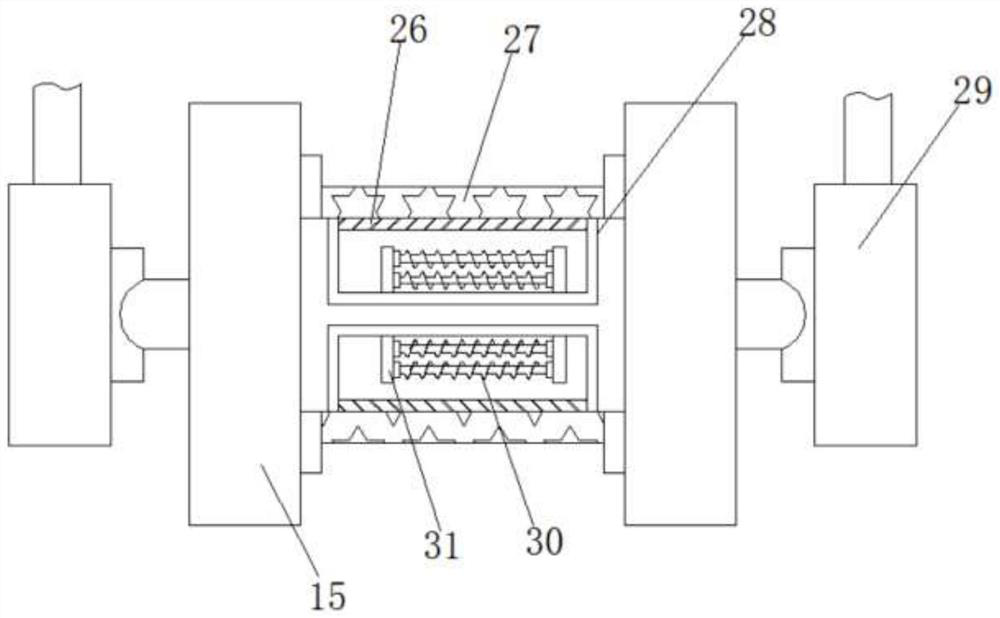

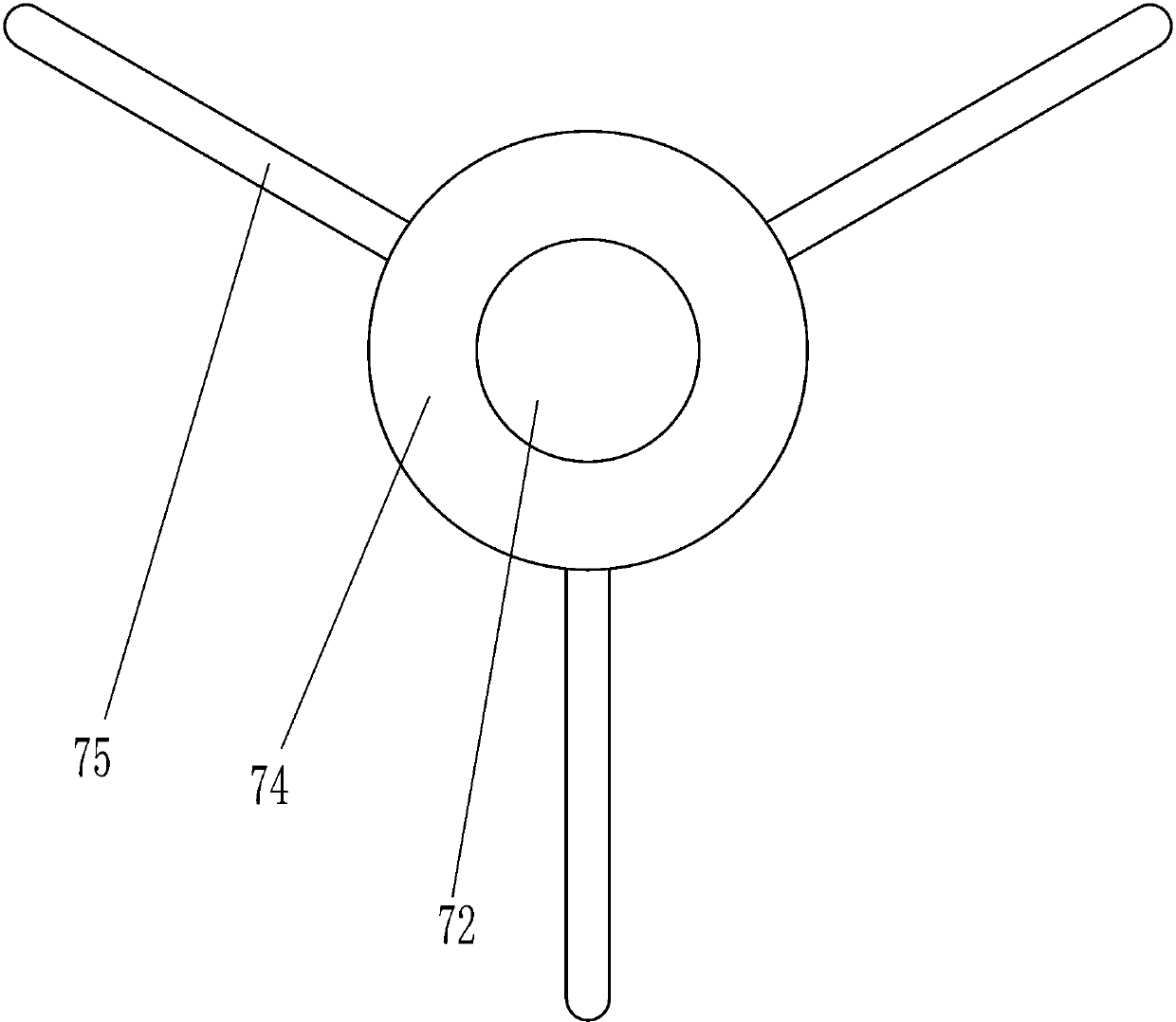

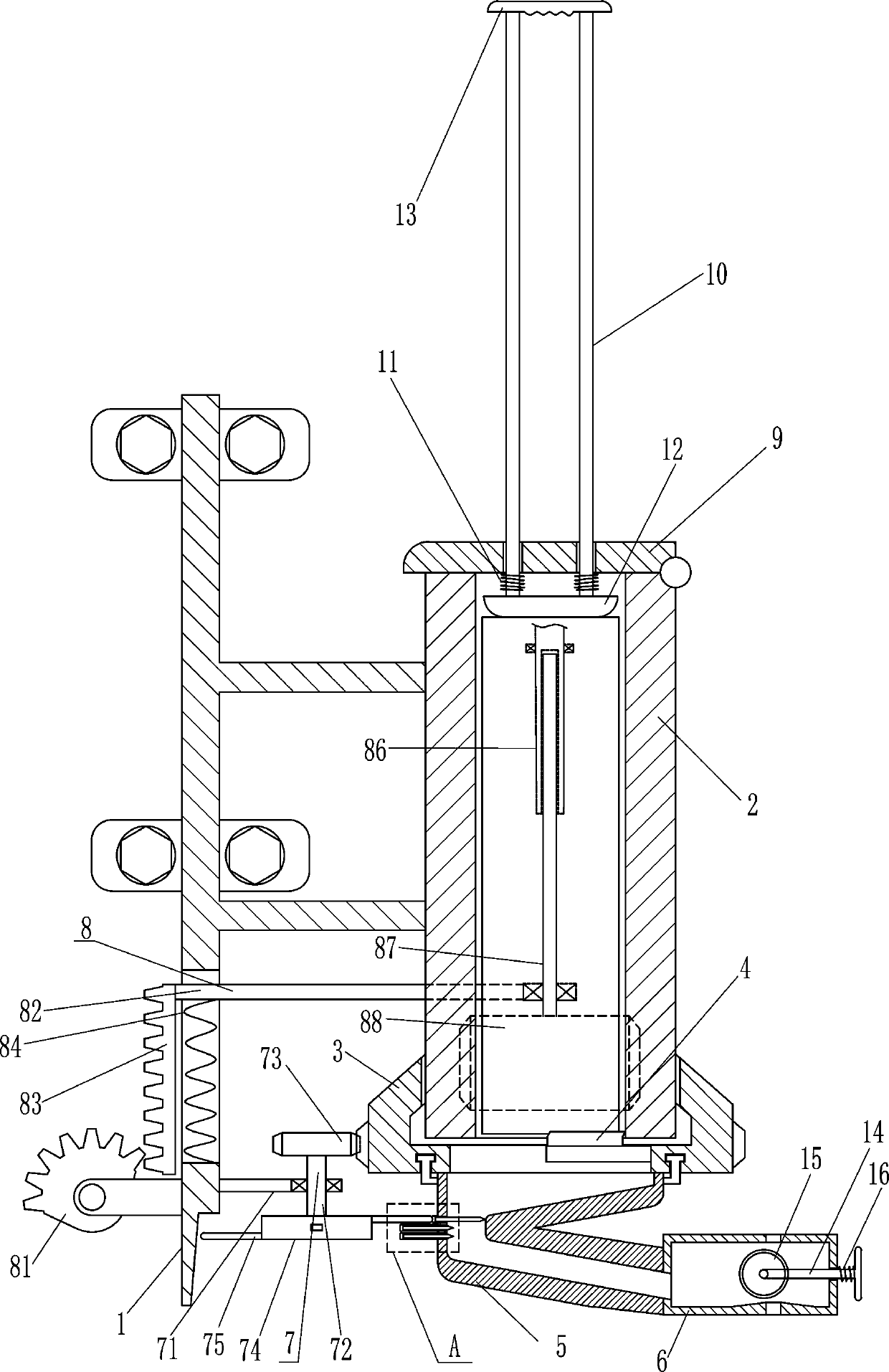

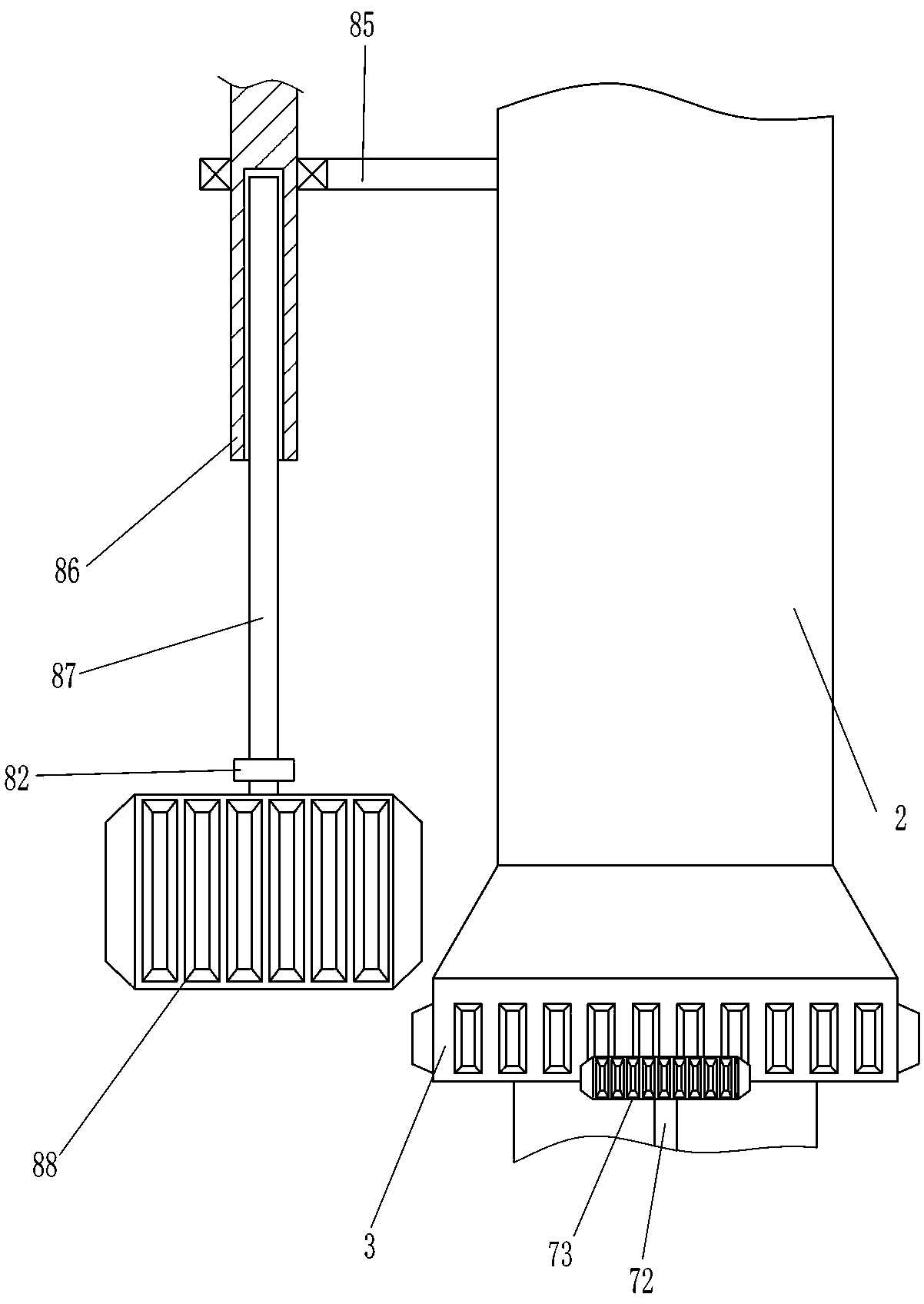

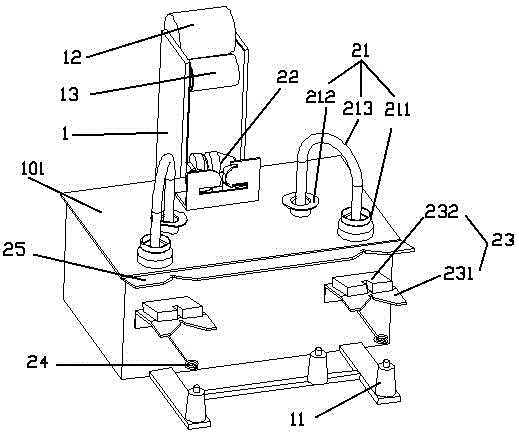

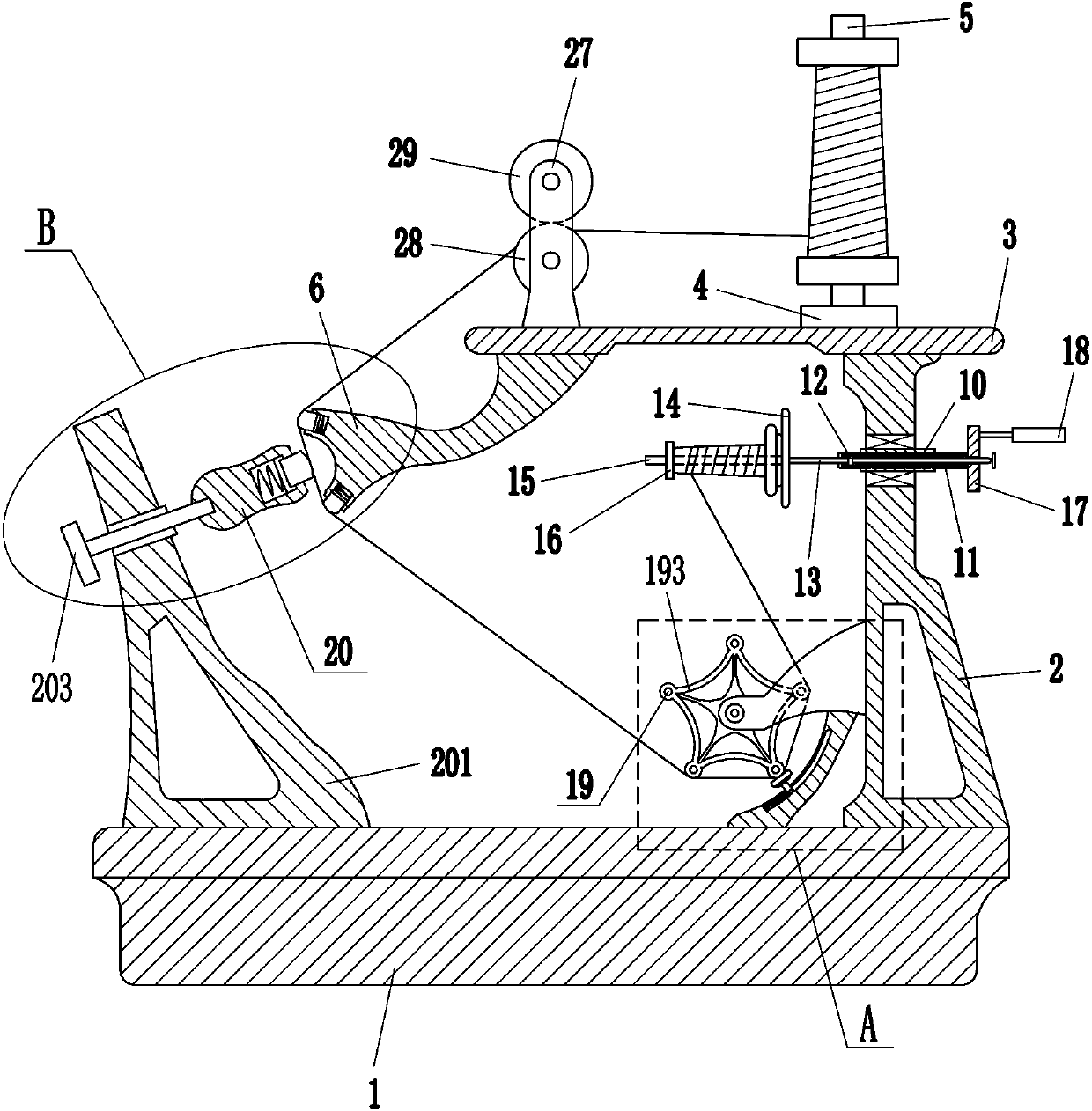

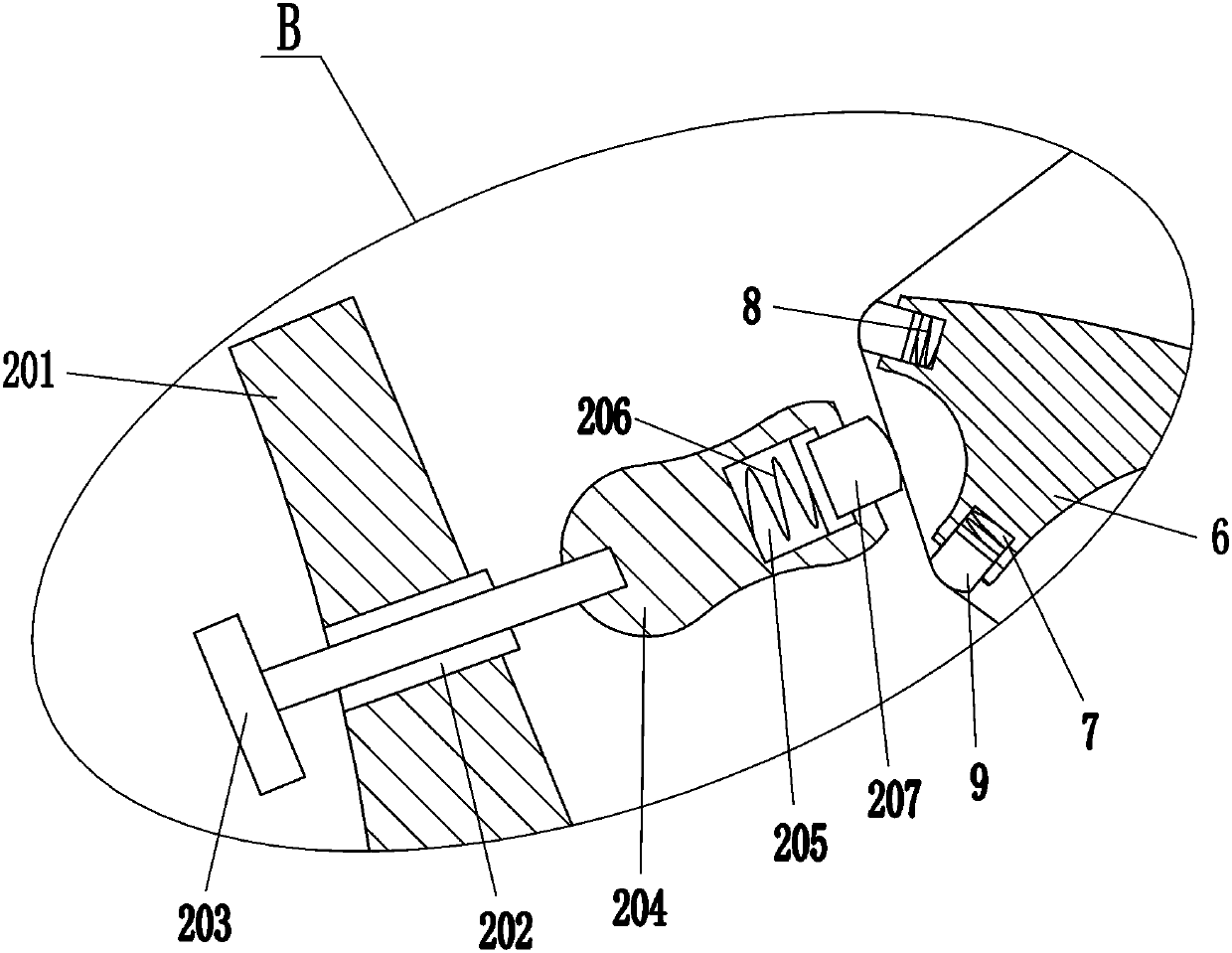

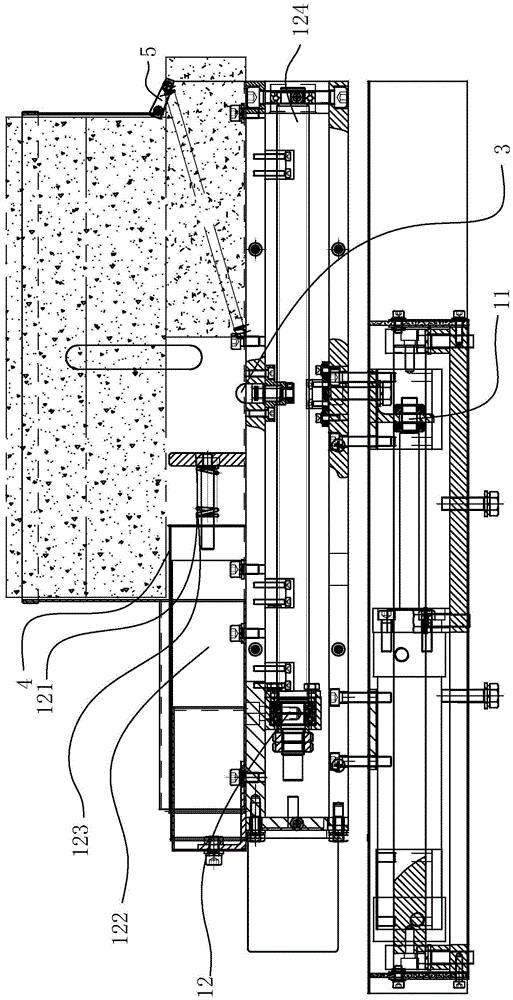

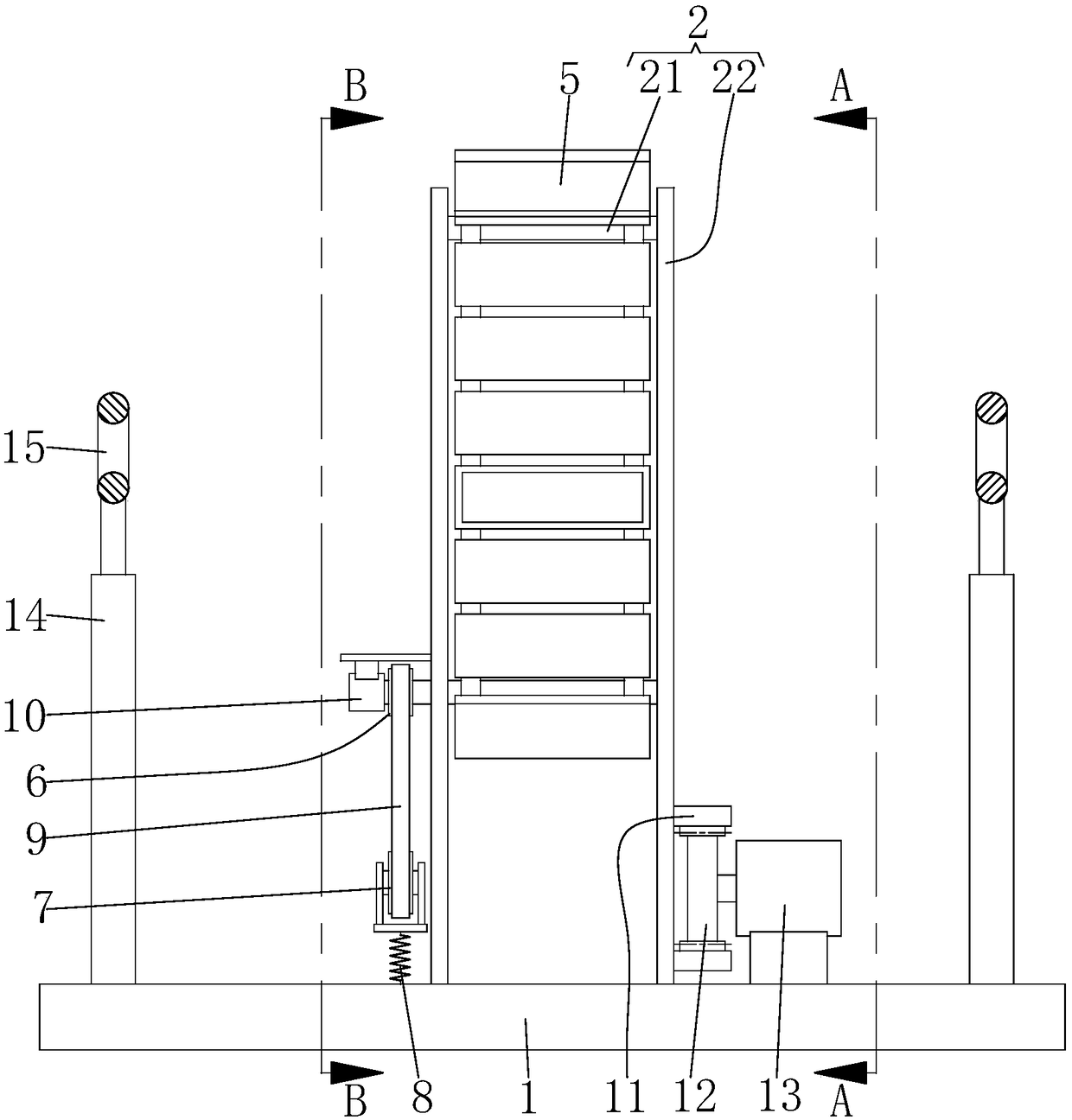

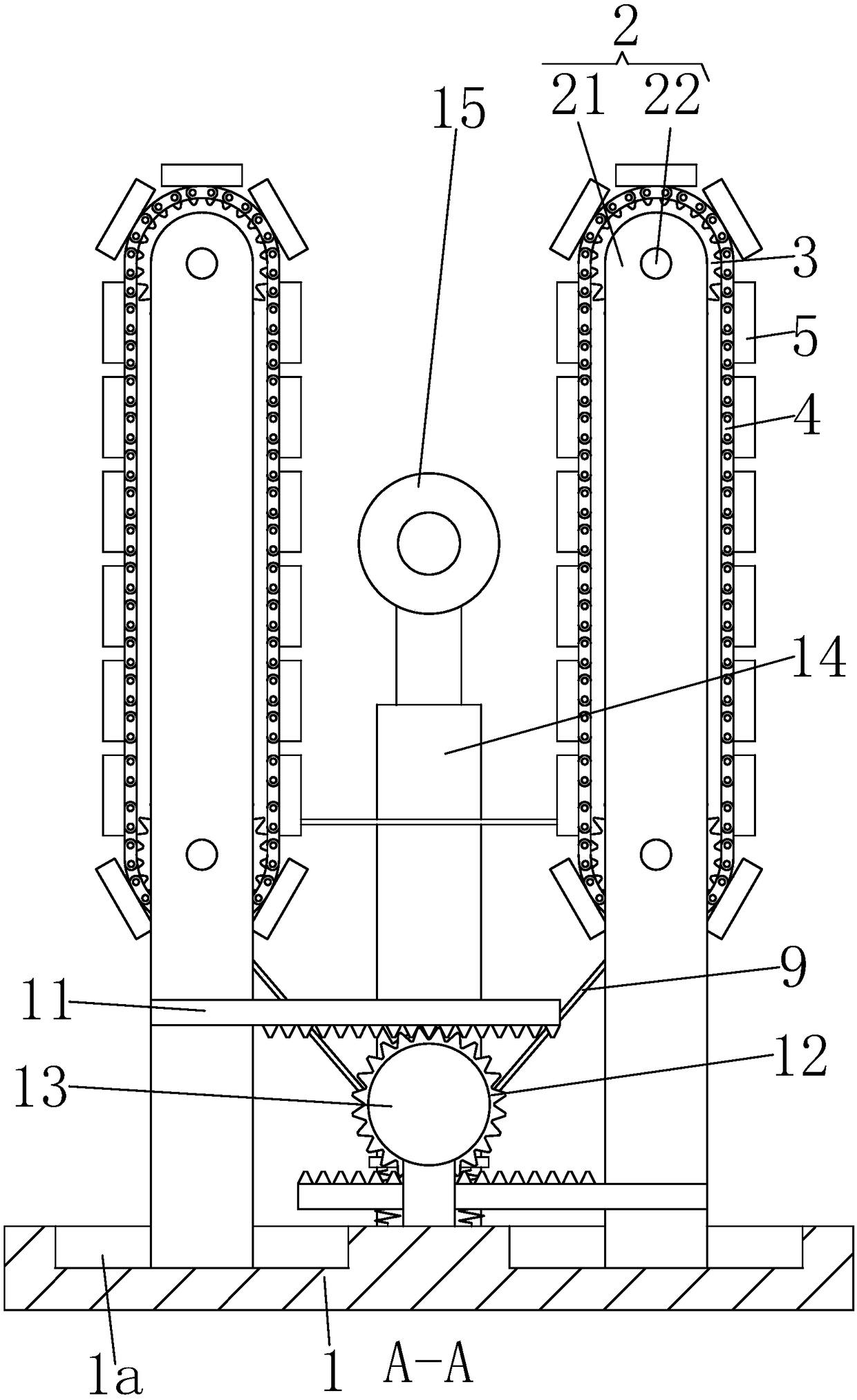

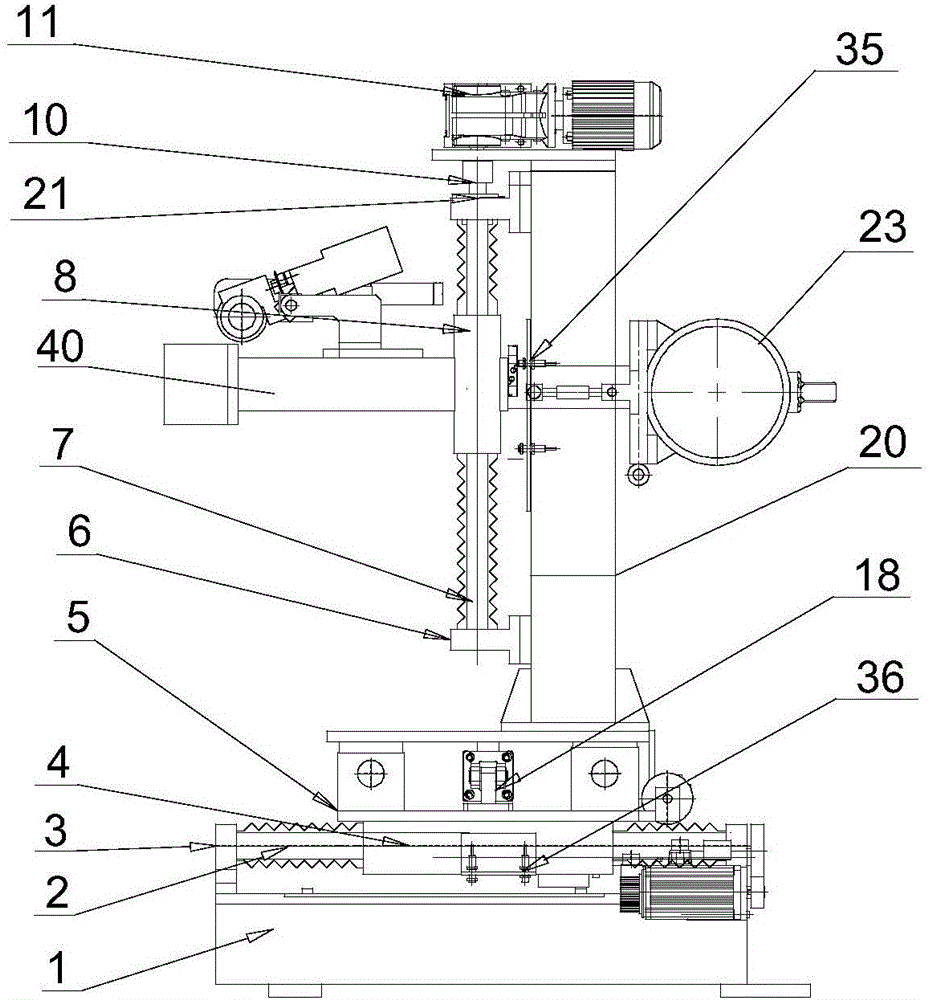

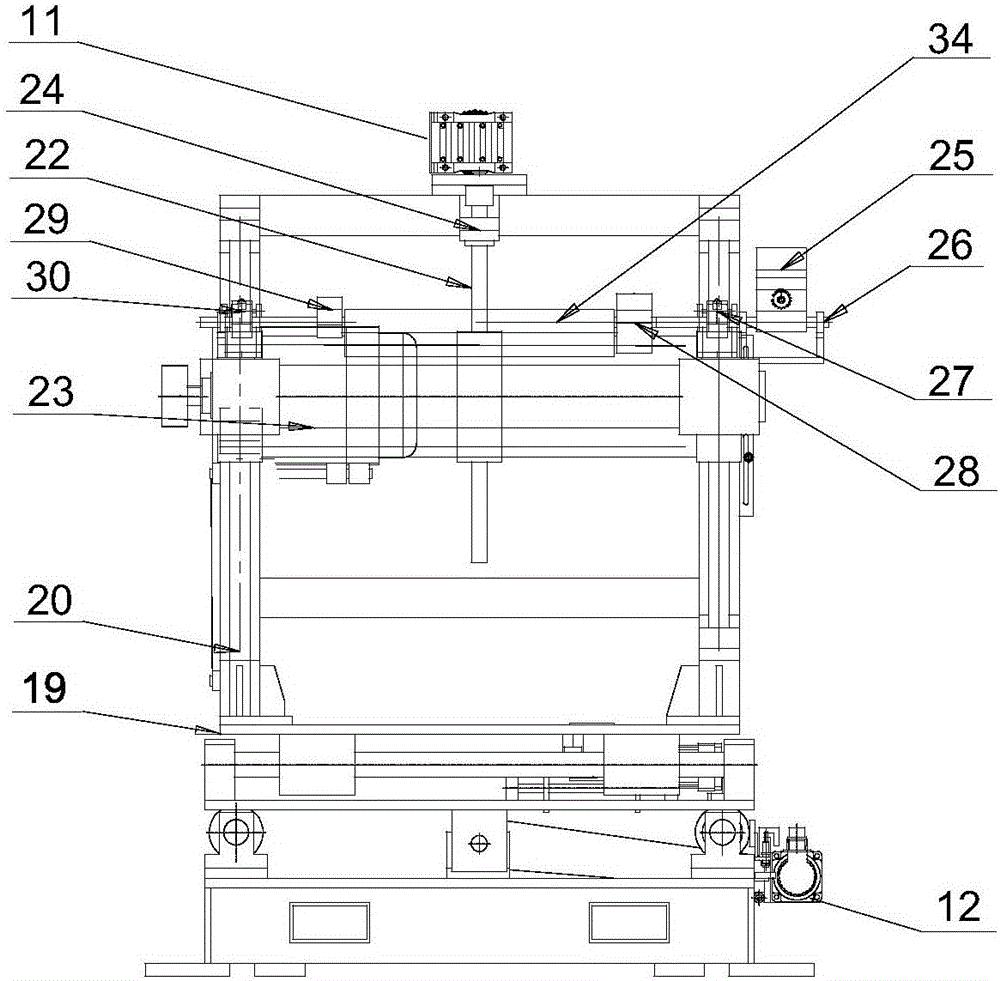

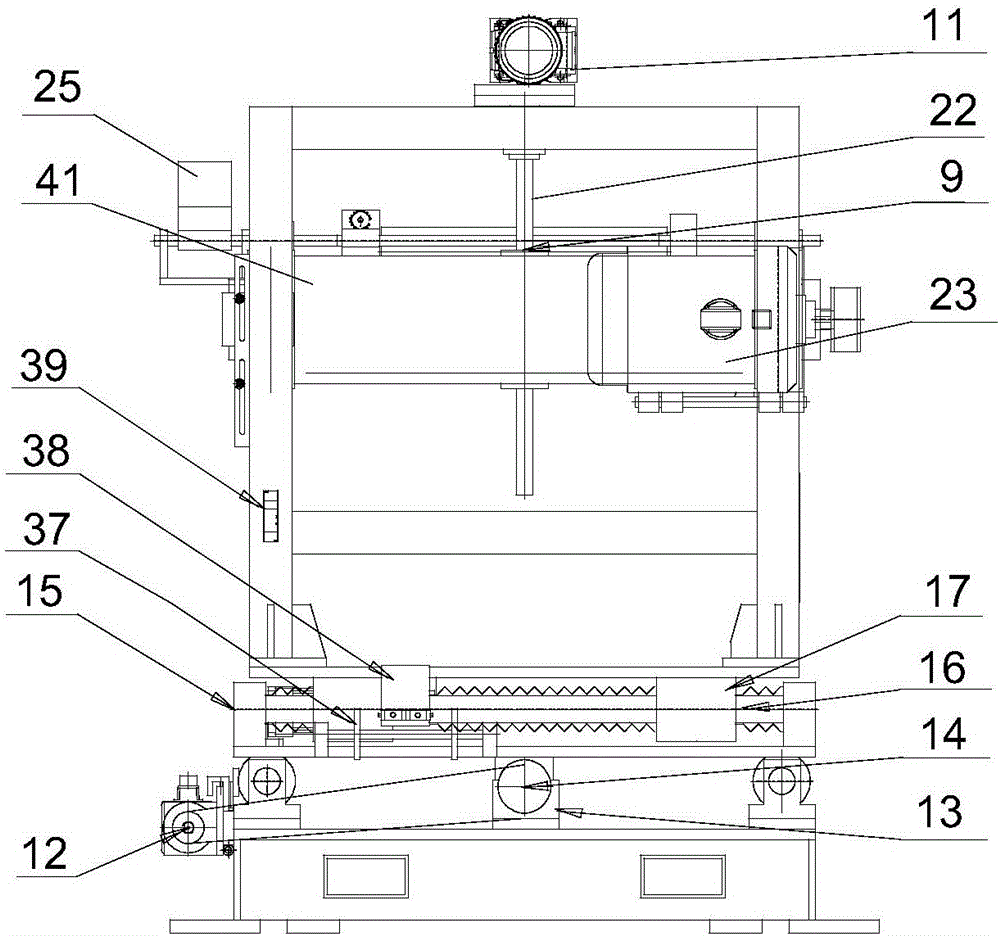

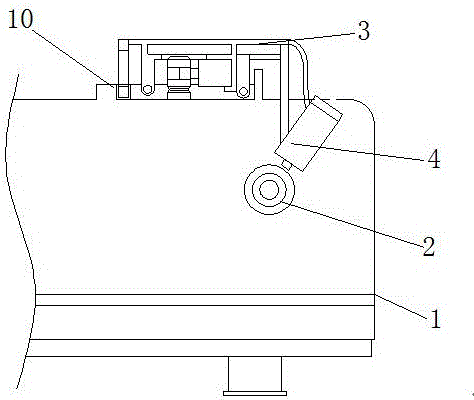

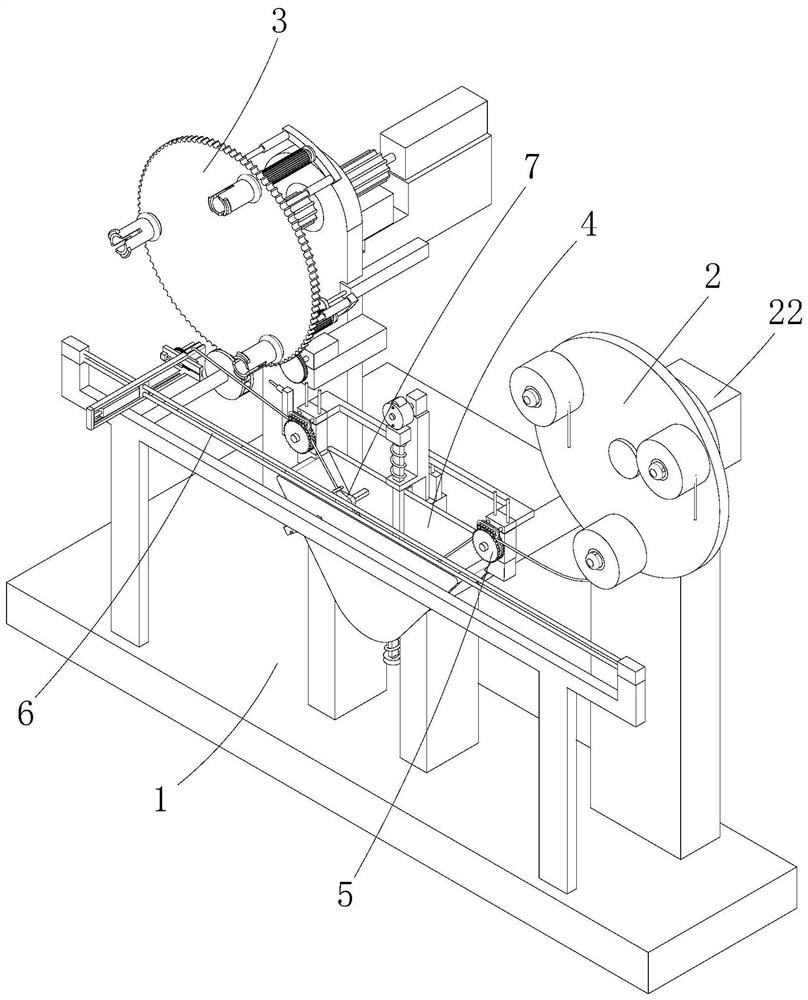

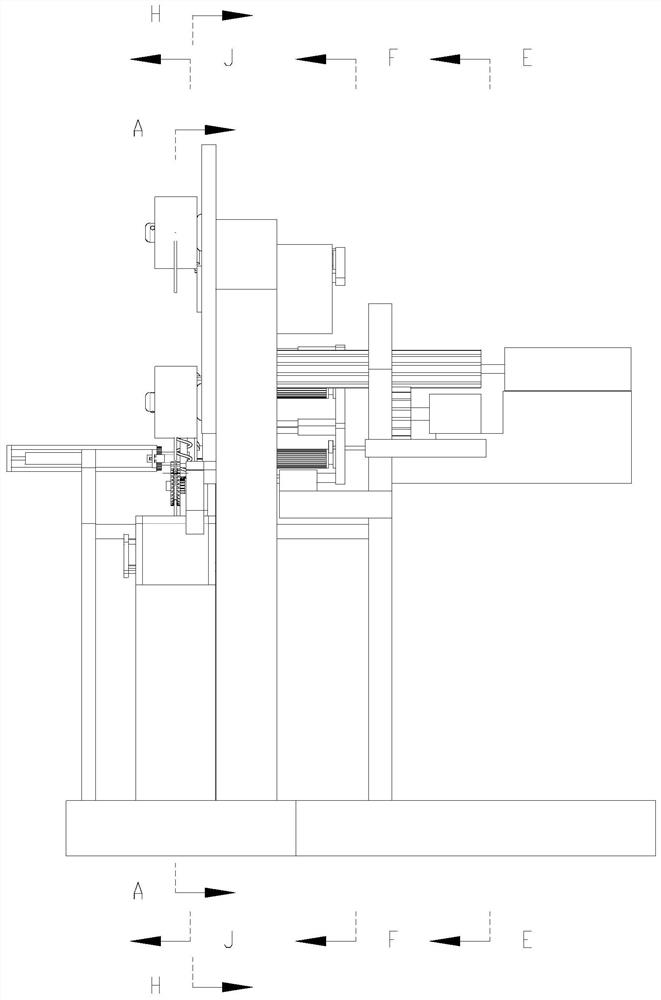

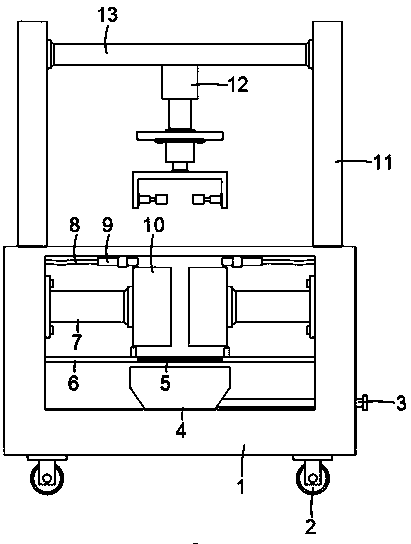

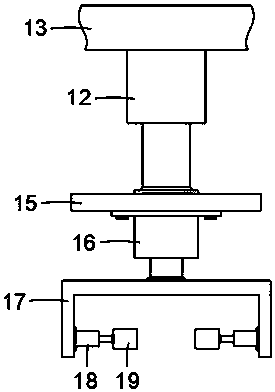

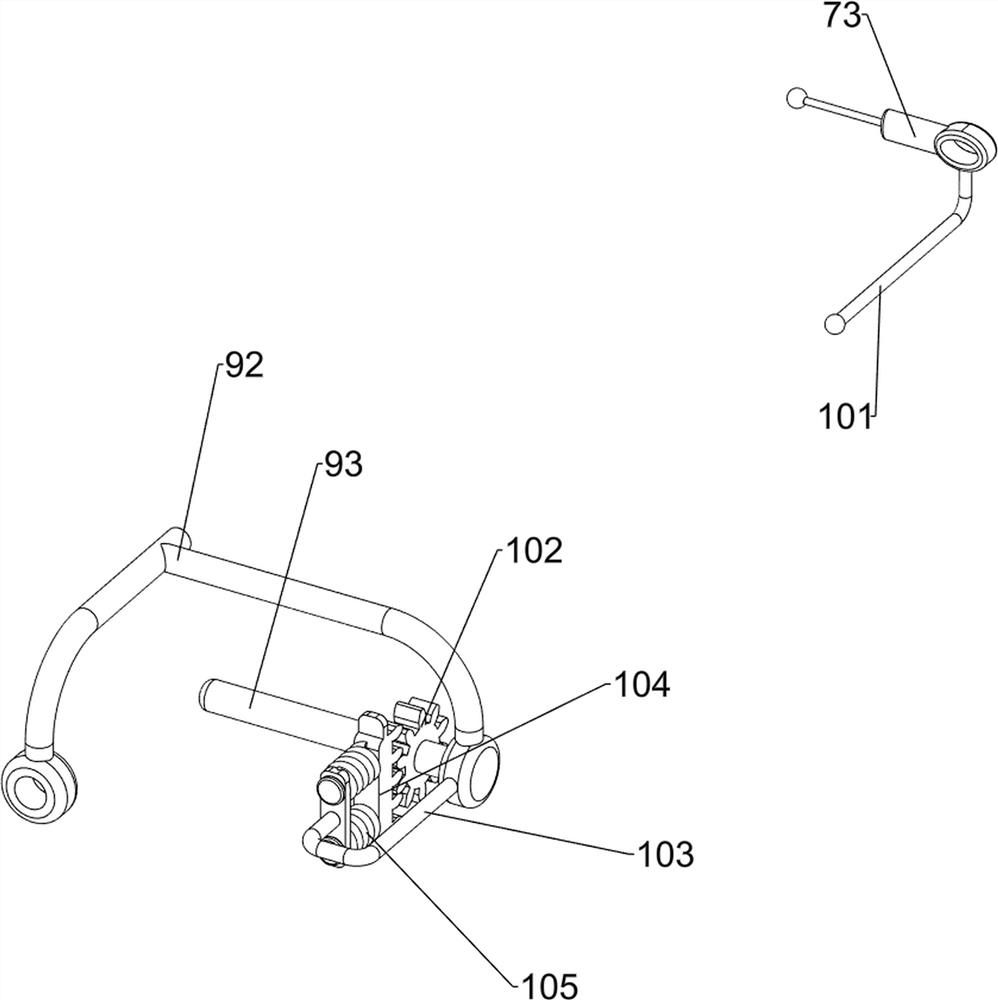

Novel constant force polishing and waxing device

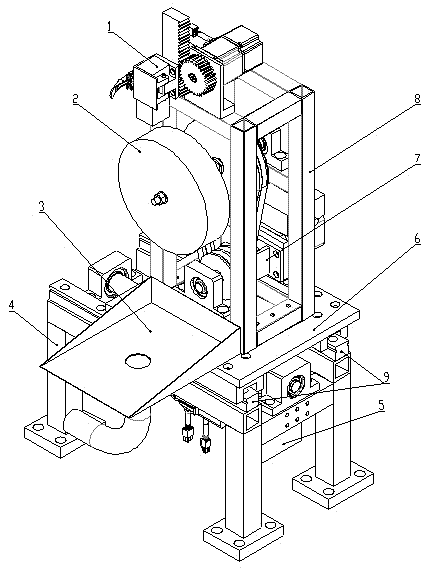

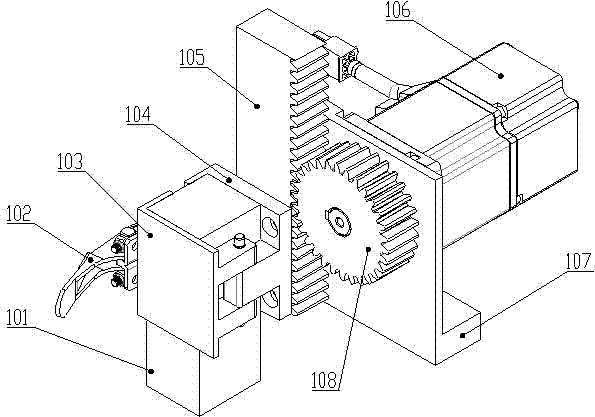

The invention relates to a novel constant force polishing and waxing device which comprises a first frame. A support plate capable of moving back and forth along a guide rail is arranged at the top end of the first frame, and a second support is arranged on the upper surface of the support plate. The device further comprises a waxing mechanism arranged at the upper end of the second support, a moving module arranged on the first frame, a polishing module arranged on the support plate and located under the waving mechanism, a cloth polishing wheel connected with the polishing module in a driving mode and a dust collection module arranged on the support plate and the second support and located under the cloth polishing wheel. The polishing and waxing device adopts a gear rack gradual wax rod feeding device, and enables the cloth polishing wheel to be even in waxing. For liquid wax which becomes common gradually at present, a four-rod wax spraying device is adopted to enable the cloth polishing wheel to be even in waxing. A quick clamp device is adopted to achieve quick replacement of wax rods and improve working efficiency. By means of a dust collection device, working environment is improved. A servo motor adopts a built-in structure, so that the polishing and waxing device is compact in structure and saves space.

Owner:SOUTH CHINA UNIV OF TECH

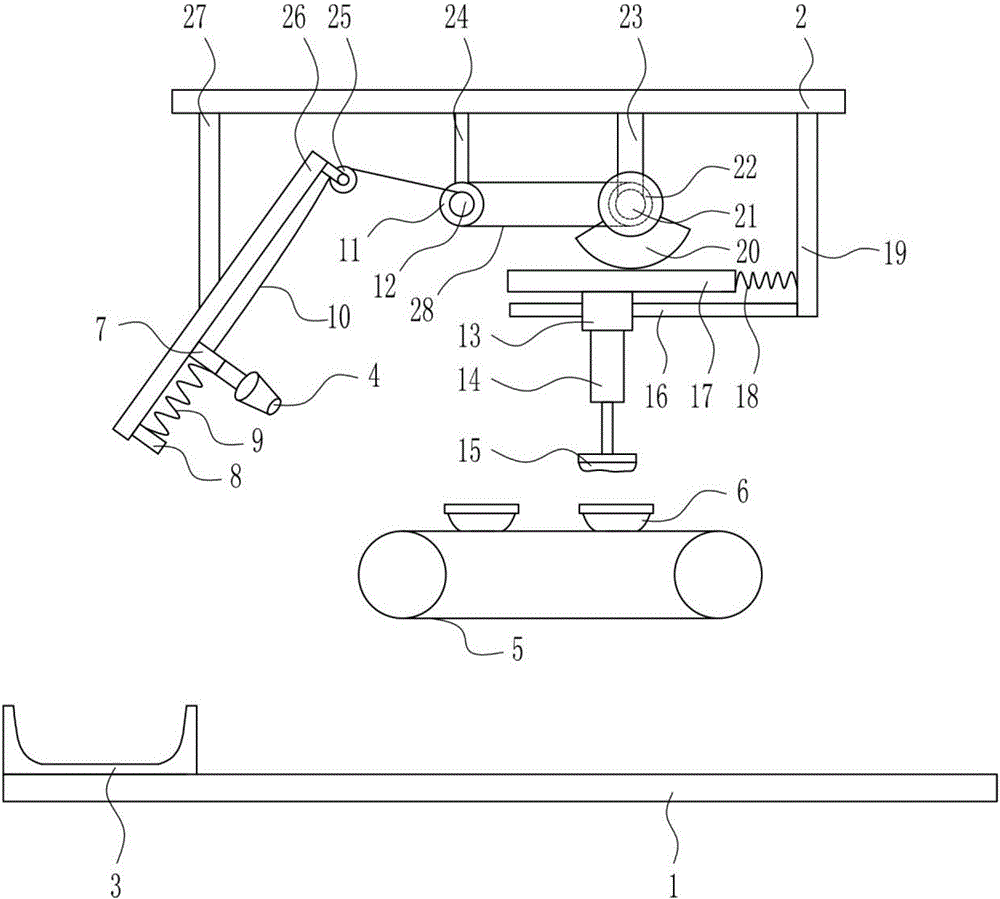

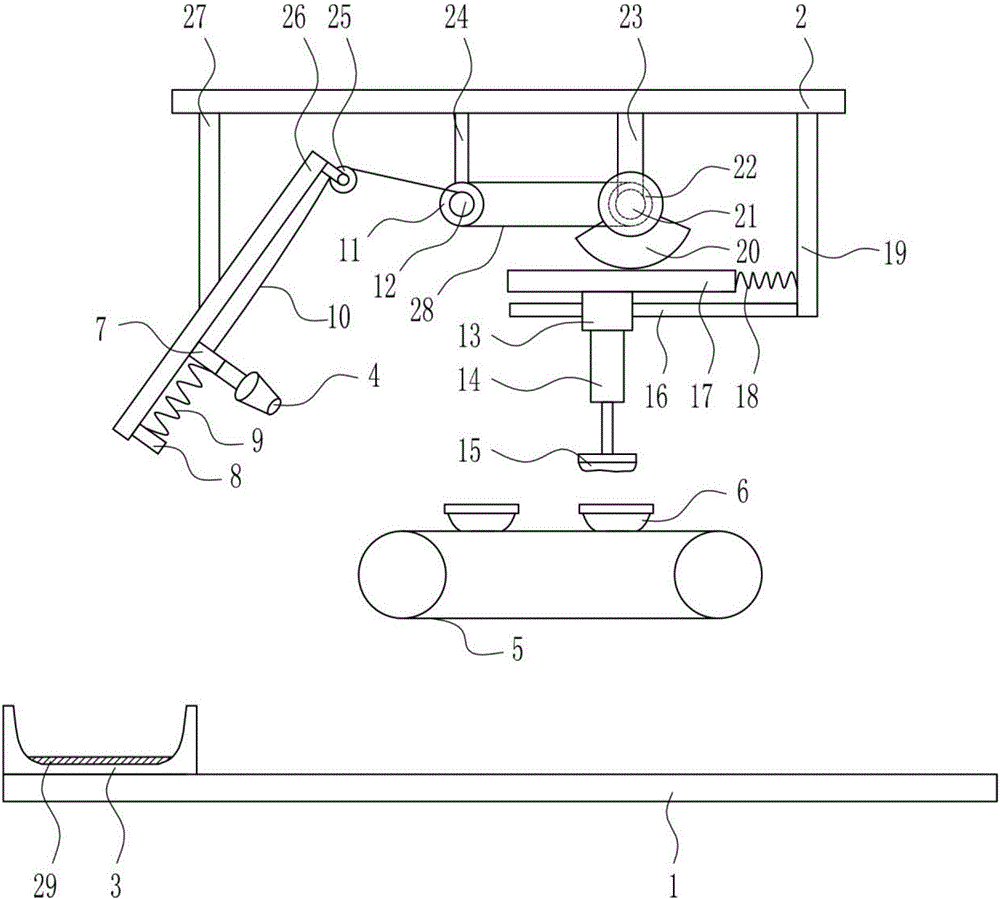

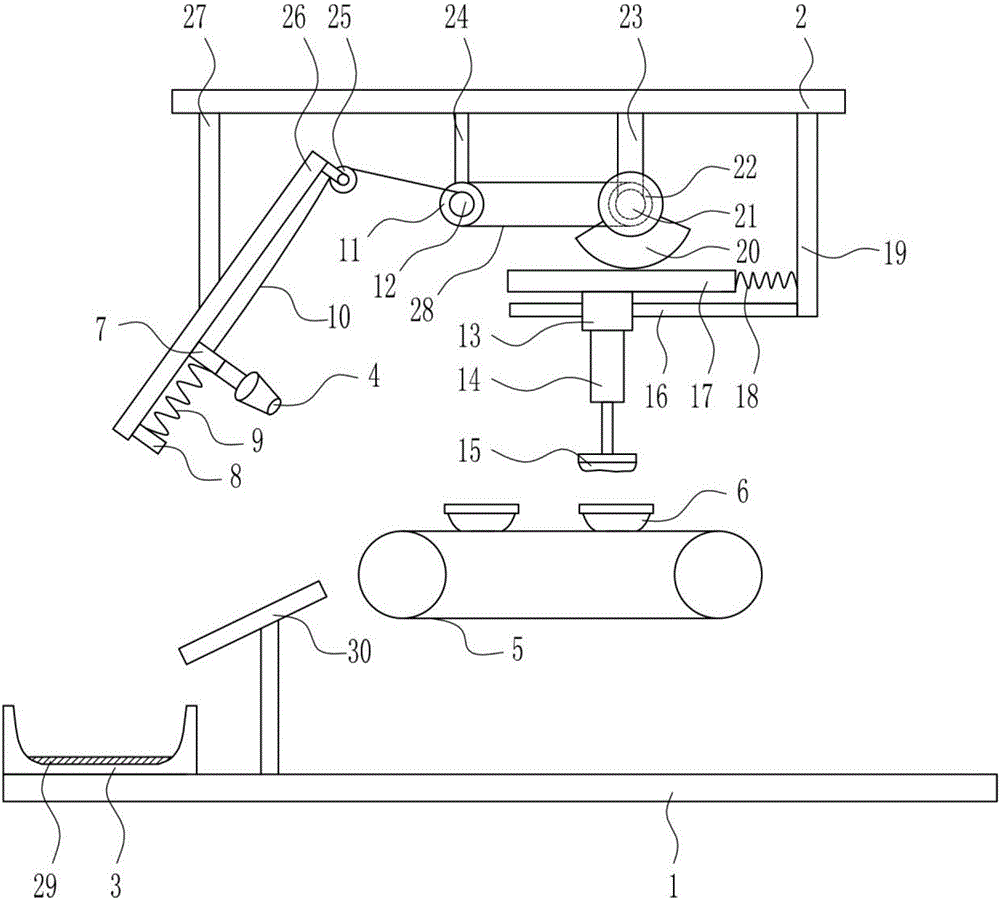

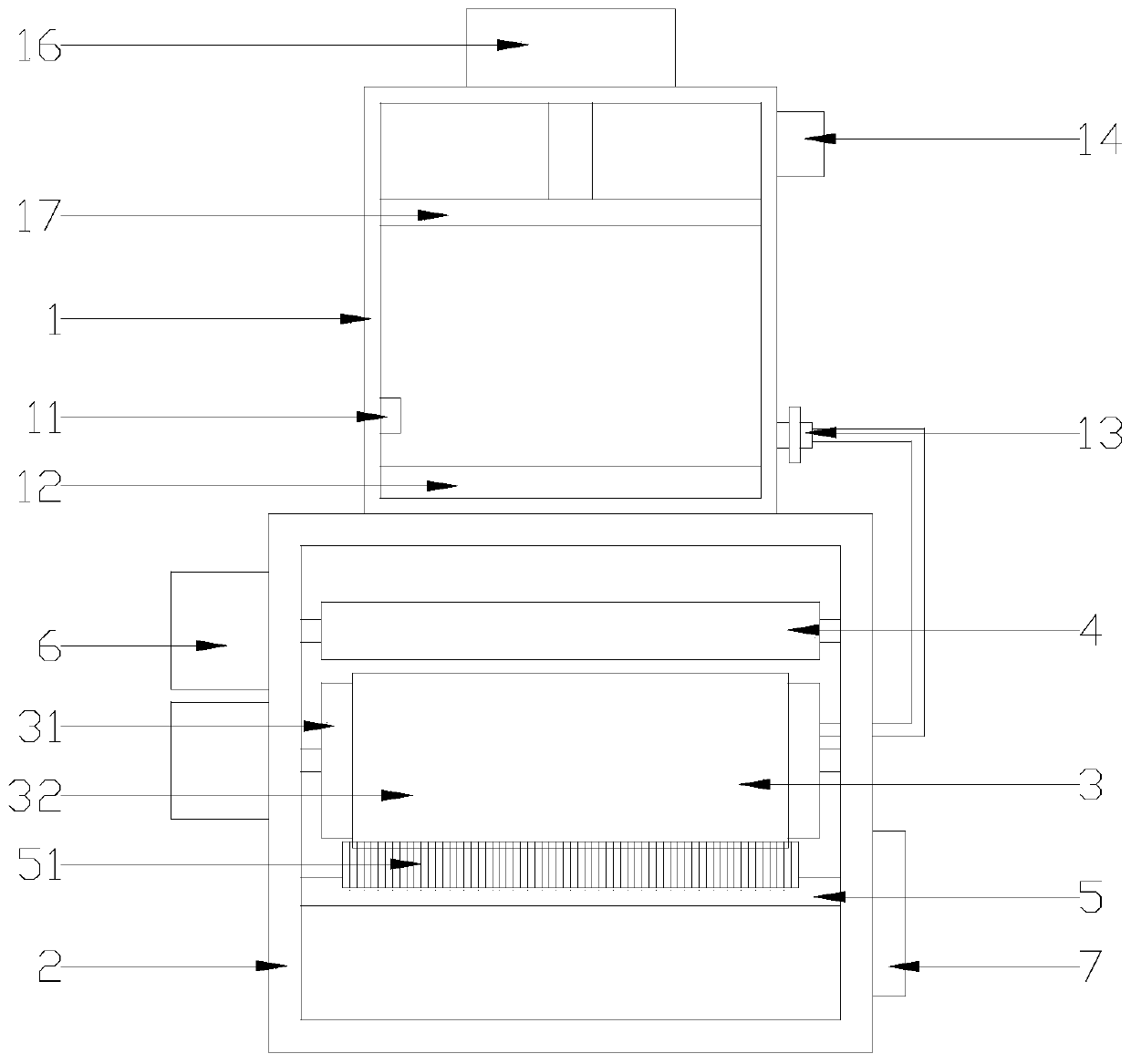

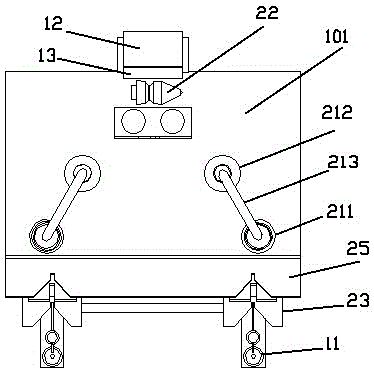

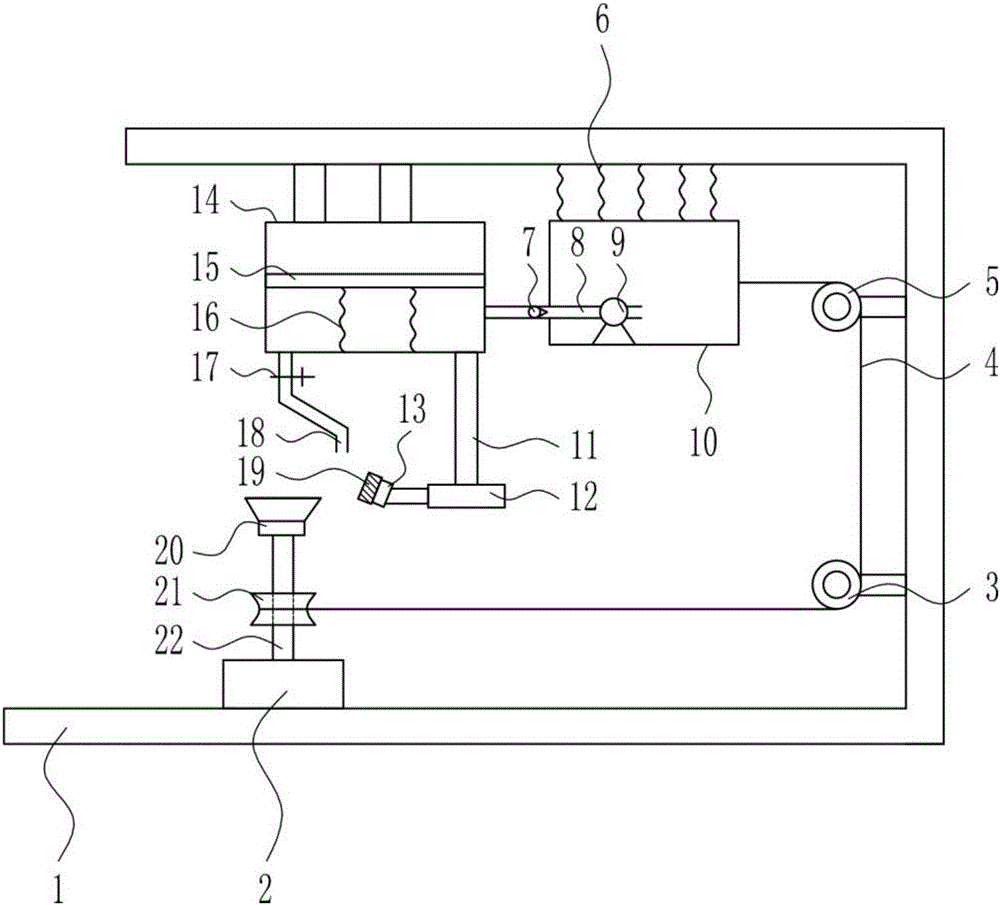

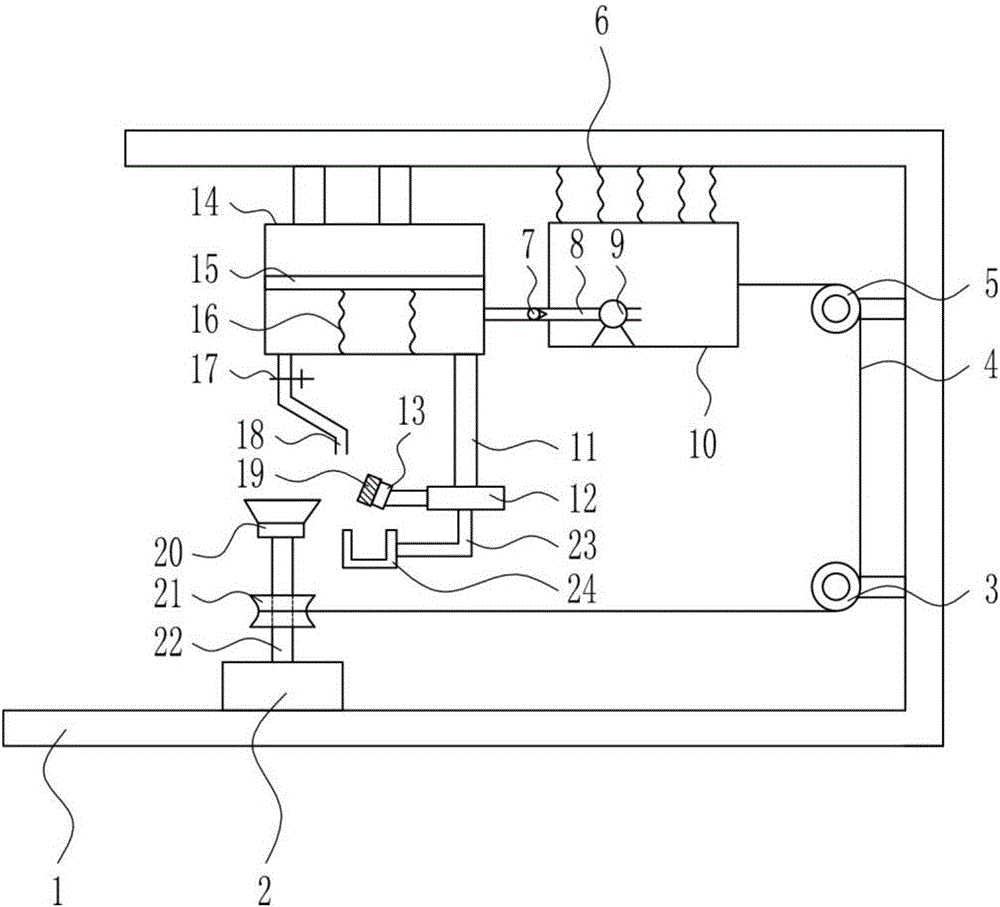

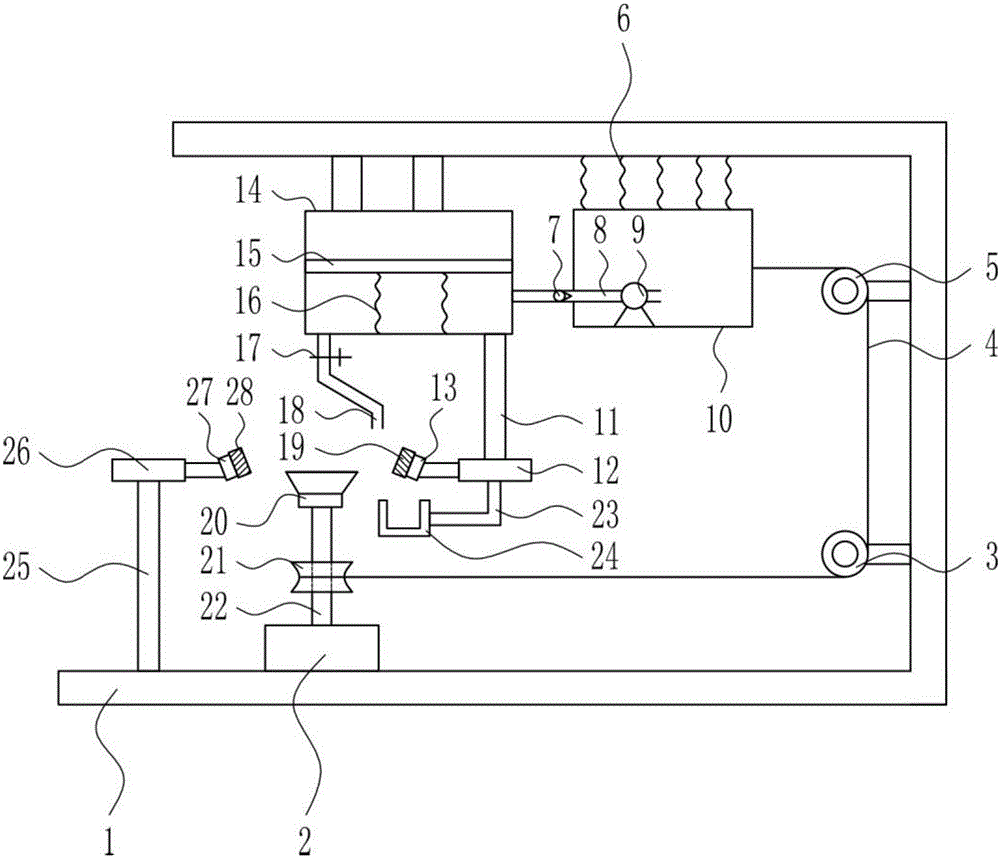

Uniform waxing device of mosaic tiles

InactiveCN106269411ASave energy on handlingConvenient for waxing workLiquid surface applicatorsCoatingsDrive wheelEngineering

The invention relates to a waxing device, in particular to a uniform waxing device of mosaic tiles. In order to achieve the technical aim, the uniform waxing device of the mosaic tiles is uniform in waxing. To achieve the technical aim, the uniform waxing device of the mosaic tiles comprises a bottom plate, a top plate, a collecting tank, a draught fan, a conveying device, electric suction discs, a sliding block, a fixed block, a first spring, a pull wire, a driven wheel, a wire winding wheel, a sliding sleeve, an electric push rod, a rubbing block, a guide rod, a gear rack, a second spring, a fixed plate, a sector gear, a rotary motor, a driving wheel, a first supporting rod, a second supporting rod, a fixed pulley, a sliding rail, a third supporting rod and a flat belt. The collecting tank is arranged at the left end of the top of the bottom plate. The uniform waxing device achieves the uniform waxing effect, the device is used for waxing the mosaic tiles, the rubbing block moves more regularly through the rotating rule of the sector gear, and therefore regular waxing is carried out.

Owner:景德镇赛德陶瓷有限公司

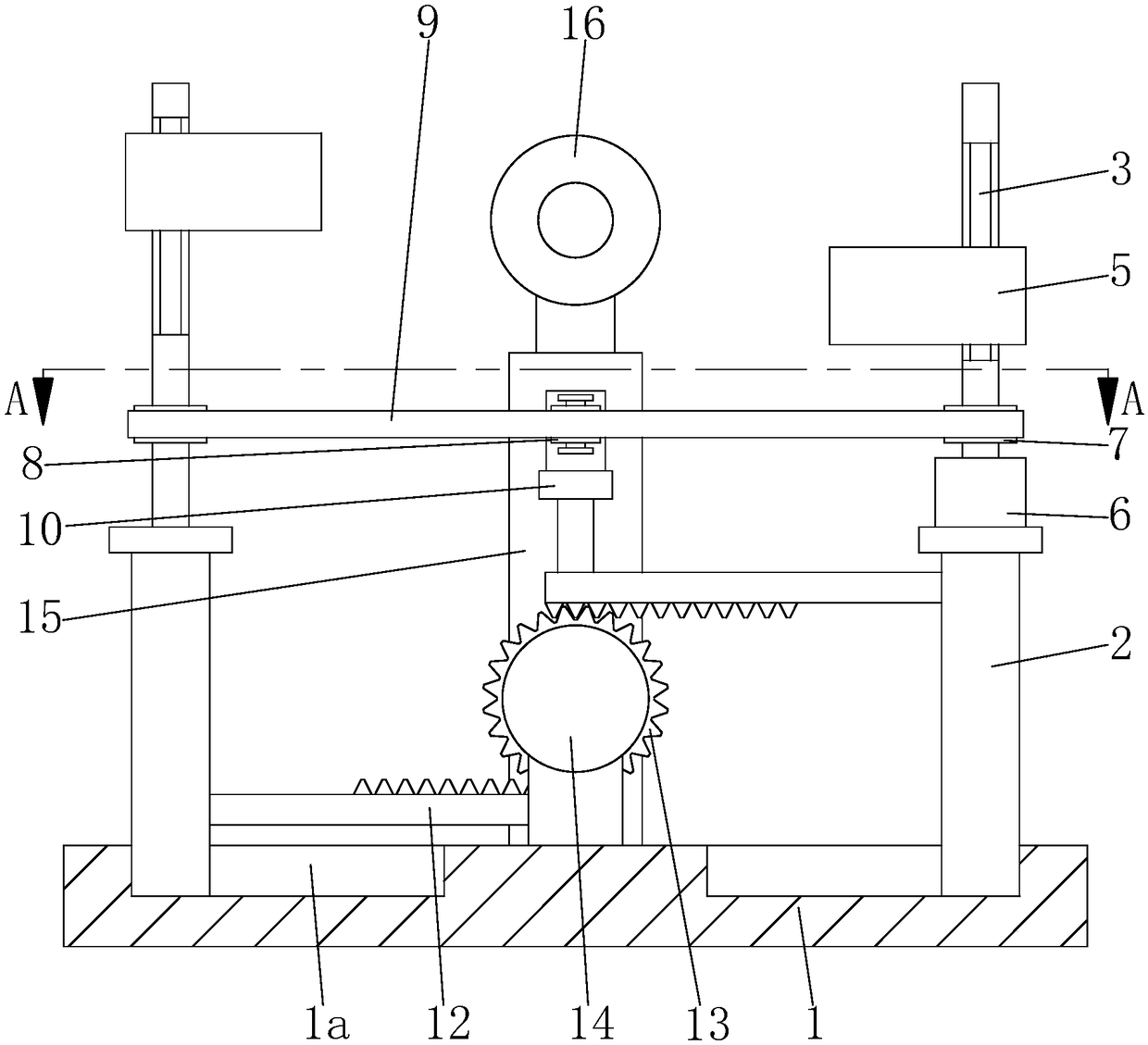

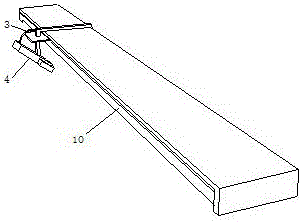

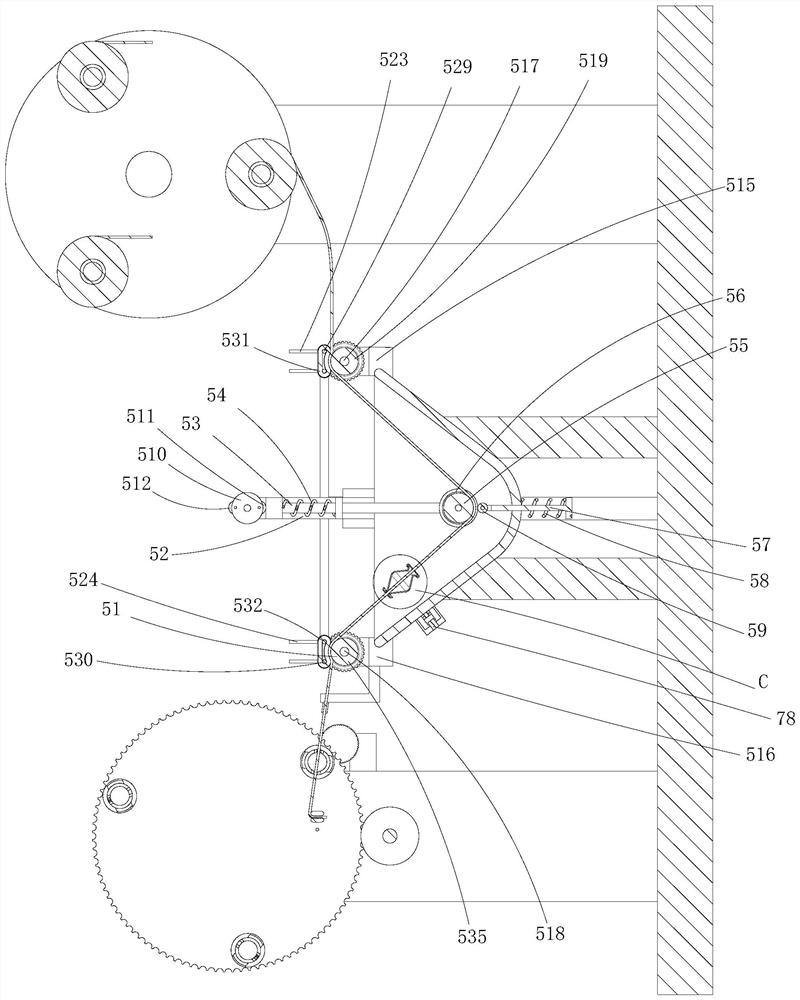

Reciprocating type uniform waxing device for textile production

The invention relates to the technical field of textile production and processing, in particular to a reciprocating type uniform waxing device for textile production. The reciprocating type uniform waxing device comprises a mounting plate, guide columns are symmetrically arranged on the mounting plate, and two supporting frames are symmetrically arranged linearly along the guide columns and both in slide fit with the mounting plate. Two lead screw mechanisms are correspondingly arranged at the upper ends of the two supporting frames and connected with wax block mounting plates respectively, and the two lead screw mechanisms are connected through a belt mechanism with a tension wheel. Two vertically staggered racks are correspondingly arranged on the two supporting frames and meshed with adriving mechanism on the mounting plate. The problem of difficulty in making full use of wax blocks due to the fact that yarns are only enabled to contact in a certain range of the wax blocks in application of an existing waxing device is solved, and the problem of wax block waste caused by failure in making full use of the wax blocks due to poor compatibility resulted from failure in multi-rangecontact under friction between the yarns and the wax blocks in application of the existing waxing device is solved as well.

Owner:ANHUI WUWEI TIANCHENG TEXTILE

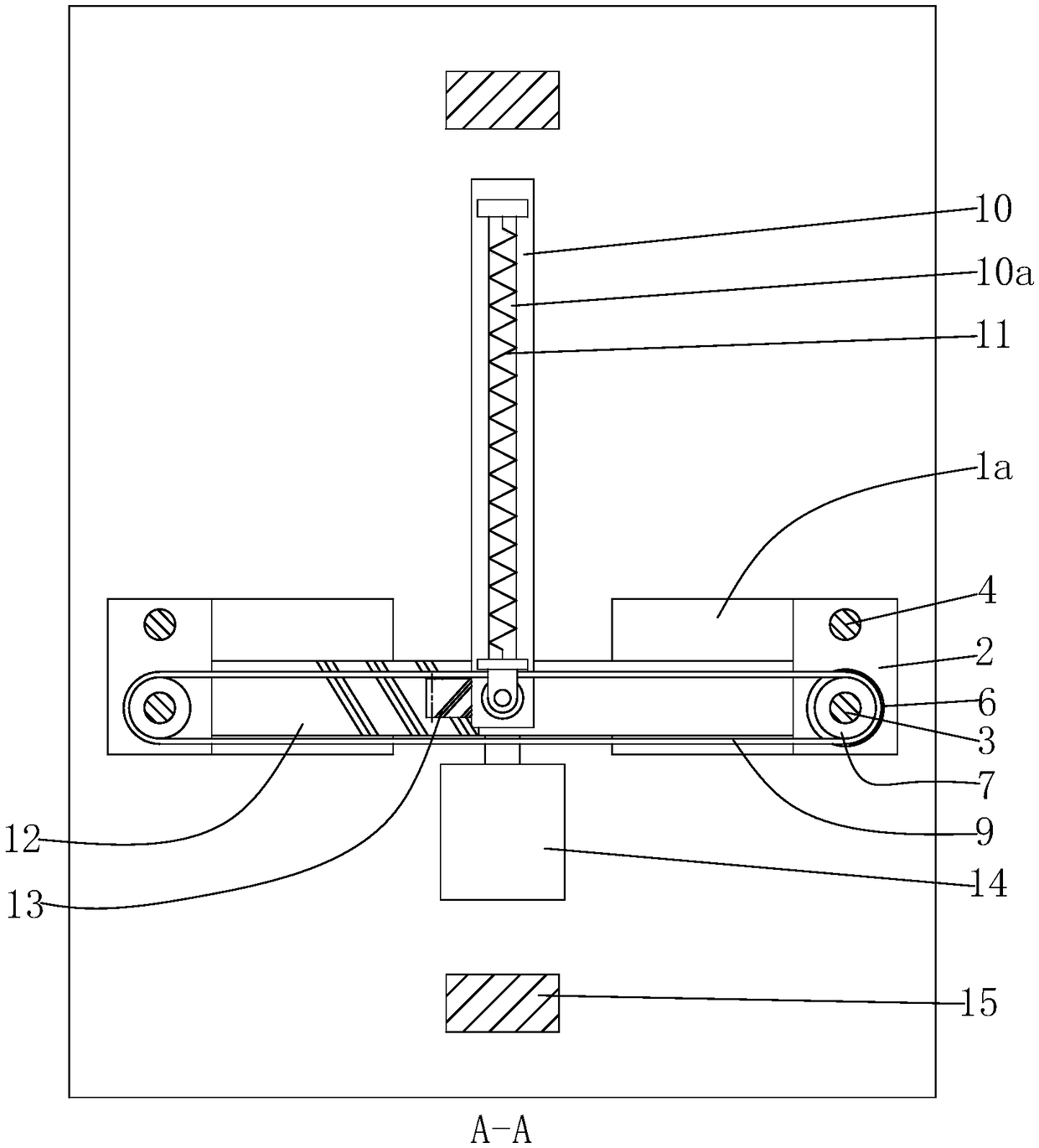

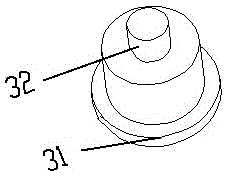

Rotary waxing device of spinning two-for-one twister

InactiveCN111155213AAvoid accumulationImprove waxing effectContinuous wound-up machinesYarnRotational axis

The invention provides a rotary waxing device of a spinning two-for-one twister, and relates to the technical field of spinning. The rotary waxing device of the spinning two-for-one twister comprisesa frame body, wherein the interior of the frame body is rotatably connected with a mounting seat through rotating shafts on two sides; a concave groove is formed in the side, close to the center of the frame body, of the mounting seat; a spring is fixedly mounted on the inner wall of the concave groove; a telescopic block is fixedly mounted at the other end of the spring; a wax disc is fixedly connected to the end, close to the center of the frame body, of a limiting block; a first gear is fixedly mounted at the other end of each rotating shaft; and a heating rotating shaft is rotationally connected to the lower part of the mounting seat in the frame body. According to the rotary waxing device of the spinning two-for-one twister, the surface of the wax disc can be ground more uniformly, itis guaranteed that yarn keeps a rotating state all the time when being in contact with the wax disc, and accumulation of fine hair on the surface of the wax disc is avoided, so that waste of paraffinis avoided, waxing on the periphery of the yarn is more uniform, and the waxing effect is improved.

Owner:曹超铨

Waxing device capable of automatically feeding wax

InactiveCN106671949AAvoid too muchAvoid the problem of too fewVehicle servicing/repairingWaxArchitectural engineering

The invention discloses a waxing device capable of automatically feeding wax, and relates to the field of auto beauty maintenance devices. The waxing device includes a housing, a motor, a fixing plate and a waxing brush; the motor is positioned on the top of the housing; an output shaft of the motor is connected to the fixing plate; the fixing plate is connected to the waxing brush; the fixing plate is rotatably connected to the housing; a material storage cavity is formed in the housing; a handle is arranged on the left side of the housing; a telescopic air bag is arranged on the upper end of the handle; the telescopic air bag is fixed on the housing; an air inlet hole and an air outlet hole are formed in the telescopic air bag; the air outlet hole communicates with the telescopic air bag and the material storage cavity, and is positioned on the upper part of the material storage cavity; discharging holes are evenly distributed in the fixing plate; one-way valves are arranged in the discharging holes; and the material storage cavity communicates with the waxing device through the one-way valves and the discharging holes. The waxing device can rapidly feed wax in a waxing process, and can improve the waxing efficiency.

Owner:GUANGXI UNIV FOR NATITIES

Waxing device for leather manufacturing

InactiveCN108754050AAvoid affecting waxing efficiencyAdd brush structureLeather/skins/hides/pelt chemical treatment apparatusLeather surface finishingWaxPulp and paper industry

The invention discloses a waxing device for leather manufacturing. The waxing device comprises a bottom plate; the top of the bottom plate is fixedly connected with an installation plate through a connection plate, and a conveying rail located below the installation plate is fixedly connected to the top of the bottom plate through supporting rods; and the bottom of the installation plate is fixedly connected with a wax dripping pipeline, and the end, away from the installation plate, of the wax dripping pipeline is fixedly connected with wax dripping nozzles located above the conveying rail. According to the waxing device, by arranging a driving motor and spiral fan blades, waxed leather is subjected to air bowing and accelerative cooling and air drying, so that the situation that the overall waxing efficiency is influenced due to natural air drying is avoided; by arranging transmission tooth blocks, a driven toothed plate and a brush plate, the effect of additionally arranging a brushing structure in the waxing and air drying processes is achieved; and through reciprocating brushing of the brush plate after waxing, the effect that uniform waxing is ensured is achieved, accordingly, the air drying efficiency and uniform waxing are ensured, and the effect of improving the integral machining efficiency and quality is achieved.

Owner:江苏研华科技有限公司

Yarn waxing device

The invention relates to the technical field of textile and specifically relates to a yarn waxing device for coating yarns with a layer of wax. The yarn waxing device comprises a supporting plate arranged vertically; a first wax roller and a second wax roller are rotatably arranged on one side of the supporting plate; a hold-down mechanism for holding down yarns is arranged between the first wax roller and the second wax roller; the hold-down mechanism comprises a support fixedly arranged on the supporting plate, a fixed shaft of which the two ends are arranged on the support, a hold-down roller arranged on the fixed shaft and rotating around the fixed shaft, a hoisting frame sleeving the fixed shaft, and a cylinder arranged on the support and pushing the hoisting frame to go up and down. Yarns pass through the first wax roller and the second wax roller; the hold-down roller is located between the two wax rollers and capable of generating appropriate pressure so that the yarns can be pressed on the first wax roller and the second wax roller; as a result, good-quality waxing and even waxing are realized.

Owner:CHANGZHOU SINO TEXTILE

Textile yarn waxing device

The invention discloses a textile yarn waxing device which comprises a waxing disc, a fixing plate, a device body, a waxing groove and a wax storage tank. The waxing groove is formed in a side of thebottom of the inside of the device body, an auxiliary chamber is arranged inside the device body and is positioned on a side of the waxing groove, a float ball valve is mounted on a side of the bottomof the inside of the waxing groove, the waxing disc is vertically mounted in the middle of the inside of the waxing groove via bearings, the fixing plate is fixed to the top of the auxiliary chamber,two press rolls which are matched with each other are vertically mounted on the inner side of the fixing plate and are connected with each other by a gear, a motor is mounted on a side of the bottomof the inside of the auxiliary chamber, an output end of the motor is fixedly connected with the press roll on a side of the fixing plate, and an air pump is mounted inside the auxiliary chamber and is positioned on a side of the motor. The textile yarn waxing device has the advantages that spray nozzles are uniformly arranged on the inner side of the fixing plate, accordingly, yarns waxed by theaid of the waxing disc can be conveniently quickly solidified, and the yarn waxing work efficiency can be improved.

Owner:JIANGSU BEILIN TEXTILE CO LTD

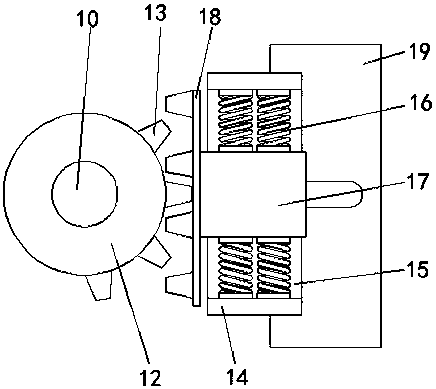

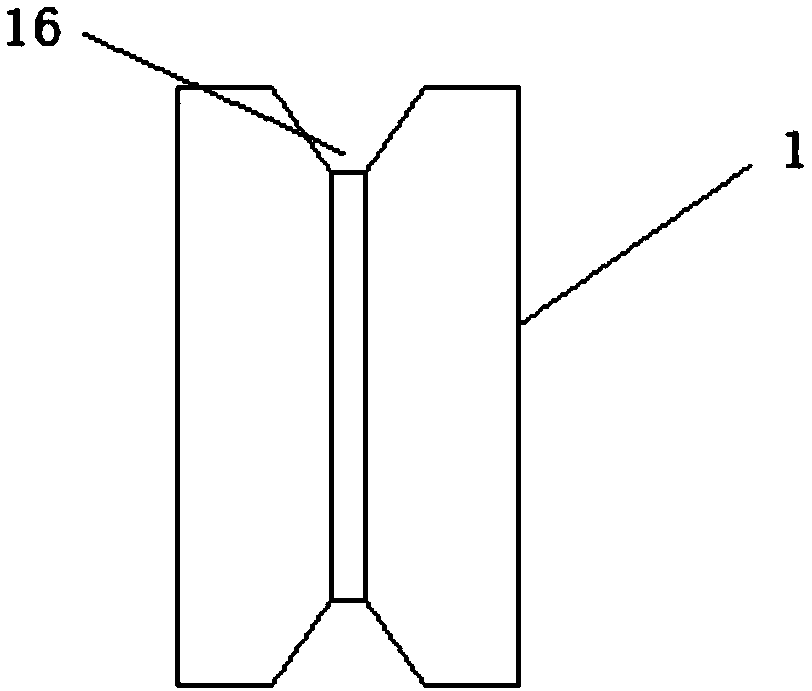

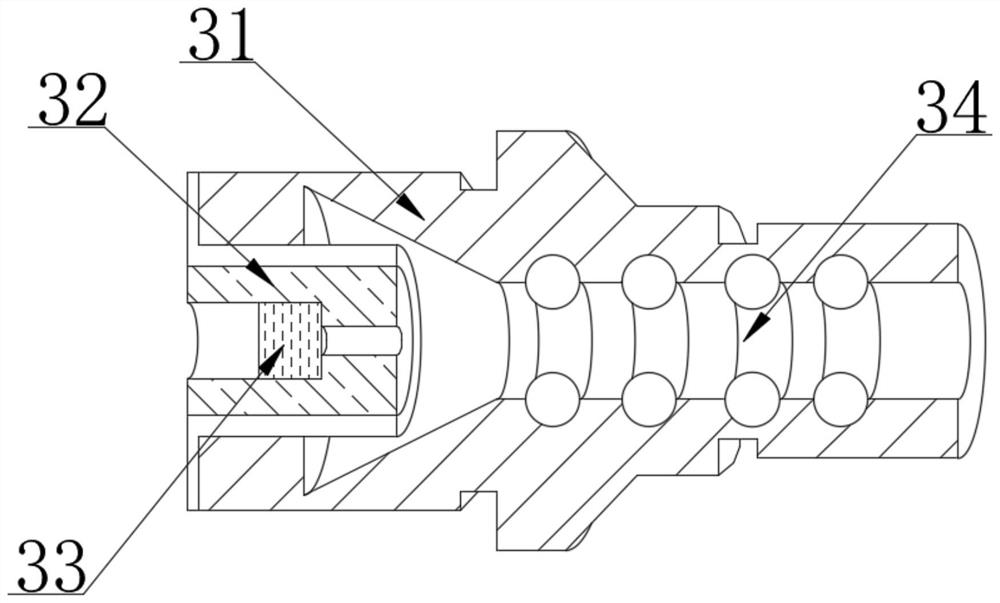

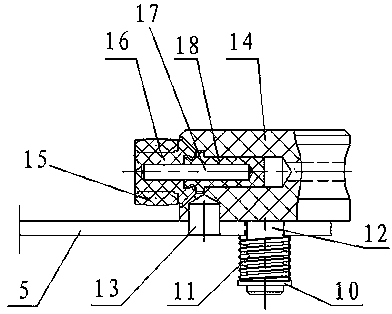

Waxing mechanism of rotor spinning machine

The invention relates to a waxing mechanism for a rotor spinning machine. The waxing mechanism comprises a fixing frame, a worm gear pin shaft, a conical compression spring, a tray, a waxing face plate and a waxing support roller mechanism, wherein the fixing frame is of a concave structure; a gear body is arranged in the middle of the worm gear pin shaft in a protruding manner; the worm gear pin shaft is arranged in the concave structure of the fixing frame and can rotate on the fixing frame; the tray sleeves the worm gear pin shaft in a sliding manner; the conical compression spring sleeves a part between a gear body side of the worm gear pin shaft and the tray; a hole for a wax block mounted on the tray to extend out is formed in the waxing face plate; the waxing support roller mechanism is respectively arranged on two sides of the hole; the waxing support roller mechanism connects a yarn to the wax block in a compression manner; the upper face plate covers the upper part of the concave structure of the fixing frame in a fixing manner. The waxing mechanism provided by the invention is added without changing the entire structure of the rotor spinning machine, so that the yarn is waxed uniformly, and the quality of the yarn is improved.

Owner:JINGWEI TEXTILE MASCH CO LTD

Waxing device for textile processing

The invention discloses a waxing device for textile processing. The waxing device comprises a box; a feeding hopper is connected to the outer wall of one side of the box in an inserted mode, and a first connecting plate is arranged on the inner wall of one side of the box; a first mounting plate is arranged on the inner wall of the bottom of the box, and a first resistance wire is arranged on theouter wall of one side of the first mounting plate; a protective shell is arranged on the outer wall of one side of the box, and a motor is arranged on the inner wall of one side of the protective shell; a waxing roller is arranged at one end of an output shaft of the motor and located in the box; a second fixing plate is arranged on the outer wall of one side of the box, and a first fixing plateis arranged on the outer wall of the bottom of the second fixing plate; and the outer wall of one side of the first fixing plate is rotationally connected with an unwinding roller, and a textile thread is wound on the circumferential outer wall of the unwinding roller. Compared with traditional waxing by wax blocks, more resources are saved, and waste generated by the inability of the large numberof wax blocks to make contact with the textile thread is avoided.

Owner:李海燕

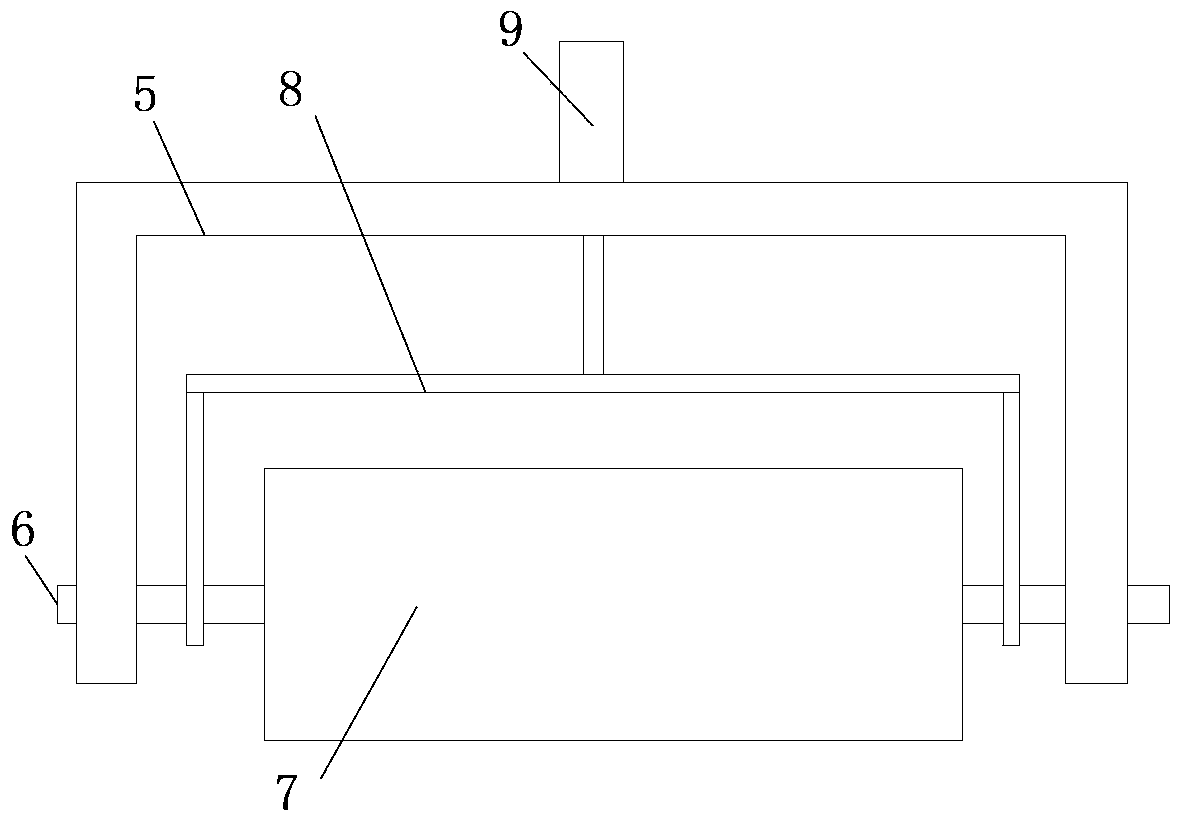

Cloth waxing device

PendingCN109811483AGuaranteed waxing effectEvenly waxedTextile treatment machine arrangementsTextile treatment cleaning apparatusEngineeringMechanical engineering

The invention discloses a cloth waxing device. The cloth waxing device comprises a wax-supplementing box, an outer shell, a waxing roller, cloth conveying rollers, a clearing comb, a motor set and a control device, wherein the cloth conveying rollers are fixed to the positions, close to a feeding inlet and a discharging outlet, of the two sides inside the outer shell, the waxing roller is fixed between the cloth conveying rollers on the two sides inside the outer shell and comprises a rotating shaft, a rotating cylinder sleeving the rotating shaft, and side covers located on the two sides of the rotating cylinder, the rotating cylinder is internally provided with a cavity, a plurality of first heating blocks are fixed to the inner wall of the rotating cylinder, a plurality of through holesare formed in the cylinder wall of the rotating cylinder, bristles are arranged on the outer surface of the rotating cylinder, the clearing comb is fixed into the outer shell and located below the waxing roller, comb teeth of the clearing comb make contact with the bristles, and a chipping discharging outlet is formed in the lower end of the outer shell. Through the rotating waxing roller, a cloth is waxed by the bristles with the surfaces being stained with wax liquid, and waxing is uniform and rapid; and impurities on the waxing roller are removed through the clearing comb, and the waxing effect of the cloth is ensured.

Owner:嘉兴市布雷塑胶新材料股份有限公司

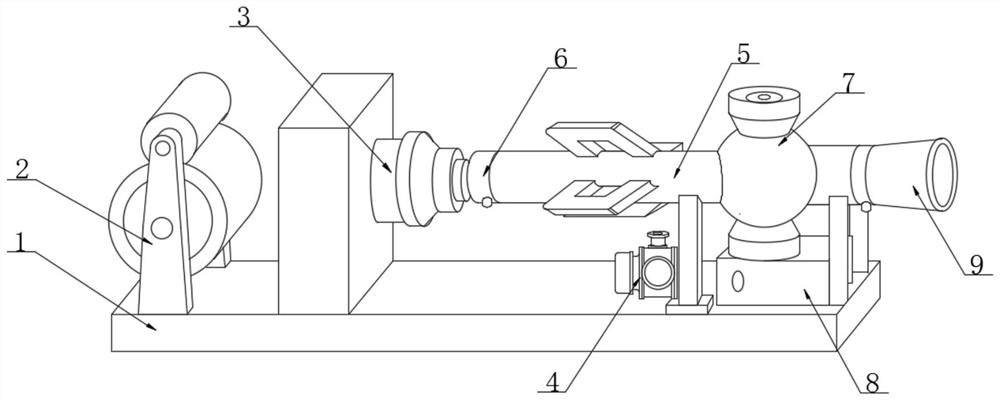

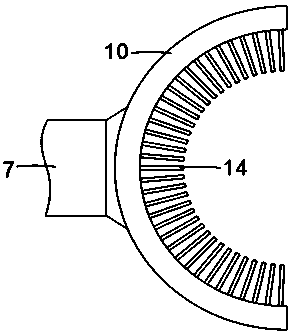

Yarn waxing device for knitting machines

The invention relates to a yarn waxing device, in particular to a yarn waxing device for knitting machines. The technical problem is how to design a yarn waxing device for knitting machines, which helps prevent a yarn from directly contacting a wax block, allows the consumption of the wax block to be reduced, and provides uniform waxing for the surface of the yarn. The yarn waxing device for knitting machines comprises a mounting rack, a cylinder and the like; the cylinder is mounted on the right side of the mounting rack. The wax block can be scraped into a sheet through a scraper; the scrapped sheet can be crushed into wax granules through cooperation of a contact rod and an elastic plate, so that a yarn can be more fully contacted with the wax granules; a sector gear can drive a cylindrical gear to intermittently cooperate with an outer gear ring, so that an operator does not need to manually shift the outer gear ring; a pressing plate cooperates with a second spring, so that the operator does not need to press the wax block by hand; a yarn guide wheel cooperates with the yarn, so that the surface of the yarn can be uniformly waxed.

Owner:抚州市中小企业服务有限公司

Improved doubling machine

The invention relates to an improved doubling machine. The improved doubling machine comprises a plurality of doubling units, wherein each doubling unit comprises a supporting rack; at least two pay-off drum placing parts and a take-up drum placing part are arranged on the supporting rack; a take-up roll is arranged at one side of the take-up drum placing part; a supporting platform is formed in the middle of the supporting rack; the pay-off drum placing parts and the take-up drum placing part are arranged at the upper and lower sides of the supporting platform; and a doubling part is arranged on the supporting platform. The improved doubling machine has the beneficial effects that the improved doubling machine has a simple structure, is smooth and efficient in doubling and avoids knotting; adjacent yarns can not be doubled in a mixed manner; and when silk yarns are waxed in the doubling process, extra waxing processes are not needed, the silk yarns are uniformly waxed, the processes are saved and waxing is more convenient to carry out.

Owner:ZHEJIANG ZHONGXIN WOOL TEXTILE

Yarn rapid waxing device

The invention relates to a waxing device, in particular to a yarn rapid waxing device. The invention aims to provide the yarn rapid waxing device capable of saving manpower and uniformly waxing. According to the technical scheme, the yarn rapid waxing device comprises a base, a vertical plate, a top plate, a shaft sleeve, a sleeve rod, a connecting plate, a first spring, a first clamping block, ahollow pipe, a sliding frame, a sliding block, a moving rod, a disc and the like; the right side of the top of the base is in bolting connection with the vertical plate with a supporting function, thetop of the vertical plate is fixedly connected with the top plate, the shaft sleeve is connected to the right side of the top of the top plate in a bolting mode, the sleeve rod with a placing function is arranged in the shaft sleeve, and the connecting plate is fixedly connected to the left side of the bottom of the top plate. A winding drum can be driven to rotate by rotating a handle, so that yarn is wound around the winding drum, and a small wax block can be used for waxing the yarn, so that the operation can be completed by one person, and manpower can be saved.

Owner:江西嘉丰纺织有限公司

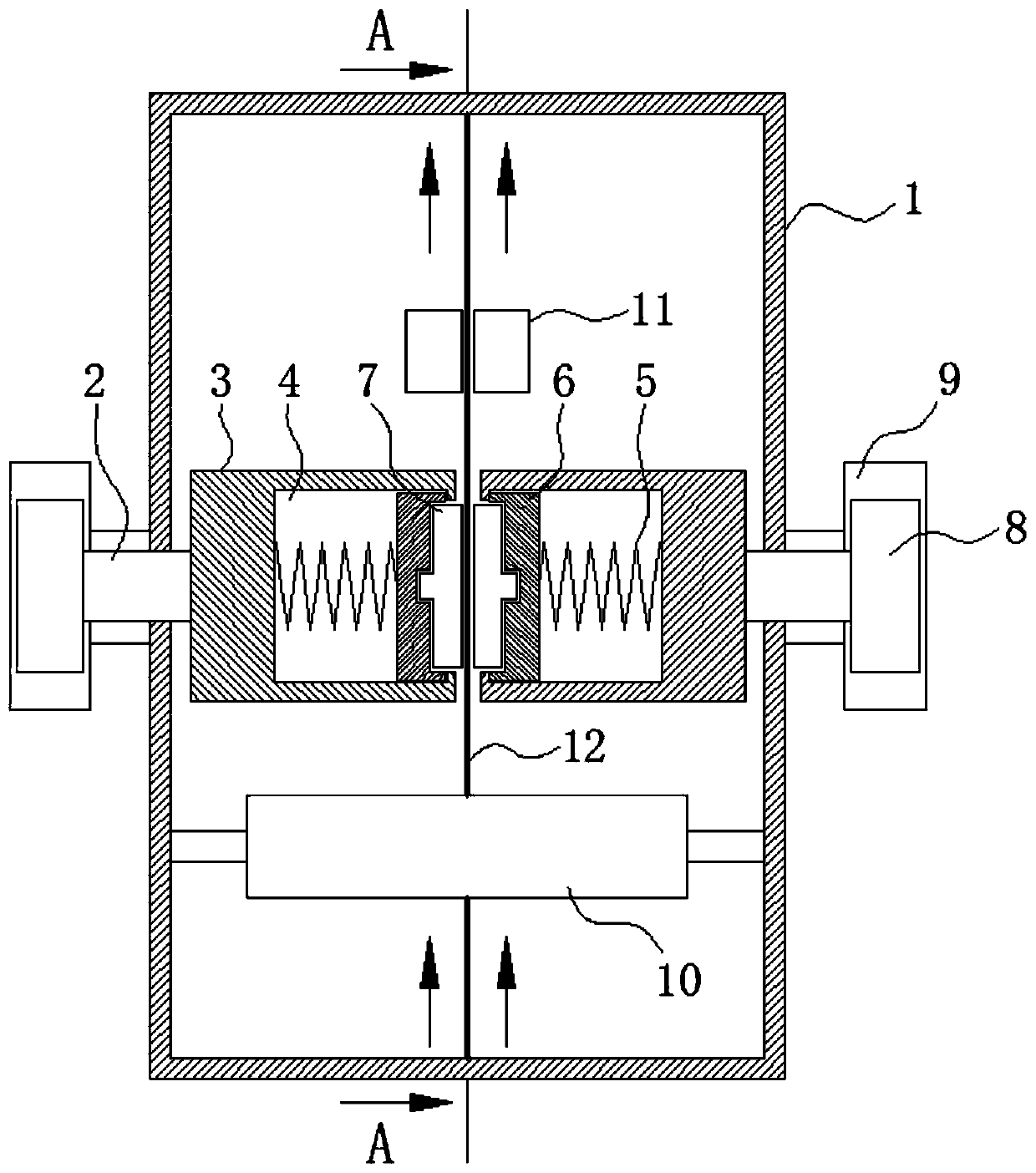

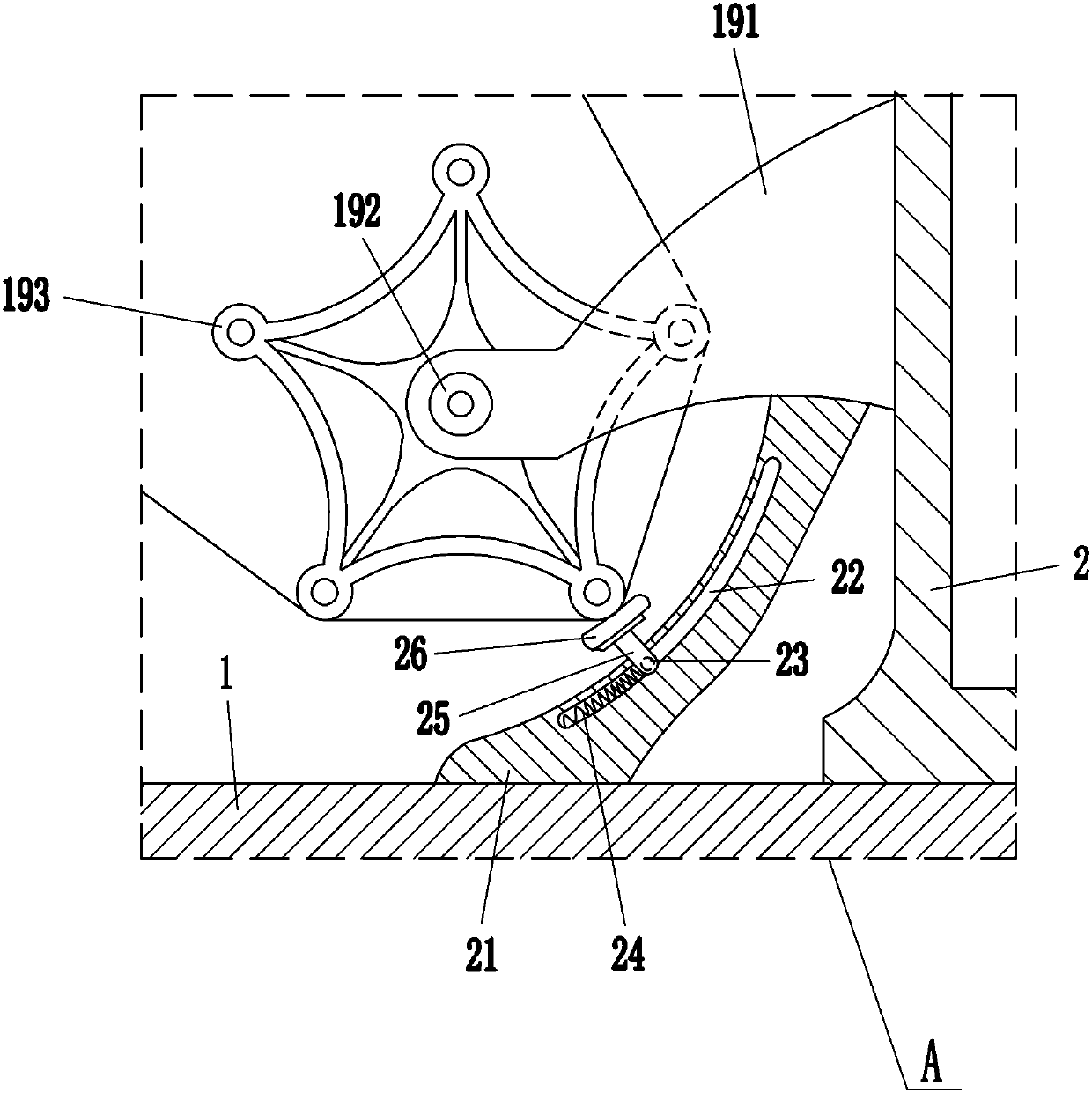

Waxing device with high stability and polishing system

InactiveCN105563297AImprove stabilityAvoid jitterGrinding machine componentsPolishing machinesWaxReciprocating motion

The invention discloses a waxing device with the high stability and a polishing system. A feeding mechanism comprises a first-stage feeding mechanism body provided with a first movement part and a second-stage feeding mechanism body provided with a second movement part. During usage, a wax block is put into a motion space of the second movement part and can approach and wax a grinding head when the grinding head needs to be waxed through reciprocating movement of the first movement part or the second movement part, and the wax block can keep away from the grinding head when waxing is not needed so as to reserve a work space of the grinding head for machining a metal container. Position compensation of a damaged wax block can be quantificationally conducted by the stepping movement of the first movement part or the second movement part, even and moderate waxing of the grinding head is achieved while wax is saved. In addition, due to the existence of an elastic wax pressing assembly, the wax block is prevented from shaking so as to achieve even waxing. The invention discloses the polishing system using the waxing device. The polishing system is used for polishing a cavity of the metal container.

Owner:FOSHAN CLEV ROBOT

Willow furniture waxing method

InactiveCN107379181AHigh surface finishCover up the smellRadiation/waves wood treatmentWood treatment detailsWaxEngineering

The invention relates to a willow furniture waxing method. The willow furniture waxing method comprises the following steps: (1) soaking willows in strong brine; and (2) waxing the willows. Experiments prove that by utilizing the willow furniture waxing method provided by the invention, the smell of the willow furniture after being waxed is faint scent; and meanwhile, the insecticidal mold-proof effect is good and far better than the existing waxing method, and the willow furniture waxing method is widely popular among consumers.

Owner:阜南县创发工艺品有限公司

National batik cerate and preparation method thereof

The invention discloses a national batik cerate and a preparation method thereof. The cerate is prepared from paraffin, beewax, sodium silicate, polyether modified organosilicon, stearic acid, polyethylene wax and triethanolamine. The national batik cerate is low in cost, good in permeating effect, strong in adhesive capacity, uniform in waxing, and unlikely to generate fracture and pigment figure.

Owner:福泉市筑梦服装有限公司

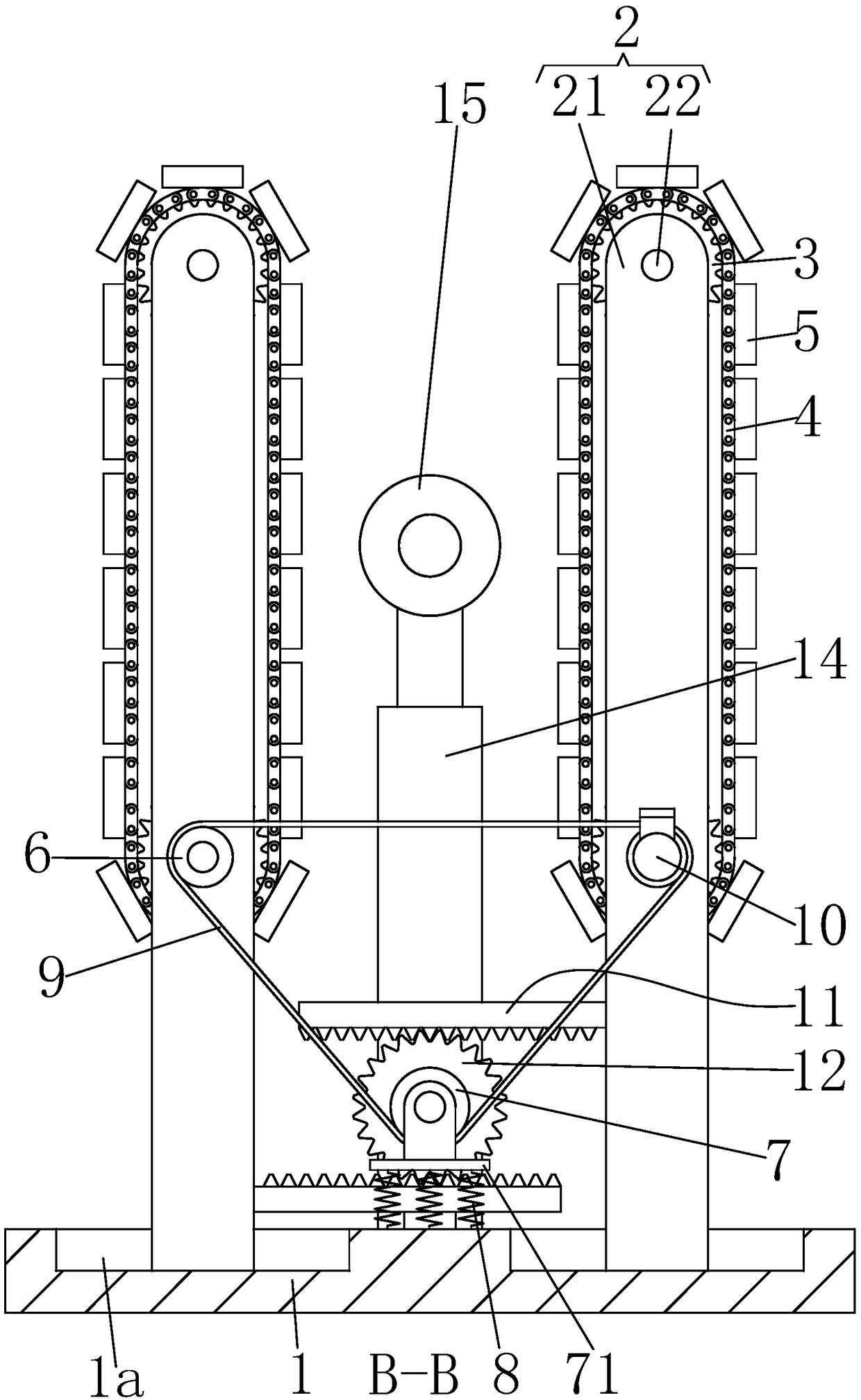

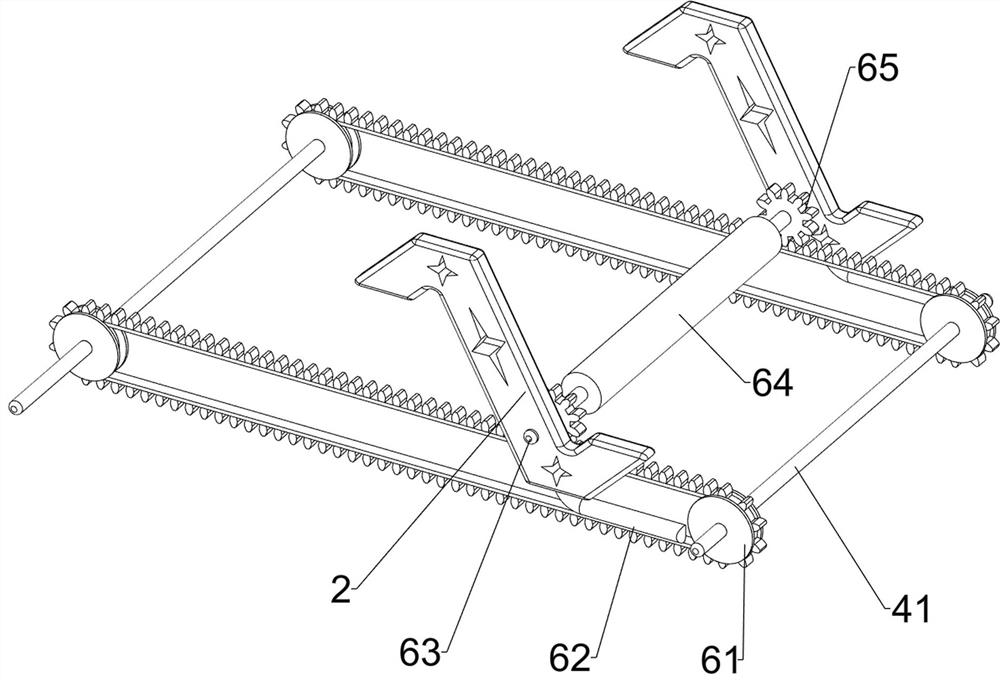

Automatic wax replacement device for textile production

The invention relates to the technical field of textile production and processing, and specifically relates to an automatic wax replacement device for textile production. The automatic wax replacementdevice comprises a mounting plate, wherein the mounting plate is provided with two symmetrically distributed guide yarn columns and two wax frames which are symmetrically and slidably arranged alongthe straight lines where the two guide yarn columns are located, the two wax frames are respectively provided with two chain wheel transportation mechanisms in a corresponding manner, the two chain wheel transportation mechanisms are connected through a coaxially connected belt tensioning mechanism, the two wax frames are respectively provided with two racks in a corresponding manner, the two racks are vertically staggered and meshed with a driving gear, and the driving gear is connected with a driving motor II located on the mounting plate. The automatic wax replacement device solves a problem that the existing wax replacement not only is time and labor consuming and tedious in step, but also has potential safety hazards for operators.

Owner:ANHUI WUWEI TIANCHENG TEXTILE

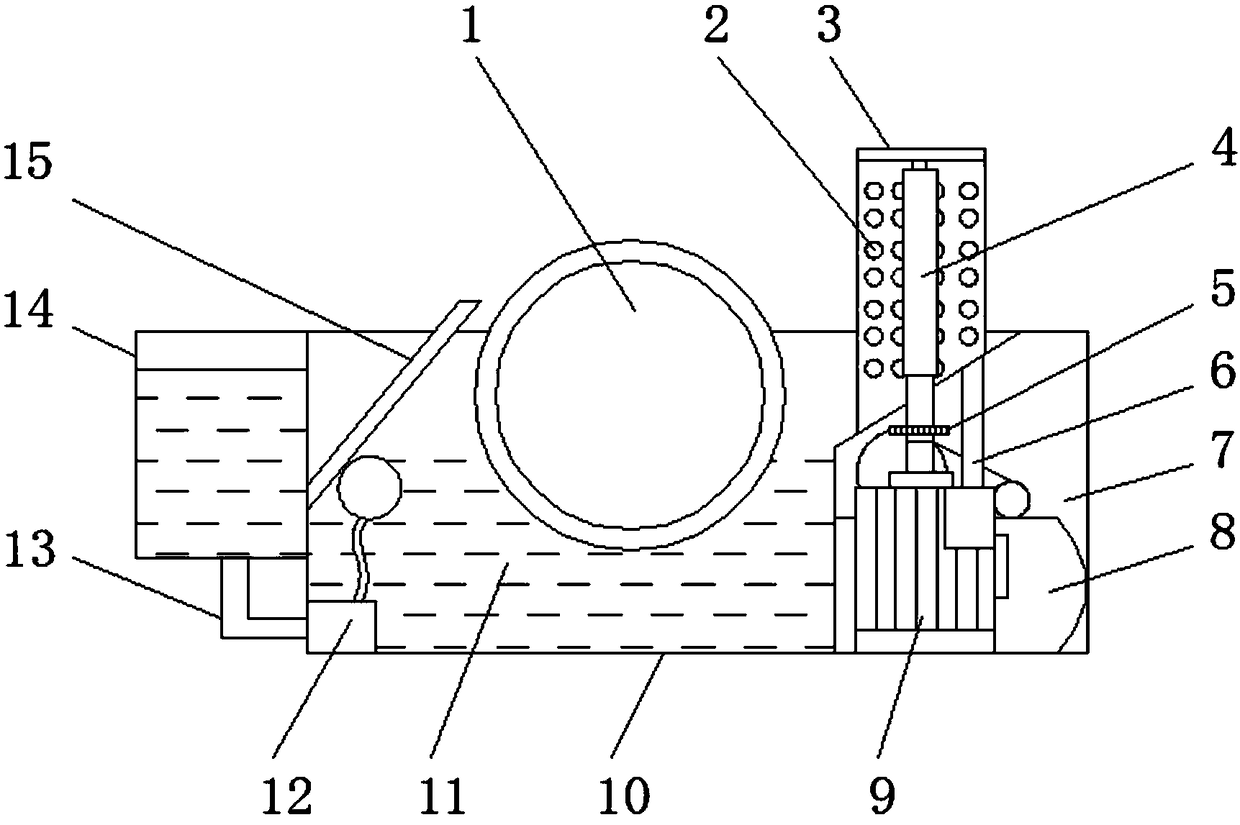

Efficient yarn jet waxing equipment for textile processing and using method thereof

InactiveCN113401732AEvenly waxedAvoid the problem of uneven waxingFilament handlingYarnIndustrial engineering

The invention discloses efficient yarn jet waxing equipment for textile processing and a using method thereof, and particularly relates to the field of textile processing. The efficient yarn jet waxing equipment comprises an equipment base, a pay-off rack is fixedly installed on the top face of the equipment base, and a yarn fuzzing mechanism, a circulating air pump, an air distribution ring and a molten wax storage box are fixedly connected and installed on the top face of the equipment base. The yarn fluffing mechanism and a jet waxing mechanism are located on the same horizontal line, the two ends of the jet waxing mechanism are fixedly connected with the gas distribution ring and a wax liquid recycling mechanism respectively, and the end of the gas distribution ring and the end of the wax liquid recycling mechanism are communicated with the air outlet end and the air inlet end of the circulating air pump respectively. According to the scheme, the yarn waxing equipment adopts the molten wax liquid jet waxing structure, the atomized and diffused molten wax liquid is coated to the surface of the yarn through siphoning by utilizing the structure that airflow and the yarn are in the same direction, uniform and all-directional waxing of the yarn is achieved, the problem that waxing is not uniform during traditional contact is solved, and the waxing effect and the forming quality are improved.

Owner:嘉兴鼎澳纺织科技有限公司

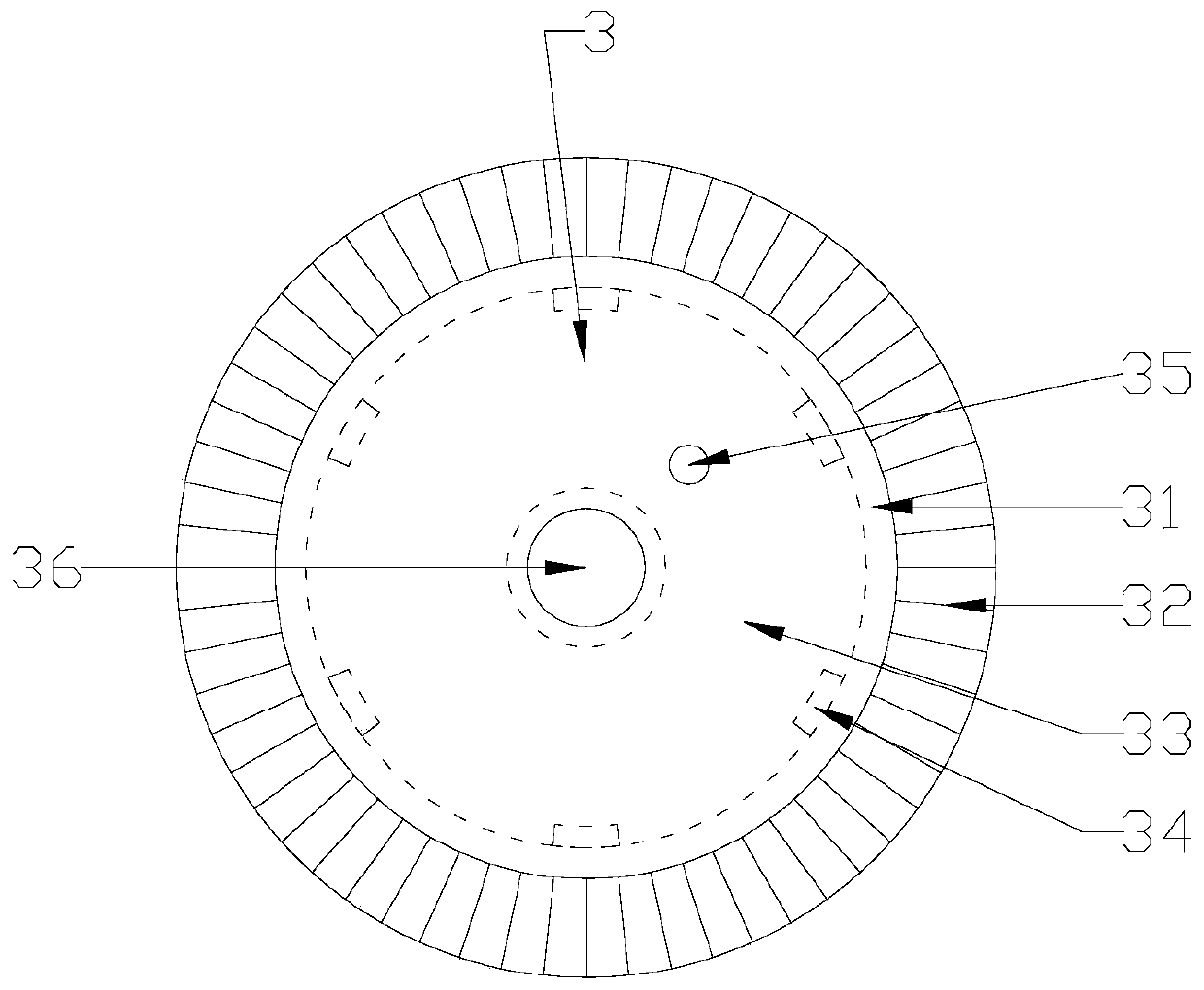

Automatic automobile waxing machine

InactiveCN105644521AGuaranteed aestheticsStable extrusion forceVehicle servicing/repairingElectric machineryDrive motor

The invention relates to an automatic automobile waxing machine. The automatic automobile waxing machine comprises a shell and a handle. The handle is fixedly installed on the side wall of the shell. A set of waxing wheels is installed in the shell. Each waxing wheel comprises an inner wheel body, and outer wheel body and a transmission wheel body, and the transmission wheel body is located between the inner wheel body and the outer wheel body and is tangent to the inner wheel body and the outer wheel body. A controller is installed on the shell. All distance sensors are electrically connected with the controller. The controller comprises control ends corresponding to all the waxing wheels. All the transmission wheel bodies are provided with transmission rods which are connected to the control ends of the controller correspondingly. A driving roller driven by a driving motor is installed in the shell and sequentially penetrates through the parts, between the inner wheel bodies and the outer wheel bodies, of all the waxing wheels. The driving roller can simultaneously drive the inner wheel bodies and the outer wheel bodies to rotate. A wax storage cavity is installed in the shell and filled with wax liquor. A nozzle of the wax storage cavity is attached to all waxing sponges.

Owner:江苏创迈达智能科技有限公司

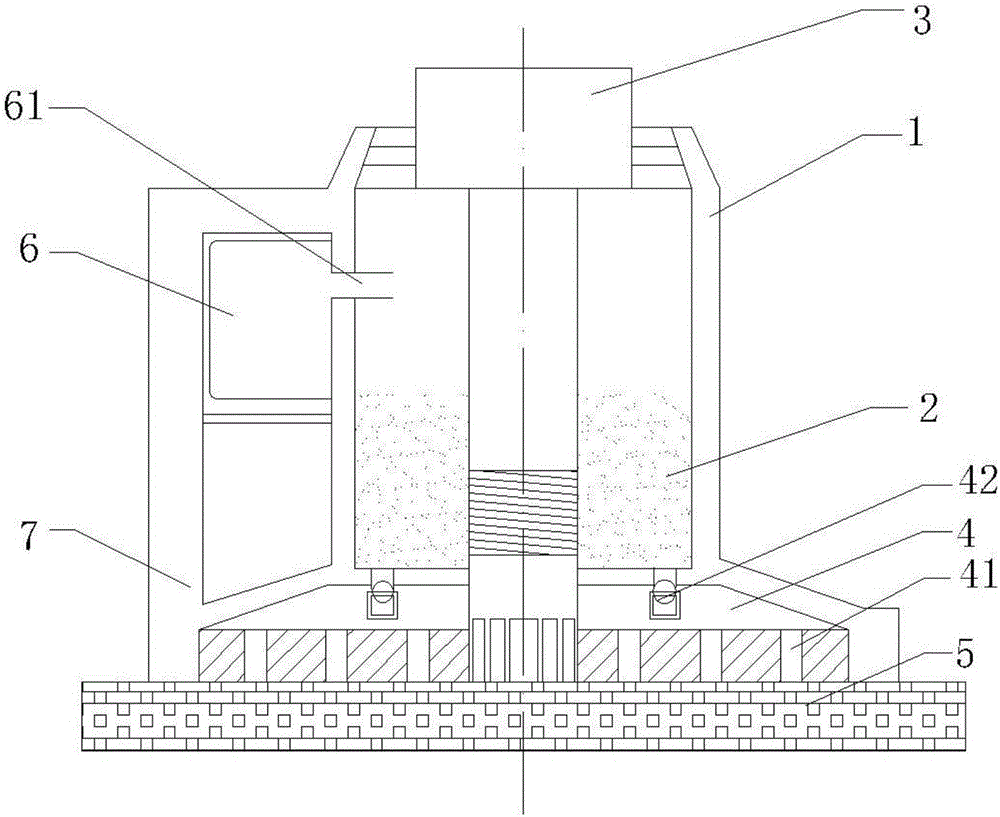

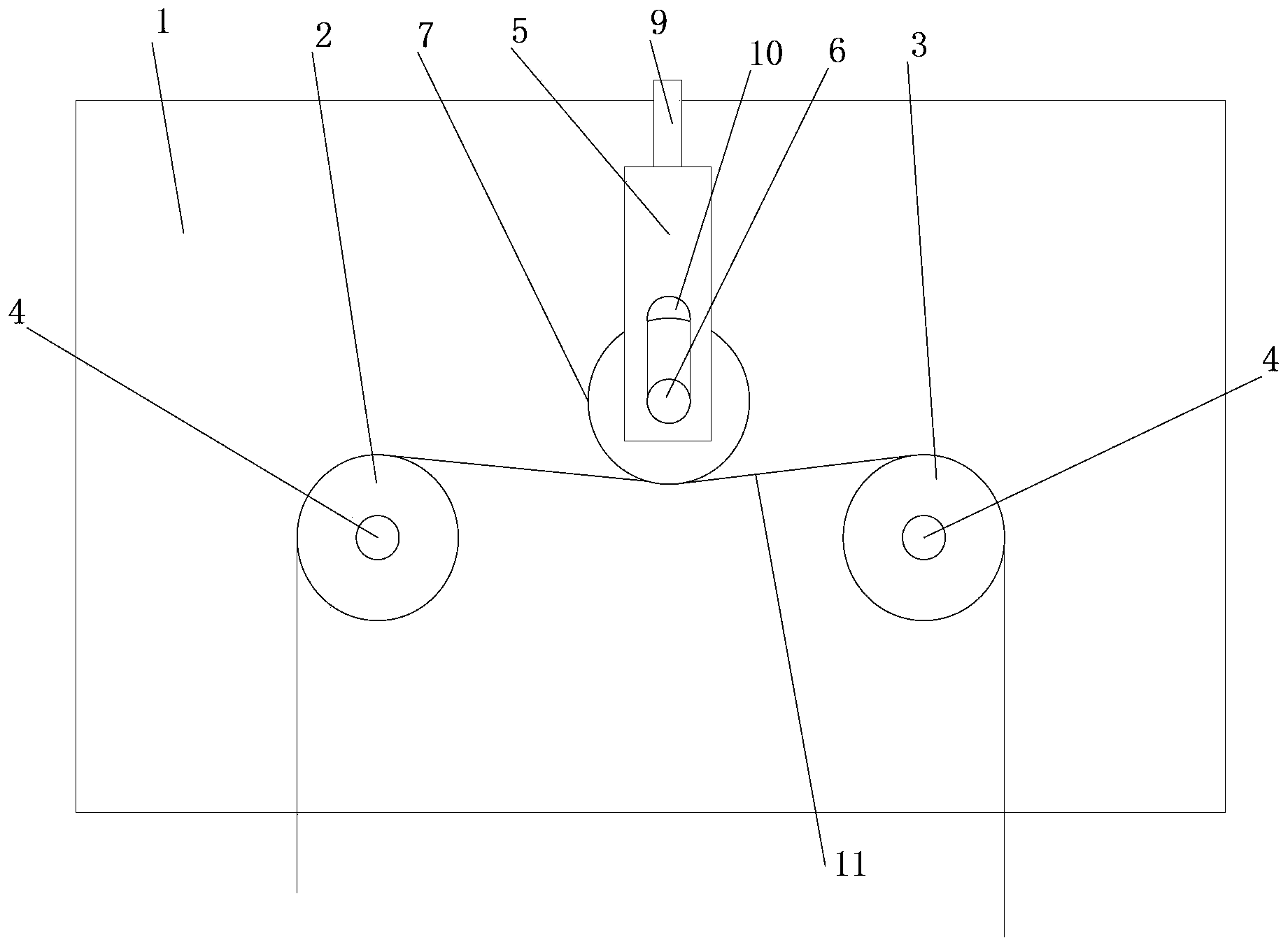

Stable waxing device for porcelain artworks

The invention relates to a waxing device, especially to a stable waxing device for porcelain artworks. The invention provides a stable waxing device for porcelain artworks and with uniform waxing effect so as to solve the technical problem. The stable waxing device for porcelain artworks comprises a support, a motor, a second guide pulley, a stay wire, a first guide pulley, a first spring, a non-return valve, a flexible pipe, an infusion pump, a second box, a first pole and the like. A first box is positioned at the left side of second springs. The second springs are symmetrically arranged at two sides of the bottom inside the first box. The upper ends of the second springs are connected to a piston which matches the first box. The bottom of the first box is provided with a drain pipe and the first pole. The effect of uniform waxing is achieved. With alternative-type clockwise rotation and anticlockwise rotation of porcelain, the porcelain is roundly waxed by sponge. Then, the porcelain waxing effect is better.

Owner:新昌县利拓科技有限公司

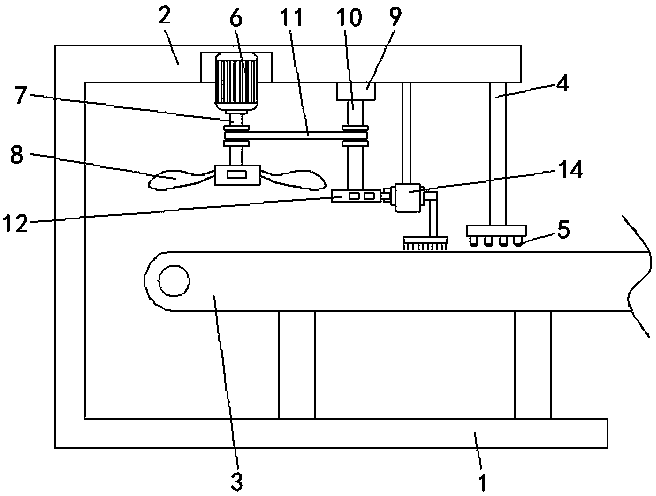

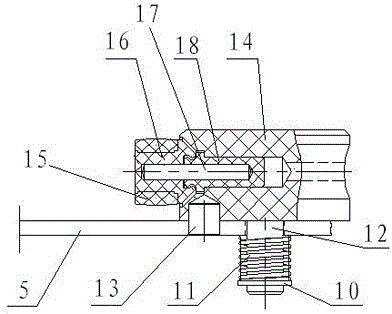

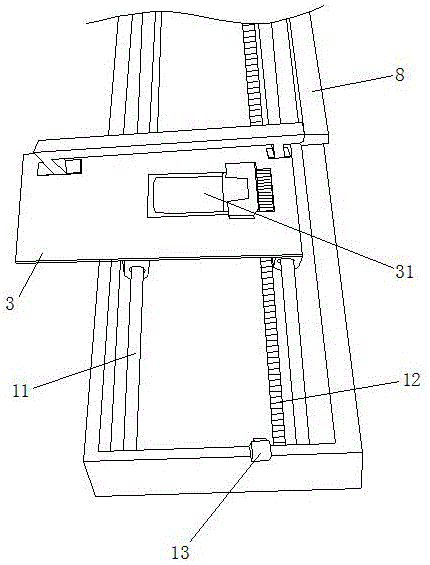

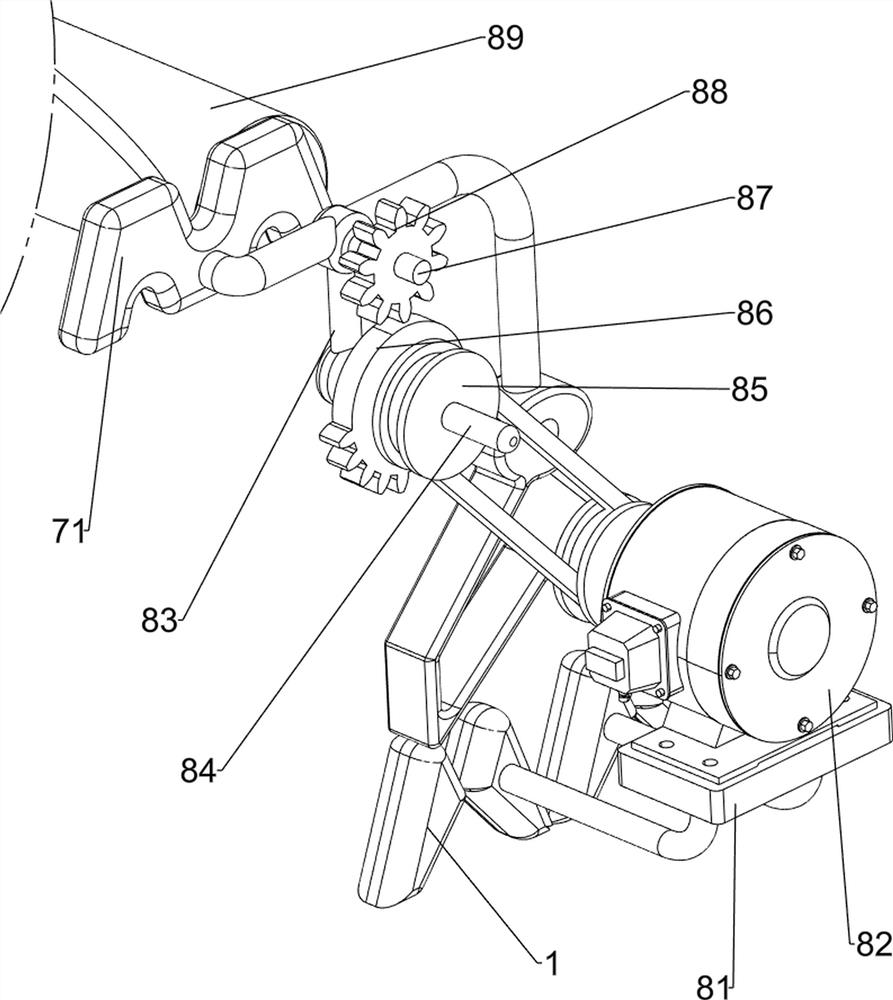

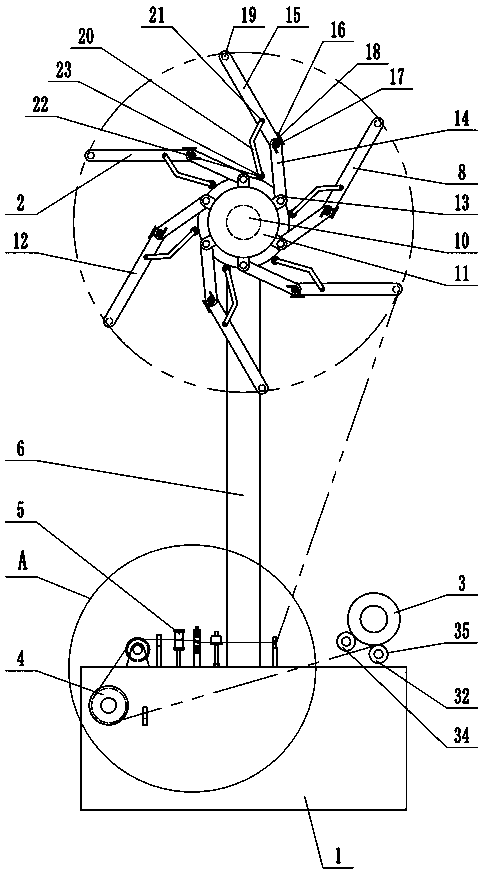

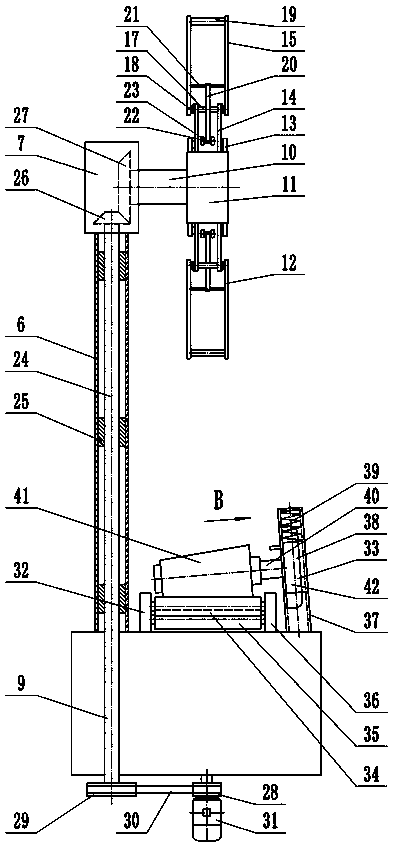

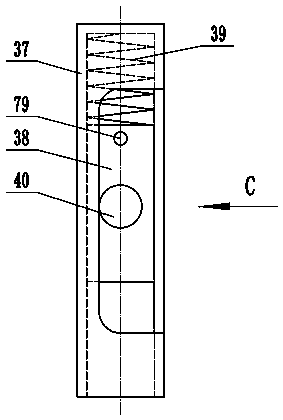

Automatic end portion edge polishing machine for stainless steel tableware

ActiveCN106312736ASimple structureCompact structureEdge grinding machinesGrinding wheel securing apparatusWheel drive

The invention relates to stainless steel tableware polishing equipment, in particular to an automatic end portion edge polishing machine for stainless steel tableware. The automatic end portion edge polishing machine comprises a base, a three-axis moving mechanism, a polishing wheel supporting frame, a waxing assembly, a polishing wheel and a polishing wheel drive motor. The three-axis moving mechanism is arranged on the base. The polishing wheel supporting frame is arranged on the three-axis moving mechanism. The polishing wheel is rotationally arranged on the polishing wheel supporting frame in the horizontal direction and is in transmission connection with an output shaft of the polishing wheel drive motor. The waxing assembly is arranged on the polishing wheel supporting frame and used for conducting waxing operation on the polishing wheel. The polishing wheel is driven by the polishing wheel drive motor to rotate around the axis of the polishing wheel and driven by the three-axis moving mechanism to swing, and therefore polishing work on the end portion of the stainless steel tableware is achieved. The automatic end portion edge polishing machine is simple and compact in structure, small in size, convenient to operate, and capable of being accurately controlled, and work efficiency is improved.

Owner:辽宁汇智机器人有限公司

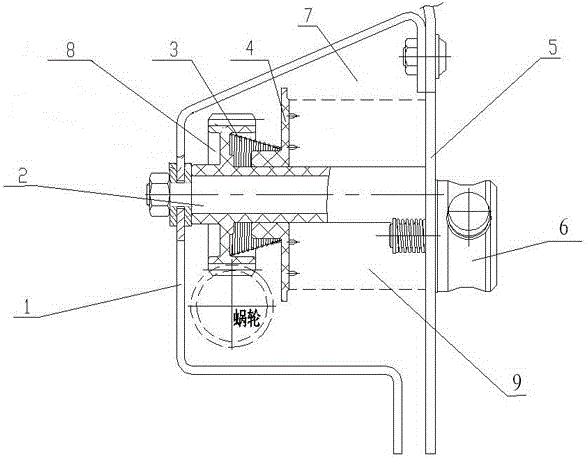

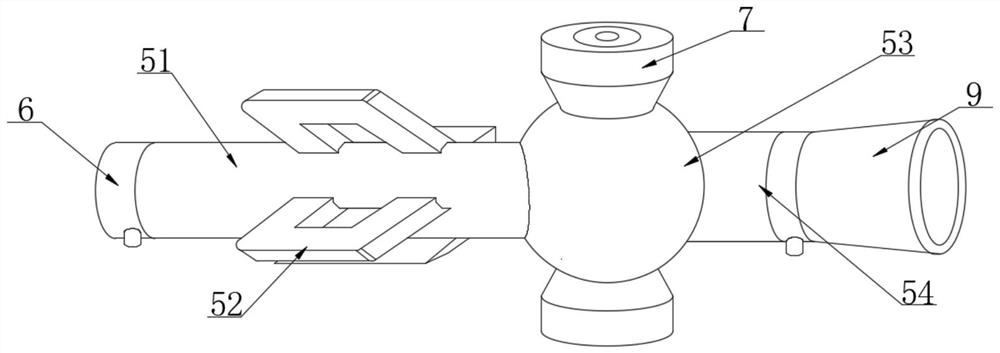

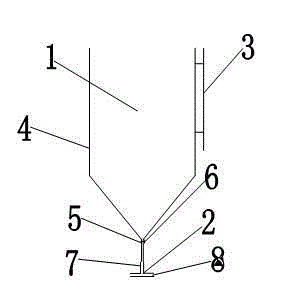

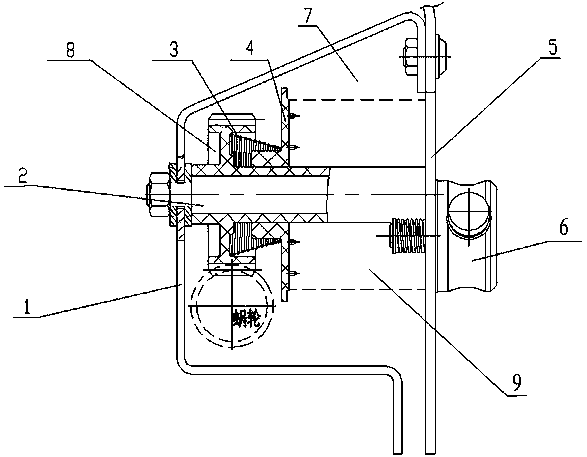

Waxing device for two-for-one twister

The invention discloses a waxing device for two-for-one twister. The waxing device for two-for-one twister comprises a wax dropping device and a waxing device and is characterized in that the wax dropping device comprises a wax storing tank and a dropping hole, the wax storing tank is provided with a liquid level balancer for keeping the liquid wax liquid level coincident and stabilizing the wax dropping speed. The waxing device is T-branch pipe, the wax receiving pipe and the dropping hole are concentric for dropping the wax into the waxing device through the dropping hole, and the yarn contacts the liquid wax through the waxing pipe for waxing for the yarn. The waxing device for two-for-one twister is simple in structure, the yarn can be directly waxed after two-for-one twisting operation, the waxing amount is controlled, the waxing is even and the waxing device for two-for-one twister is suitable for promotion use for wide range.

Owner:GUANGXI UNIV

Circulation type waxing device

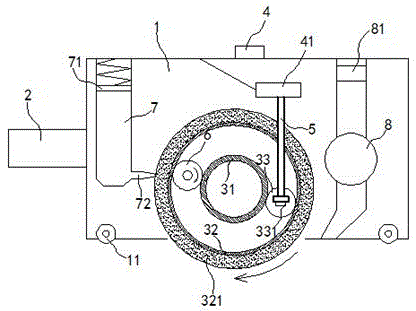

InactiveCN106002636APrevent waxing dead endsWax evenlyPolishing machinesEngine lubricationDrive motor

The invention relates to a circulation type waxing device. The circulation type waxing device is used for waxing polishing hemp wheels arranged on a rack side by side, and the polishing hemp wheels are in transmission connection with a drive motor. The circulation type waxing device comprises a sliding installation base, a mechanical arm arranged on the sliding installation base, a waxing device body arranged in the mechanical arm and a sliding rail used for installing the sliding installation base. The sliding rail is arranged on the upper portion of the rack and internally provided with at least one transversely-arranged guide rod and a rack. The sliding installation base is in sliding connection with the guide rod in a sleeving mode. The sliding installation base is internally provided with the drive motor. A main shaft of the drive motor is provided with a gear in meshed transmission with the rack. By means of the circulation type waxing device, waxing dead corners are prevented, waxing is uniform, hidden installation dangers are eradicated, and the production efficiency is improved.

Owner:苏添

Textile processing equipment

ActiveCN111876928AEvenly waxedThe wax layer is firmLiquid/gas/vapor removal by scrapingTextile treatment carriersTextile yarnWoven fabric

The invention discloses textile processing equipment which comprises a machine body, an unwinding device arranged on the machine body, a winding device arranged on the machine body, a wax melting boxlocated between the unwinding device and the winding device and arranged on the machine body, a waxing device arranged on the wax melting box, a yarn pulling device and a wax applying device used forapplying wax on textile yarns. According to the textile processing equipment, automatic feeding and discharging of the yarns are achieved, the automation degree is high, waxing is uniform, and a wax layer is firm.

Owner:义乌市大鼎纺织有限公司

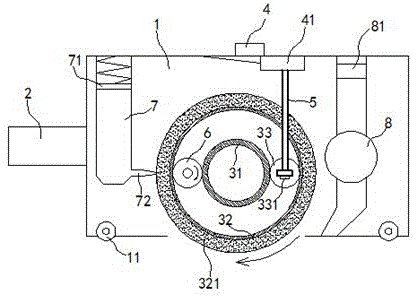

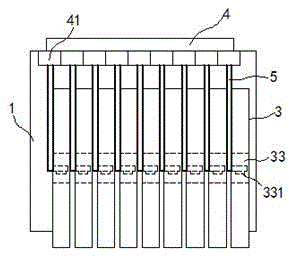

A waxing mechanism of a rotor spinning machine

The invention relates to a waxing mechanism for a rotor spinning machine. The waxing mechanism comprises a fixing frame, a worm gear pin shaft, a conical compression spring, a tray, a waxing face plate and a waxing support roller mechanism, wherein the fixing frame is of a concave structure; a gear body is arranged in the middle of the worm gear pin shaft in a protruding manner; the worm gear pin shaft is arranged in the concave structure of the fixing frame and can rotate on the fixing frame; the tray sleeves the worm gear pin shaft in a sliding manner; the conical compression spring sleeves a part between a gear body side of the worm gear pin shaft and the tray; a hole for a wax block mounted on the tray to extend out is formed in the waxing face plate; the waxing support roller mechanism is respectively arranged on two sides of the hole; the waxing support roller mechanism connects a yarn to the wax block in a compression manner; the upper face plate covers the upper part of the concave structure of the fixing frame in a fixing manner. The waxing mechanism provided by the invention is added without changing the entire structure of the rotor spinning machine, so that the yarn is waxed uniformly, and the quality of the yarn is improved.

Owner:JINGWEI TEXTILE MASCH CO LTD

Surface waxing equipment for producing and processing wooden products

The invention discloses surface waxing equipment for producing and processing wooden products. The surface waxing equipment includes a processing station, and is characterized in that the upper end ofthe processing station is symmetrically vertically and fixedly connected with two supporting rods, a horizontal frame is fixedly connected onto the two supporting rods, the bottom of the horizontal frame is provided with a driving mechanism, the driving mechanism is arranged above the processing station, a cavity is formed in the processing station, two horizontally arranged struts are symmetrically fixedly connected to the inner side wall of the cavity, one end, far away from the inner side wall of the cavity, of each strut is connected with a brush block, a collecting barrel is fixedly connected on the bottom of the cavity, and a discharge pipe communicates with the side wall of the collecting barrel. The surface waxing equipment has the advantages of stable structure, simple operation,scientific and reasonable design and short production period, and can more conveniently pull the orientation of wooden products for moving, so that the wooden products are uniformly waxed in the processing station, and the excess wax can be filtered and reused.

Owner:湖州世合纺织有限公司

Leather waxing device for garment production

InactiveCN112609026AEasy to collect and processConvenient cutting workLeather clicking/perforating/clickingLeather surface finishingManufacturing engineeringMechanical engineering

The invention relates to a waxing device, in particular to a leather waxing device for garment production. The technical problem to be solved by the invention is to provide the leather waxing device for garment production, which is relatively simple to operate, relatively high in working efficiency and capable of uniformly waxing leather. The leather waxing device for garment production comprises: a first supporting base; second supporting frames which are installed on the two sides of the first supporting base; a first sliding rail which is mounted between the second supporting frames; a rotating mechanism which is mounted on the first supporting base; and a waxing mechanism is mounted on the first sliding rail. According to the leather waxing device, leather is controlled to move through the rotating mechanism, so that the waxing mechanism waxes the leather conveniently, and meanwhile, the waxing mechanism can be controlled to reciprocate front and back, so that the waxing mechanism waxes the leather more uniformly.

Owner:郭铭鸿

Reeling equipment for wool yarn

InactiveCN111232744AGuaranteed stabilityEasy accessFilament handlingTextiles and paperYarnStructural engineering

The invention provides reeling equipment for wool yarn, and belongs to the technical field of textile machines. The reeling equipment comprises a reeling rack, a reeling mechanism, an unreeling mechanism, a guide mechanism and a hair removing and waxing mechanism. A reeling frame of the reeling mechanism is rotationally arranged on one side of a reeling bearing box, three or more reeling frame assemblies are evenly arranged on a reeling frame supporting disc, and the unreeling mechanism comprises an unreeling bearing assembly and an unreeling compressing assembly. An unreeling bearing slidingblock of the unreeling compressing assembly is slidably and rotationally arranged in an unreeling compressing bearing tube, an unreeling shaft is rotationally arranged on one side of the unreeling bearing sliding block, and the unreeling shaft penetrates through a tube replacing groove of the unreeling compressing bearing tube. The hair removing and waxing mechanism is arranged between a second guide screen ad a guide ring, and comprises a tensioning assembly, a hair removing assembly and a waxing assembly. According to the reeling equipment, fast discharging of hank yarn can be achieved afterreeling is completed, hair can be effectively removed in the reeling process of the wool yarn, and the glossiness and elasticity of the wool yarn are improved.

Owner:周顺尧

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com