Yarn waxing device for knitting machines

A weaving machine and yarn technology, applied in textiles and papermaking, etc., can solve the problems of wax block consumption, uneven waxing on the yarn surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

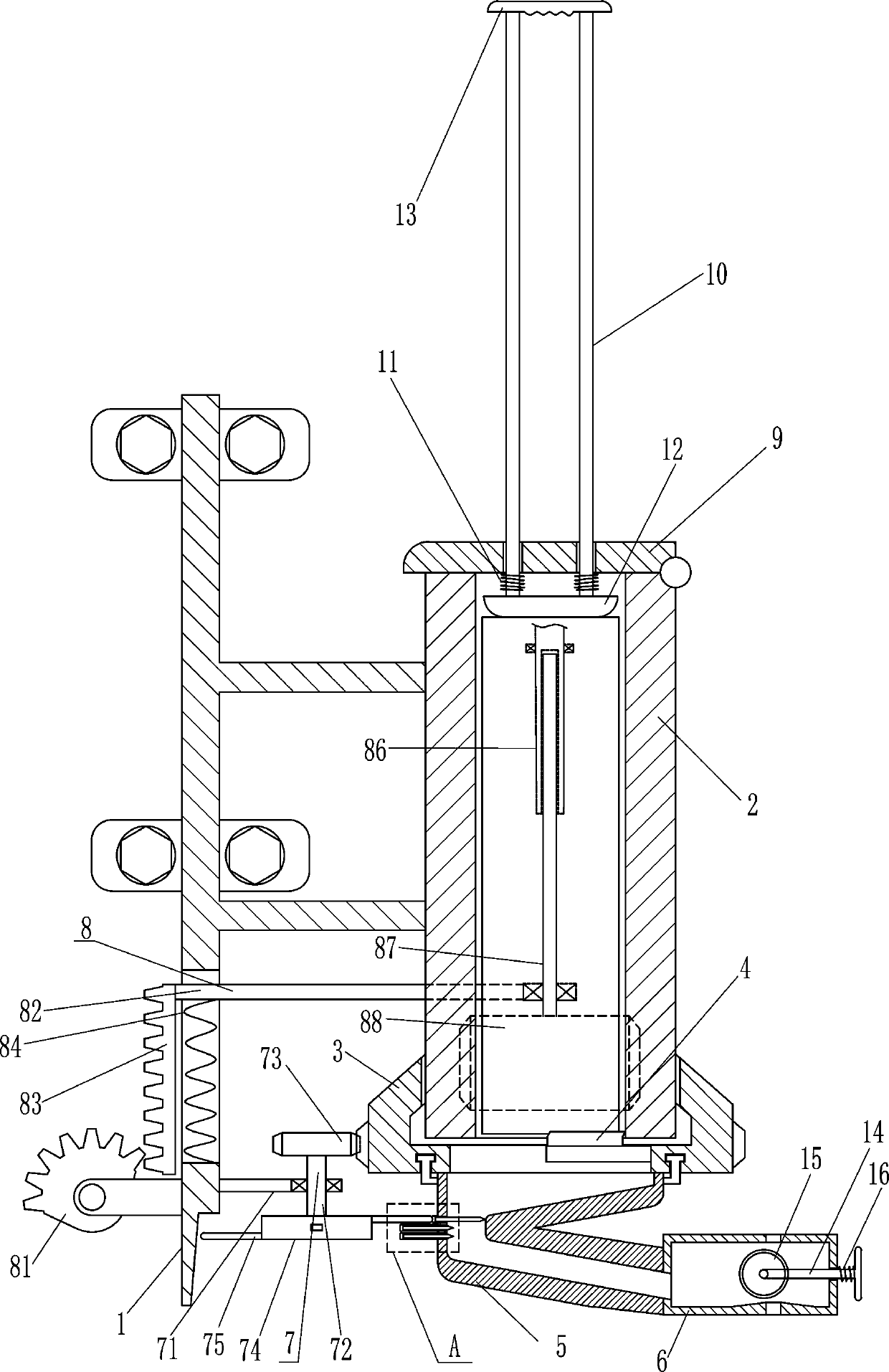

[0023] A yarn waxing device for knitting machines, please refer to figure 1 , image 3 and Figure 5 , including mounting frame 1, cylinder 2, outer ring gear 3, scraper 4, discharge pipe 5, waxing frame 6 and chopping device 7, cylinder 2 is installed on the right side of mounting frame 1, and the lower part of cylinder 2 rotates The outer gear ring 3 is equipped with an outer gear ring 3, and a scraper 4 for scraping the wax block is installed in the outer gear ring 3. The scraper 4 is located at the lower part of the cylinder 2, and the lower part of the outer gear ring 3 is rotated. The pipe 5 communicates with the outer ring gear 3, the right side of the discharge pipe 5 is equipped with a waxing frame 6 for storing wax debris, the waxing frame 6 communicates with the discharge pipe 5, and the left side of the outer ring gear 3 is provided with a chopping device 7, wherein the chopping device 7 is used to chop the scraped wax block.

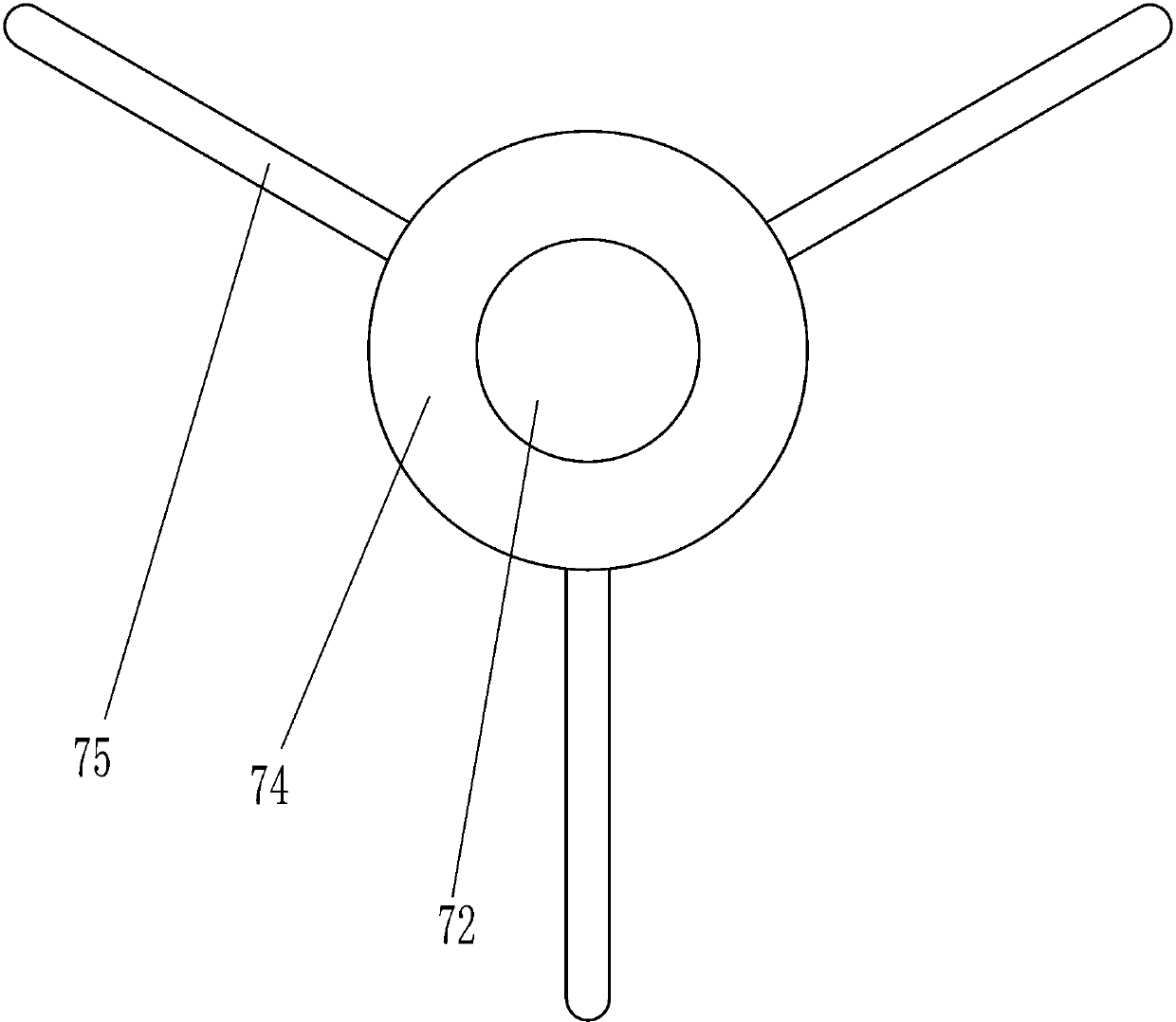

[0024] The shredding device 7 incl...

Embodiment 2

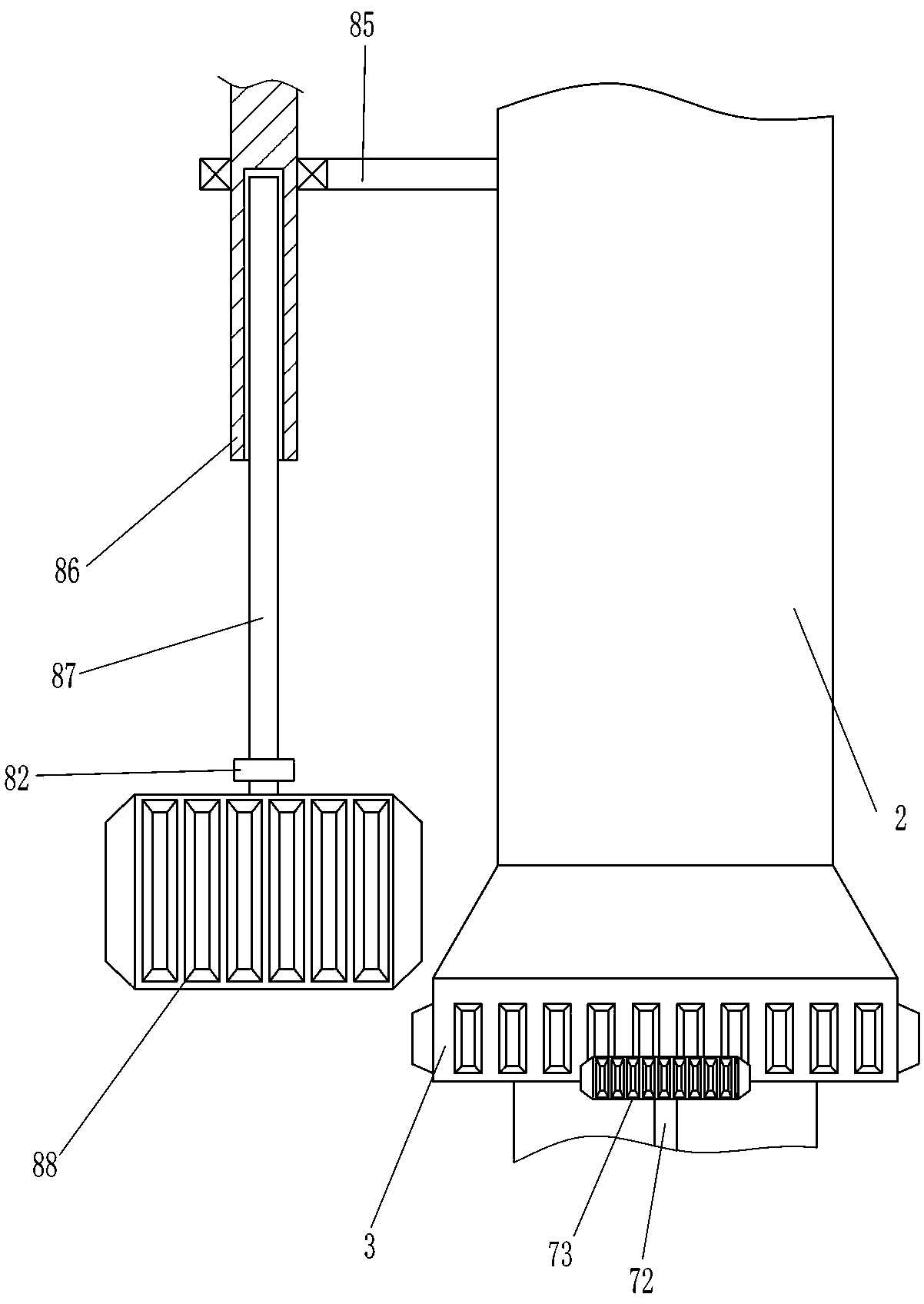

[0027] On the basis of Example 1, please refer to figure 1 , figure 2 , Figure 6 and Figure 7 , also includes driving device 8, and driving device 8 includes sector gear 81, movable rod 82, rack 83, first spring 84, cross bar 85, hexagonal cylinder 86, hexagonal rod 87 and column gear 88, mounting frame 1. A sector gear 81 is installed on the lower left side, and the power source of the knitting machine is connected with the sector gear 81. The sliding type of the mounting frame 1 bottom is provided with a movable rod 82, and a rack 83 is vertically installed on the left end of the movable rod 82. The rack 83 is connected to the Sector gear 81 is meshed, first spring 84 is connected between the bottom of movable bar 82 and mounting frame 1, cross bar 85 is installed on cylinder 2 rear side upper part, and cross bar 85 rear end rotation type is provided with hexagonal cylinder 86, and knitting machine The power source is connected with the hexagonal cylinder 86, and the h...

Embodiment 3

[0030] On the basis of Example 2, please refer to figure 1 and Figure 4, also includes a cover plate 9, a slide bar 10, a second spring 11, a pressure plate 12 and a handle 13, the top right side of the cylinder 2 is rotatably provided with a cover plate 9, and the cover plate 9 is slidably provided with two slide bars 10 , the lower part of the slide bar 10 is located in the cylinder 2, the second spring 11 is connected between the lower part of the slide bar 10 and the bottom of the cover plate 9, the second spring 11 is in a compressed state, the bottom of the slide bar 10 is equipped with a pressure plate 12, and the top of the slide bar 10 A handle 13 is installed.

[0031] Also comprise pull bar 14, guide wheel 15 and the 3rd spring 16, waxing frame 6 right wall sliding type is provided with pull bar 14, pull bar 14 left ends are equipped with guide wheel 15, between pull bar 14 right parts and waxing frame 6 outer right walls A third spring 16 is connected between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com