Waxing mechanism of rotor spinning machine

A technology of rotor spinning machine and pin shaft, which is applied in the direction of textiles and papermaking, and can solve the problems of affecting yarn quality and uneven waxing on yarn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

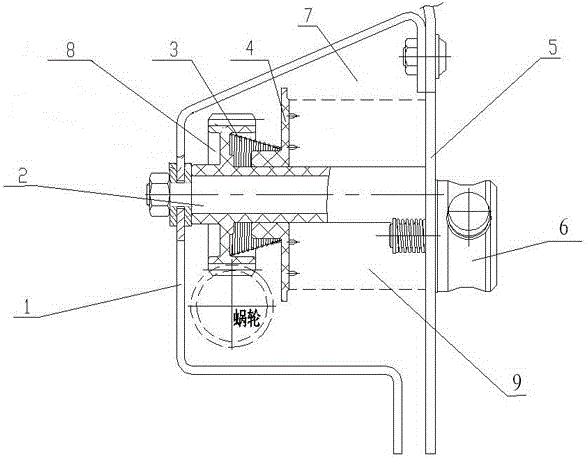

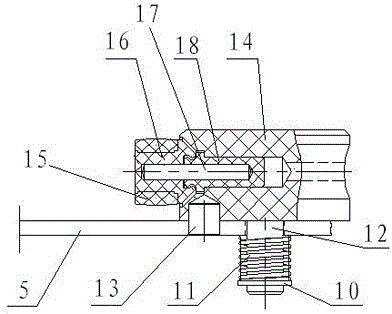

[0012] Such as figure 1 As shown, a waxing mechanism of a rotor spinning machine, which includes a fixed frame 1, a worm gear pin shaft 2, a conical pressure spring 3, a tray 4, a waxing panel 5 and a waxing support roller mechanism 6, the fixed The frame 1 is a concave structure 7, and the middle part of the worm gear pin shaft 2 is protrudingly provided with a gear body 8, the worm gear pin shaft 2 is arranged in the concave structure 7 of the fixed frame 1 and can rotate on the fixed frame 1, and the tray 4 slides Set on the worm gear pin shaft 2, a tapered pressure spring 3 is set between the side of the gear body 8 of the worm gear pin shaft 2 and the tray 4, and a wax block 9 protruding from the waxing panel 5 is provided. Holes, a waxing support roller mechanism 6 is respectively arranged on both sides of the hole, the waxing support roller mechanism 6 presses the yarn on the wax block 9, and the waxing panel 5 is covered with a concave shape fixed on the fixed frame 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com