Cloth waxing device

A cloth and control device technology, which is applied in the direction of cleaning device for processing textile materials, equipment configuration for processing textile materials, processing of textile materials, etc. Wax effect, effect of reduced time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

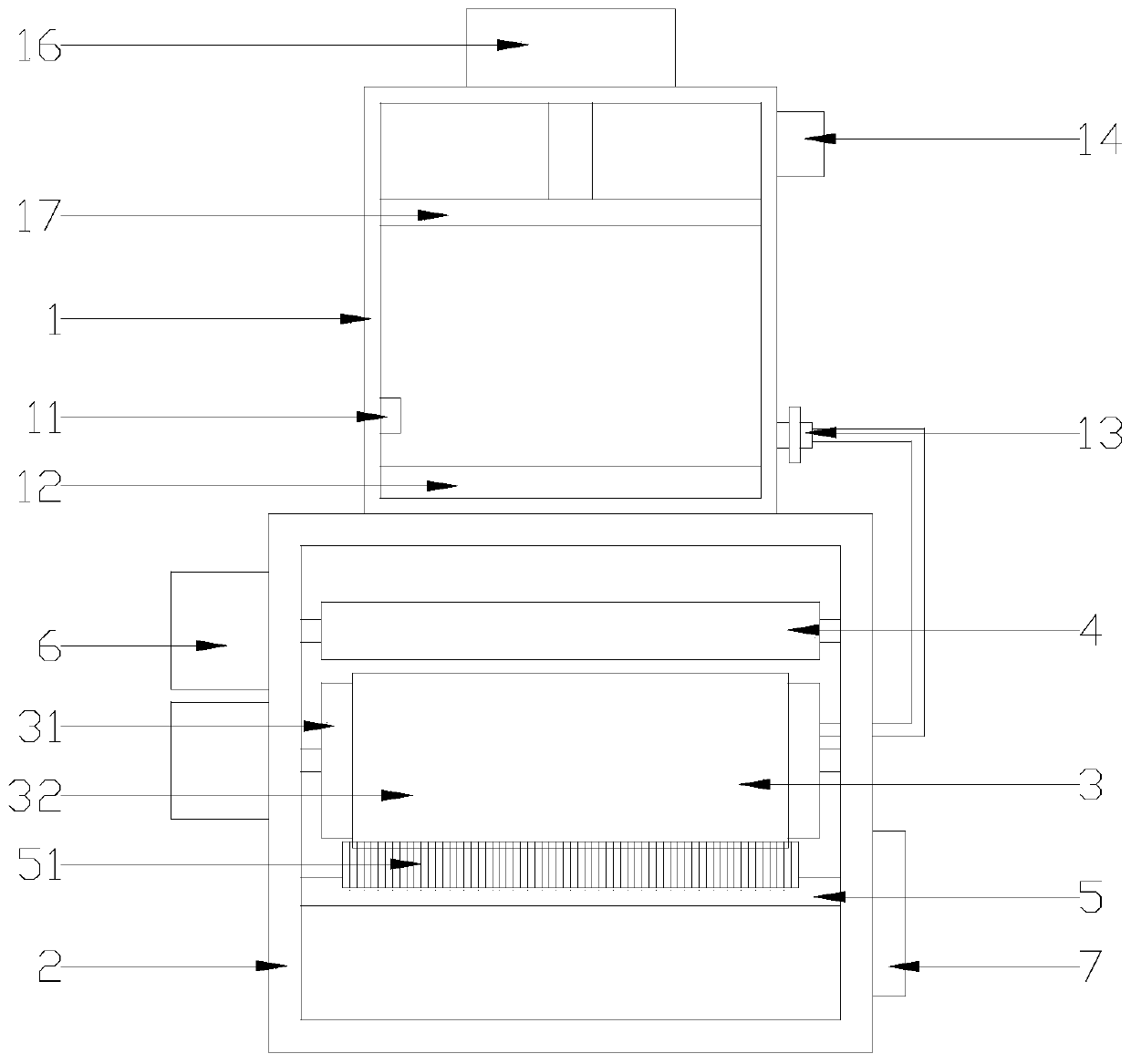

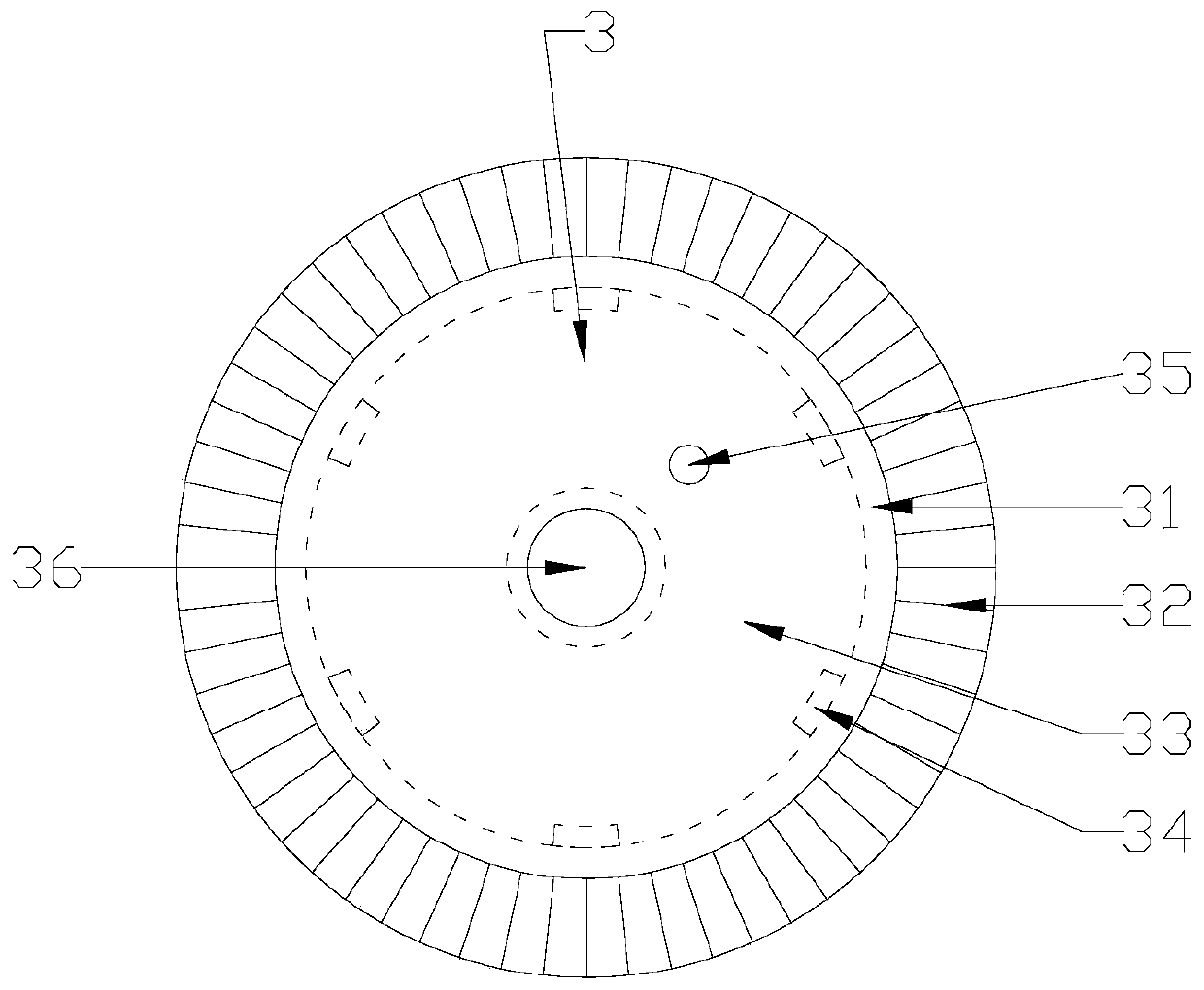

[0014] refer to figure 1 with figure 2 , a fabric waxing device of the present invention, comprising a wax filling box 1, an outer shell 2, a waxing roller 3, a cloth conveying roller 4, a cleaning comb 5, a motor unit 6 and a control device 7, and the cloth conveying roller 4 is fixed on Both sides inside the outer casing 2 are close to the feed inlet and the outlet. The waxing roller 3 is fixed between the cloth delivery rollers 4 on both sides of the outer casing 2. The waxing roller 3 includes a rotating shaft 36, sleeved The drum 31 on the rotating shaft 36 and the side covers 33 positioned at both sides of the drum 31, the drum 31 is provided with a cavity and the inner wall is fixed with several first heating blocks 34, the drum wall of the drum 31 There are several through holes and the outer surface is provided with bristles 32, the cleaning comb 5 is fixed inside the outer shell 2, the cleaning comb 5 is located under the waxing roller 3 and the comb teeth 51 are i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com