Intelligent stainless steel product starting die head wax injection machine

A wax injection machine, stainless steel technology, applied in the direction of casting molding equipment, etc., can solve the problems of wax splash, environmental pollution, poor wax injection effect, etc., to ensure the uniformity of wax injection, ensure the efficiency of wax injection, and ensure the protection effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

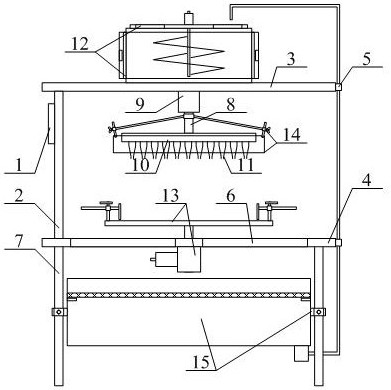

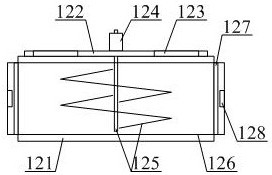

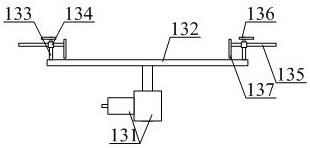

[0034]The present invention will be described in detail below in conjunction with the accompanying drawings. As shown in accompanying drawings 1 and 2, an intelligent stainless steel product starting touch wax injection machine includes an intelligent control panel 1, a support base 2, a frame 3, and a machine base 4. Clamp 5, material leakage hole 6, support leg 7, wax injection pipe 8, hydraulic wax injection pump 9, wax spray row 10, wax spray head 11, stirring anti-freezing heating insulation cylinder structure 12, adjustable by rotation The product clamping plate structure 13, the movable splash guard structure 14 and the recycled wax recovery filter box structure 15, the intelligent control panel 1 is connected to the upper left side of the support base 2 by longitudinal screws; the support base 2 One end of the longitudinal bolt is connected to the lower left side of the frame 3, and the other end is bolted to the upper left side of the frame 4; the right ends of the fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com