Citrus cleaning, waxing and polishing integrated machine high in integrity and high in speed

A waxing, polishing, and high-speed technology, applied in applications, food processing, food science, etc., can solve the problems of uncontrollable process, increased production time, time-consuming and labor-intensive problems, and achieve scientific overall design of equipment, reduce production time, and concise process smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

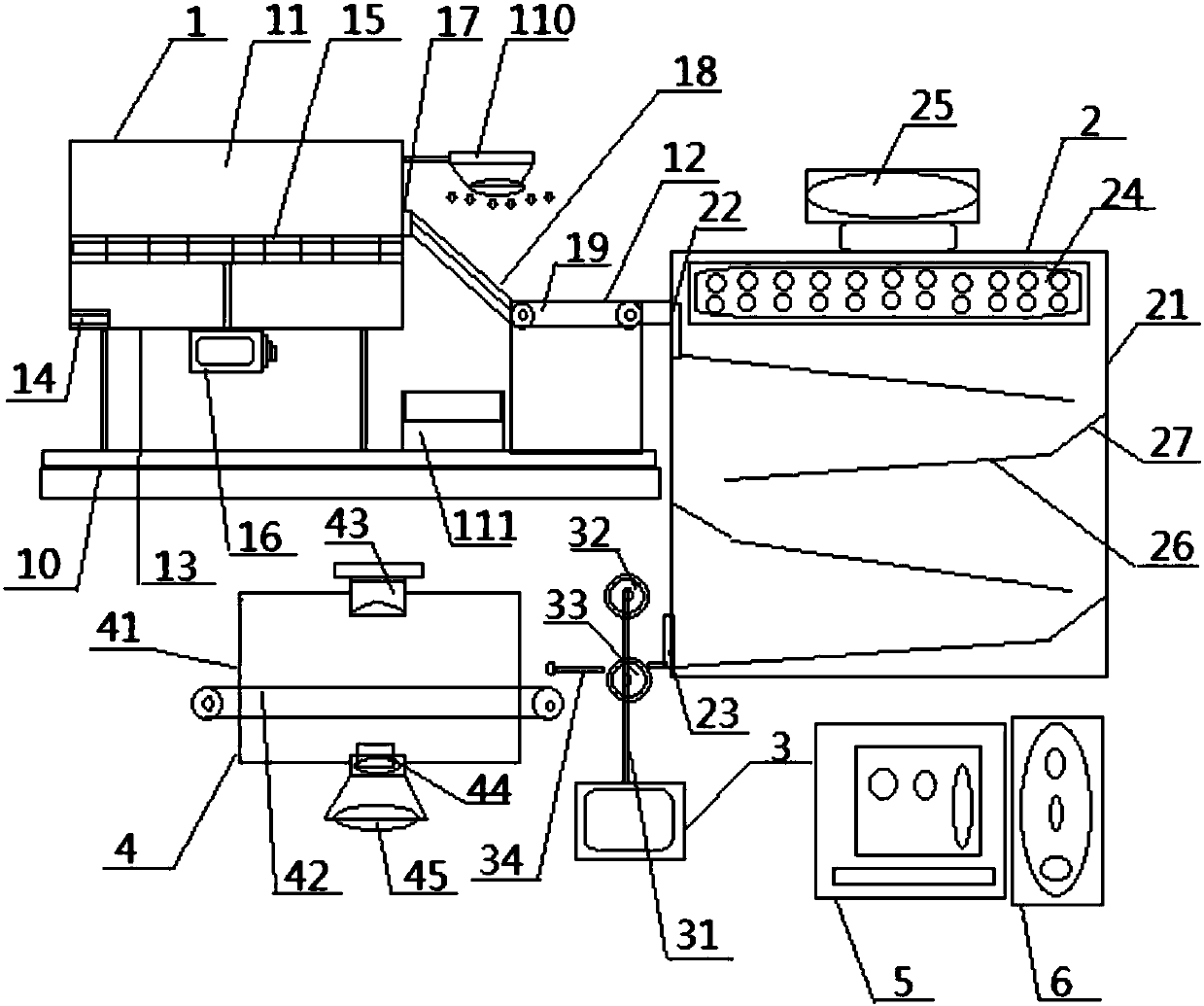

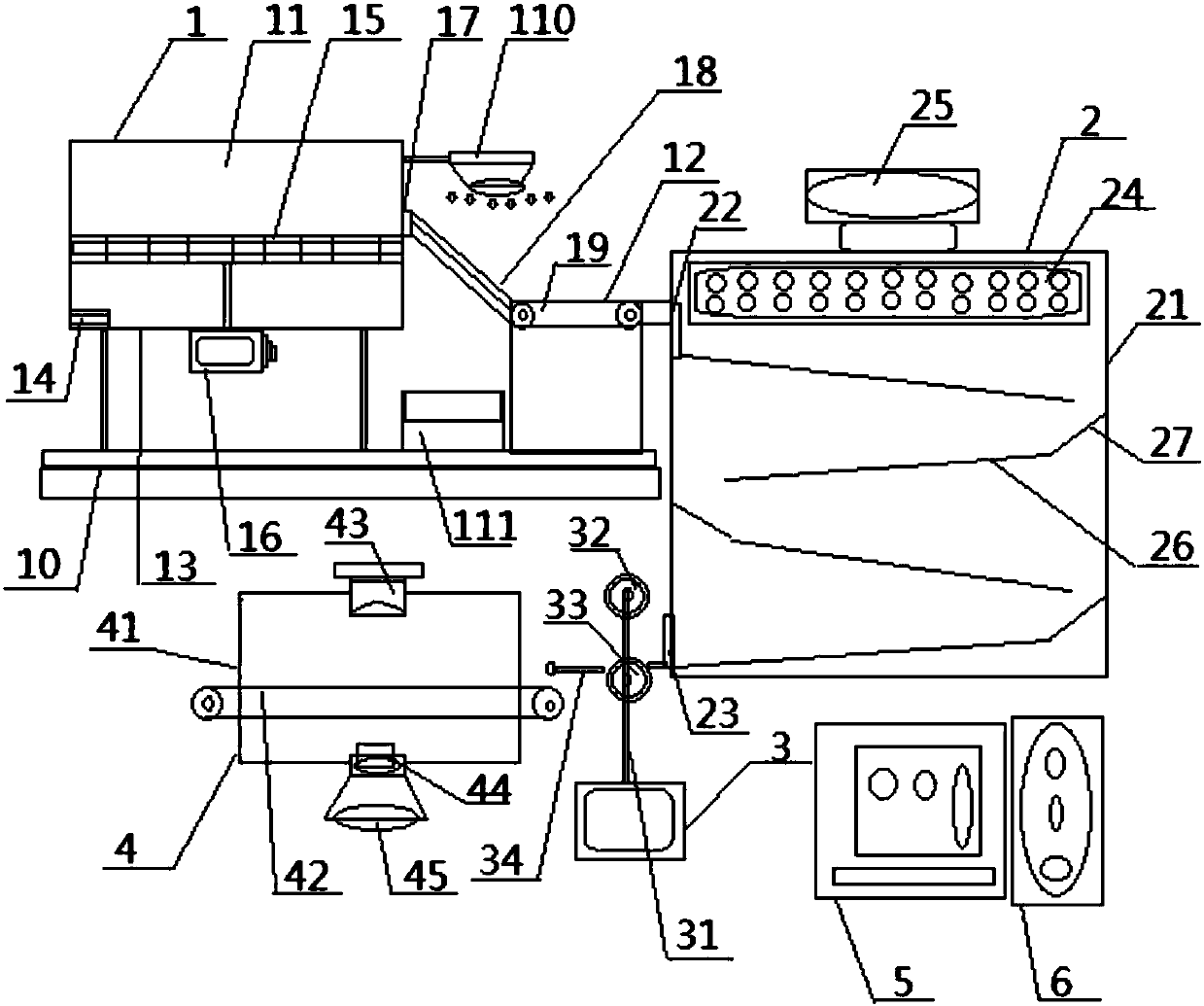

[0030] In the following, in conjunction with the accompanying drawings, the technical solution of a citrus cleaning, waxing and polishing integrated machine with high integration and fast speed provided by the present invention will be further described, so that those skilled in the art can better understand and implement the present invention.

[0031] See figure 1 , An integrated citrus cleaning, waxing and polishing machine with high integration and high speed, which is characterized in that it includes a washing dryer 1, a citrus waxing machine 2, a polishing machine 3, a constant temperature air dryer 4, a safety power supply 5 and an equipment controller 6. The citrus is first washed and dried in a washing and drying machine, then waxed in a citrus waxing machine, polished in a polishing machine, and finally dried in a constant temperature air dryer. The citrus waxing process is simple and smooth, with high integration and fast speed. The overall design is scientific, energ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com