Waxing device for textile processing

A technology of textile thread and wax roller, applied in the field of textile processing, can solve the problems of waste and low utilization rate of wax blocks, and achieve the effect of avoiding waste and saving resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

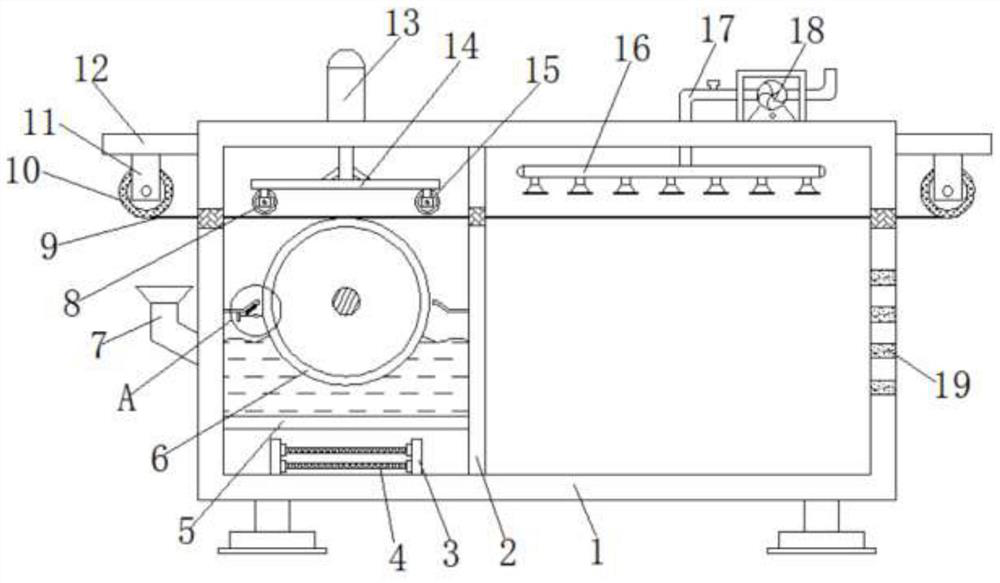

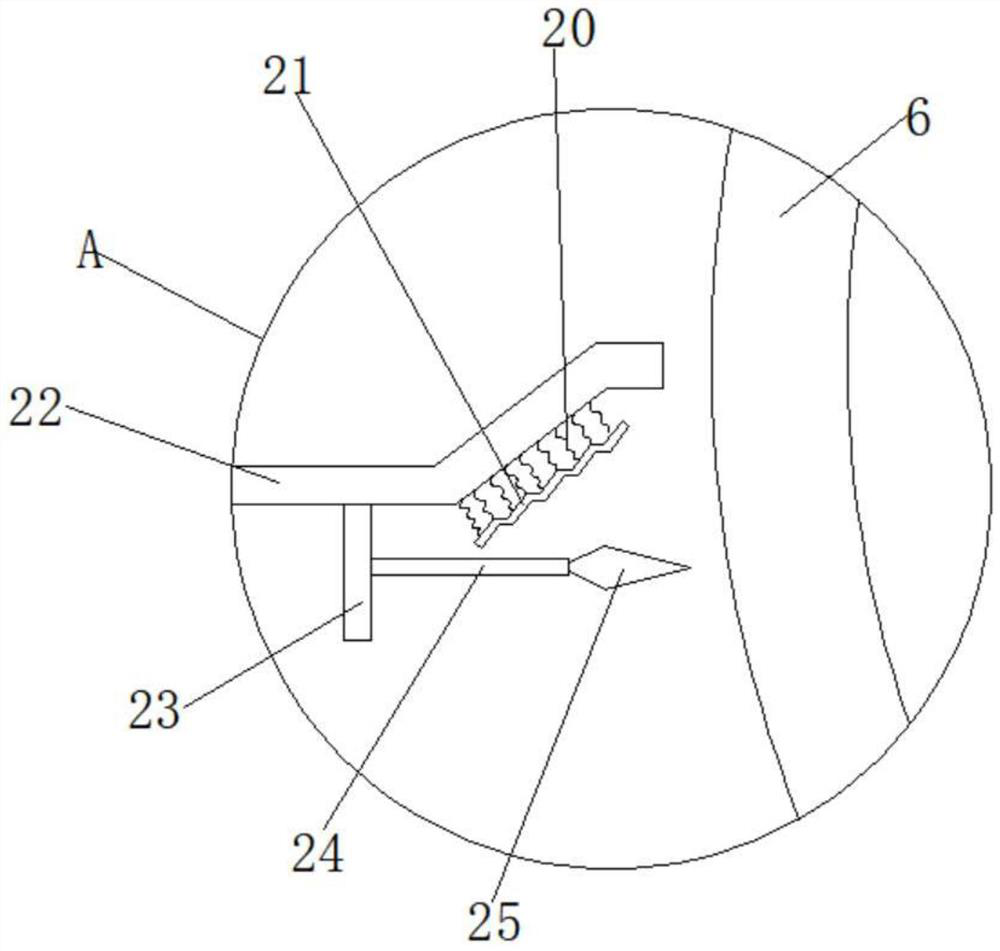

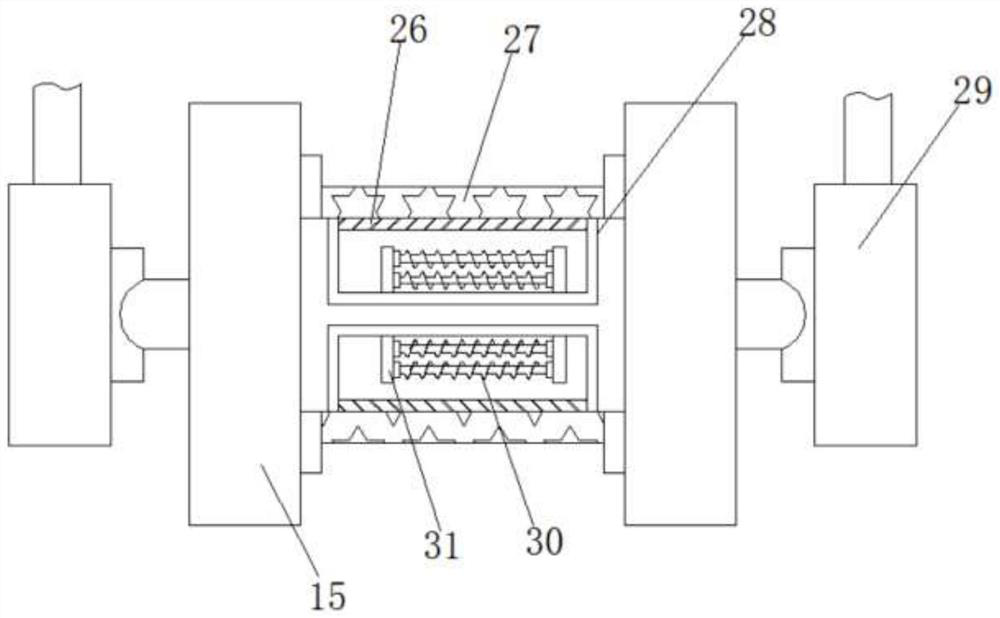

[0034] refer to Figure 1-5 , a waxing device for textile processing, comprising a box body 1, a feed hopper 7 is plugged into one side of the box body 1, and a first connecting plate 5 is welded on one side of the box body 1 inner wall, and the box body 1 The inner wall of the bottom is connected with the first mounting plate 3 by bolts, and the first resistance wire 4 is connected to the outer wall of one side of the first mounting plate 3 by bolts, and the outer wall of one side of the box body 1 is connected with the protective shell 32 by bolts, and the protective shell One side inner wall of 32 is connected with a motor by bolts, and one end of the output shaft of the motor is provided with a waxing roller 6, and the waxing roller 6 is located inside the box body 1, and one side outer wall of the box body 1 is connected with a second fixing plate 12 by bolts , and the bottom outer wall of the second fixed plate 12 is connected with the first fixed plate 11 by bolts, one ...

Embodiment 2

[0045] refer to Image 6 , a waxing device for textile processing. Compared with Embodiment 1, the inner walls of both sides of the box body 1 are rotatably connected with transmission rollers 33, and the textile thread 9 and the transmission roller 33 form a transmission connection.

[0046] Working principle: when waxing the textile thread, people can first add the wax block to the bottom of the box body 1 through the feed hopper 7, and the wax block added to the bottom of the box body 1 can be heated by the first resistance wire 4 to form wax oil Then people start the motor, and the motor drives the waxing roller 6 to rotate, and the wax oil at the bottom of the casing 1 can be adhered to its surface when the waxing roller 6 rotates, and then the textile thread 9 contacts with the waxing roller 6, which can Completing the waxing work on the textile thread 9 saves resources more than traditional wax block waxing, and avoids the waste of a large number of wax blocks due to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com