Novel constant force polishing and waxing device

A constant force and new technology, applied in the field of polishing machinery, can solve the problems of non-compact structure of cloth throwing wheel, uneven waxing, complex structure, etc., and achieve the effect of compact structure, uniform waxing and improved working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

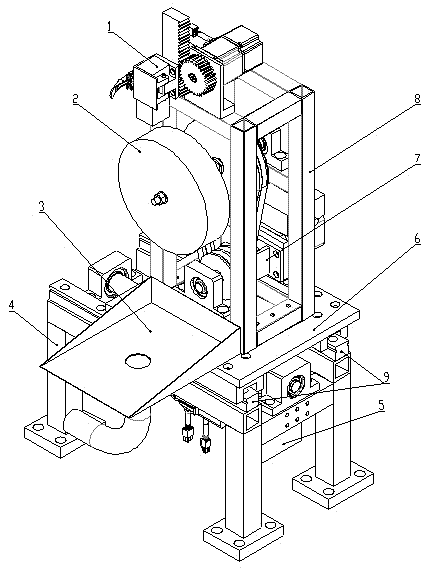

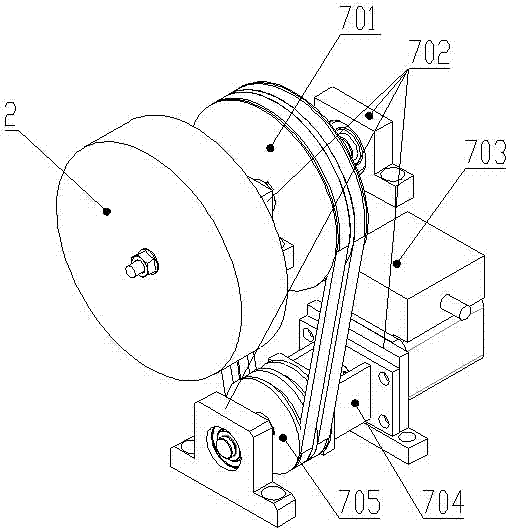

[0026] like Figure 1 to Figure 5 As shown, a new type of constant force polishing and waxing device includes a first frame 4, the top of the first frame 4 is provided with a support plate 6 that can move back and forth along the guide rail, and the upper surface of the support plate 6 is provided with There is a second support 8, which also includes a waxing mechanism arranged on the upper end of the second support 8, a mobile module 5 arranged on the first frame 4, a polishing module 7 arranged on the support plate 6 and positioned below the waxing mechanism and The cloth throwing wheel 2 drivingly connected with the polishing module 7 , and the dust collection module 3 arranged on the support plate 6 and the second support 8 and located below the cloth throwing wheel 2 .

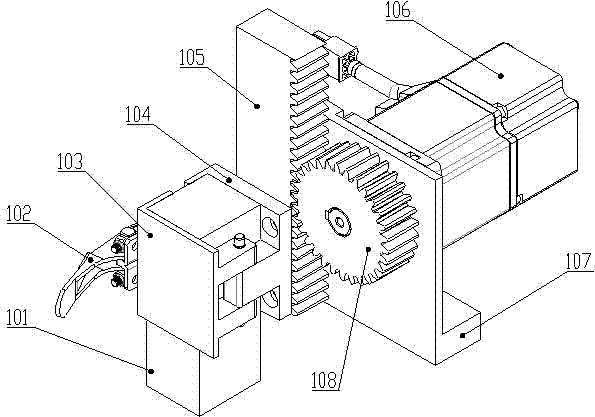

[0027] like figure 2 As shown, the waxing mechanism includes a waxing module 1, the fixed plate 107 of the waxing module 1 is fixed on the second frame 8, and the wax strip 101 passes through the hinged...

Embodiment 2

[0033] like Image 6 and Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that the waxing mechanism includes a wax spraying module 10, the cylinder 1002 of the wax spraying module 10 is fixed on the second frame 8 through the cylinder fixing plate 1001, and the wax bottle 1011 is fixed on the second frame 8 through the first support seat 1008 of the wax bottle and the second support seat 1010 of the wax bottle, the moving plate 1004 is fixed on the slide block 1005, and the cylinder 1002 drives the moving plate 1004 along with the The slide block 1005 slides along the guide rail 1006 fixed on the second frame 8, thereby driving the push plate 1007 fixed on the moving plate 1004 to move along the direction of the guide rail 1006, and then presses the nozzle of the wax bottle 1011 to spray the liquid wax onto the cloth. Above the throwing wheel 2, a rotation stopper pin 1009 to prevent the wax bottle 1011 from rotating is set on the first support s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com