Waxing device capable of automatically feeding wax

An automatic waxing and fixing plate technology, which is applied in transportation and packaging, vehicle maintenance, vehicle maintenance/repair, etc., can solve the problems of unfixed waxing amount, troublesome operation, too much or too little waxing, etc., to avoid The effect of too much or too little wax and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

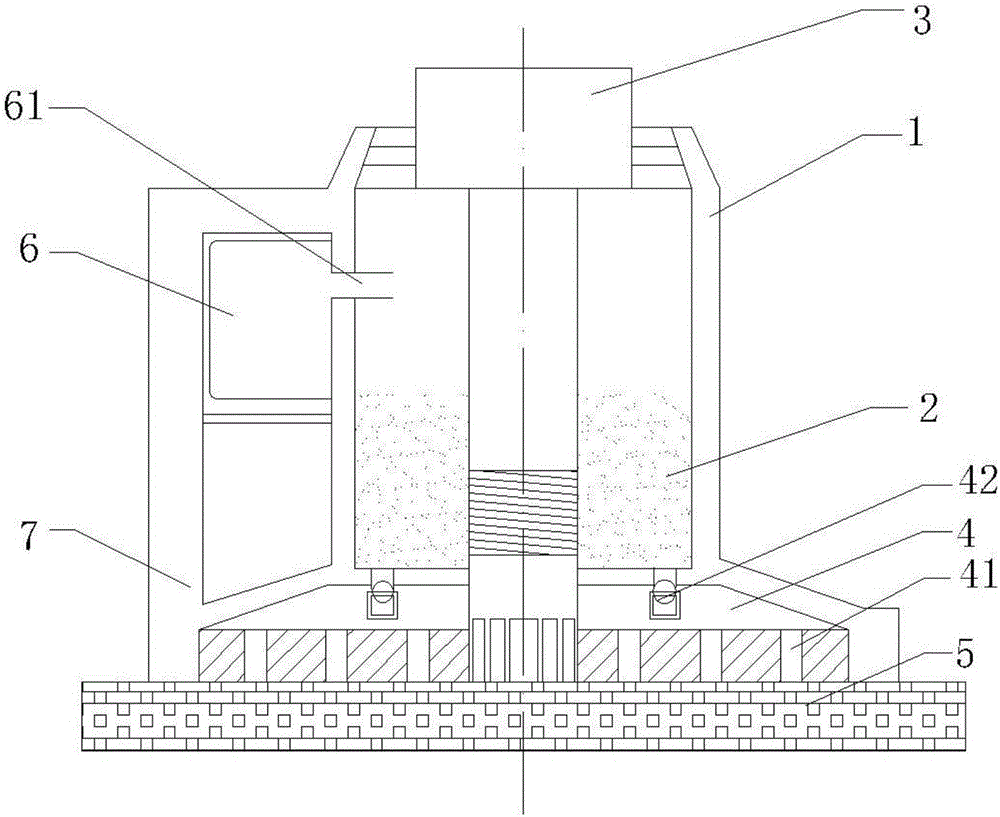

[0016] The embodiment is basically as figure 1 Shown:

[0017] The waxing device that can wax automatically in this embodiment includes a housing 1, a motor 3, a fixed plate 4 and a waxing brush 5, the motor 3 is located at the top of the housing 1, the output shaft of the motor is splined with the fixed plate 4, and the fixed plate 4 and the waxing brush 5 are connected by a detachable connection such as a lock connection. The fixed plate 4 is connected to the housing 1 in rotation. The housing 1 is provided with a storage chamber 2 with a closed upper end, and the motor output inside the storage chamber 2 A heating wire is wound around the lower end of the shaft to heat the wax in the storage chamber 2 to reduce the viscosity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com