Simple multilayer isolation garment and manufacturing method thereof

A production method and technology of isolation gowns, which are applied in the field of textiles and clothing, can solve the problems of thick isolation gowns, increased cross-infection, and lack of wearing comfort, and achieve the effects of ensuring breathability and comfort, reducing sewing time, and avoiding cross-infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

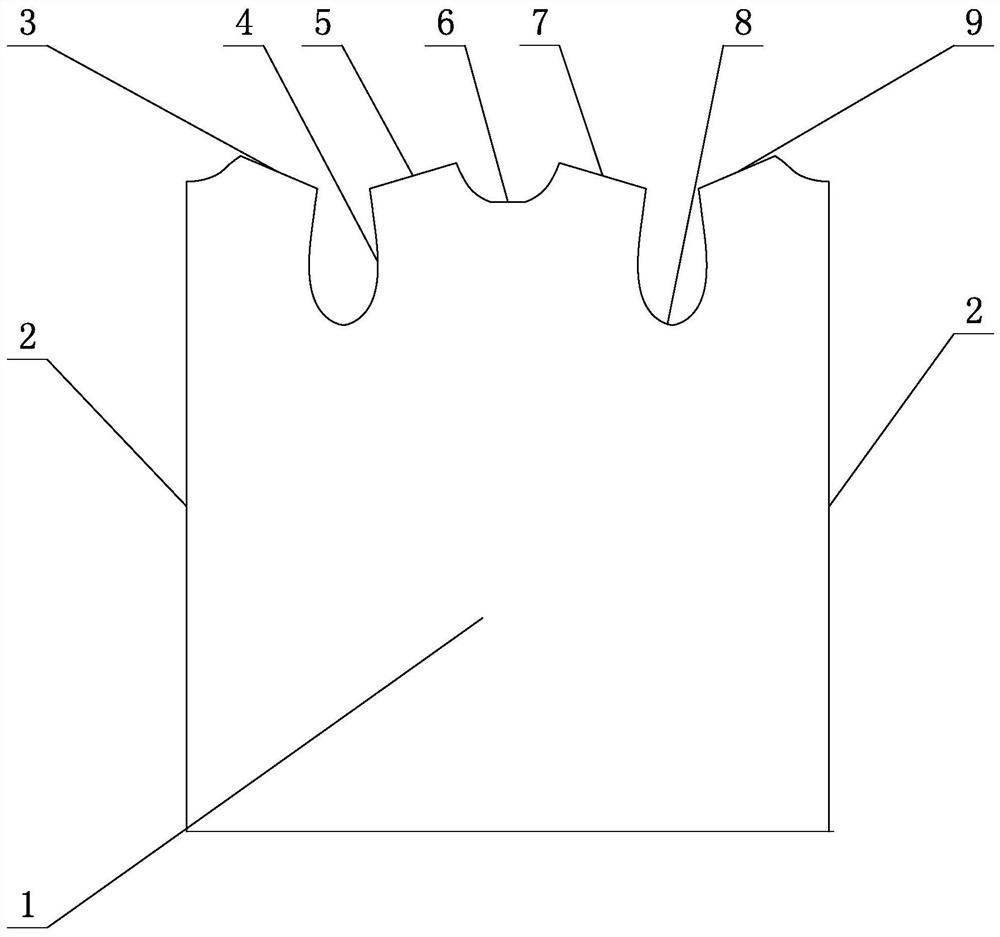

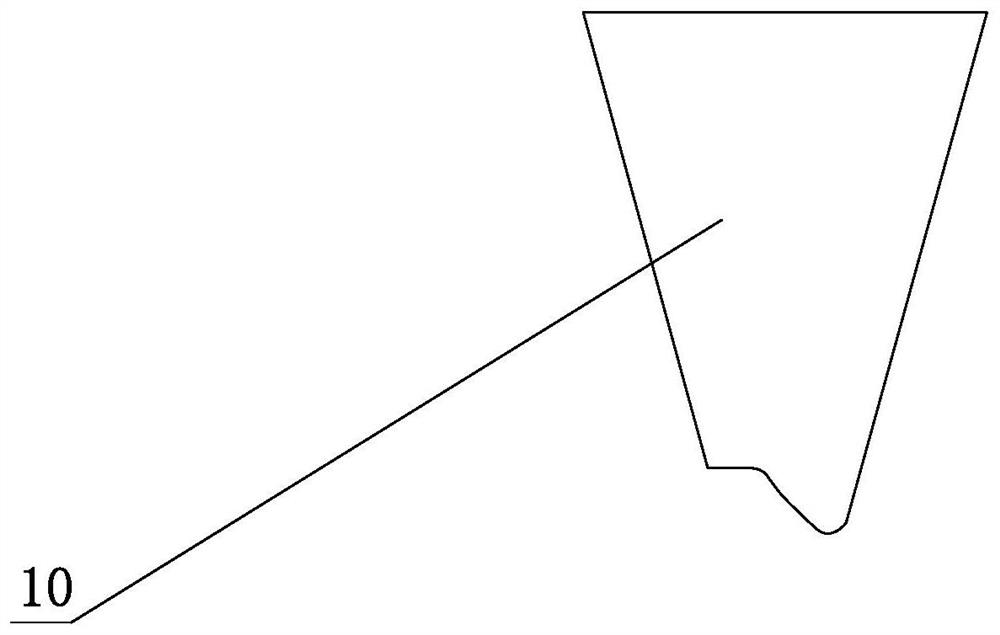

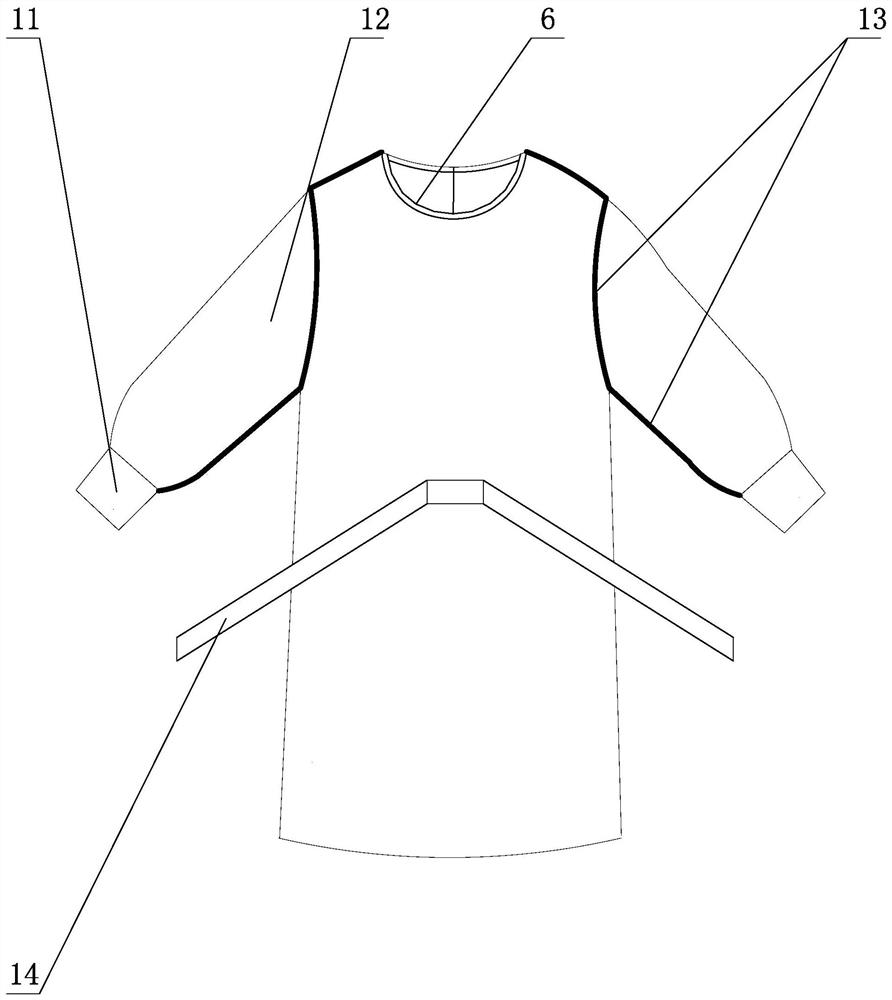

[0035] Such as Figure 1-Figure 4 , the simple multi-layer isolation gown described in the present embodiment comprises a piece body 19, and the surface of the piece body 19 is covered with a multi-layer isolation film 16; Garment part 1 and two sleeve body parts 10, one-piece garment part 1 integral structure.

[0036] The garment piece body 19 comprises a jumpsuit piece 1 and two sleeve body garment pieces 10, the edge lines on both sides of the jumpsuit piece 1 are split clothing lines 2, and the top middle position of the jumpsuit piece 1 is provided with a neckline 6, and the neckline 6 both sides are respectively provided with left sleeve hole 4 and right sleeve hole 8; The line is the left shoulder line 2 3, the left shoulder line 1 5 is stitched with the left shoulder line 2 3; the top edge line between the right sleeve hole 8 and the neckline 6 is the right shoulder line 1 7, the right sleeve hole 8 and the split garment line 2 The top edge line is the right shoulde...

Embodiment 2

[0043] Such as Figure 6 As shown, the number of layers of the multilayer isolation film 16 described in this embodiment is 4 layers; other structures are the same as those in Embodiment 1.

Embodiment 3

[0045] Such as Figure 5 As shown, the preparation method described in the present embodiment is the preparation method of the simple isolation clothing described in embodiment 1, and the specific steps are as follows,

[0046] Step 1, cutting the garment parts, cutting the whole piece of clothing material into jumpsuit parts 1 and sleeve body parts 10;

[0047] Step 2, first sew the two sleeve body parts 10 with the left sleeve hole 4 and the right sleeve hole 8 of the jumpsuit part 1, and then sew the left shoulder line 1 5 and the left shoulder line 2 3 of the jumpsuit part 1 Right shoulder line one 7 and right shoulder line two 9 are sewed up respectively, and finally the two sleeve body parts 10 are sewed into sleeve tube 12 respectively, and the sewing of the part body 19 is completed;

[0048] Step 3, the seam of the sleeve body part 10 and the jumpsuit part 1, the seam of the left shoulder line 15 and the left shoulder line 23, the seam of the right shoulder line 17 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com