Continuous filtering device adopting up-flow type flowing bed and filtering method

A filter device and fluidized bed technology, applied to loose filter material filters, filter separation, filter treatment, etc., can solve the problems of adding coagulant, high operation and maintenance costs, active sand process engineering and high investment , to achieve the effects of small head loss, easy reconstruction and expansion, low operating and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

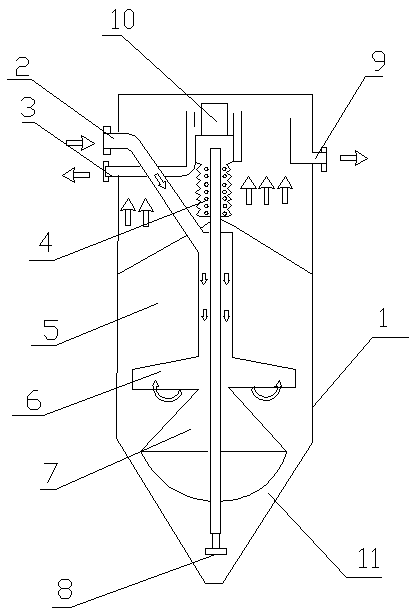

[0017] A continuous filter device using an upflow fluidized bed, which consists of: a housing 1, the housing is respectively connected to the raw water inlet 2, the sand washing sewage outlet 3, and the water purification outlet 9, and the inside of the housing has Dirty sand 11, sand bed 5, sand dumping bucket 7, described sand dumping bucket is formed by welding fan-shaped structural parts and conical structural parts.

Embodiment 2

[0019] According to the upflow fluidized bed continuous filtration device described in embodiment 1, the sand dump bucket is connected to the water distributor 6, the water distributor is connected to the raw water inlet, and the sand washing sewage The outlet is connected to the water collection container 10 through a pipeline, and the water collection container is connected to the sand washer 4 .

Embodiment 3

[0021] According to embodiment 1 or 2, using upflow fluidized bed continuous filter device, the air lift pump 8 is installed on the lower part of the sand guiding bucket, the surface of the sand washer is processed with circular holes, and the cloth The water container is a trapezoidal structural member installed on the top of the sand dumping bucket.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com