Narrow L-shaped film and production method thereof

A production method, L-shaped technology, applied in the direction of chemical instruments and methods, layered products, lamination auxiliary operations, etc., can solve the problems of waste of raw materials, L-shaped mold edge warping, high defect rate, etc., to avoid excessive, prevent The effect of warping edges and improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

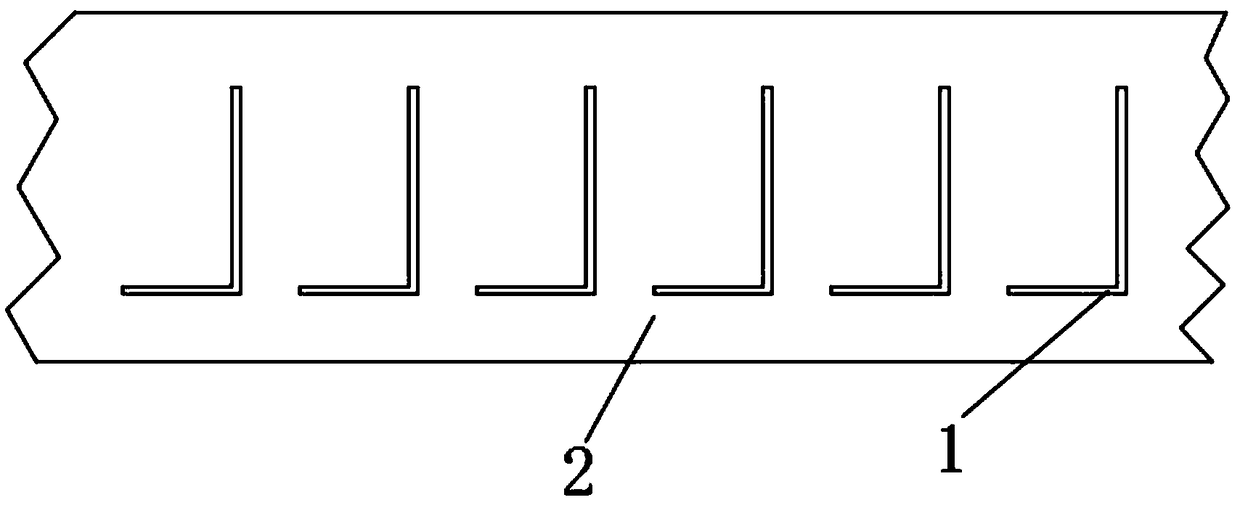

[0021] attached Figure 5 A narrow L-shaped membrane according to the present invention includes a bottom membrane 2; a plurality of L-shaped membranes 1 are arranged at intervals in an oblique shape on the bottom membrane 2.

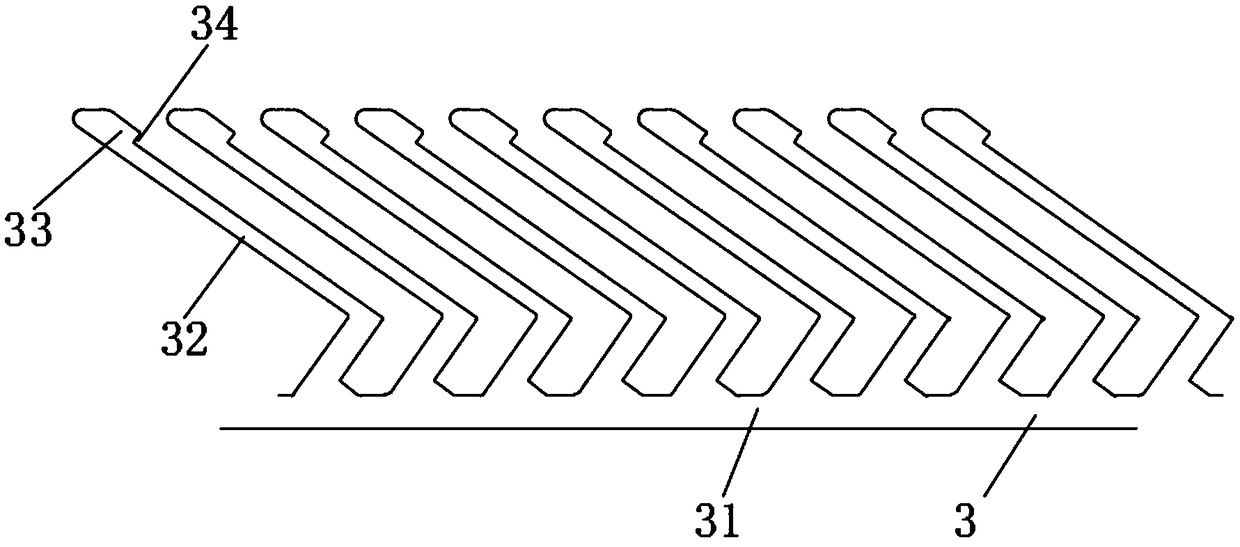

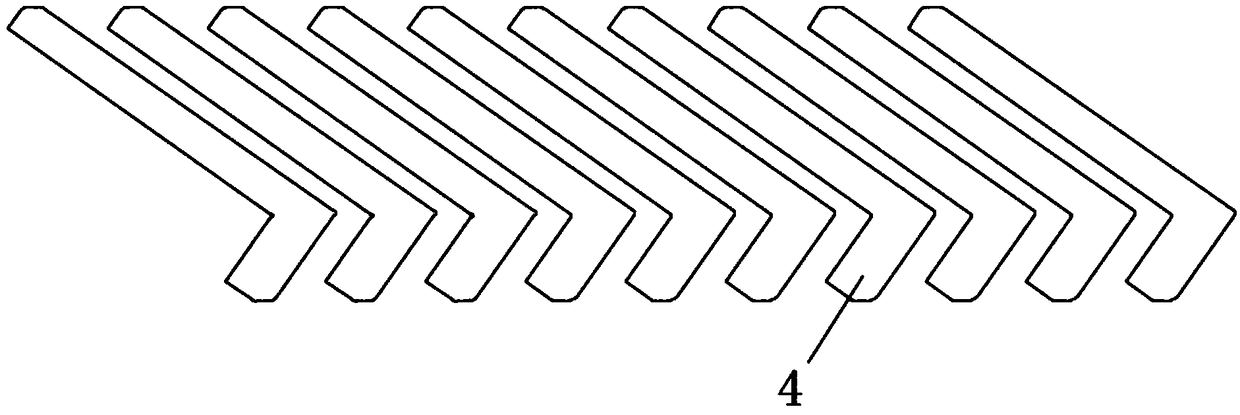

[0022] attached Figure 2-4 It is a production method of a narrow L-shaped film of the present invention, including two hob processes of the first hob film 3 and the second hob film 4; the first hob film 3 includes a bottom edge 31 and a plurality of Evenly arranged inclined L-shaped tentacles 32 connected with the bottom edge 31; the top of the tentacles 32 is provided with a top 33, and the top 33 and the side of the tentacles 32 are provided with a corner 34 at a right angle; the second hob Membrane 4 is composed of a plurality of L-shaped frame membranes that are evenly spaced and arranged obliquely; Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com