Automobile waxing machine with a continuous discharge structure

A technology for automobiles and wax machines, which is applied in vehicle maintenance, vehicle maintenance/repair, transportation and packaging, etc. It can solve the problems of long time consumption, heavy workload of operators, uneven dispersion of wax blocks, etc., and achieves accurate and improved wax removal process. Waxing efficiency, easy application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

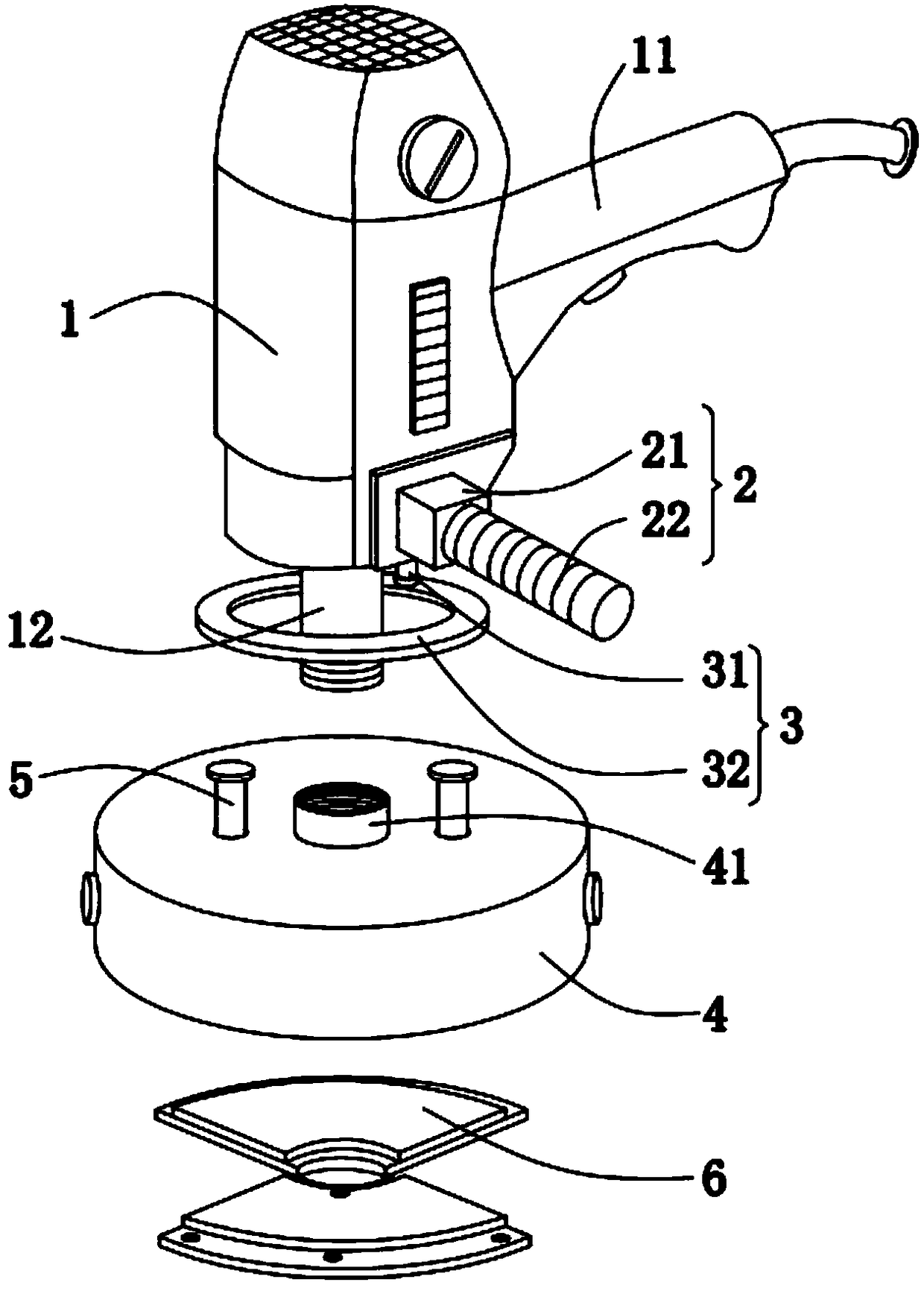

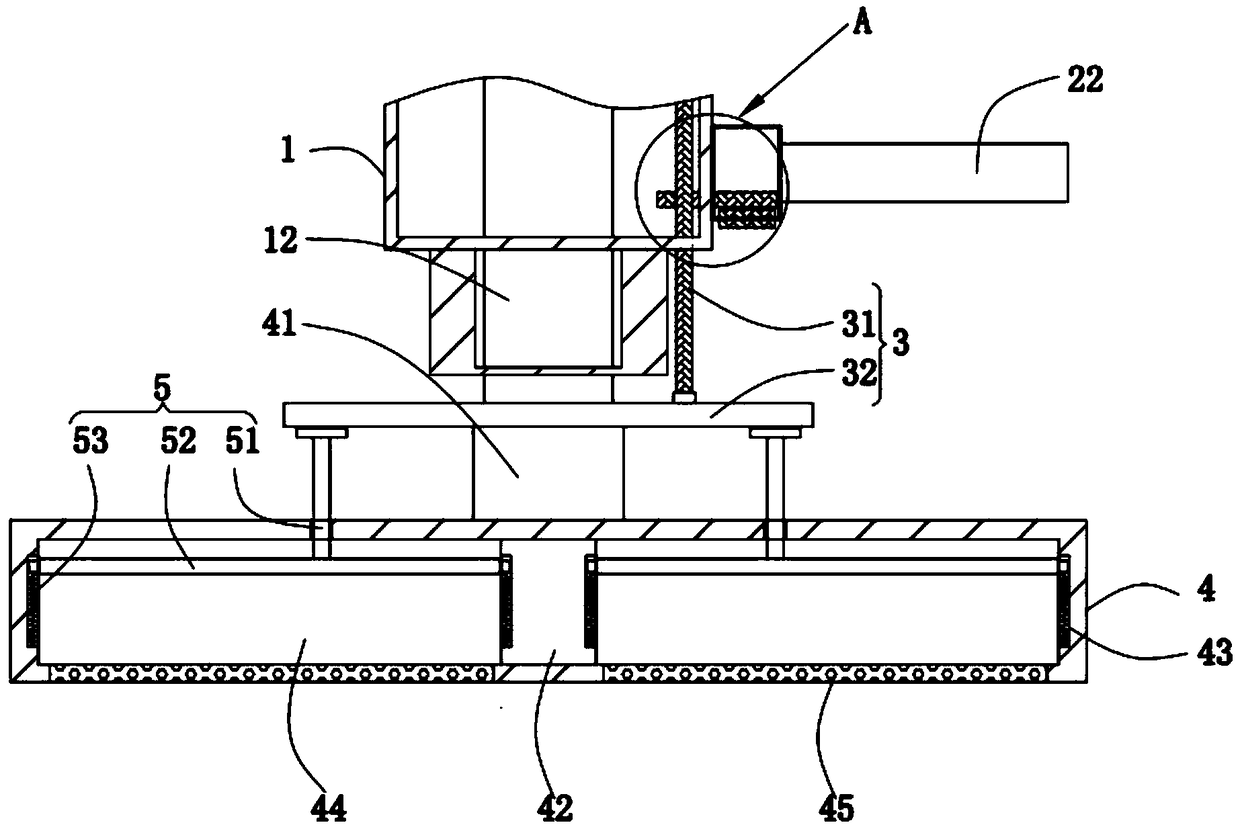

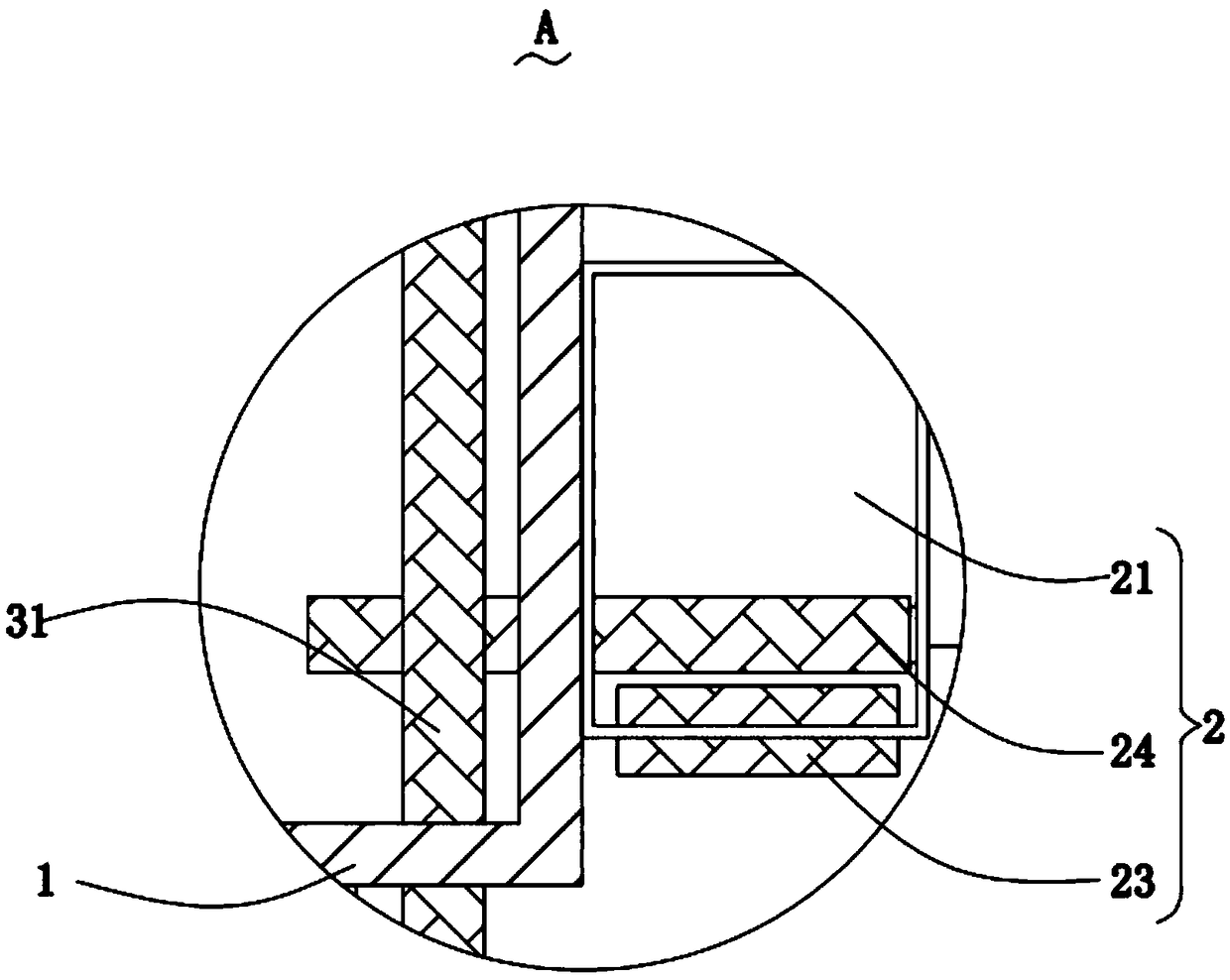

[0025] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 as well as Figure 6 ,in, figure 1 A schematic structural view of a preferred embodiment of a car waxing machine with a continuous discharge structure provided by the present invention; figure 2 for figure 1 The schematic diagram of the manual control mechanism, the extrusion mechanism and the internal connection structure of the box shown; image 3 for figure 2 The schematic diagram of the enlarged structure at A shown; Figure 4 for figure 2 The schematic diagram of the overall structure of the box shown; Figure 5 for Figure 4 The schematic diagram of the cooperation between the box body and the sponge board is shown; Figure 6 for Figure 5 The schematic diagram of the enlarged structure at B is shown. The car waxing machine with a continuous discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com