Gear waxing device and waxing method therefor

A technology of gears and wax pots, which is applied to the device and coating of the surface coating liquid, which can solve the problems of high manufacturing cost, uneven wax spraying, inconvenient gear clamping and rotation, etc. The effect of high wax efficiency and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

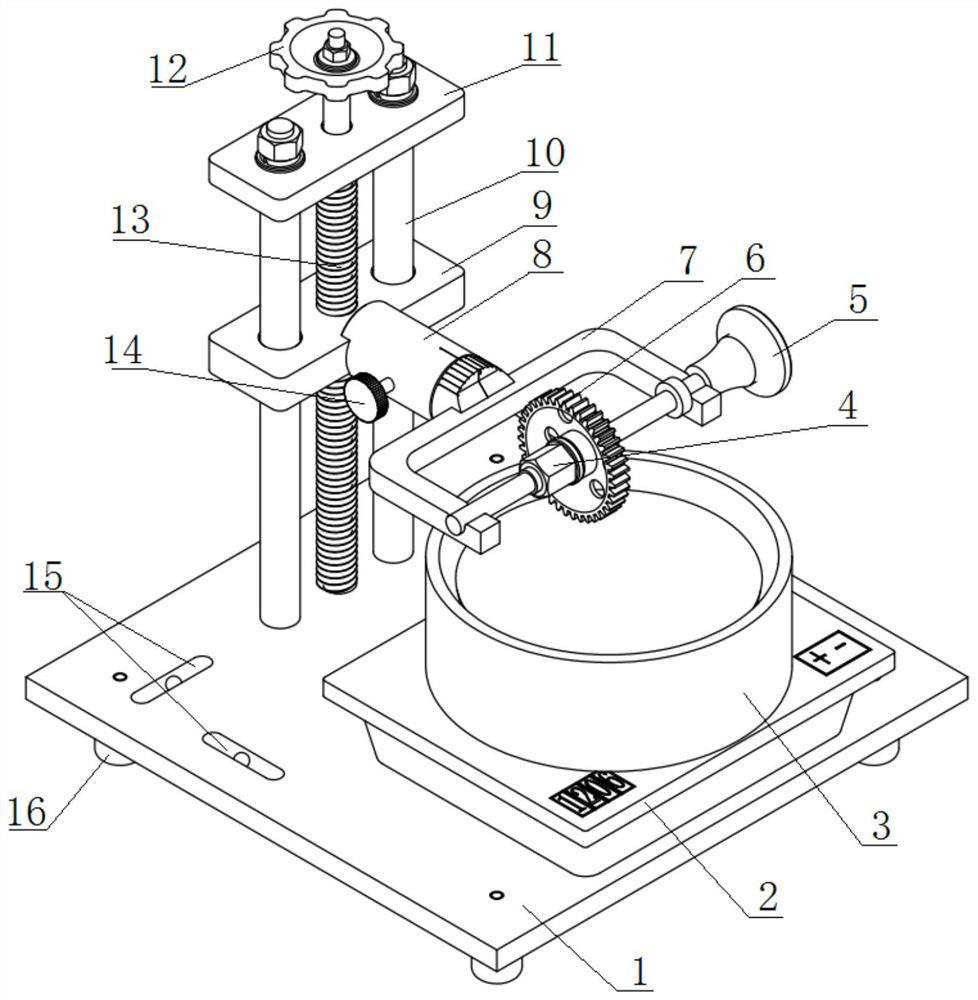

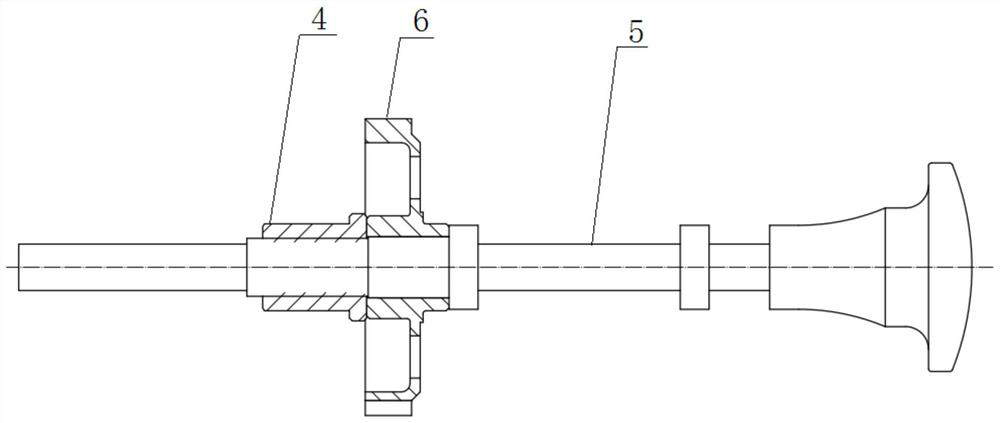

[0037] Such as figure 1 To and figure 2 As shown, a gear waxing device according to the present invention includes a base 1, a lifting assembly, a support frame and a gear clamping assembly, an electric furnace 2 is placed on the base 1, and a wax pot 3 is placed on the electric furnace 2 , the lifting assembly is installed on the base 1, the support frame is connected with the lifting assembly, the gear clamping assembly is movably connected with the support frame, and both the gear clamping assembly and the support frame are located above the wax pot 3. When in use, heat the wax in the wax pot 3 through the electric furnace 2, clamp the gear 6 through the gear clamping assembly, adjust the relative position between the gear 6 and the wax liquid level in the wax pot 3 through the lifting assembly, and then slowly rotate the gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com