Waxing device capable of performing comprehensive waxing on yarn

A yarn and comprehensive technology, applied in the field of waxing devices, can solve the problems of affecting the quality of fabrics, uneven waxing, fluff, etc., and achieve the effect of improving the effect of waxing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

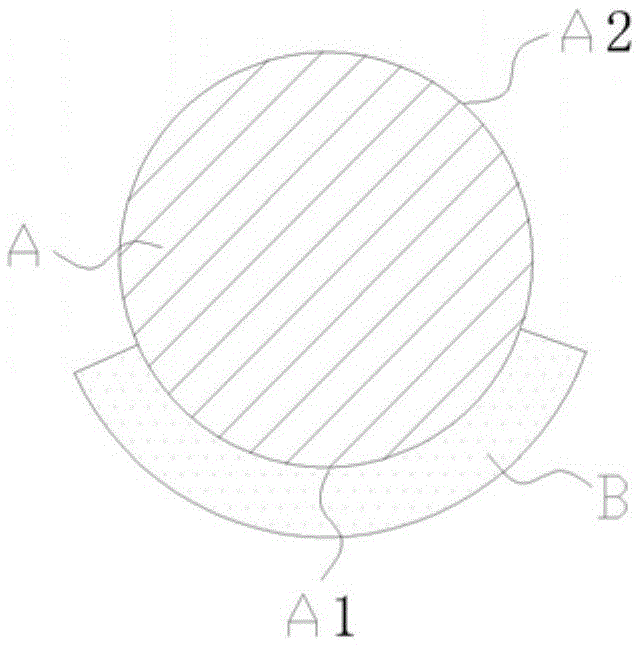

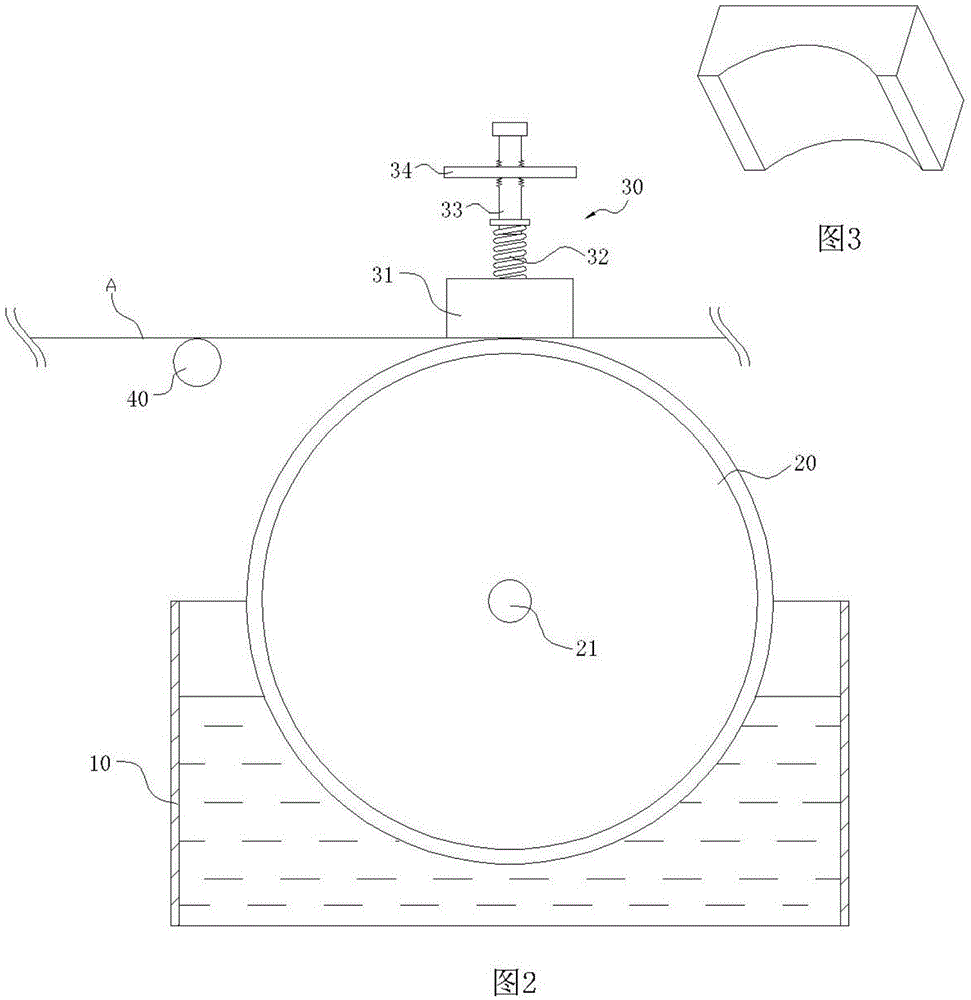

[0021] Such as Figure 2~3 As shown, a waxing device capable of fully waxing yarns includes a wax oil tank 10, an oil guide wheel 20 partially immersed in the wax oil tank 10, and a yarn guide wheel 40 located on one side of the oil guide wheel 20 , the oil guide wheel 20 can rotate around the central shaft 21, the central shaft 21 is connected with the transmission device, the yarn A passes through the circumferential surface of the oil guide wheel 20, and the advancing direction of the yarn A is in line with the center of the oil guide wheel 20 The shaft 21 is vertical in space and also includes a wax block device 30 located above the oil guide wheel 20 .

[0022] The wax block device 30 includes a wax block 31, a telescopic spring 32 connected to the wax block 31, an adjusting screw connected to the telescopic spring 32, a fixing plate 34 for fixing the adjusting screw, and the fixing plate 34 is fixed on the machine. On the frame main body, the adjusting screw is threaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com