Turnover conveying device

A transmission equipment and flipping technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of bright surface pollution and bright surface pollution of wooden floors, and achieve the effect of ensuring smooth transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

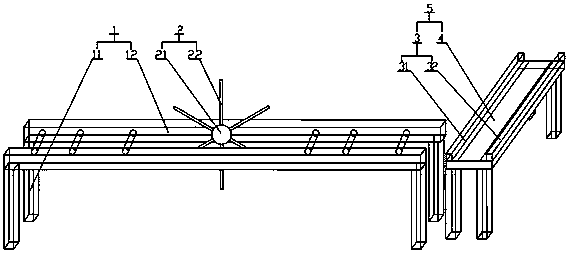

[0019] as attached figure 1 The present embodiment shown comprises conveying device 1, support 11, track 12, turning over device 2, rotating shaft 21, turning over bar 22, gear chute 3, material retaining plate one 31, material retaining plate two 32, conveyor belt 4, Conveying device 5, the wooden floor treated by the wax spraying process, with the smooth side facing down, the conveyor belt 1 transports the wooden floor, and through the function of the flipping device 2 clamped in the middle of the conveying device 1, the smooth side is turned up, thus solving the problem of wooden floor transportation It is easy to cause bright surface pollution.

[0020] The conveying device 1 transmits the wooden floor into the turning device 2, drives the rotating shaft 21 to rotate through the driving device 2, and the rotating shaft 21 and the turning rod 22 are connected in a fixed manner, so that the rotation of the rotating shaft 21 drives the turning rod 22 to rotate. Bar 22 has re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com