Waxing treatment device for intelligent community related LED wafer patch workpiece

A processing device and community technology, applied in the electronic field, can solve problems such as uneven thickness, incomplete wax layer at the attachment position, and product quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

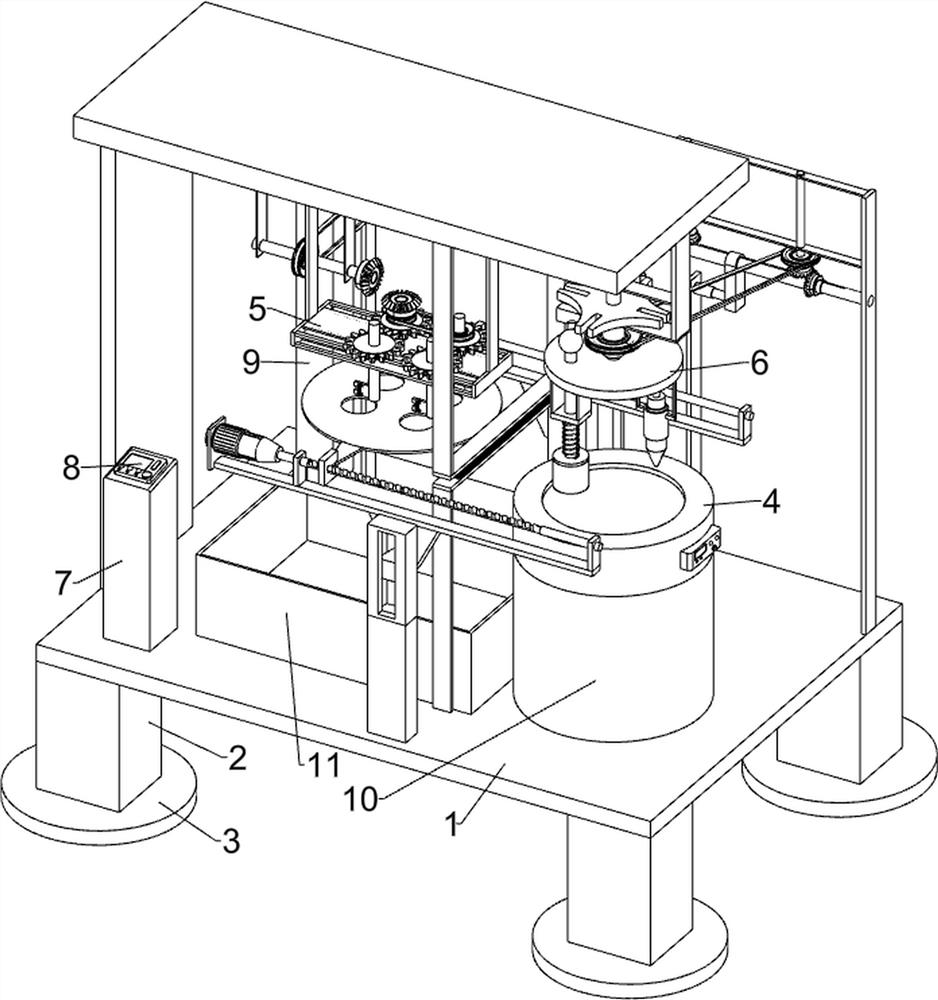

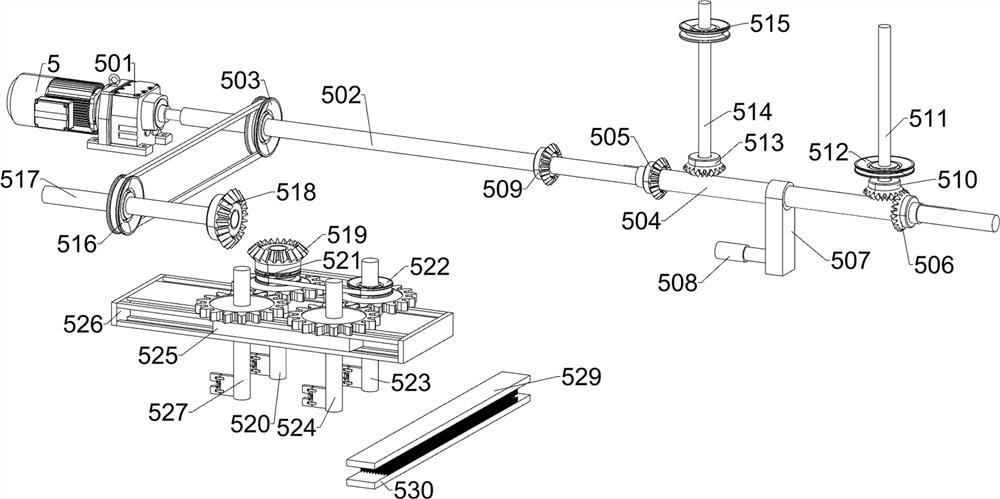

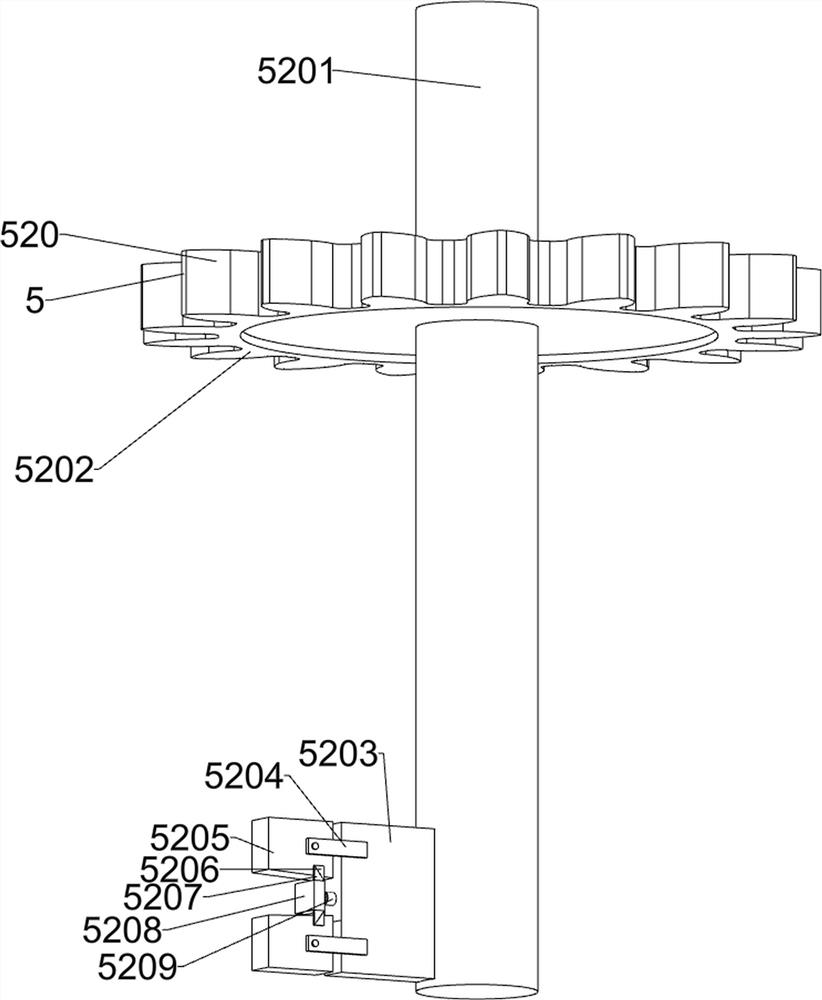

[0031] A kind of wax coating treatment device for LED chip patch workpiece related to smart community, such as Figure 1-10 As shown, it includes a chassis 1, a support column 2, a backing plate 3, a limit assembly 4, a cleaning assembly 5, a wax coating assembly 6, a support table 7, a controller 8, a fixed table 9, a bearing table 10 and a waste box 11 There are four sets of supporting columns 2 connected to the bottom of the bottom frame 1; the bottom frame 1 is connected with the limit assembly 4; the bottom frame 1 is connected with the cleaning assembly 5; the bottom frame 1 is connected with the wax coating assembly 6; The support platform 7 is connected; the bottom frame 1 is connected with the fixed platform 9; the bottom frame 1 is connected with the load-bearing platform 10; the bottom frame 1 is connected with the waste box 11; The limit assembly 4 is connected with the load-bearing platform 10; the limit assembly 4 is connected with the cleaning assembly 5; the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com