Shoe making process based on drying effect improvement

A process and drying room technology, which is applied in the field of shoemaking technology, can solve problems such as low drying efficiency, and achieve the effects of improving drying efficiency, reducing resistance and improving rotation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

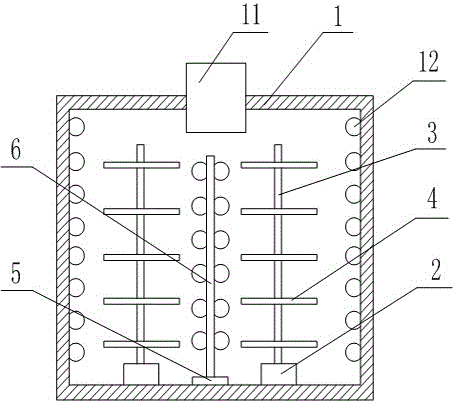

[0034] Such as figure 1 As shown, the shoemaking process based on improving the drying effect includes the following steps:

[0035] 1) Sole forming: prepare the sole in the mold;

[0036] 2) Preparation of shoe upper material: the shoe upper and the lining are compounded and formed by gluing;

[0037] 3) Cutting of the upper material: cutting the upper material prepared in step 2) into an upper matching the sole;

[0038] 4) Glue or sew the upper prepared in step 3) to the sole;

[0039] 5) Paint and wax the upper;

[0040] 6) Put the sprayed and waxed shoes into the drying system for drying treatment: the drying system includes an infrared drying room and a shelf set in the infrared drying room, and the infrared drying room includes a drying room Drying main body 1, a number of infrared heating lamps 12 are arranged in the drying main body 1, an exhaust pipe 11 is arranged on the top of the drying main body 1, and a fan is arranged in the exhaust pipe 11, and the placing...

Embodiment 2

[0043] Such as figure 1 As shown, this embodiment is based on Embodiment 1, and the infrared heating lamp tube 12 is arranged parallel to the bottom of the drying main body 1; several infrared heating lamp tubes 12 are evenly arranged on the inner wall of the drying main body 1; 3 are vertically arranged, and a plurality of shoe body placement plates 4 are arranged on the same rotating shaft 3; the shoe body placement plates 4 are disc structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com