Four-component spandex covering composite yarn and preparation method of fabric made of four-component spandex covering composite yarns

A technology of spandex core-spun and composite yarn, which is applied in yarn, textile and papermaking, weft knitting and other directions, can solve many problems, and achieve the effects of good wear resistance, heat preservation, and good antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

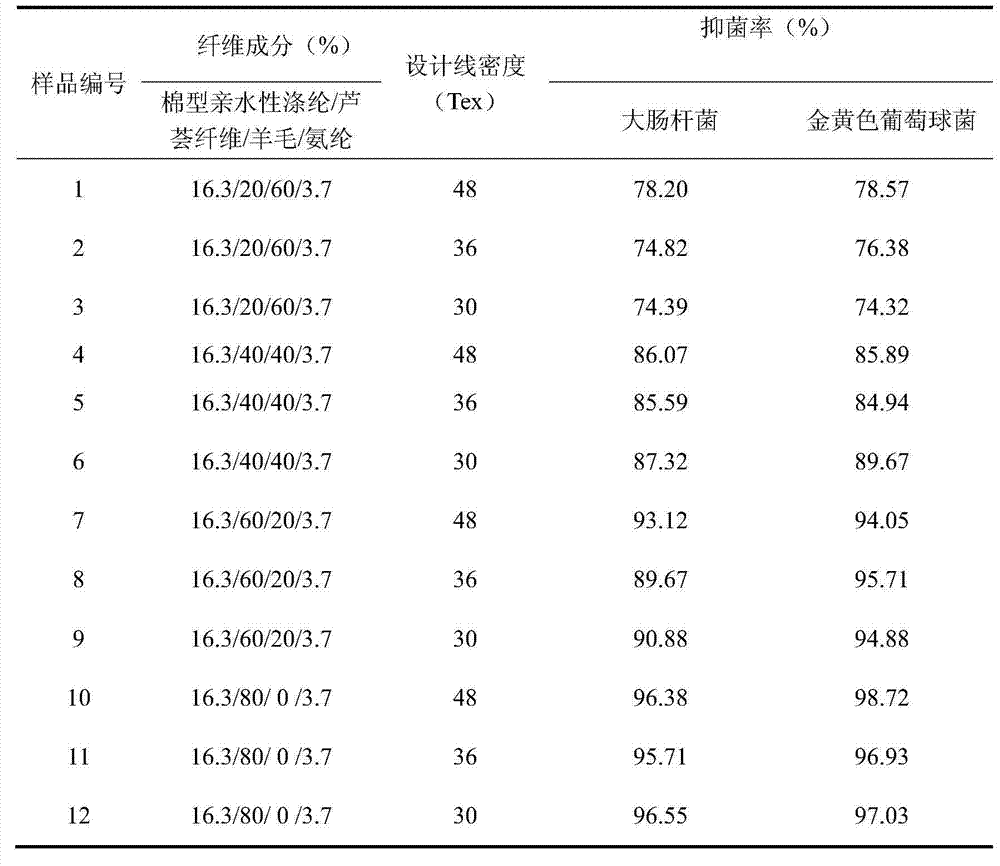

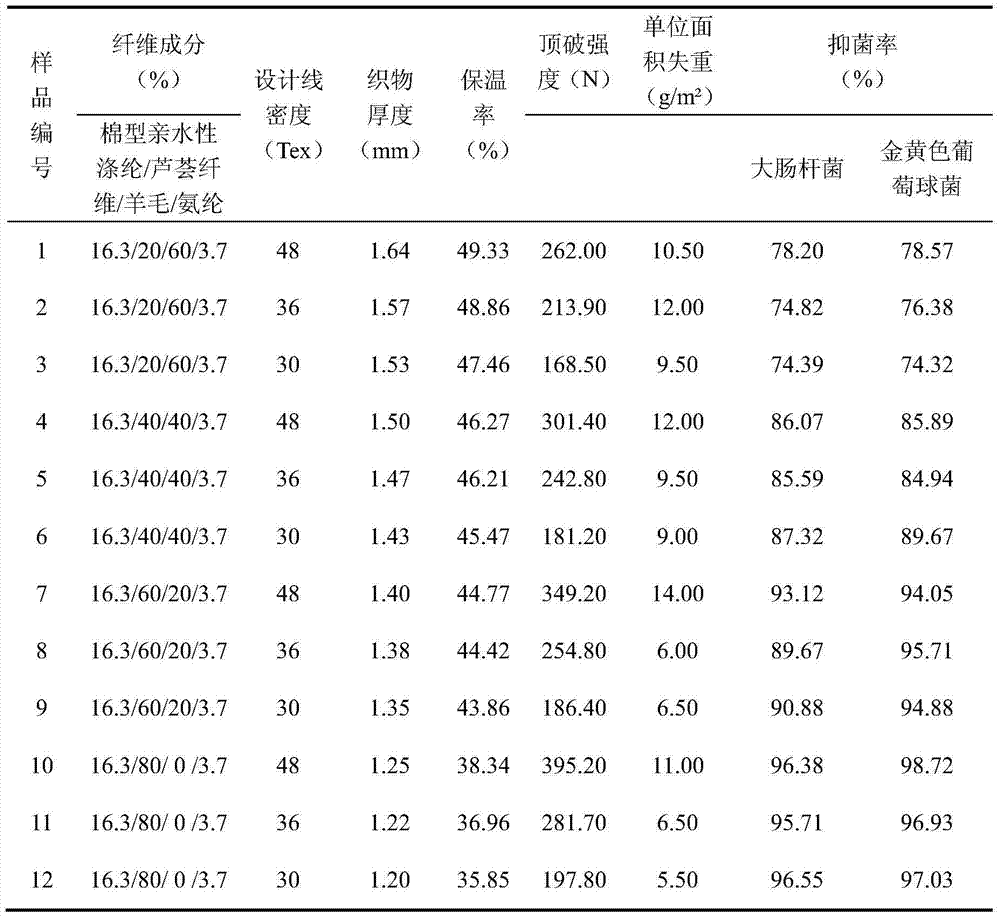

Examples

preparation example Construction

[0046] The preparation method of the four-component spandex core-spun composite yarn of the present invention is specifically implemented according to the following steps:

[0047]Step 1. According to the blending ratio of 16.3 / 20 / 60 / 3.7~16.3 / 80 / 0 / 3.7, respectively take hydrophilic polyester fiber, aloe fiber, wool top and spandex filament;

[0048] The selected raw materials have good wear resistance, antibacterial properties and warmth retention respectively;

[0049] Among them, cotton-type hydrophilic polyester fiber is a kind of polyester fiber. It not only has the high strength, good elasticity, good heat resistance and thermal stability, abrasion resistance, light resistance and corrosion resistance of ordinary polyester fiber. In addition, its moisture regain is twice that of ordinary polyester fibers;

[0050] The chemical and physical properties of aloe fiber and cotton fiber are relatively close, with high moisture regain, good dyeability, soft hand feeling, good d...

Embodiment 1

[0076] Cotton-type hydrophilic polyester fiber, aloe fiber, wool top, and spandex filament are selected; the blending ratio of cotton-type hydrophilic polyester fiber, aloe fiber, wool top, and spandex filament is 16.3 / 20 / 60 / 3.7;

[0077] Mix cotton-type hydrophilic polyester fibers and aloe vera fibers evenly, card them into a web on a carding machine, and make a mixed strip. The speeds of doffer and doffer are 434.03r / min, 500r / min and 5.21r / min respectively, and the netting speed is 27.49m / min; the mixed strip formed by cotton-type hydrophilic polyester fiber and aloe fiber is divided into 6 pieces, and the wool strip Divide into 10 strands, first cut 3 mixed strands and 5 wool strands to form strand A, then divide strand A into 8 strands to obtain strand B, then divide strand B into 8 strands to obtain strand C , in the three-time drawing process, set the draft ratio in the rear area of the draw frame to 1.00, the draft ratio in the middle area to 1.02, the draft ratio i...

Embodiment 2

[0080] Cotton-type hydrophilic polyester fiber, aloe fiber, wool top, and spandex filament are selected; the blending ratio of cotton-type hydrophilic polyester fiber, aloe fiber, wool top, and spandex filament is 16.3 / 20 / 60 / 3.7;

[0081]Evenly mix cotton-type hydrophilic polyester and aloe fibers, card them into a web on a carding machine, and make a mixed strip. During the carding process, set the feeding roller to 0.29r / min. The speeds of doffer and doffer are 434.01r / min, 500r / min and 5.2r / min respectively, and the netting speed is 27.49m / min; the mixed strip formed by cotton-type hydrophilic polyester fiber and aloe fiber is divided into 6 pieces, and the wool strip Divide into 10 strands, first cut 3 mixed strands and 5 wool strands to form strand A, then divide strand A into 8 strands to obtain strand B, then divide strand B into 8 strands to obtain strand C , when drawing the frame, set the draft ratio in the rear area of the draw frame to 1.00, the draft ratio in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com