Polyester and cotton blended novel carbon filament anti-static water and oil repellent composite functional fabric

A polyester-cotton blended, water-repellent and oil-repellent technology, applied in the textile field, can solve problems such as loss of anti-static, easy disconnection of metal wires, loss of protective metal wires in the covering layer, etc., to overcome fatal shortcomings and have a high degree of refining and bleaching resistance , excellent long-lasting anti-static effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

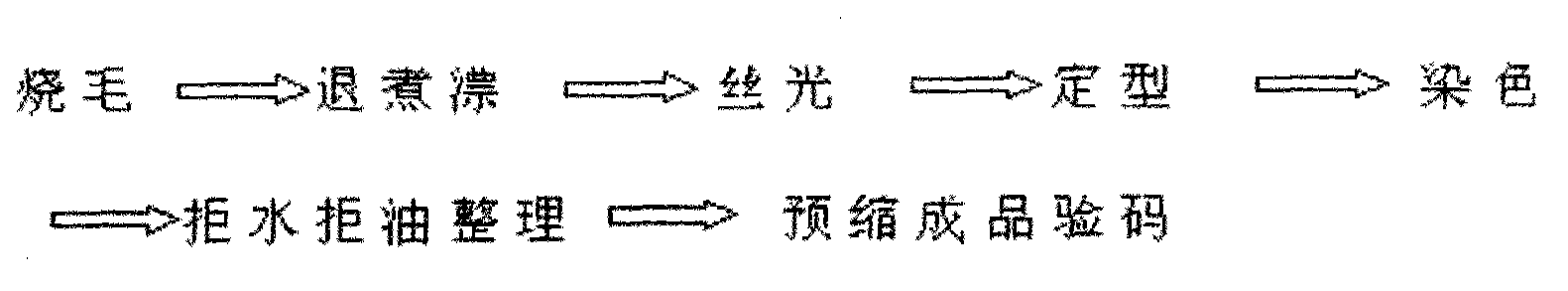

[0035] Production process reference figure 1 , in this example:

[0036] Polyester-cotton blended new carbon filament anti-static, water-repellent and oil-repellent composite functional fabric is made of polyester-cotton and conductive carbon fiber blended to obtain a new type of carbon filament anti-static gray fabric, which is processed by the following process:

[0037] Fabric specification: T30 / C70 16X16 108X56 new carbon anti-static gray fabric

[0038] T30 / C70 16X16 108X56 wire anti-static gray fabric

[0039] The first step of singeing: process conditions: two positive and one negative; speed: 110 m / min; uniform flame without jagged;

[0040] Cloth inspection after unloading: the singeing effect is above grade 4.

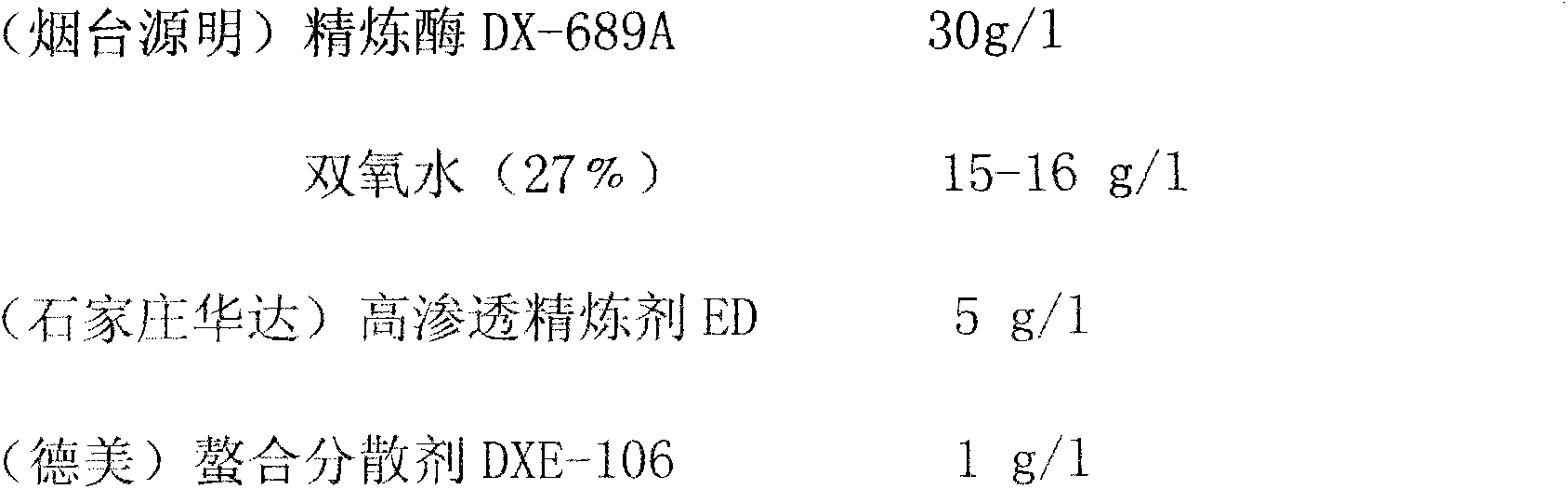

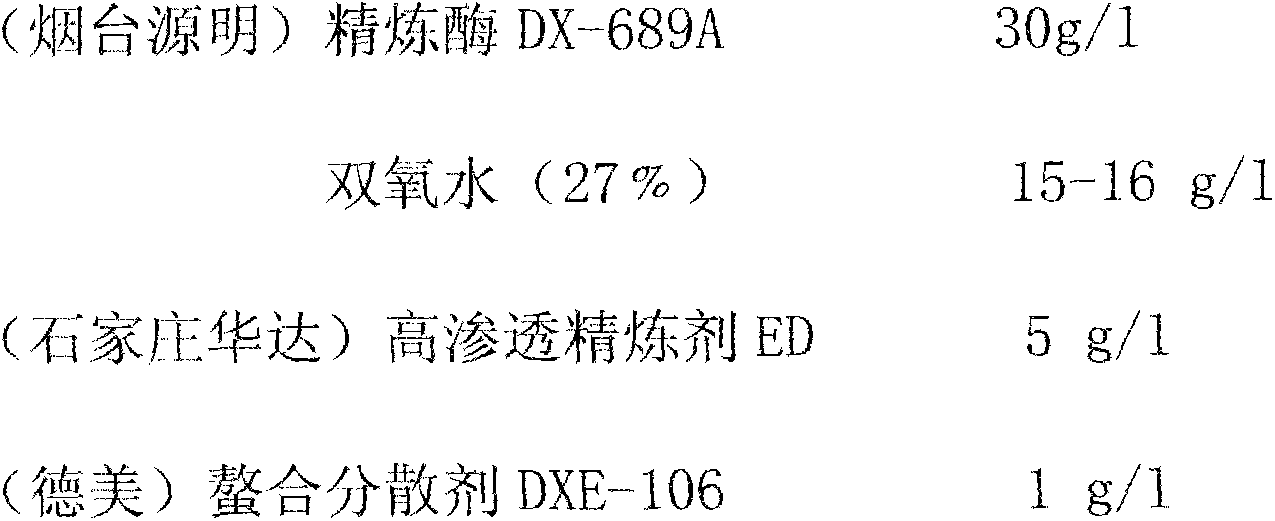

[0041] The second step of decoiling and bleaching: process conditions: rolling material pressure: 0.2Mpa liquid rolli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com