Anti-infrared military camouflage fabric and printing and dyeing process thereof

A printing and dyeing technology, anti-infrared technology, applied in dyeing, fabric surface trimming, textile, etc., can solve the problems of fabric hygroscopicity, air permeability, washing resistance, excessive absorption of thermal infrared bands, unfavorable detector stealth, etc., to achieve Improve printing and dyeing adsorption function, improve tensile performance, improve the effect of mobility and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

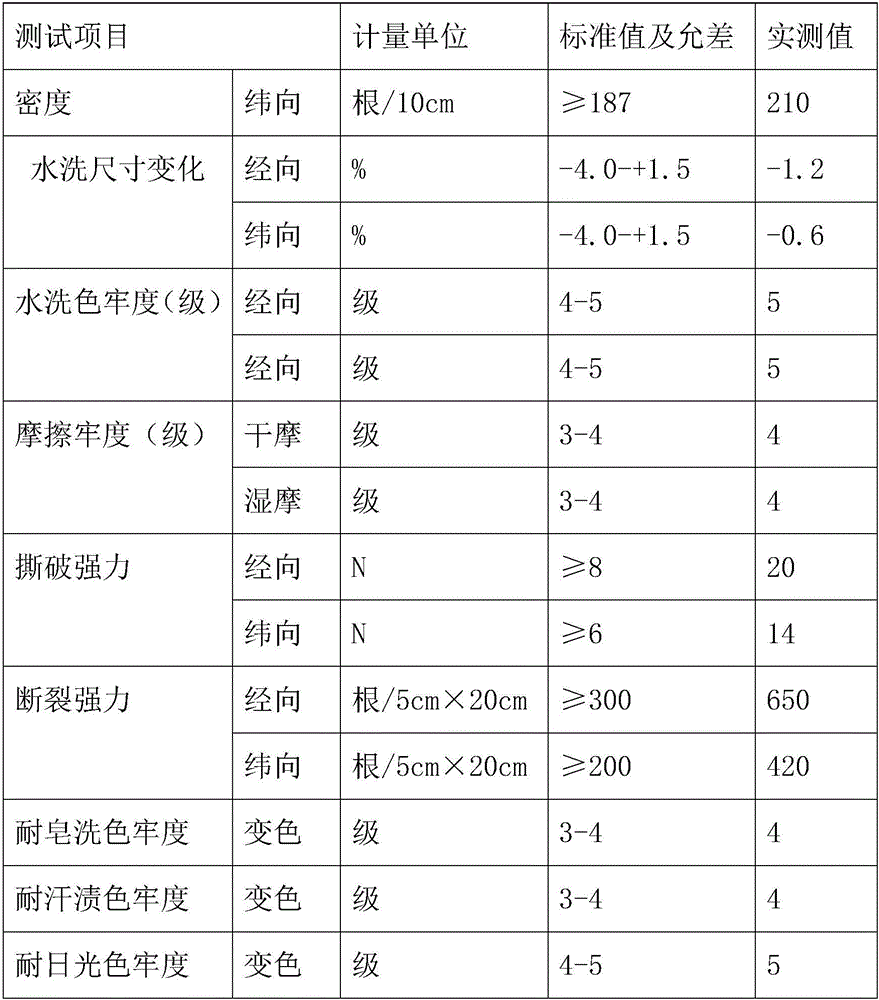

Embodiment 1

[0022] In this embodiment, a kind of printing and dyeing process of anti-infrared military camouflage fabric, the warp and weft yarns of the camouflage fabric all adopt cotton-polyester blended yarn, and the cotton-polyester blended yarn is made of 40wt% cotton fiber, 50wt% polyester fiber, 5wt% % nylon fiber and 5wt% spun silk fiber are blended, and its printing and dyeing process includes the following steps:

[0023] S1, pretreatment process, it comprises:

[0024]S11, singeing, singeing with a singeing machine, the speed of the machine is 100m / min, two positive and two reverse, four burners, the singeing grade is 4-5;

[0025] S12. Cold stacking, normal temperature padding and rolling working fluid, three dipping and three rolling, the excess rate is 60%, the speed is 40m / min, the working fluid includes: caustic soda 30g / L, hydrogen peroxide 15g / L, penetrating agent 1g / L, boiling Refining agent 10g / L, chelating dispersant 1g / L, stacked at room temperature for 20 hours at ...

Embodiment 2

[0035] In this embodiment, a printing and dyeing process of an anti-infrared military camouflage fabric, the warp and weft yarns of the camouflage fabric are made of cotton-polyester blended yarn, and the cotton-polyester blended yarn is composed of 60wt% cotton fiber, 30wt% polyester fiber, 5wt% % nylon fiber and 5wt% spun silk fiber are blended, and its printing and dyeing process includes the following steps:

[0036] S1, pretreatment process, it comprises:

[0037] S11, singeing, singeing with a singeing machine, the speed of the machine is 110m / min, two positive and two reverse, four burners, the singeing grade is 4-5;

[0038] S12. Cold stacking, normal temperature padding and rolling working fluid, three dipping and three rolling, the excess rate is 90%, the speed is 30m / min, the working fluid includes: caustic soda 40g / L, hydrogen peroxide 5g / L, penetrant 5g / L, boiling Refining agent 8g / L, chelating dispersant 5g / L, stacked at room temperature for 25 hours at a speed ...

Embodiment 3

[0048] In this embodiment, a kind of printing and dyeing process of anti-infrared military camouflage fabric, the warp and weft yarns of the camouflage fabric all adopt cotton-polyester blended yarn, and the cotton-polyester blended yarn is composed of 40wt% cotton fiber, 40wt% polyester fiber, 10wt% % nylon fiber and 10wt% spun silk fiber are blended, and its printing and dyeing process includes the following steps:

[0049] S1, pretreatment process, it comprises:

[0050] S11, singeing, singeing with a singeing machine, the speed of the machine is 105m / min, two positive and two reverse, four burners, the singeing grade is 4-5;

[0051] S12. Cold stacking, normal temperature padding and rolling working fluid, three dipping and three rolling, the excess rate is 75%, the speed is 35m / min, the working fluid includes: caustic soda 35g / L, hydrogen peroxide 10g / L, penetrating agent 3g / L, boiling Refining agent 9g / L, chelating dispersant 3g / L, stacked at room temperature for 22 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com