Nylon/cotton fabric hair removal and reactive dye dyeing one-bath process

A technology for reactive dyes and cotton fabrics, applied in heating/cooling fabrics, liquid/gas/steam textile processing, dyeing, etc., can solve the problems of high energy consumption, high sewage discharge, low production efficiency, etc., and reduce production. The effect of reducing process and energy consumption and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

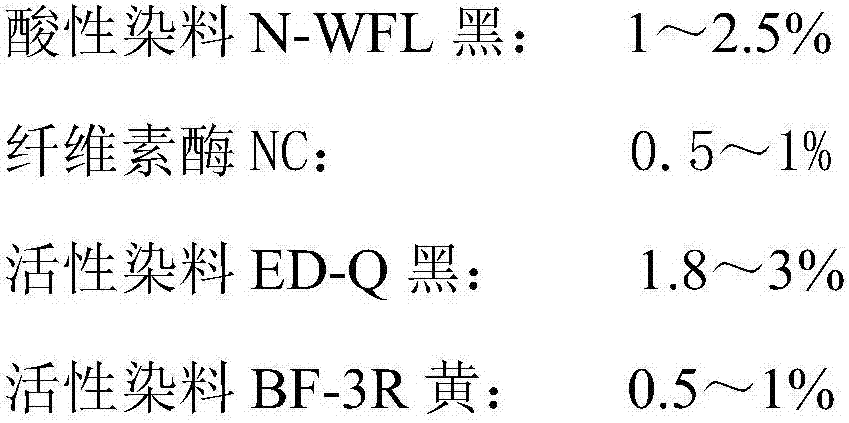

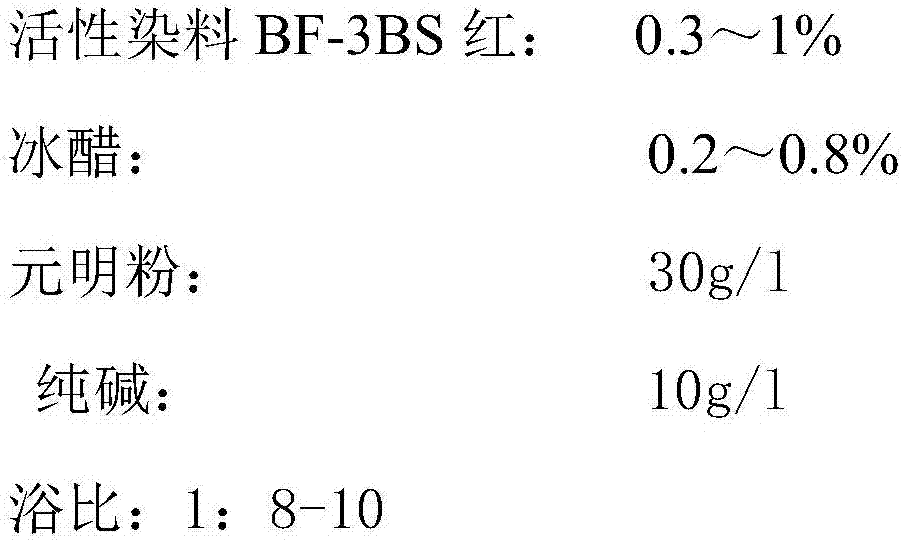

Method used

Image

Examples

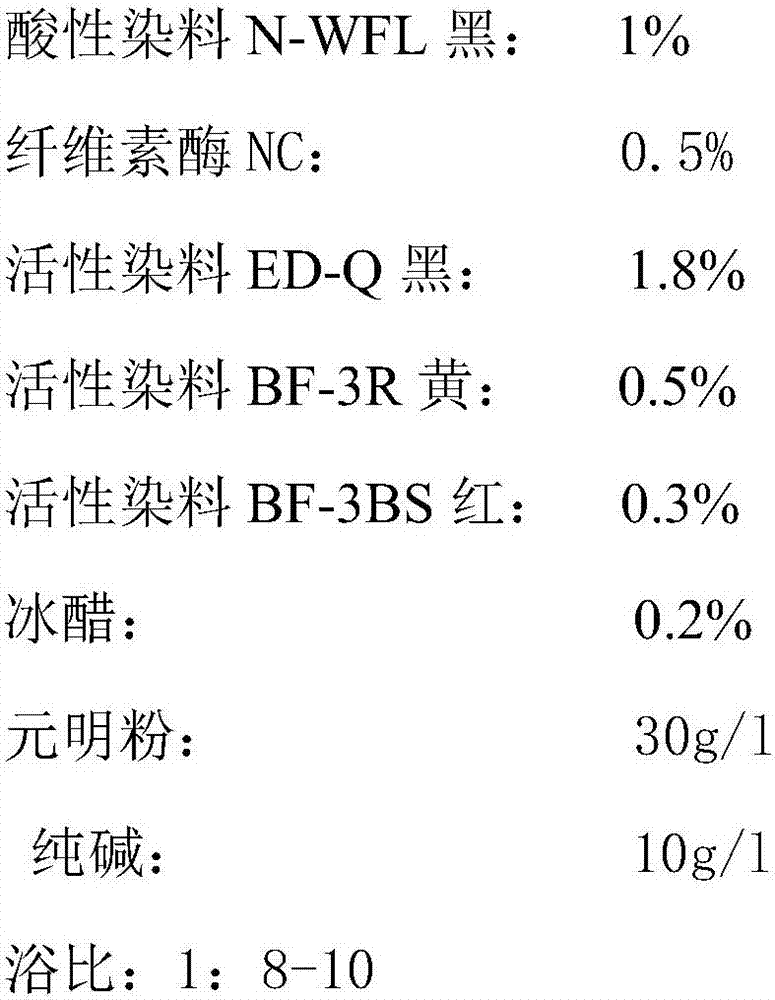

Embodiment 1

[0090] Embodiment 1: a kind of nylon / cotton fabric hair removal and reactive dye dyeing one-bath process, carry out according to the following steps:

[0091] (1) Select sample cloth:

[0092] Choose a piece of nylon / cotton fabric sample cloth, white blank door width 166cm, gram weight 227g / m, dyed black; Nylon / cotton product is a woven fabric composed of 58% nylon fiber and 42% cotton fiber;

[0093] (2) Gray cloth desizing:

[0094] The LMH023-200L combined descaling and bleaching machine of Jiangsu Hongqi Printing and Dyeing Machinery Co., Ltd. is used to desizing and bleaching the gray cloth to remove the starch size and cottonseed hull related impurities in the gray cloth. The additive formula and process used are:

[0095] Desizing agent OD: 4g / l

[0096] Hydrogen peroxide: 6g / l

[0097] OPE penetrant: 1g / l

[0098] PAW refining agent: 1.5g / l

[0099] Liquid caustic soda (30% NaOH solution): 30g / l

[0100] With two immersion and two rolling, the liquid rolling rate...

Embodiment 3

[0151] Embodiment 3: a kind of brocade / cotton fabric hair removal and reactive dye dyeing one-bath process, carry out according to the following steps:

[0152] (1) Select sample cloth:

[0153] Choose a piece of nylon / cotton fabric sample cloth, white blank door width 166cm, gram weight 227g / m, dyed black; Nylon / cotton product is a woven fabric composed of 58% nylon fiber and 42% cotton fiber;

[0154] (2) Gray cloth desizing:

[0155] The LMH023-200L combined descaling and bleaching machine of Jiangsu Hongqi Printing and Dyeing Machinery Co., Ltd. is used to desizing and bleaching the gray cloth to remove the starch size and cottonseed hull related impurities in the gray cloth. The additive formula and process used are:

[0156] Desizing agent OD: 5g / l

[0157] Hydrogen peroxide: 7g / l

[0158] OPE penetrant: 1.2g / l

[0159] PAW refining agent: 2g / l

[0160] Liquid caustic soda (30% NaOH solution): 30g / l

[0161] With two dipping and two rolling, the liquid rolling rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com