Liquid ammonia mercerizer equipment of knitting fabric

A technology of liquid ammonia mercerizing and knitted fabrics, which is applied in the processing of textile materials, mercerizing of indefinite length fabrics, and accessories of textile processing machines. Shrinkage, cost saving, tension reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

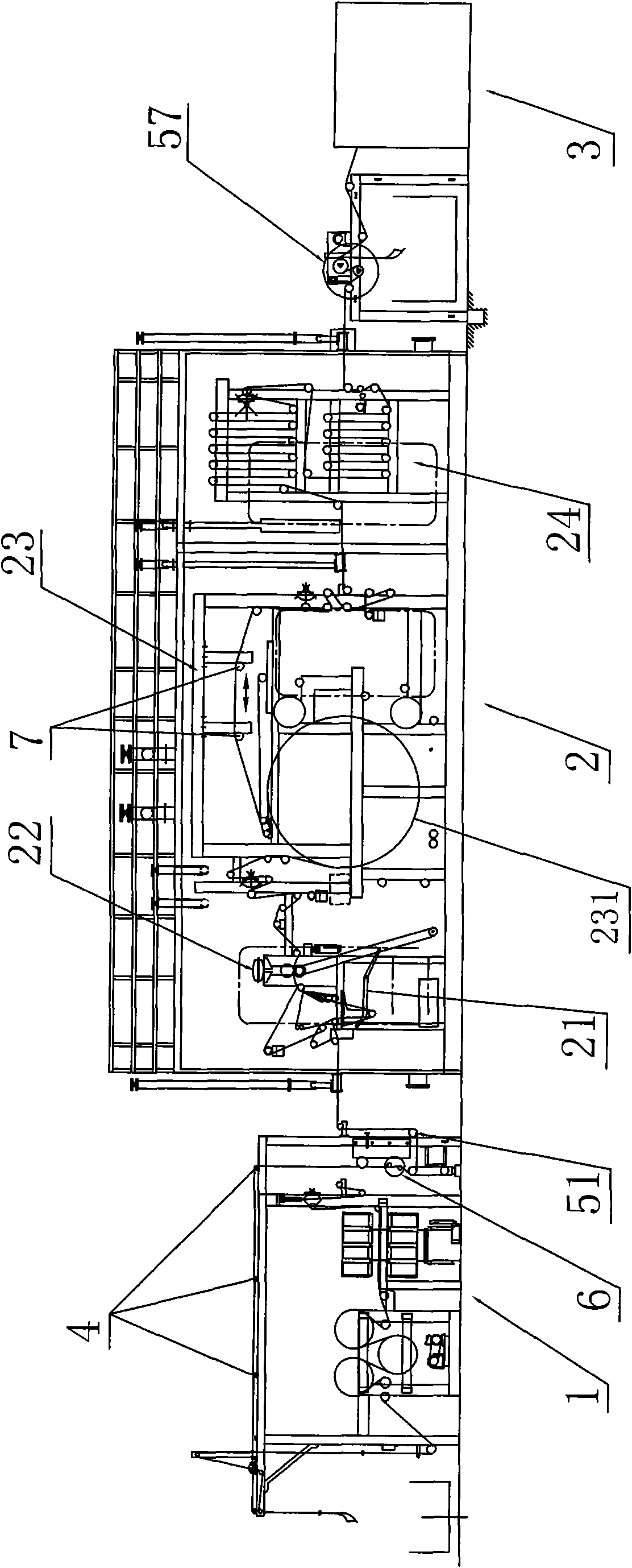

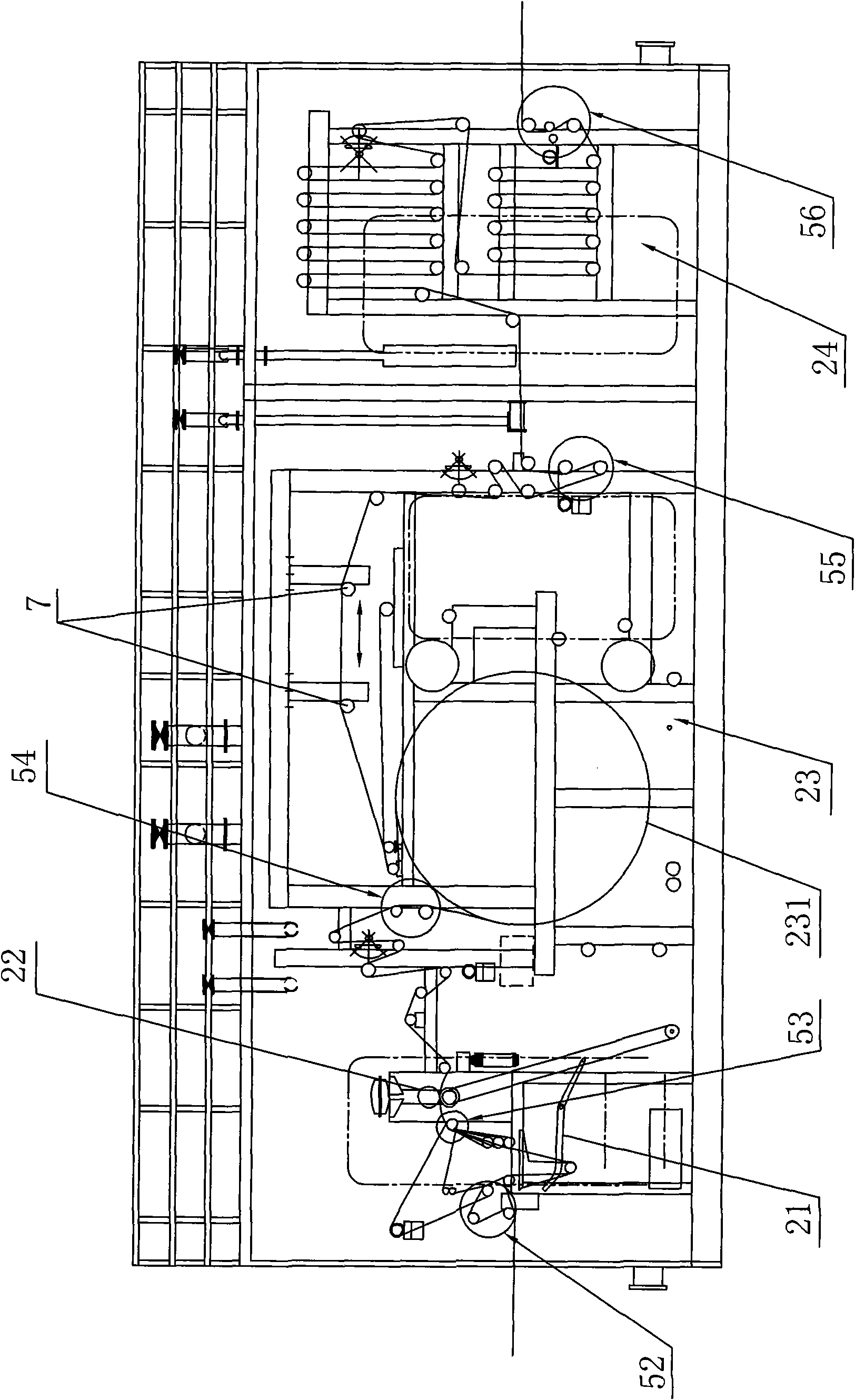

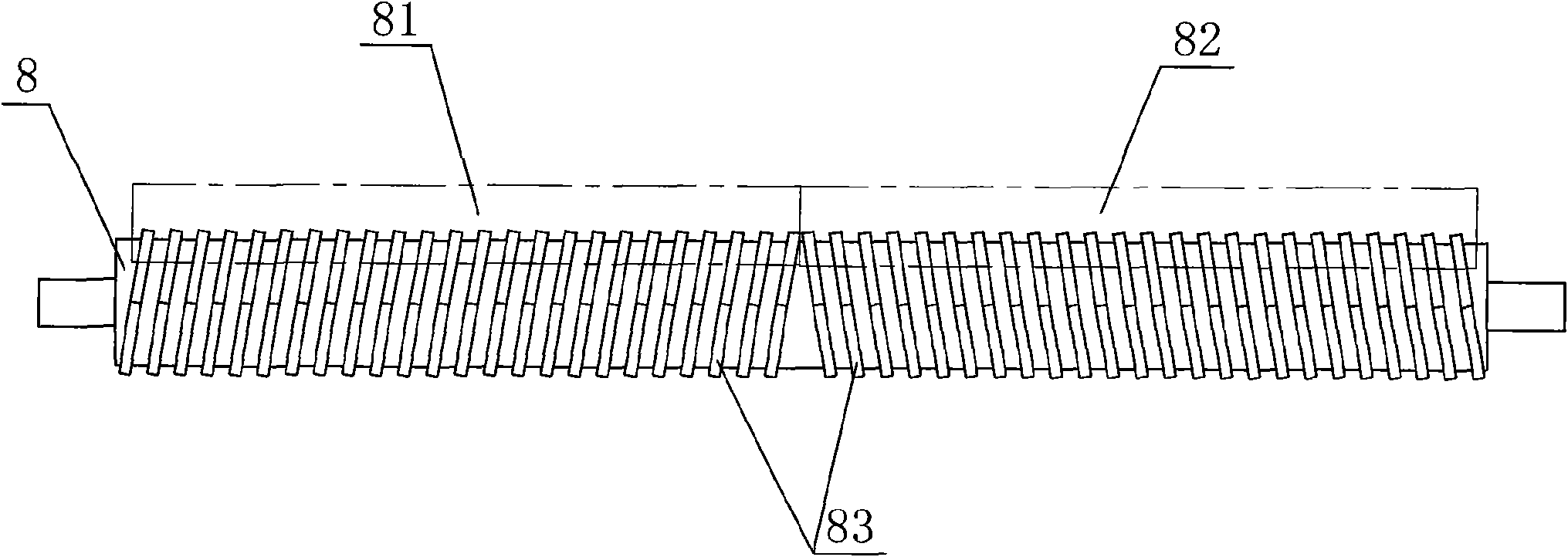

[0016] As shown in the figure, a liquid ammonia mercerizing machine equipment for knitted fabrics includes a weaving input device 1, a liquid ammonia mercerizing device 2 and a liquid ammonia recovery device 3, and the liquid ammonia mercerizing device 2 includes a liquid ammonia tank 21 and padding Device 22, reaction unit 23 and steaming chamber 24, a first group of cloth guide rollers 4 is arranged above the weaving input device 1, the reaction unit 23 includes a cylinder 231, and a second group of cloth guide rollers is arranged above the cylinder 231 7. A first set of expanding roller combination 51 is set between the weaving input device 1 and the liquid ammonia mercerizing device 2, and an automatic centering device 6 is set between the weaving input device 1 and the first set of expanding roller combination 51 , the entrance of the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com