Intelligent chainless and clip mercerizing machine adopting wet cloth and thermal alkali for knitted fabric

A technology for knitted fabrics and mercerizing machines, which is used in the mercerizing of indefinite length fabrics and the configuration of equipment for processing textile materials, etc., can solve the problems of short action time between fibers and lye, the treatment cannot meet the actual needs, and the dimensional stability of the fabric is affected. The effect of improving mercerizing efficiency, good luster and improving mercerizing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

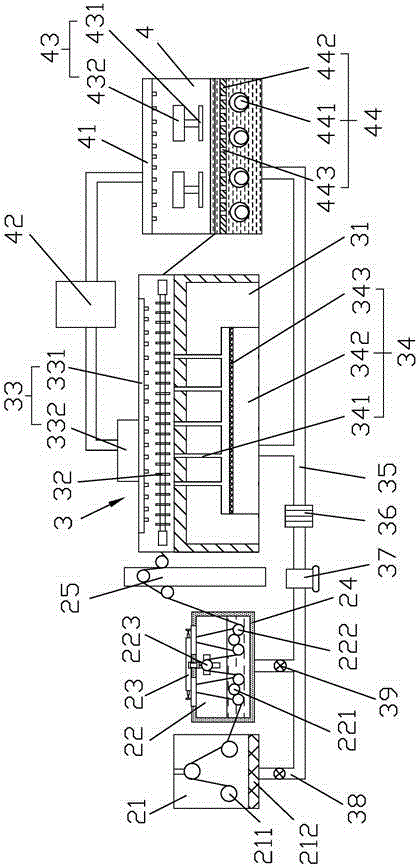

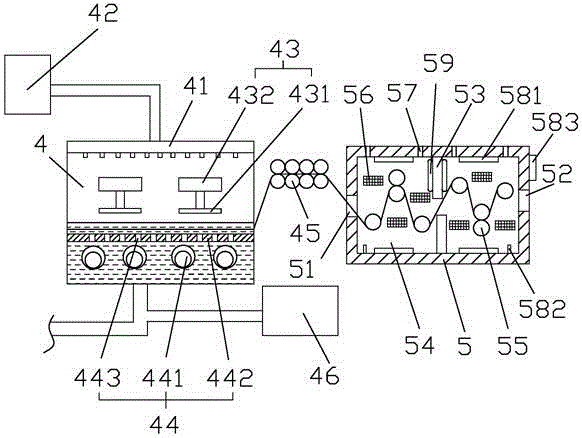

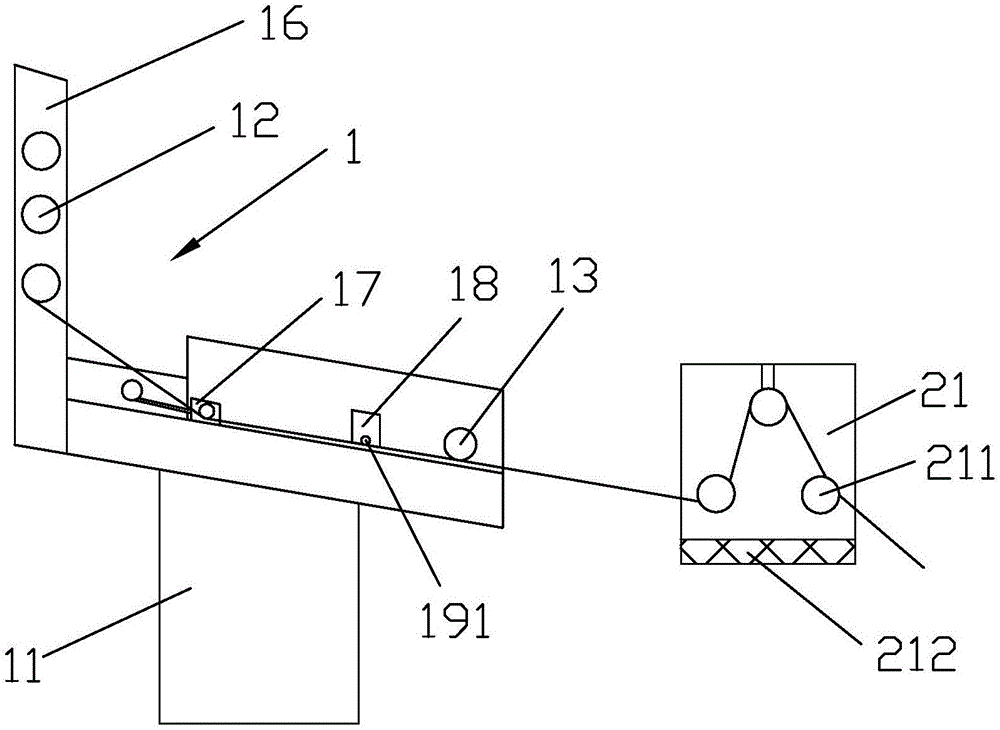

[0029] Such as Figure 1-6 As shown, it is an intelligent wet cloth hot-alkali straight roller clip knitted fabric mercerizing machine of the present invention, which includes an open-width cloth feeding device 1, a concentrated alkali dipping tank, a clip expanding device 3, and an oscillating Washing box 4, drying machine 5 and flat-width cloth outlet device 6, open-width cloth feeding device 1 includes cloth feeding frame 11, cloth releasing roller 12, conveying roller 13, conveying motor 14 and conveying platform 15, and conveying platform 15 is arranged obliquely on On the cloth feeding frame 11, the cloth feeding end of the conveying platform 15 is provided with a cloth releasing frame 16, and the cloth releasing roller 12 is evenly installed on the cloth releasing frame 16, and the conveying roller 13 is arranged on the cloth discharging end of the conveying platform 15, and the conveying roller 13 and the The conveying motor 14 is connected, and a meter counter 17 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com