Dyeing and finishing technology for cotton/viscose ammonia multi-fiber stretch fabric employing bio-enzyme low-temperature treatment

A technology of low-temperature treatment and biological enzymes, which is applied in the field of textile printing and dyeing, can solve the problems of complex dyeing and finishing process, easy creases and stripes, and deformation of fabric structure, so as to optimize the dyeing process parameters, achieve full dyeing quality, and benefit The effect of smooth production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

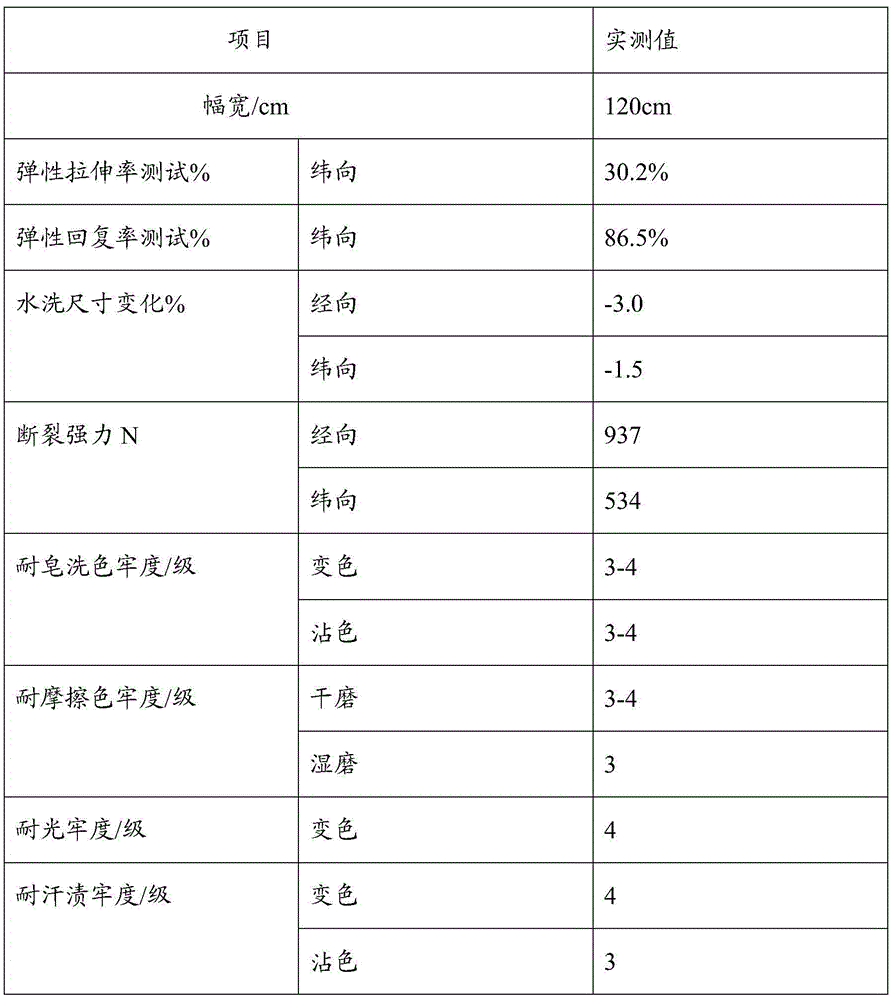

Embodiment 1

[0055] A kind of dyeing and finishing process of the cotton viscose ammonia multi-fiber elastic fabric that utilizes biological enzyme low-temperature treatment described in this embodiment, the process includes pretreatment process, dyeing process and post-finishing process;

[0056] Described pretreatment process comprises the following steps:

[0057] (1) Enzyme rolling process

[0058] Prepare the treatment solution: add 450L of water, stop heating after raising the temperature to 50°C, add penetrant, and then add biological desizing enzyme, activate for 3 minutes before use, the concentration of penetrant is 5g / L, and the concentration of biological desizing enzyme is 20g / L; The biological desizing enzyme is selected from 2000L of Novozymes, and the penetrant is selected from TA-1 of Binzhou Chenguang Chemical Industry;

[0059] Rolling with enzyme rolling, fix the second fabric guide roller on the 1# groove of the rolling, no creases, adjust the angle between the cloth...

Embodiment 2

[0090] A kind of dyeing and finishing process of the cotton viscose ammonia multi-fiber elastic fabric that utilizes biological enzyme low-temperature treatment described in this embodiment, the process includes pretreatment process, dyeing process and post-finishing process;

[0091] Described pretreatment process comprises the following steps:

[0092] (1) Enzyme rolling process

[0093] Prepare the treatment solution: add 450L of water, stop heating after raising the temperature to 50°C, add penetrant, then add biological desizing enzyme, activate for 3 minutes before use, the concentration of penetrant is 6g / L, and the concentration of biological desizing enzyme is 22g / L;

[0094] Rolling with enzyme, fix the second cloth guide roller on the 1# groove of the rolling, so that no wrinkles can be formed, adjust the angle between the cloth drop frame and the rolling roller, so that no wrinkles can be formed, pile up at room temperature for 15 hours, wash with water, 100 Und...

Embodiment 3

[0124] A kind of dyeing and finishing process of the cotton viscose ammonia multi-fiber elastic fabric that utilizes biological enzyme low-temperature treatment described in this embodiment, the process includes pretreatment process, dyeing process and post-finishing process;

[0125] Described pretreatment process comprises the following steps:

[0126] (1) Enzyme rolling process

[0127] Prepare treatment solution: add 450L of water, stop heating after raising the temperature to 50°C, add penetrant, and then add biological desizing enzyme, activate for 3 minutes before use, wherein the concentration of penetrant is 4.5g / L, and the concentration of biological desizing enzyme is 21g / L;

[0128] Rolling with enzyme rolling, fix the second fabric guide roller on the 1# groove of the rolling, no creases, adjust the angle between the cloth drop frame and the rolling roller, so that no creases can be rubbed, stack at room temperature for 13 hours, wash with water, 95 Under the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com