Hemp/silkworm (kiginu) silk high-count blended knitted fabric and manufacturing method thereof

A technology for knitted fabrics and manufacturing methods, applied in textiles and papermaking, knitting, weft knitting, etc., can solve problems such as excessive hairiness, holes in the cloth surface, and difficulty in splitting into satisfactory fineness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

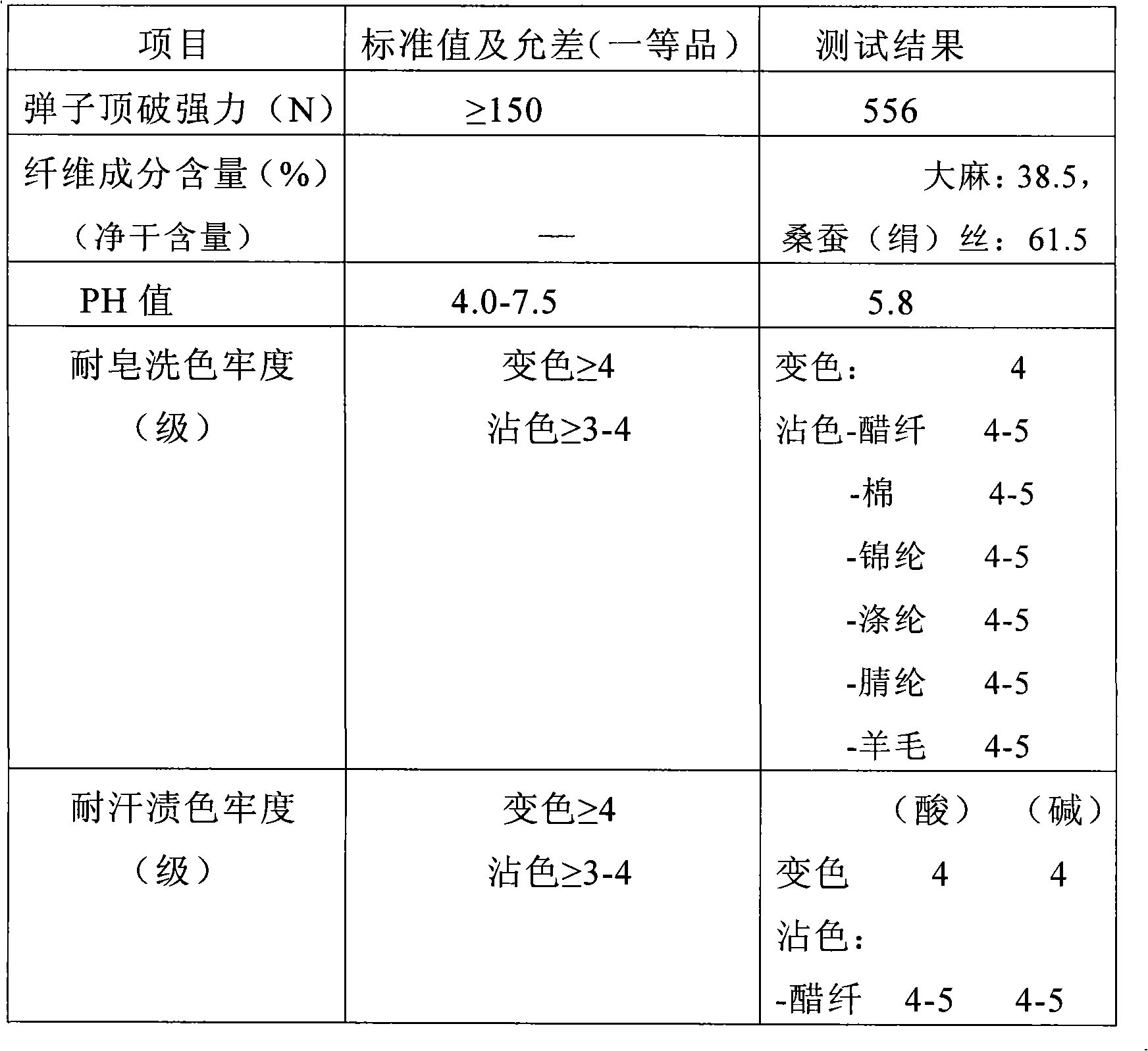

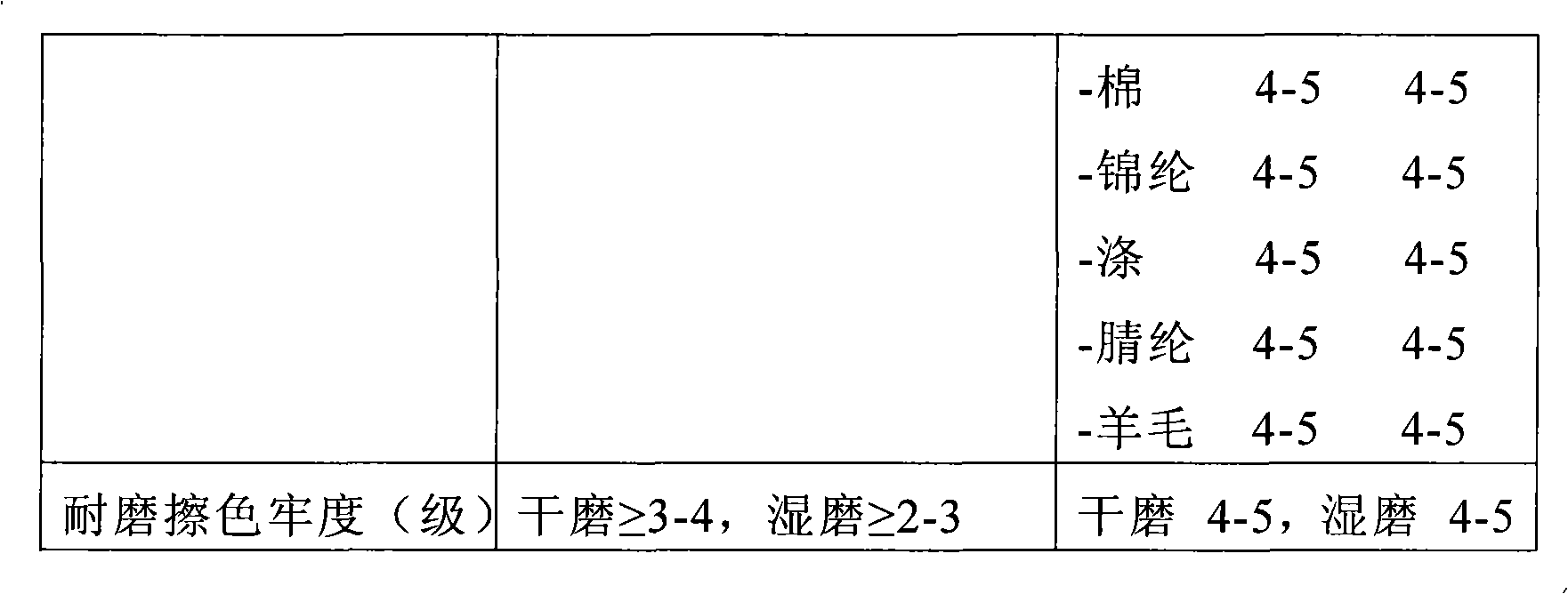

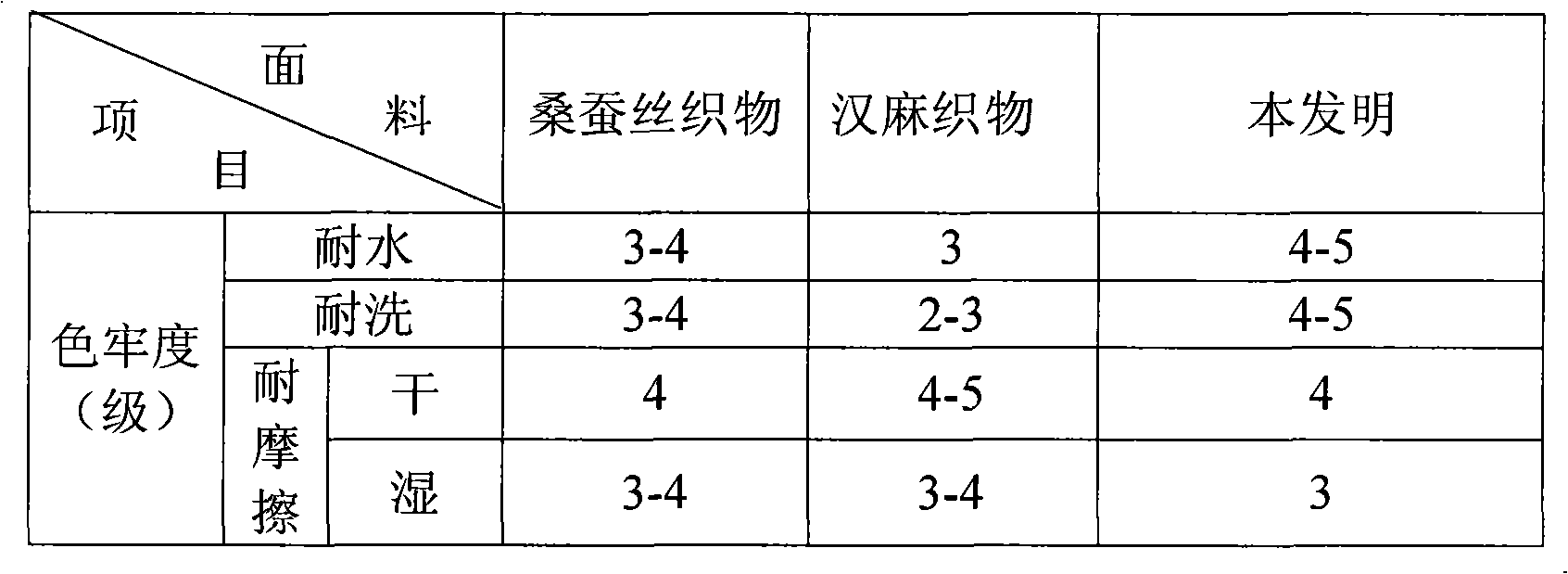

Embodiment 1

[0053] The hemp silk fabric adopted in the invention has a weight percentage content of 35%-50% of hemp, which is the result of taking into account the excellent performance of hemp and the processing performance of the hemp silk fabric. If the content of hemp is less than 35%, the above-mentioned advantages of hemp can not be effectively reflected, and if the content of hemp is greater than 50%, the performance of the advantages of mulberry silk as mentioned above will be inhibited again, and the defects such as the increase of hemp knots will be inhibited. The appearance of the fabric increases the difficulty of processing and reduces the weaving rate.

[0054] The hemp silk fabric of the present invention is a high-count blended fabric, which is reflected in that the count of the single yarn fineness is 60s-80s (s represents the British system, 60s represents the 60 British system count, and the following analogy), the higher the count, the thinner the yarn , the lighter an...

Embodiment 2

[0072] The manufacturing method of the hemp / silk silk high-count blended knitted fabric of the present invention is described in detail below, and the manufacturing method includes a thread forming process and a cloth forming process.

[0073] 1. Wire forming process

[0074] The specific steps included in the wire forming process are as follows:

[0075] A. Blending into thread: first select special hemp fiber, the length of hemp fiber is 4cm--6cm, in order to make the color of hemp pure white, you can also use bleaching agent such as hydrogen peroxide to bleach the hemp fiber. After bleaching, the hemp and mulberry silk fiber strips whose weight percentage is 35%-50% of hemp strips and 65%-50% of silk strips are drawn and processed, and the drawn strips are mixed and combined for the fiber strips. For the hemp thread of this embodiment, the number of drawing passes is 2-5 times, and the more the number of drawing passes, the better the thickness uniformity of the hemp threa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com