Tencel Jutecell dense weft clipped shell fabric

A fabric and tencel technology, applied in the direction of fabric surface trimming, mercerizing fabrics of indefinite length, fabrics, etc., can solve the problems of thin and dense roads, and achieve the effect of overcoming thin and dense roads, good moisture absorption and air permeability, and comfortable hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

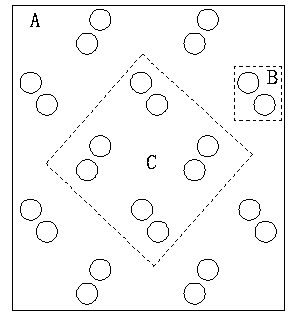

[0015] A kind of Tencel hemp selmi weft cut flower fabric, which is made of warp yarn, ground weft and two sets of flower wefts of different colors. Purcell blended yarn, beige C80S / 2 is used for flower weft 1, pink blue C80S / 2 is used for flower weft 2, such as figure 1 As shown, the ground structure A is a diamond-shaped structure, and the ground part starts with a dot weft flower B, and the dot weft flower B is composed of two dots of pink blue and beige. The two dots are arranged obliquely, and there are two adjacent rows Or the arrangement direction of dots in two adjacent columns is opposite, the pattern of the flower part adopts twill weave, and the pattern on the fabric is formed by the large diamond-shaped area C of dot weft flowers as a cycle. The finished fabric has a warp density of 551cm / 10 pieces and a weft density of 476cm / 10 root.

[0016] Arrangement sequence of weft yarns: 11 pieces of 40S Tencel / Masser blended yarn, plus one beige C80S / 2, two 40S Tencel / Mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com