Polyurethane aqueous dispersion and preparation method thereof

A technology of polyurethane water dispersion and polyurethane prepolymer, which is applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve the difficulty of source of sulfonic acid type hydrophilic chain extender and the difficulty of large-scale industrial production , PUD solid content is not high and other problems, to achieve the effect of low preparation cost, broaden the source of synthetic raw materials, good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) In a dry flask equipped with an electric stirrer and a thermometer, add 1 mole of trimethylolpropane and 1 mole of phthalic anhydride, and heat up to 95°C for 3.5 hours under stirring within 30 minutes. The acid value of the reaction system was measured by GB / T601-1998. After the acid value reached the theoretical value, the reaction was stopped, the temperature was lowered to 50°C, and the material was discharged to obtain a new carboxylate hydrophilic monomer. The obtained hydrophilic compound is separated through a silica gel column, and the monoesterification component is collected, and the solvent is removed by a rotary evaporator to obtain the target carboxylic acid type hydrophilic chain extender trimethylolpropane phthalate monoester (TMPPs) .

[0035] Its reaction formula is as follows:

[0036]

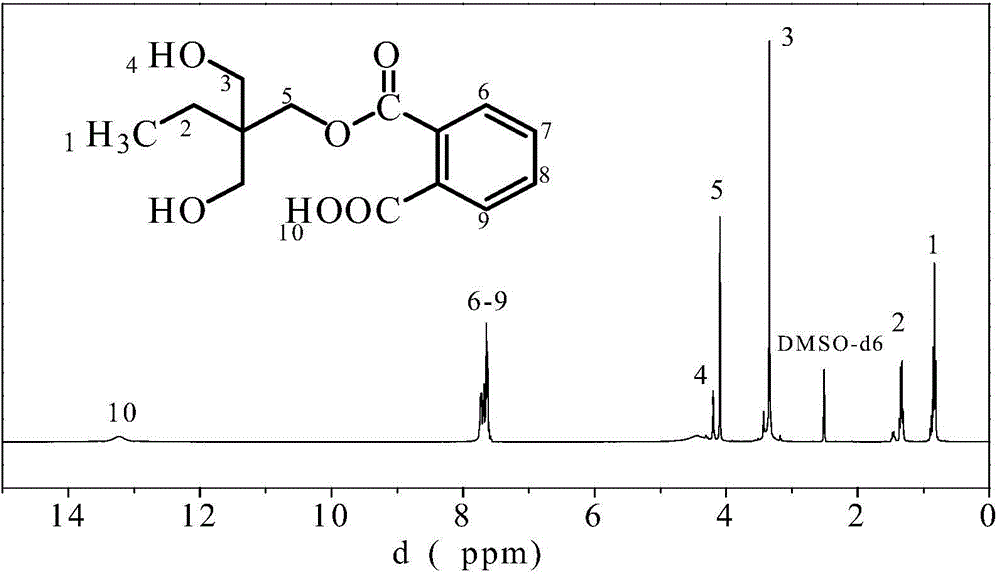

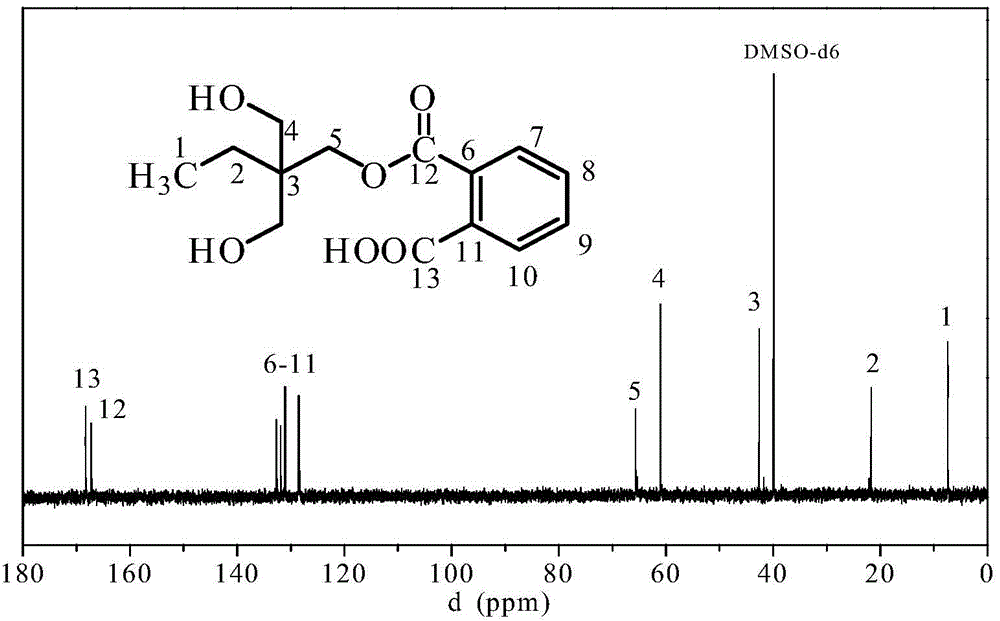

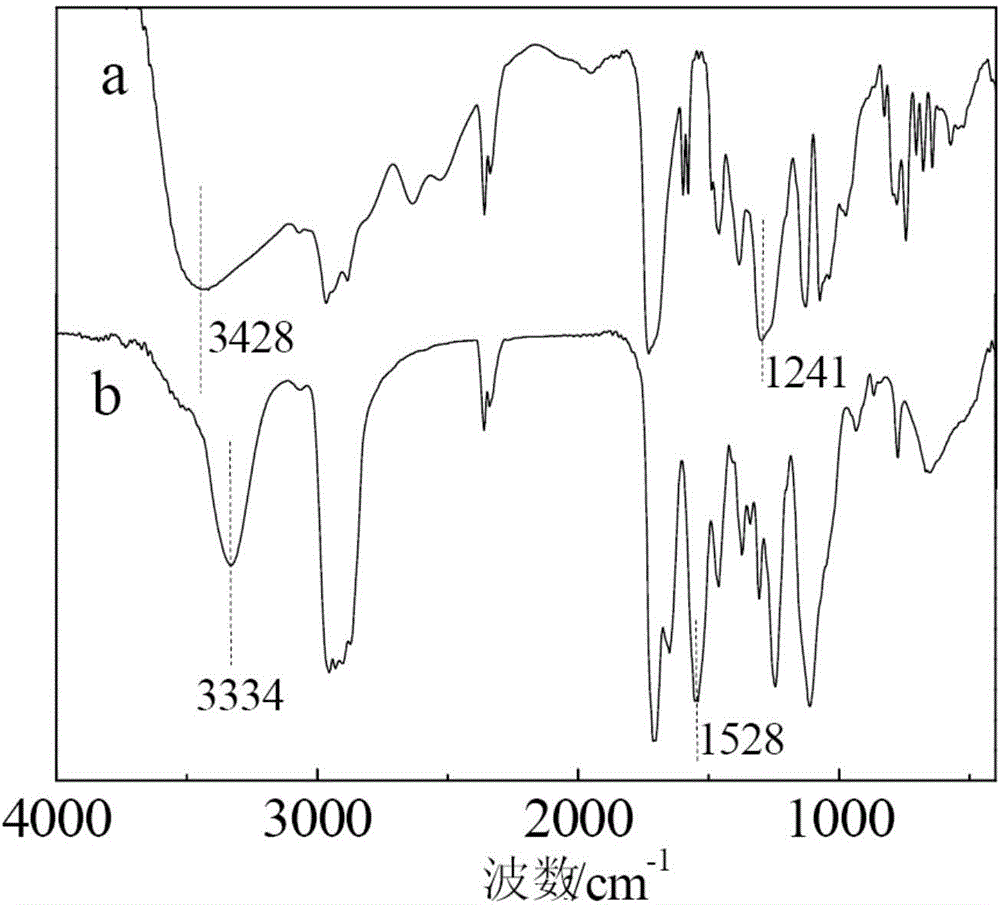

[0037] The purified TMPPs were dissolved using a deuterated DMSO reagent, and nuclear magnetic resonance analysis was performed. figure 1 for TMPPs 1 H-NMR,...

Embodiment 2

[0049] (1) In a dry flask equipped with an electric stirrer and a thermometer, add 1 mole of trimethylolpropane and 0.85 mole of tetrahydrophthalic anhydride, and raise the temperature to 90°C for 4 hours under stirring within 30 minutes. The acid value of the reaction system was measured by GB / T601-1998. After the acid value reached the theoretical value, the reaction was stopped, the temperature was lowered to 50°C, and the material was discharged to obtain a new carboxylate hydrophilic monomer.

[0050] (2) The dosage of each component of polyurethane prepolymer:

[0051] table 3

[0052]

[0053] In a reaction kettle equipped with a stirring blade, a thermometer and a condenser, add polybutadiene diol, a hydrophilic chain extender trimethylolpropane tetrahydrophthalate monoester and a diisocyanate monomer hexacyclohexyl Diisocyanate, heat up to about 75°C, keep warm for 1.5 hours; add small molecule diol chain extender hexylene glycol, non-ionic hydrophilic chain exten...

Embodiment 3

[0058] (1) In a dry flask equipped with an electric stirrer and a thermometer, add 1 mole of trimethylolpropane and 1.25 moles of succinic anhydride, and raise the temperature to 100°C for 3 hours under stirring within 30 minutes. The acid value of the reaction system was measured by GB / T601-1998. After the acid value reached the theoretical value, the reaction was stopped, the temperature was lowered to 50°C, and the material was discharged to obtain a new carboxylate hydrophilic monomer.

[0059] (2) The dosage of each component of polyurethane prepolymer:

[0060] table 5

[0061]

[0062] In the reaction kettle equipped with stirring blade, thermometer and condenser, add polymer diol T-1136 polyester diol and N210 polyether diol, carboxylic acid type hydrophilic chain extender trimethylolpropane butane Diacid monoester and diisocyanate monomer diphenylmethane diisocyanate, heat up to about 75°C, keep warm for 2.0 hours; add small molecule diol chain extender propylene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com