Water-based laser transfer coating for wine bottle glass baking paper, and preparation method thereof

A technology of laser transfer and glass, applied in polyurea/polyurethane coatings, coatings, etc., to achieve good temperature resistance, clear pattern effect, and wide temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

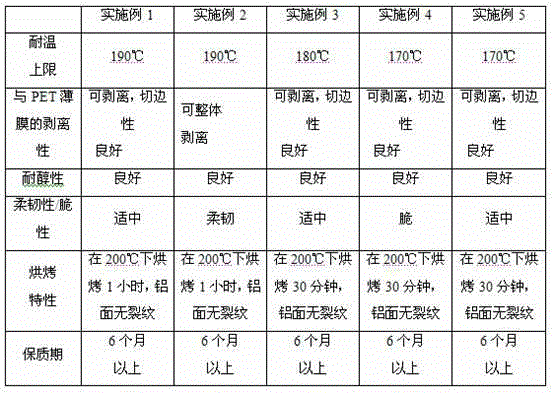

Examples

Embodiment 1

[0035] Example 1: The mass percent of each component of the water-based laser transfer coating for wine bottle glass decal paper is:

[0036] Silicone acrylic emulsion 23%

[0037] Silicone modified waterborne polyurethane 32%

[0038] Ethanol 5%

[0039] Deionized water 39%

[0040] BYK-1770 0.4%

[0041] Hydropalat 875 0.4%

[0042] Ammonia 0.2%.

[0043] Embodiment 1 preparation method comprises the following steps:

[0044] Step 1: put 39% deionized water in the reaction kettle according to the mass percentage, and keep the stirring rate at 80rpm;

[0045] Step 2: put 23% of silicon-acrylic emulsion and 32% of silicone-modified water-based polyurethane into the reaction kettle in sequence, adjust the stirring speed to 120rpm, and continue stirring for 5 minutes;

[0046] Step 3: put 5% ethanol into the reaction kettle according to the mass percentage, the stirring speed is 120rpm, and continue to stir for 1min;

[0047] Step 4: put 0.2% ammonia water into the react...

Embodiment 2

[0051] Example 2: The mass percent of each component of the water-based laser transfer coating for wine bottle glass decal paper is:

[0052] Silicone acrylic emulsion 18%

[0053] Silicone modified waterborne polyurethane 36%

[0054] Ethanol 5%

[0055] Deionized water 40%

[0056]BYK-1770 0.4%

[0057] Hydropalat 875 0.4%

[0058] Ammonia 0.2%.

[0059] Embodiment 2 preparation method comprises the following steps:

[0060] Step 1: Put 40% deionized water in the reaction kettle according to the mass percentage, and keep the stirring rate at 60rpm;

[0061] Step 2: Put 18% of silicon-acrylic emulsion and 36% of silicone-modified water-based polyurethane into the reaction kettle in sequence according to the mass percentage, adjust the stirring speed to 150rpm, and continue stirring for 3min;

[0062] Step 3: put 5% ethanol into the reaction kettle according to the mass percentage, the stirring speed is 150rpm, and continue to stir for 3min;

[0063] Step 4: put 0.2% a...

Embodiment 3

[0067] Example 3: The mass percent of each component of the water-based laser transfer coating for wine bottle glass decal paper is:

[0068] Styrene-acrylate copolymer 23%

[0069] Polyester type aliphatic waterborne polyurethane 32%

[0070] Ethanol 5%

[0071] Deionized water 39.6%

[0072] Wet 500 0.4%.

[0073] Embodiment 3 preparation method comprises the following steps:

[0074] Step 1: 39.6% deionized water is placed in the reactor according to the mass percentage, and the stirring rate is kept at 100rpm;

[0075] Step 2: Put 23% styrene-acrylate copolymer and 32% polyester-type aliphatic waterborne polyurethane into the reaction kettle in turn according to the mass percentage, adjust the stirring speed to 170rpm, and continue stirring for 4min;

[0076] Step 3: put 5% ethanol into the reaction kettle according to the mass percentage, the stirring speed is 170rpm, and continue to stir for 5min;

[0077] Step 4: Put 0.4% of Wet 500 into the reaction kettle accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com