Waterborne two-component woodware coating and preparation method thereof

A wood coating, two-component technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problem of compatibility without matte effect, and achieve the effect of good transparency, good water resistance and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] This embodiment provides a water-based two-component wood coating, which is prepared from raw materials including main agent A and curing agent B;

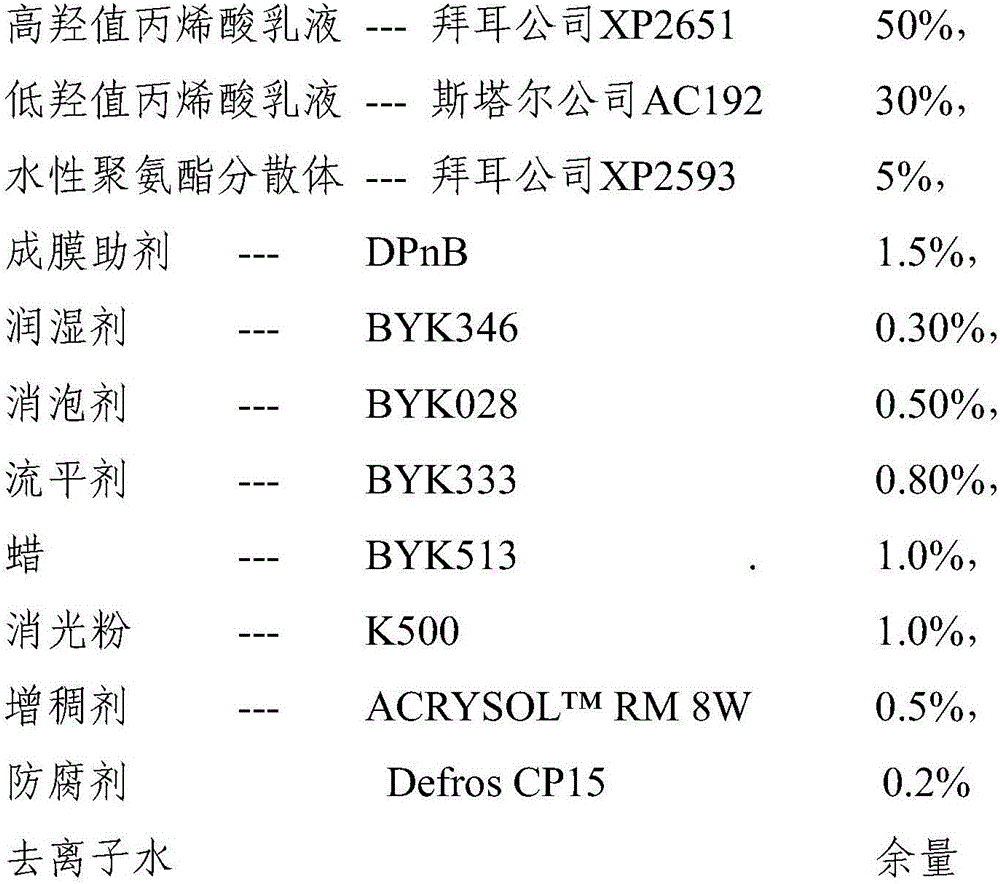

[0058] Wherein, the main agent A is prepared from the following raw materials in mass percentage:

[0059]

[0060] The curing agent B is prepared from the following raw materials in mass percentage:

[0061]

[0062] The molar ratio of OH in the main agent A to NCO in the curing agent B is 1:1.4.

Embodiment 2

[0064] This embodiment provides a water-based two-component wood coating, which is prepared from raw materials including main agent A and curing agent B;

[0065] Wherein, the main agent A is prepared from the following raw materials in mass percentage:

[0066]

[0067]

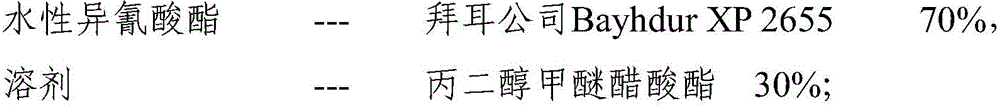

[0068] The curing agent B is prepared from the following raw materials in mass percentage:

[0069]

[0070] The molar ratio of OH in the main agent A to NCO in the curing agent B is 1:1.2.

Embodiment 3

[0072] This embodiment provides a water-based two-component wood coating, which is prepared from raw materials including main agent A and curing agent B;

[0073] Wherein, the main agent A is prepared from the following raw materials in mass percentage:

[0074]

[0075]

[0076] The curing agent B is prepared from the following raw materials in mass percentage:

[0077]

[0078] The molar ratio of OH in the main agent A to NCO in the curing agent B is 1:1.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com