Eco-friendly energy-saving middle-temperature bronze glaze and method for preparing eco-friendly energy-saving middle-temperature bronze glazed ceramic through eco-friendly energy-saving middle-temperature bronze glaze

An environment-friendly, energy-saving, ceramic product technology, applied in the field of ceramics, can solve the problems of PbO human injury and easy breakage, and achieve the effect of low dissolution rate, reducing firing cost and labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

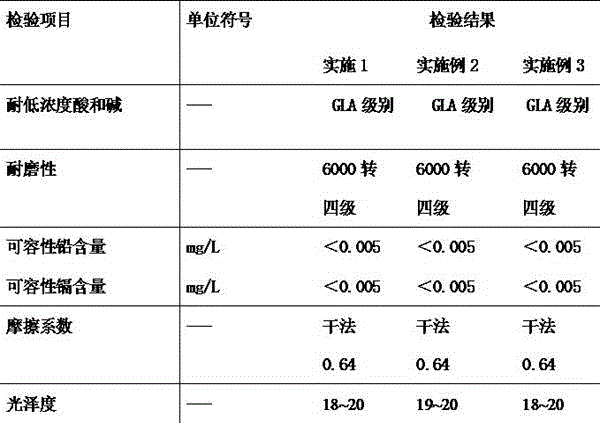

Examples

Embodiment 1

[0026] Environmentally friendly and energy-saving medium-temperature bronze glaze, including the following raw materials in terms of parts by mass: 49 parts of Sanming potassium feldspar, 14 parts of barium carbide, 4 parts of Longyan kaolin, 14 parts of calcium carbide, 6 parts of quartz, and 1 part of copper tailings copper tailings 9 parts, 9 parts of 2# frit, wherein, described 2# frit comprises the following raw material according to mass parts: 9 parts of potassium oxide, 14 parts of sodium oxide, 2 parts of calcium oxide, 21 parts of zinc tailings, magnesium oxide 4 parts.

[0027] The method for making ceramic products with the described environment-friendly and energy-saving medium-temperature bronze glaze comprises the following steps:

[0028] Step 1, ingredients ball milling and sieving:

[0029] 1) Proportioning the raw materials according to the mass parts to obtain a proportioning material, and putting the proportioning material in a ball mill for ball milling ...

Embodiment 2

[0036] Environmental protection and energy saving medium temperature bronze glaze, including the following raw materials in terms of mass fraction: 53 parts of Sanming potassium feldspar, 16 parts of barium carbide, 6 parts of Longyan kaolin, 5 parts of calcium carbide, 8 parts of quartz, 3 parts of copper tailings, 2# 12 parts of frit, wherein, the 2# frit includes the following raw materials in parts by mass: 12 parts of potassium oxide, 16 parts of sodium oxide, 3 parts of calcium oxide, 23 parts of zinc tailings, and 6 parts of magnesium oxide.

[0037] The method for making ceramic products with the described environment-friendly and energy-saving medium-temperature bronze glaze comprises the following steps:

[0038] Step 1, ingredients ball milling and sieving:

[0039] 1) Proportion the raw materials according to the mass parts to obtain a proportioning material, put the proportioning material in the ball mill according to the proportioning material: ball: water = 1:2:...

Embodiment 3

[0046] Environmentally friendly and energy-saving medium-temperature bronze glaze, including the following raw materials in terms of parts by mass: 56 parts of Sanming potassium feldspar, 17 parts of barium carbide, 7 parts of Longyan kaolin, 17 parts of calcium carbide, 11 parts of quartz, and 4 parts of copper tailings 14 parts, 14 parts of 2# frit, wherein, described 2# clinker comprises the following raw material according to mass parts: 14 parts of potassium oxide, 17 parts of sodium oxide, 4 parts of calcium oxide, 25 parts of zinc tailings, magnesium oxide 8 servings.

[0047] The method for making ceramic products with the described environment-friendly and energy-saving medium-temperature bronze glaze comprises the following steps:

[0048] Step 1, ingredients ball milling and sieving:

[0049]1) Proportioning the raw materials according to the mass parts mentioned above to obtain the proportioning material, putting the proportioning material in the ball mill accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com