Retaining wall in lightweight, and construction method

A construction method and retaining wall technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of high cost, large number of masonry, unsightly appearance, etc., and achieve less consumables, overall light weight, landscape good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The steps of lightweight retaining wall of the present invention and construction method thereof are as follows:

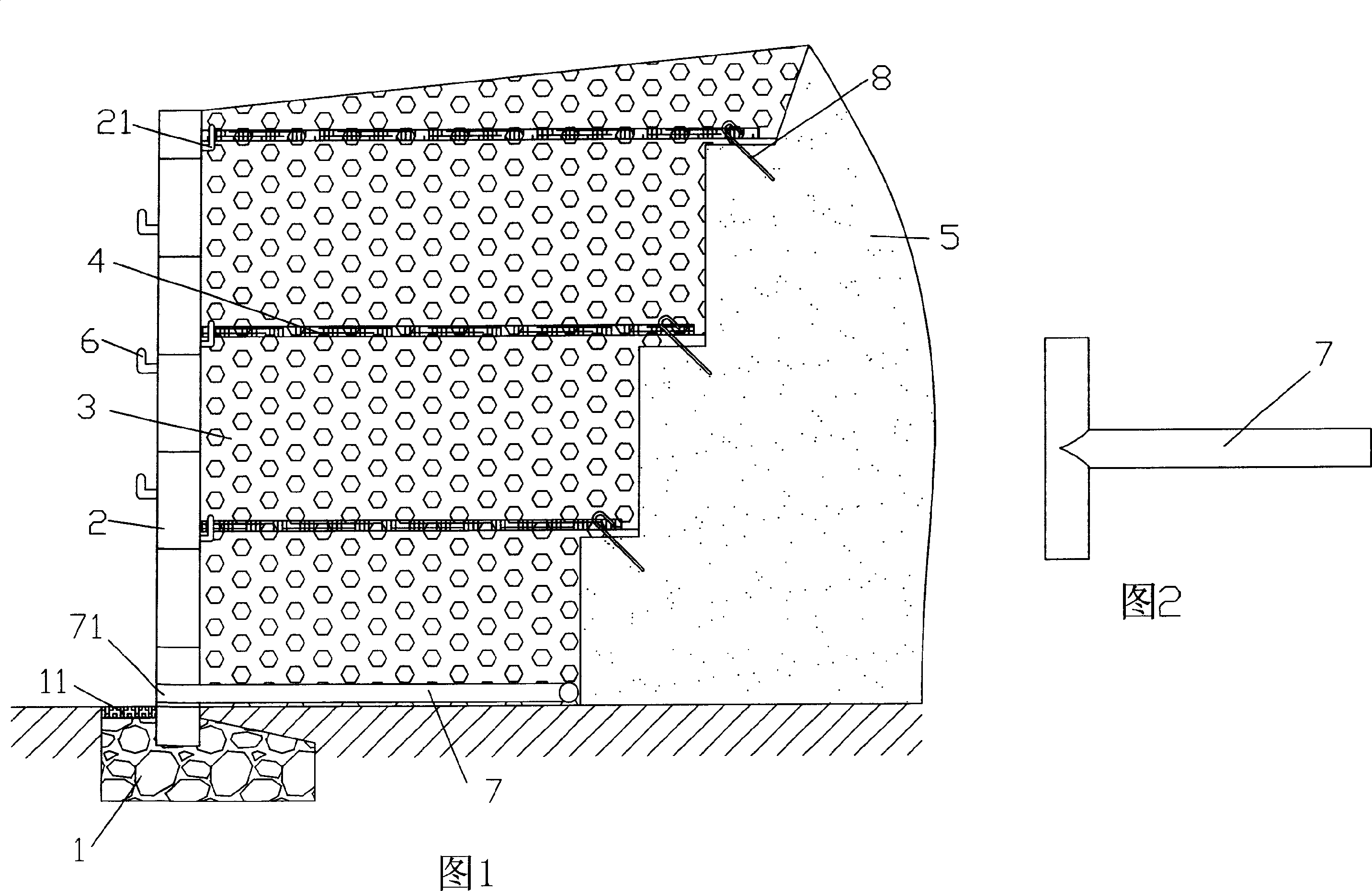

[0021] (1) Prepare the foundation: Excavate the foundation groove at the position where the retaining wall needs to be installed, tamp the original soil, lay a graded crushed stone cushion on the foundation groove, and then build a concrete or crushed stone foundation on the crushed stone cushion to form For the foundation 1 shown in Figure 1, an expansion joint is set every 10m on the foundation 1, and materials such as asphalt board, cork board or asphalt lint are used as joint fillers for the expansion joint;

[0022] (2) The first layer of wall panel 2 is installed on the foundation 1: on the foundation 1 prepared in the above step (1), the cement mortar of about 2 cm is first placed to form a cement mortar layer 11, so that the surface of the cement mortar layer 11 is equal to the horizontal plane. Parallel, install the first layer of wall panel 2 on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com